A device and method for laying reinforcing fiber filaments for the production of composite grids

A technology of reinforcing fibers and composite materials, applied in the field of composite grid production equipment and technology, can solve the problems of high cost of mold equipment, high labor intensity, low production efficiency, etc., to improve versatility and utilization, and reduce labor intensity. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with the accompanying drawings.

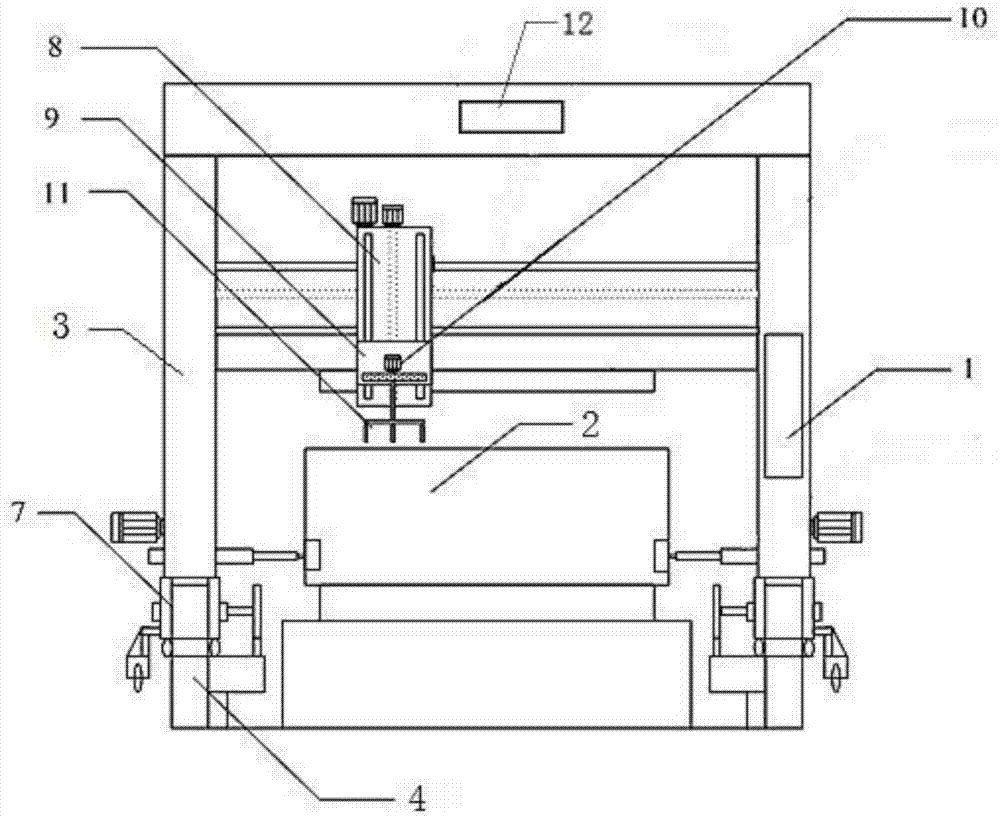

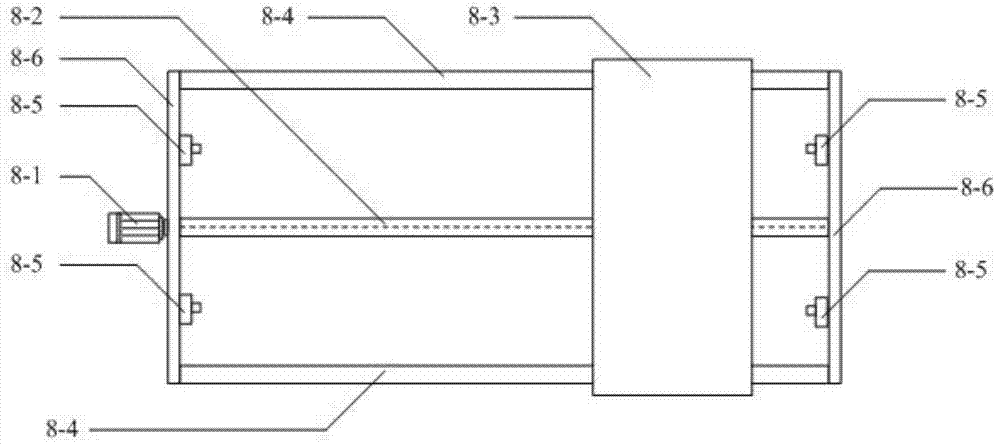

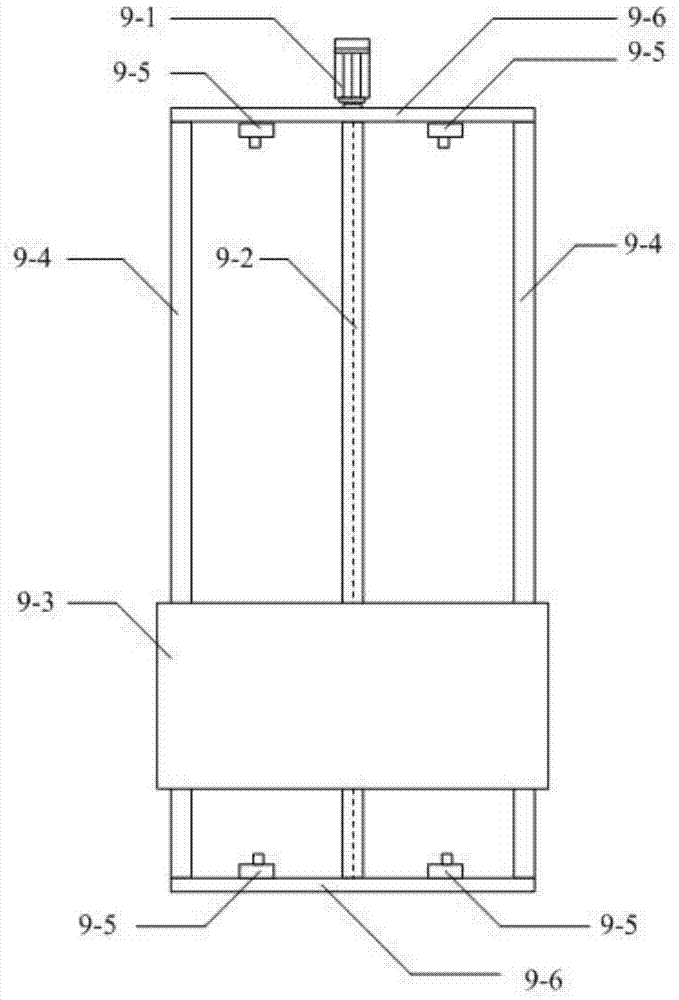

[0024] Such as figure 1 As shown, the reinforcing fiber yarn laying device for composite grid production of the present invention includes a mold table 2, a gantry frame 3, a track 4, a walking wheel 7, a sliding table mechanism 8, an elevating table mechanism 9, a rotary table Mechanism 10, laying head 11, wire feeding mechanism 12 and computer control system 1. Rails 4 are laid on both sides of the mold platform 2, and the gantry-shaped vehicle frame 3 spans over the mold platform 2, and the bottom of the gantry-shaped vehicle frame 3 is provided with a traveling wheel 7, which drives the gantry-shaped vehicle frame 3 along the Move on track 4. The gantry frame 3 is provided with a computer control system 1, a slide mechanism 8 and a wire supply mechanism 12, the slide mechanism 8 is provided with a lift mechanism 9, and the lift mechanism 9 is provided with a turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com