High-pressure slurry conveying pump system and method

A technology for conveying pumps and slurries, applied in the components, pumps, piston pumps, etc. of pumping devices for elastic fluids, can solve problems affecting the service life and reliability of pumping equipment, poor fluidity of high-concentration slurries, and pumping It can improve the working efficiency, simplify the structure and reduce wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

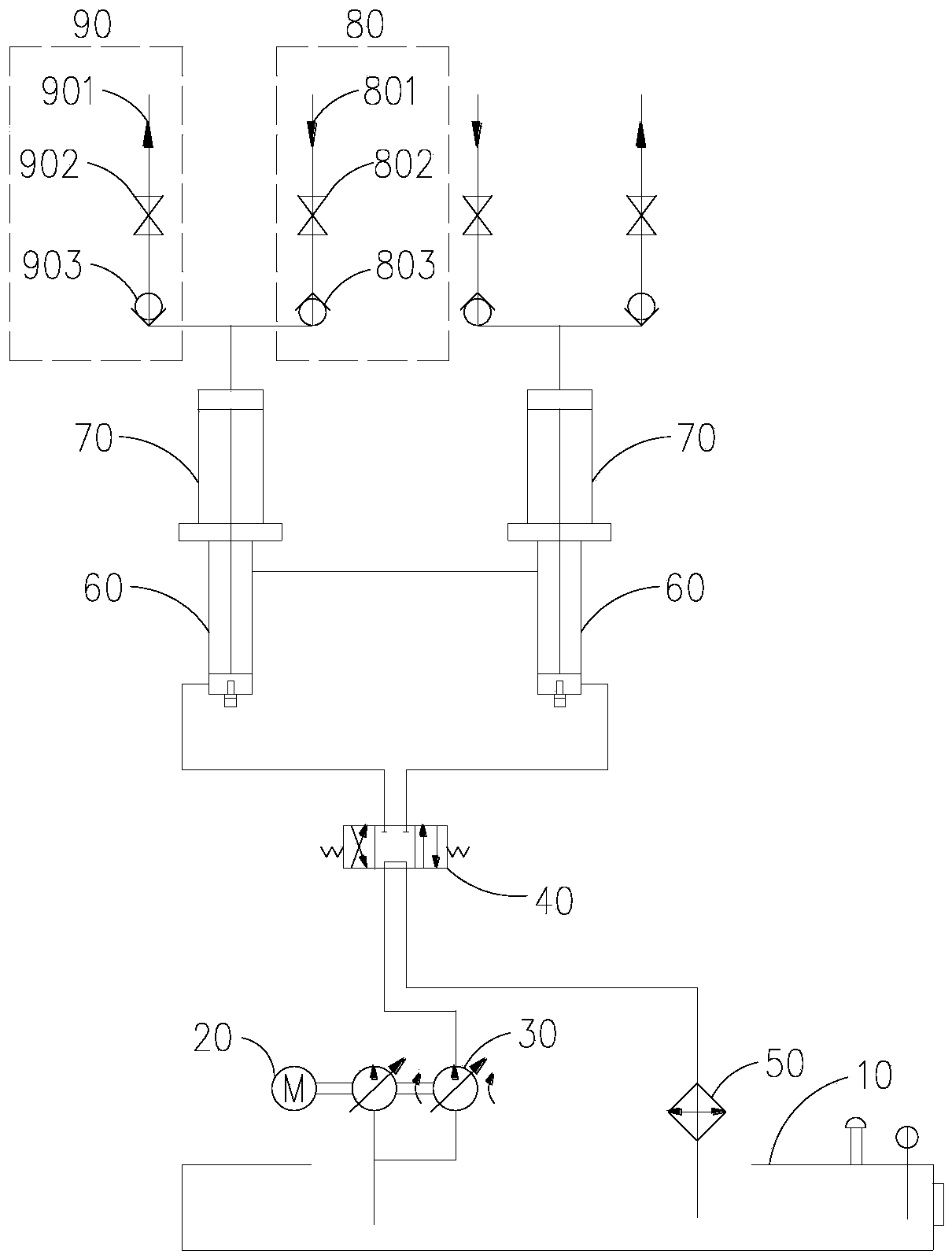

[0067] Example 1, such as Figure 5 As shown, a high-pressure slurry delivery pump system includes a power system and a hydraulic system, and the power system includes: a hydraulic oil tank 10, a main motor 20, a main oil pump 30, a hydraulic reversing valve 40, a cooler 50 and a main oil cylinder 60, The hydraulic system includes: delivery cylinder 70, feed subsystem 80 and discharge subsystem 90; wherein, feed subsystem 80 includes: feed pipe 801, feed pipe inspection valve 802 and feed cone valve 803, and the discharge subsystem 90 includes: discharge pipe 901, discharge maintenance valve 902 and discharge cone valve 903;

[0068] The main motor 20 is connected with the main oil pump 30, the main oil pump 30 is connected with the hydraulic oil tank 10, the hydraulic reversing valve 40 is respectively connected with the main oil pump 30, the cooler 50, the main oil cylinder 60a and the main oil cylinder 60a' through pipelines, and the main oil cylinder 60a is connected with ...

Embodiment 2

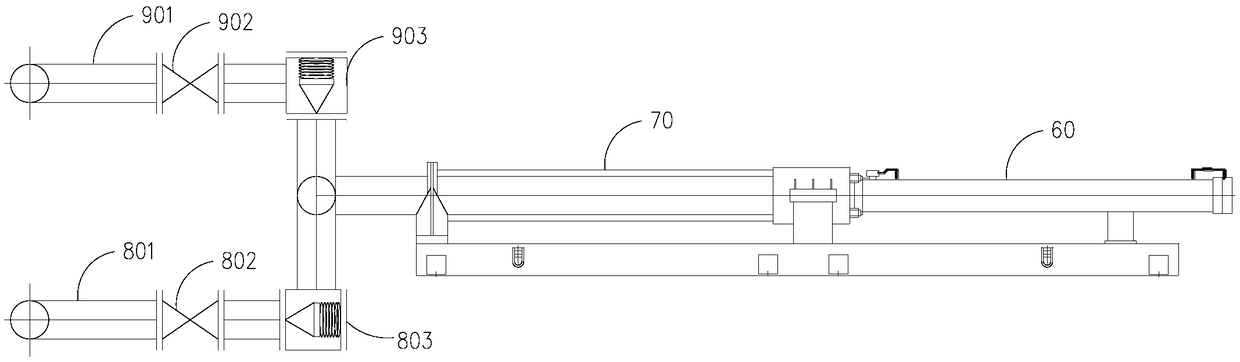

[0071] Example 2, such as Figure 6 As shown, a high-pressure slurry delivery pump system includes a power system and a hydraulic system, and the power system includes: a hydraulic oil tank 10, a main motor 20, a main oil pump 30, a hydraulic reversing valve 40, a cooler 50 and a main oil cylinder 60, The hydraulic system includes: delivery cylinder 70, feed subsystem 80 and discharge subsystem 90; wherein, feed subsystem 80 includes: feed pipe 801, feed pipe inspection valve 802 and feed cone valve 803, and the discharge subsystem 90 includes: discharge pipe 901, discharge maintenance valve 902 and discharge cone valve 903;

[0072] The main motor 20 is connected with the main oil pump 30, the main oil pump 30 is connected with the hydraulic oil tank 10, and the hydraulic reversing valve 40 is respectively connected with the main oil pump 30, the cooler 50, the main oil cylinder 60a, the main oil cylinder 60a', the main oil cylinder 60b and the main oil cylinder through pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com