Hydraulic pressure pressure-regulating automatic reverse combined valve for double line grease lubricating system

A lubricating system and automatic reversing technology, applied in lubricating oil control valves, lubricating parts, engine lubrication, etc., can solve problems such as wasting power and consumption, and achieve large reversing and pressure adjustment range, flexible reversing, and work reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described in conjunction with the accompanying drawings, and the embodiments are used to illustrate the present invention, but not to limit it in any way.

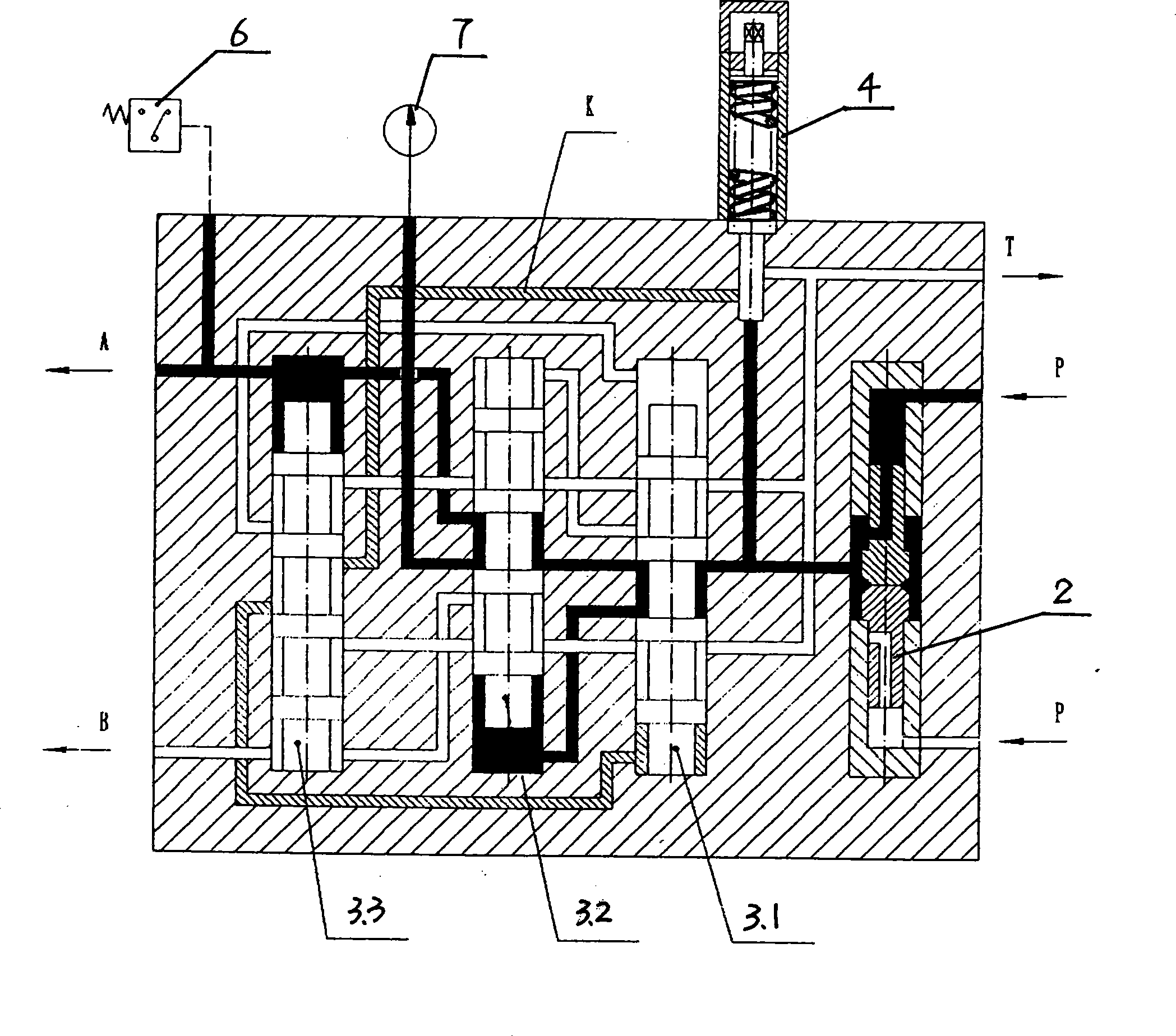

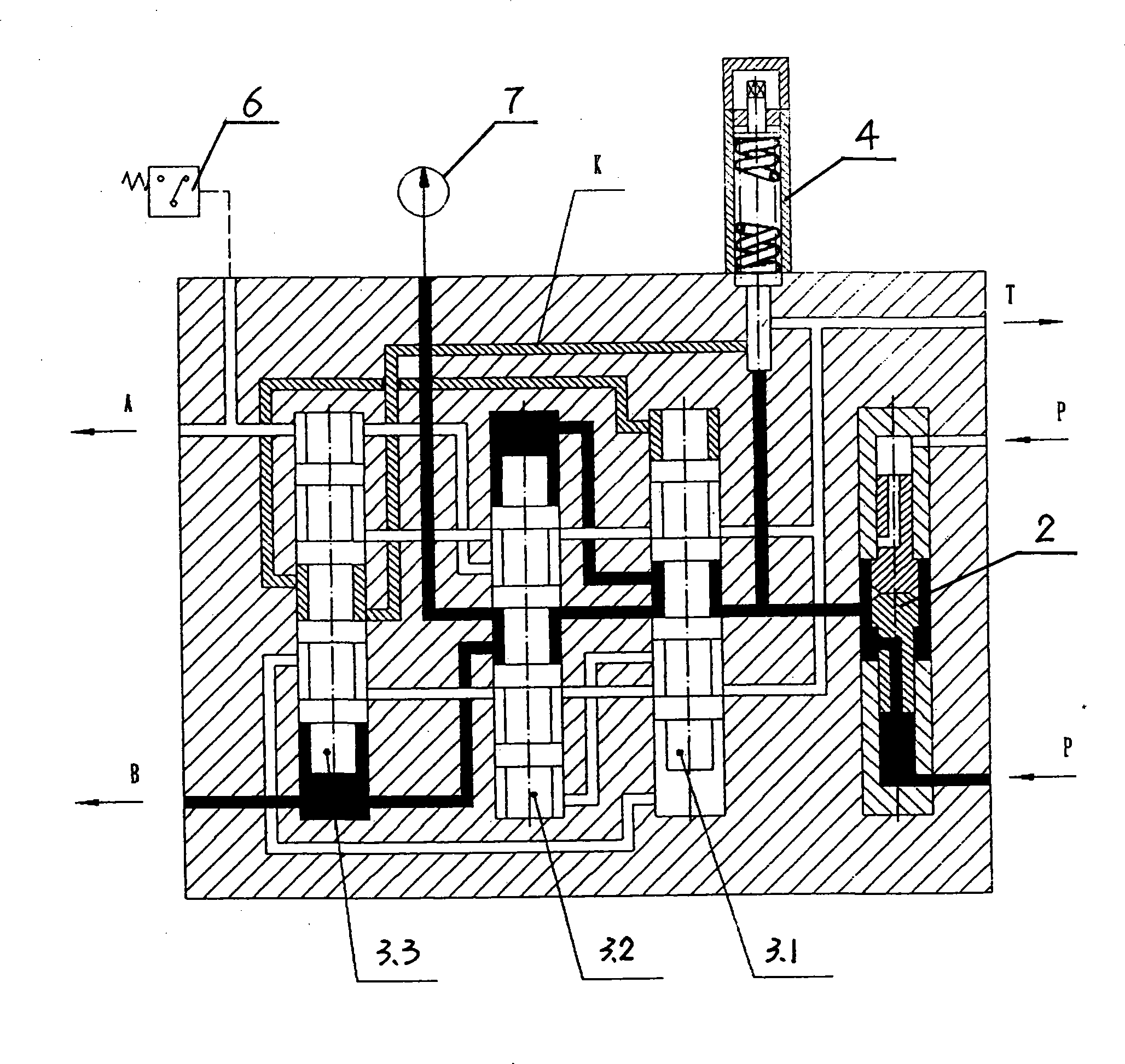

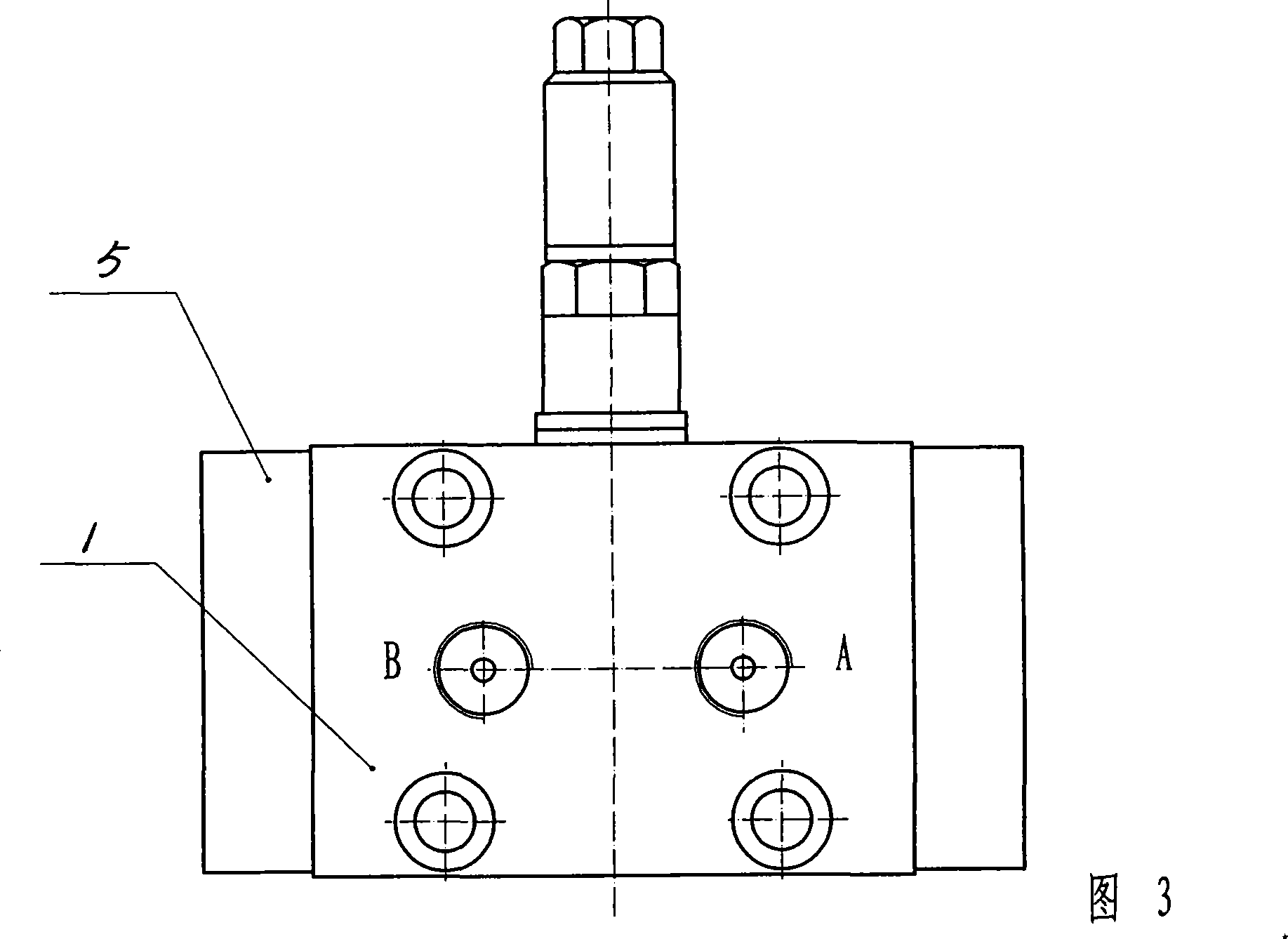

[0020] The invention is a multifunctional valve group which combines a plunger type oil distribution check valve, a pressure regulating valve, a safety valve, a reversing slide valve, a pressure gauge and a pressure sensor. The structure and functions are introduced as follows:

[0021] 1. Oil distribution check valve—the two plungers alternately supply oil. In order to ensure the vacuum degree of the oil suction chamber and prevent the oil supply pressure from failing, the present invention changes the oil distribution check valve 2 from spring reset to forced oil pressure. Reset structure. That is to say, when one plunger discharges oil, the check valve at the outlet of the other plunger is forcibly closed (see figure 1 , 2 ). The combination of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com