Elactro magnetic commutator

A commutator, electromagnet technology, applied in the direction of components with teeth, belts/chains/gears, mechanical equipment, etc., can solve problems such as infeasibility, and achieve the effects of convenient operation, flexible commutation, and smooth transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

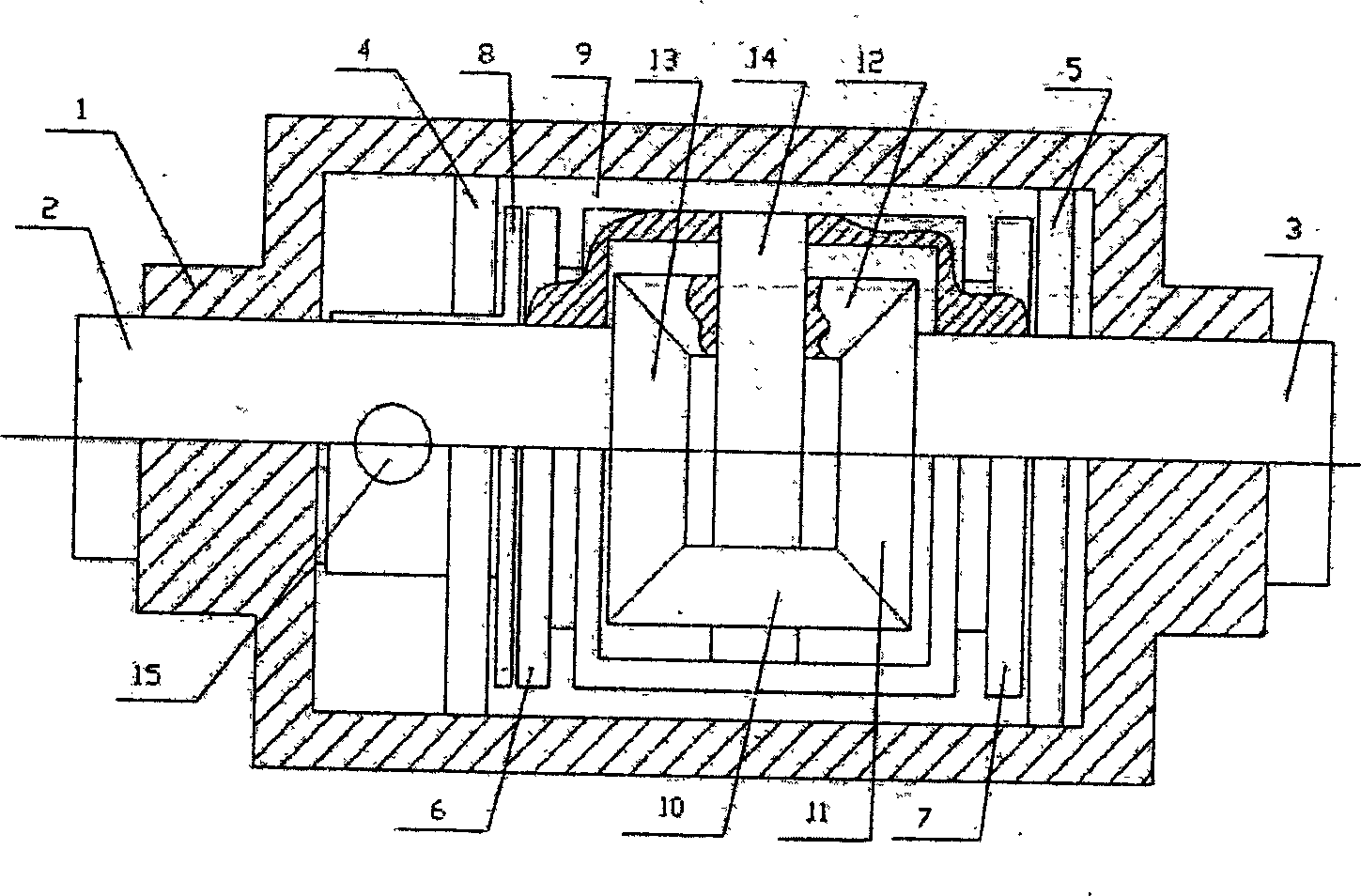

[0010] As shown in the figure, the commutation principle and working state of the electromagnetic commutator are as follows: when rotating in the same direction, the input shaft 2 is connected to the power source. The electromagnet 4 is energized to make the friction plate 8 of the input shaft and the left end friction plate 6 of the commutator 9 rotate synchronously through the connection of electromagnetic force, so that the same direction rotation of the input shaft and the output shaft is realized. When rotating in the opposite direction, the electromagnet 5 is energized, and the electromagnet 4 is de-energized simultaneously, and the friction plate 7 at the right end of the commutator housing 9 then remains fixed with the housing 1 due to electromagnetic force. At this time, the input shaft still drives the bevel gear train to move, because the bevel gear 10 and the bevel gear 12 are installed on the commutator housing 9 through the bevel gear fixed shaft 14, and are loope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com