Refrigeration system and control method thereof

A refrigeration system and control valve technology, which is applied in the field of air conditioning, can solve the problems that the unit cannot be started, cannot operate refrigeration, cannot guarantee the unit to start and operate reliably, and achieve the effect of easy control, implementation and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

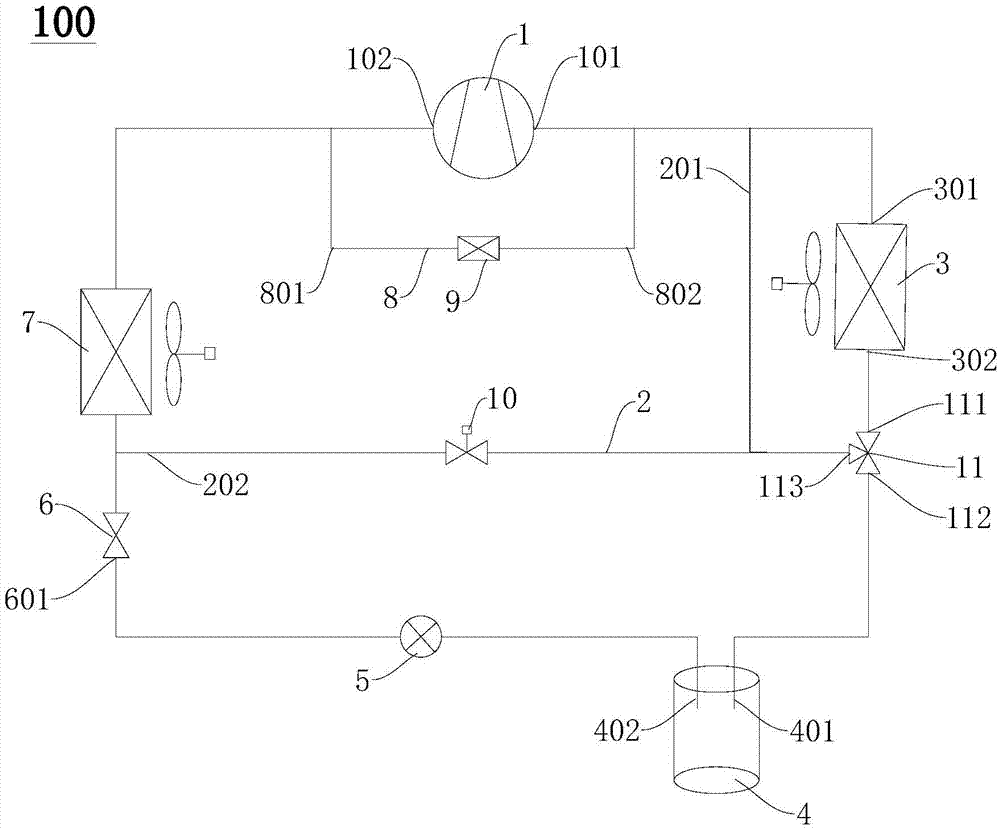

[0042] Such as figure 1 As shown, in this embodiment, the refrigeration system 100 includes a compressor 1 , a condenser 3 , a throttling device 6 , an evaporator 7 , a bypass circuit 2 and a control valve group connected end to end in order to form a circuit. The connection relationship of the above-mentioned components in the refrigeration system 100 has been described above, and will not be repeated here.

[0043] Further, the refrigeration system 100 also includes a liquid accumulator 4 and a dry filter 5 . The reservoir 4 has a reservoir inlet 401 and a reservoir outlet 402, the reservoir inlet 401 is connected to the outlet 302 of the condenser 3, the reservoir outlet 402 is connected to the inlet 601 of the throttling device 6, and the dry filter 5 It is connected in series between the outlet 402 of the liquid reservoir and the inlet 601 of the throttling device 6 . Thus, the refrigerant flowing out from the condenser 3 can flow into the accumulator 4 through the accu...

Embodiment 2

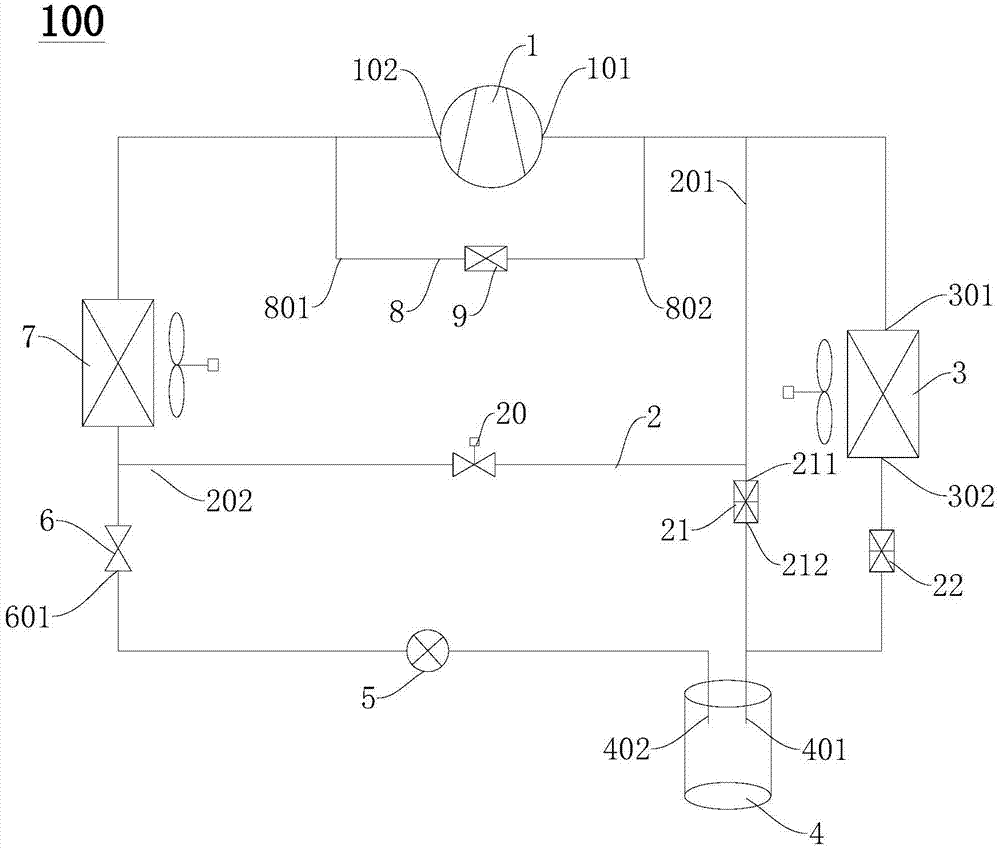

[0062] Such as figure 2 As shown, the structure of the refrigeration system 100 in this embodiment is substantially the same as that of the first embodiment above, and the only difference lies in the structure of the control valve group.

[0063]Specifically, the control valve group in this embodiment includes a second solenoid valve 20 , a differential pressure valve 21 and a condensing pressure regulating valve 22 . The second solenoid valve 20 is arranged on the bypass circuit 2, and the second solenoid valve 20 is configured to conduct the bypass circuit 2 when the suction pressure of the compressor 1 is lower than a third predetermined value and when the suction pressure of the compressor 1 When the pressure is higher than or equal to the third predetermined value, the bypass circuit 2 is cut off.

[0064] The first end 211 of the differential pressure valve 21 is connected between the first end 201 of the bypass circuit 2 and the second solenoid valve 20 , and the seco...

Embodiment 3

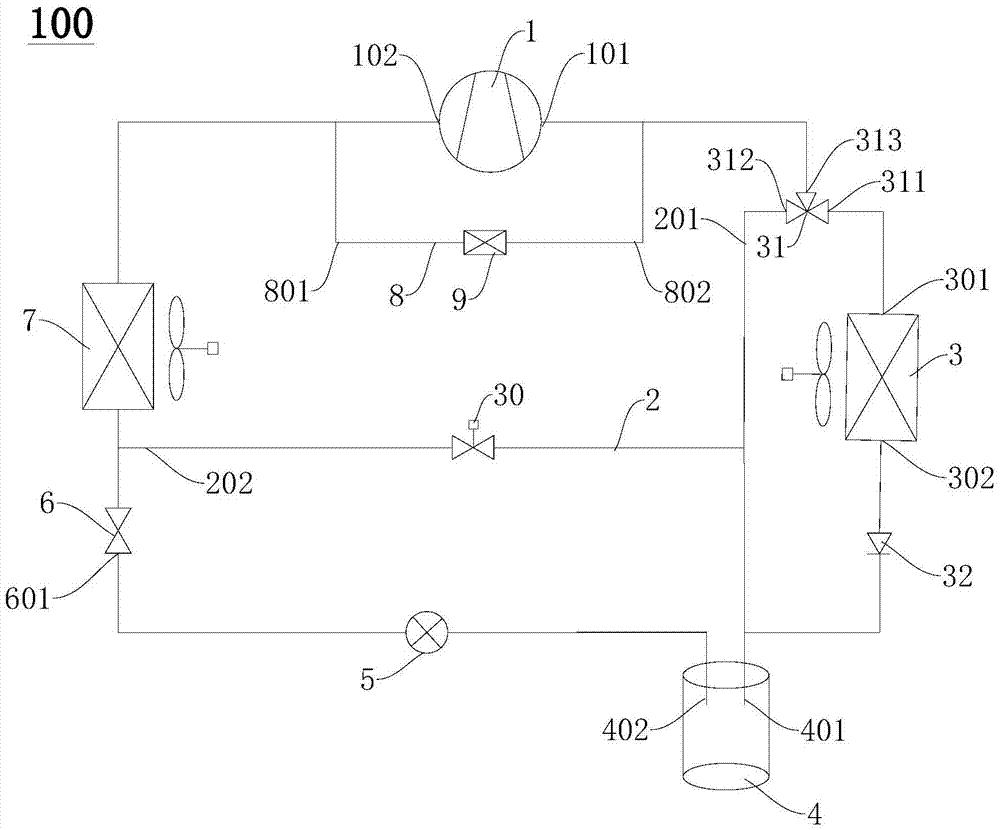

[0073] Such as image 3 As shown, the structure of the refrigeration system 100 in this embodiment is substantially the same as that in the first embodiment above, and the only difference lies in the structure of the control valve group.

[0074] The control valve group in this embodiment includes a third solenoid valve 30 and a second pressure three-way valve 31 . The third solenoid valve 30 is arranged on the bypass circuit 2, and the third solenoid valve 30 is configured to conduct the bypass circuit 2 when the suction pressure of the compressor 1 is lower than the sixth predetermined value and when the suction pressure of the compressor 1 When the pressure is higher than or equal to the sixth predetermined value, the bypass circuit 2 is cut off. The first valve port 311 of the second pressure three-way valve 31 is connected to the exhaust port 101 of the compressor 1, and the second valve port 312 of the second pressure three-way valve 31 is connected to the first end 201...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com