Jet tee joint

A jet and tee technology, applied in the field of jet tee, can solve the problems of complicated installation, use, maintenance, long running time, lack of operation and maintenance skills, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

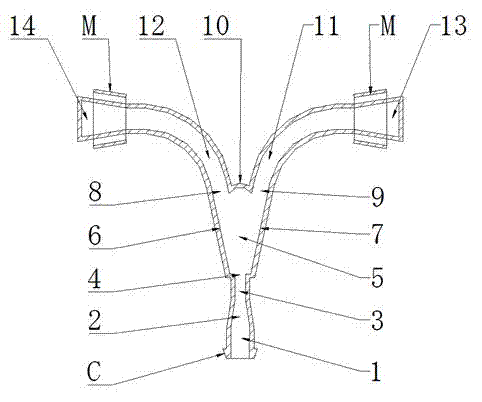

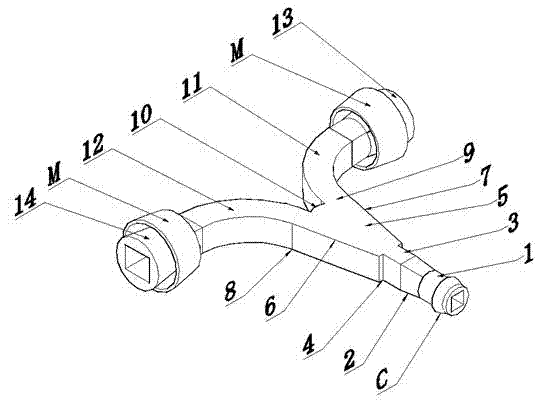

[0023] Embodiment 1: refer to figure 1 , figure 2 and image 3 , The jet tee is composed of an inlet section 1, a jet element F, an outlet section I14 and an outlet section II13.

[0024] refer to figure 1 and figure 2 , the jet element F includes a constriction section 2, a diversion section 3, a nozzle 4, a jet space 5, a side wall I6, a side wall II7, an output port I8, an output port II9, a splitter 10, an output channel I12, and an output channel II11; The front end of the element F is a contraction section 2 with a large front and a small rear shape. The front end of the contraction section 2 is connected to the end of the water inlet section 1, and the end of the contraction section 2 is connected to the front end of the diversion section 3. The end of the diversion section 3 is a nozzle 4. Behind the nozzle 4 is a jet space 5 with a small front and a large rear. The two sides of the jet space 5 are side wall I6 and side wall II7 respectively; It is divided into ...

Embodiment 2

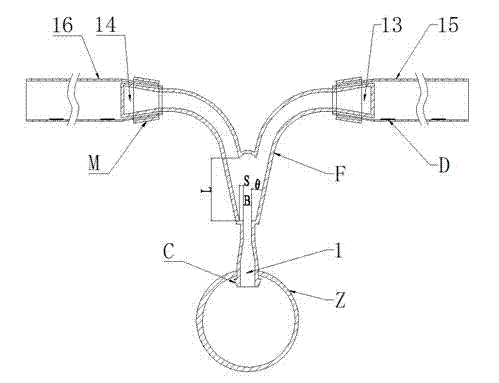

[0031] Embodiment 2: refer to Figure 5 , Figure 6 and Figure 7 . For a jet tee shown in Example 2, the angle between the central axis of the nozzle 4 and the central axis of the outlet section I14 is 12°, the angle between the central axis of the nozzle 4 and the central axis of the outlet section II13 is 12°, and the capillary I16 It is distributed on one side of branch Z with capillary II15. The structural features of the rest of the components are the same as those in Embodiment 1, and the parts with the same structure are denoted by the same reference numerals, and will not be described again. The principle and implementation process of this embodiment are also the same as those of the first embodiment, so the description thereof is omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com