Two-position three-way normally opened type micro fuel oil electromagnetic valve with buffer mechanism

A buffer mechanism and solenoid valve technology, applied in valve details, valve devices, mechanical equipment, etc., can solve the problems of heavy weight, high energy consumption for startup, and large volume, and achieve the effects of light weight, large volume, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

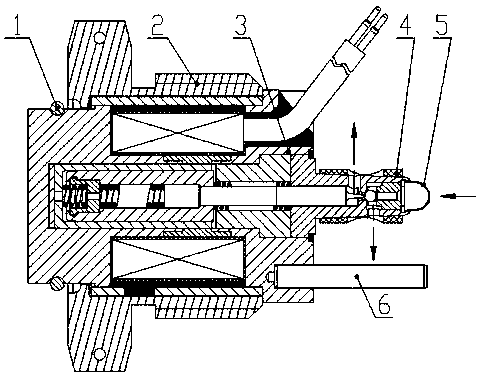

[0029] Embodiment of the present invention: a two-position three-position normally open miniature fuel solenoid valve with a buffer mechanism, which mainly consists of a steel wire retaining ring 1; an installation housing 2; a coil assembly 3; a sealing bush 4; an inlet filter screen 5; positioning pin 6 and so on.

[0030] as attached figure 1 As shown, when assembling the solenoid valve, install the inlet filter 5 on the coil assembly 3; the inlet filter 5 is used to filter out impurities in the hydraulic oil, and the positioning pin 6 is pressed into the hole of the coil assembly 3; the installation shell The body 2 is put into the coil assembly 3; the steel wire retaining ring 1 is fastened into the coil assembly 3; the sealing bush 4 is installed into the coil assembly 3.

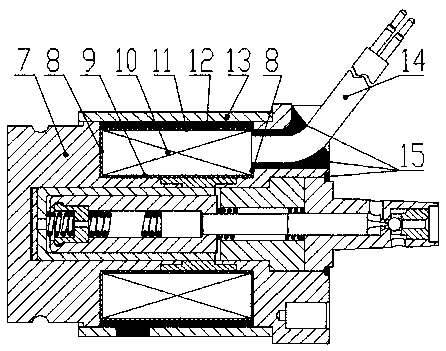

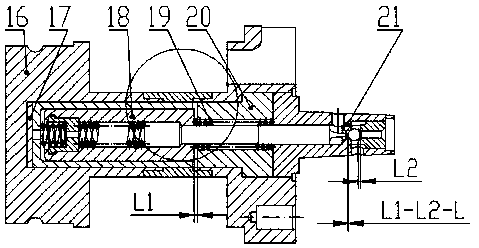

[0031] as attach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com