Piston ring for optical controlled engine

An optical engine and piston ring technology, applied in the field of piston rings, can solve the problems of difficulty in ensuring sealing, loss, and small elasticity, and achieve the effects of ensuring working pressure, reducing temperature rise, and improving sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

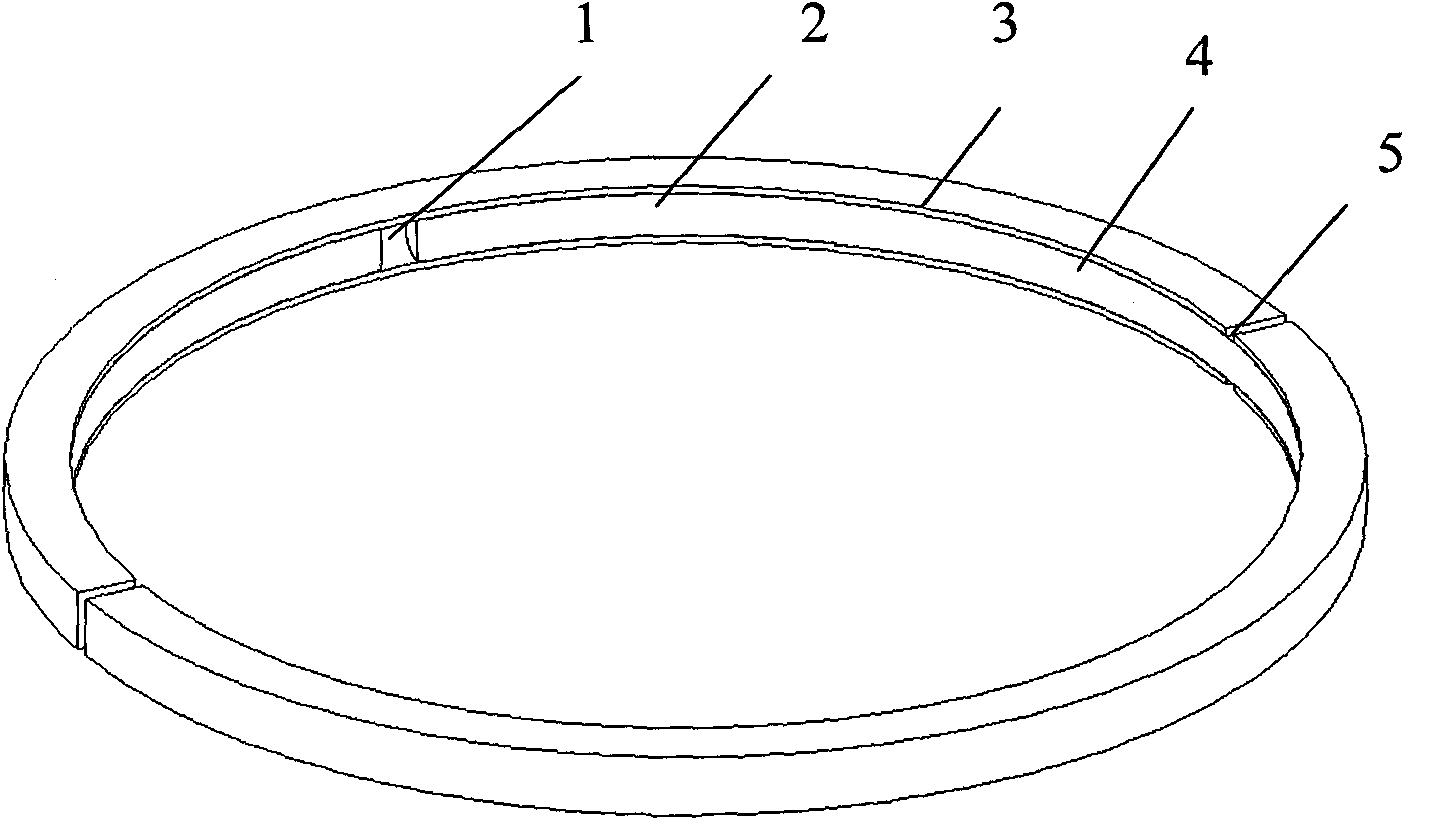

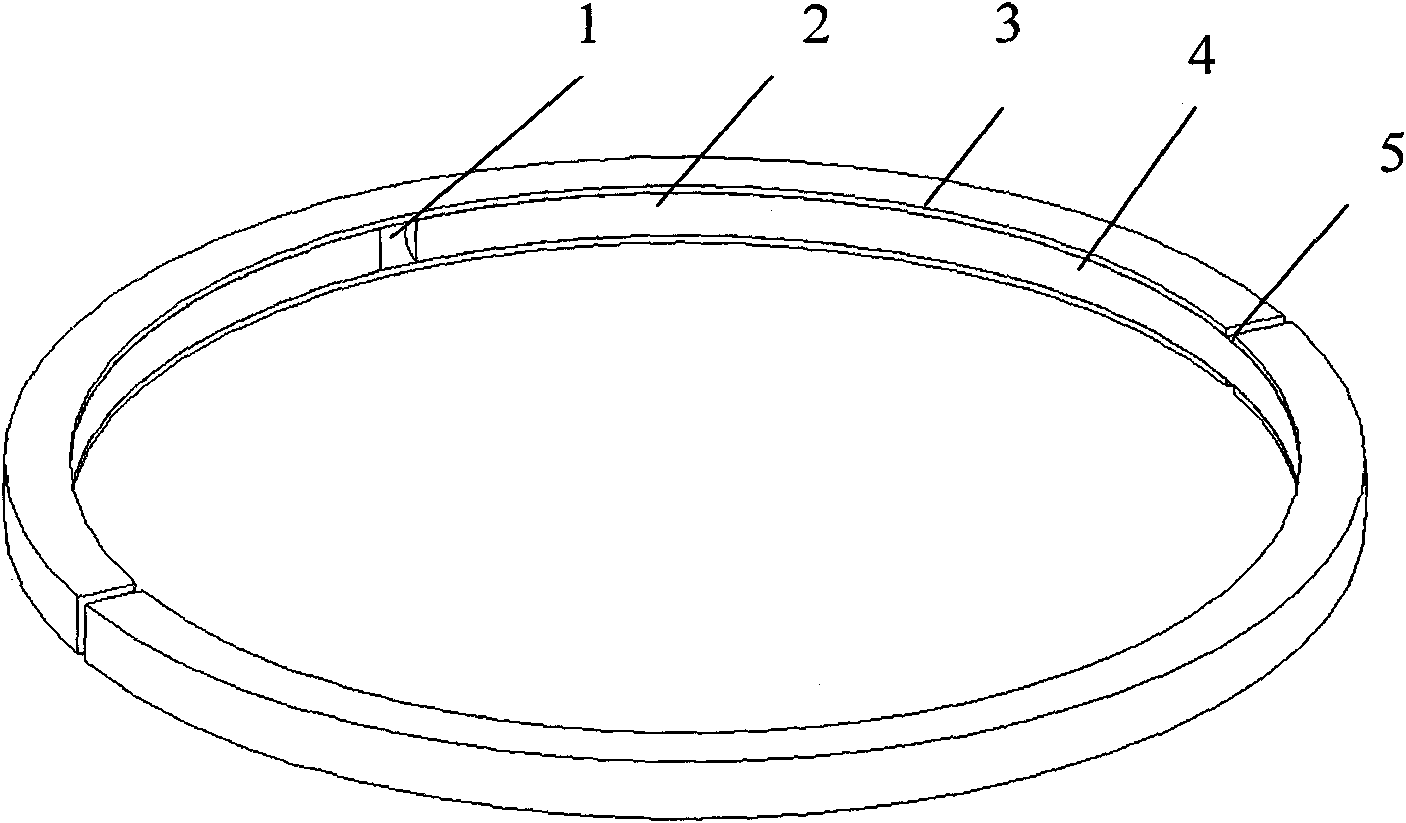

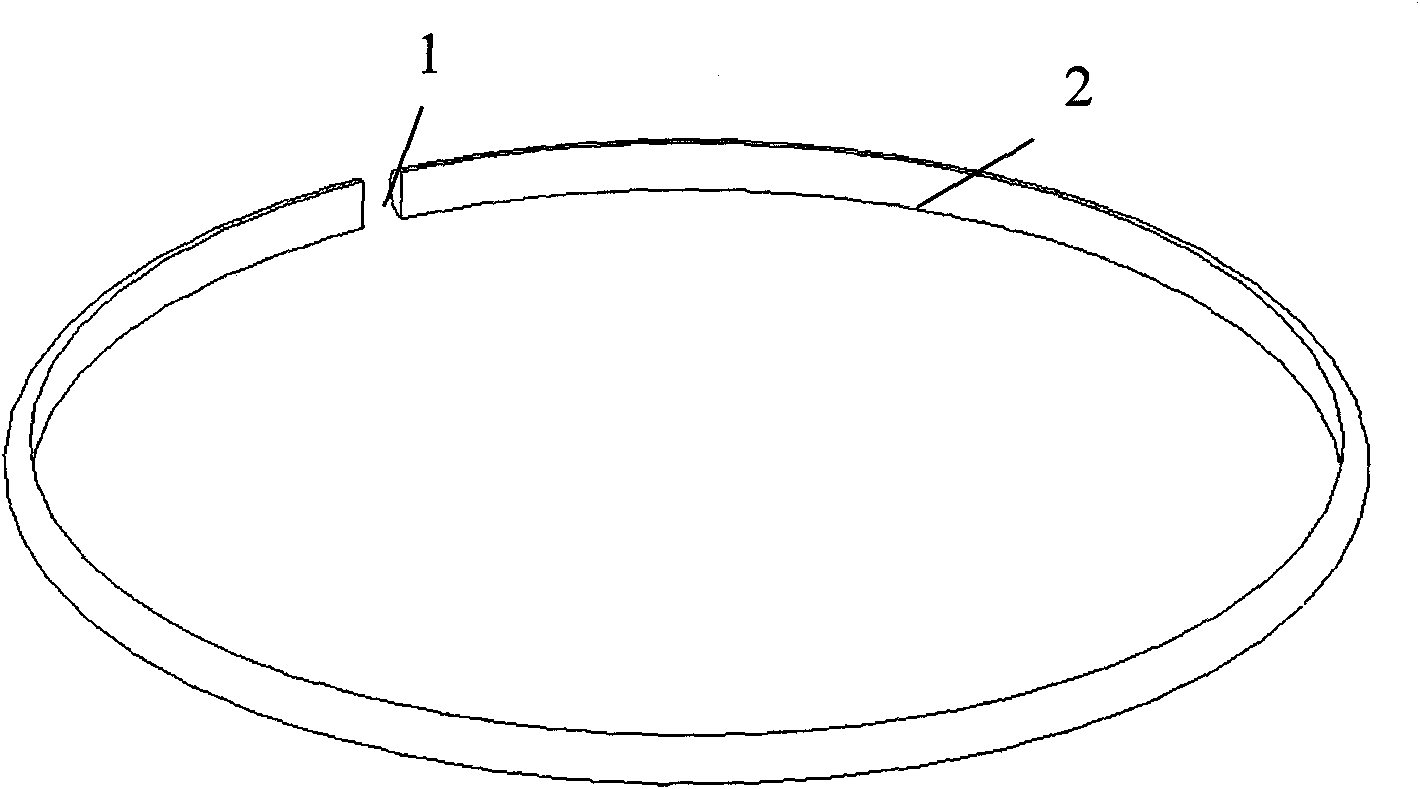

[0014] Embodiment 1, as shown in Fig. 1, Fig. 2, Fig. 3, present embodiment is the piston ring used on a kind of optical engine, and this piston ring comprises the outer ring 3 that is made of graphite material and has elastic inner ring 2, The inner peripheral surface of the outer ring 3 is provided with an arc groove 6 , the inner ring 2 has an inner ring opening 1 , and the inner ring 2 is set in the arc groove 6 . In this embodiment, as shown in FIG. 3 , the outer ring 3 is composed of two graphite semicircular rings merged together, and has two outer ring openings 5 . The inner ring 2 is a split ring made of nickel alloy material, as shown in FIG. 2 . During assembly, the inner surface of the inner ring 2 and the inner surface 4 of the outer ring are kept on the same circumferential surface. The relative positions of the outer ring opening 5 and the inner ring opening 1 form a set angle. Preferably 90 degrees.

[0015] The assembly process of this embodiment is as fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com