Multi-head polishing machine for annularly uniformly distributed circular holes

A ring-shaped uniform distribution and polishing machine technology, which is applied in the direction of grinding/polishing equipment, machine tools designed for grinding the rotating surface of workpieces, grinding machines, etc., and can solve the problems of high processing cost, time-consuming, laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

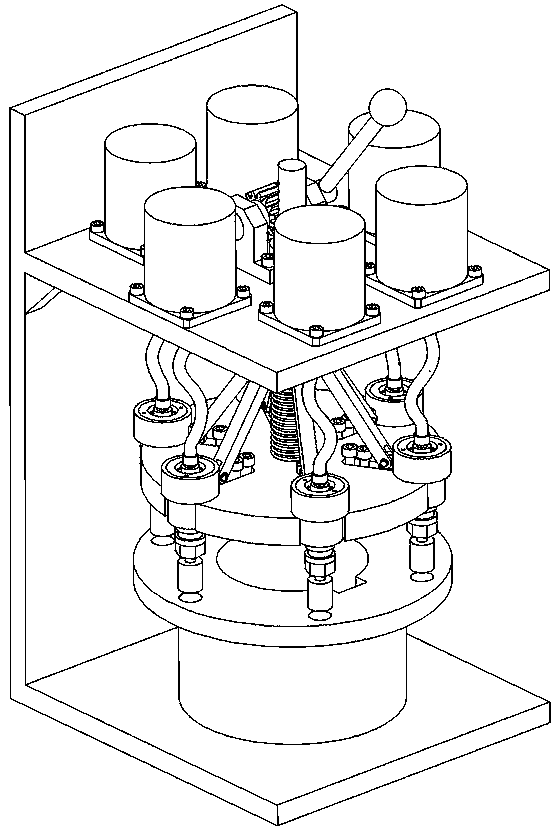

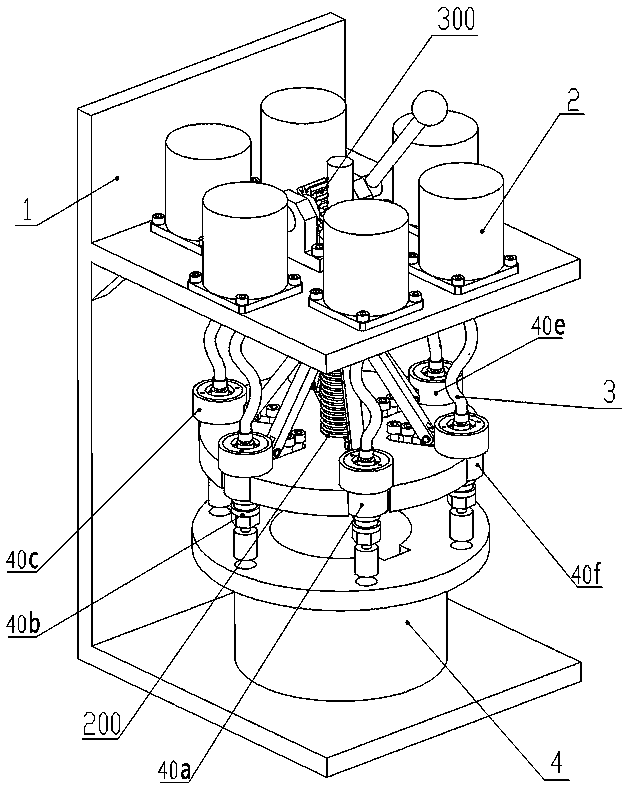

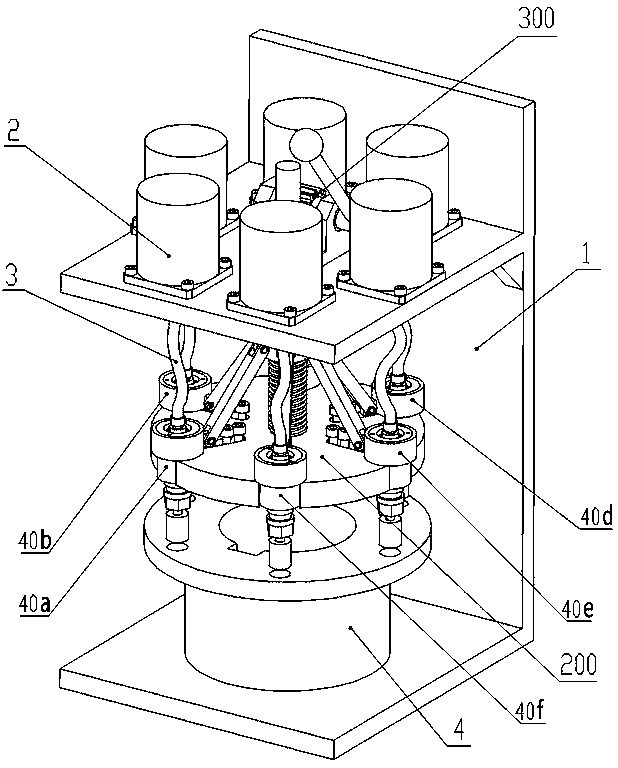

[0031]A multi-head grinding and polishing machine for circular uniformly distributed circular holes is a mechanical processing equipment, especially a special mechanical processing equipment for simultaneously grinding and polishing circular uniformly distributed circular holes to improve the processing quality of the circular hole surface , the main functional components of this equipment include frame (1), DC motor (2), flexible shaft (3), grinding head installation and adjustment mechanism (200), rack and pinion lifting and feeding mechanism (300) and the same structural composition Round hole grinding rotary mechanism a (40a), round hole grinding rotary mechanism b (40b), round hole grinding rotary mechanism c (40c), round hole grinding rotary mechanism d (40d), round hole grinding rotary mechanism e (40e) and Round hole grinding rotary mechanism f (40f).

[0032] A multi-head grinding and polishing machine for uniformly distributed circular holes of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com