Grinding method for starwheel oval straight channel

A star wheel and channel technology, which is applied in grinding/polishing equipment, grinding machines, metal processing equipment, etc., can solve the problems that cannot meet the accuracy requirements of aviation high-precision star wheels, and achieve the accuracy requirements and stable dimensional accuracy , Reduce the effect of processing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

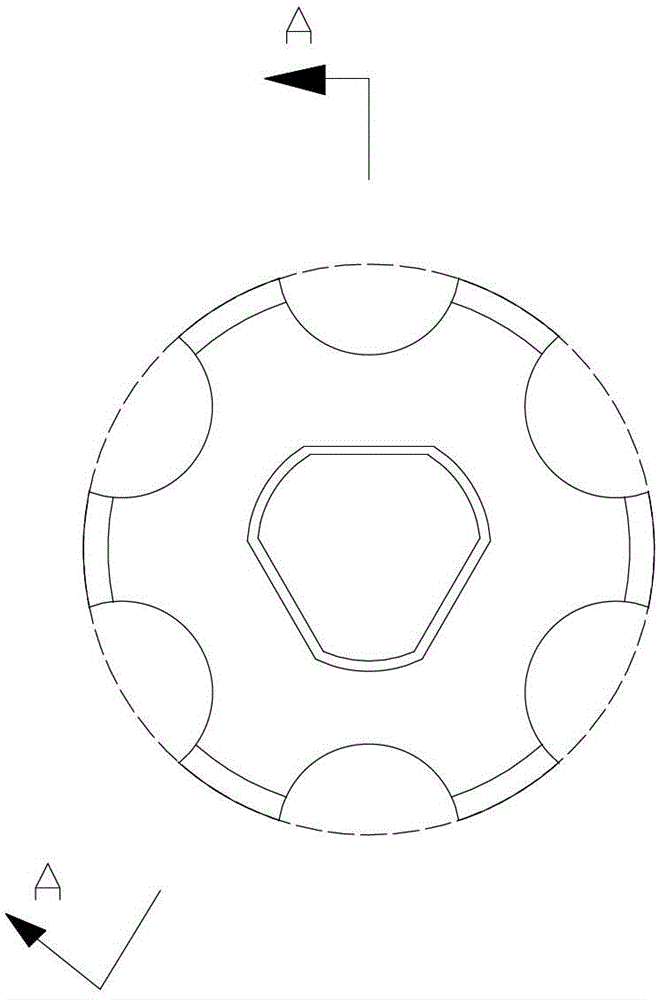

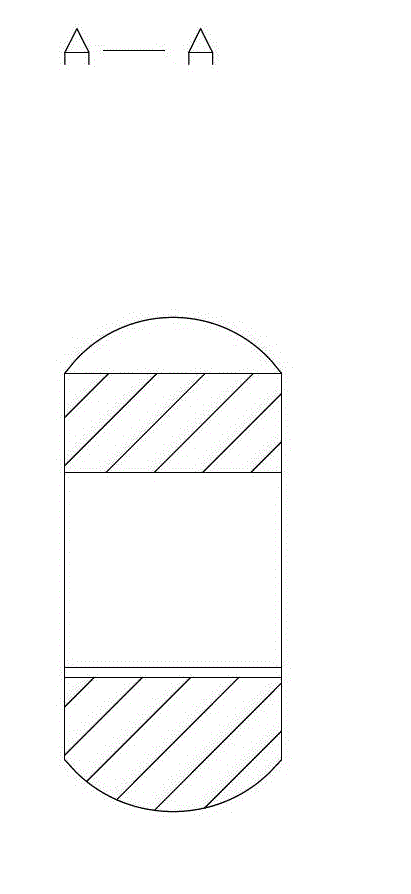

[0035] A certain type of engine coupling star wheel elliptical straight channel grinding, star wheel spherical outer diameter 52mm, width 21±0.05mm, straight channel ellipse short axis 18.37mm, long axis 19.12mm, star wheel elliptical straight groove The surface roughness of the raceway is not higher than Ra0.4mm, the roundness error of the arc channel of the star wheel parts is not greater than 0.008mm, the angle difference between any two raceways of the star wheel is not greater than 1.5′, and the pitch circle diameter error of the raceway is not greater than 0.008mm. Not more than 0.01mm.

[0036] The implementation process is as follows:

[0037] 1) Preparation: prepare the star wheel of the oval straight channel to be processed;

[0038] 2) Processing: Process the inner mounting hole of the star wheel to a qualified size, and process the end face and outer spherical surface of the star wheel. The maximum flatness of the machined end face is 0.003mm, and the maximum roun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com