Swing device for eccentric arc grinding

An oscillating device and arc technology, which is applied to the grinding drive device, the parts of the grinding machine, the grinding frame, etc., can solve the problems of inaccurate eccentric positioning, performance, inconsistent arc size, etc. The effect of positioning accuracy, simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

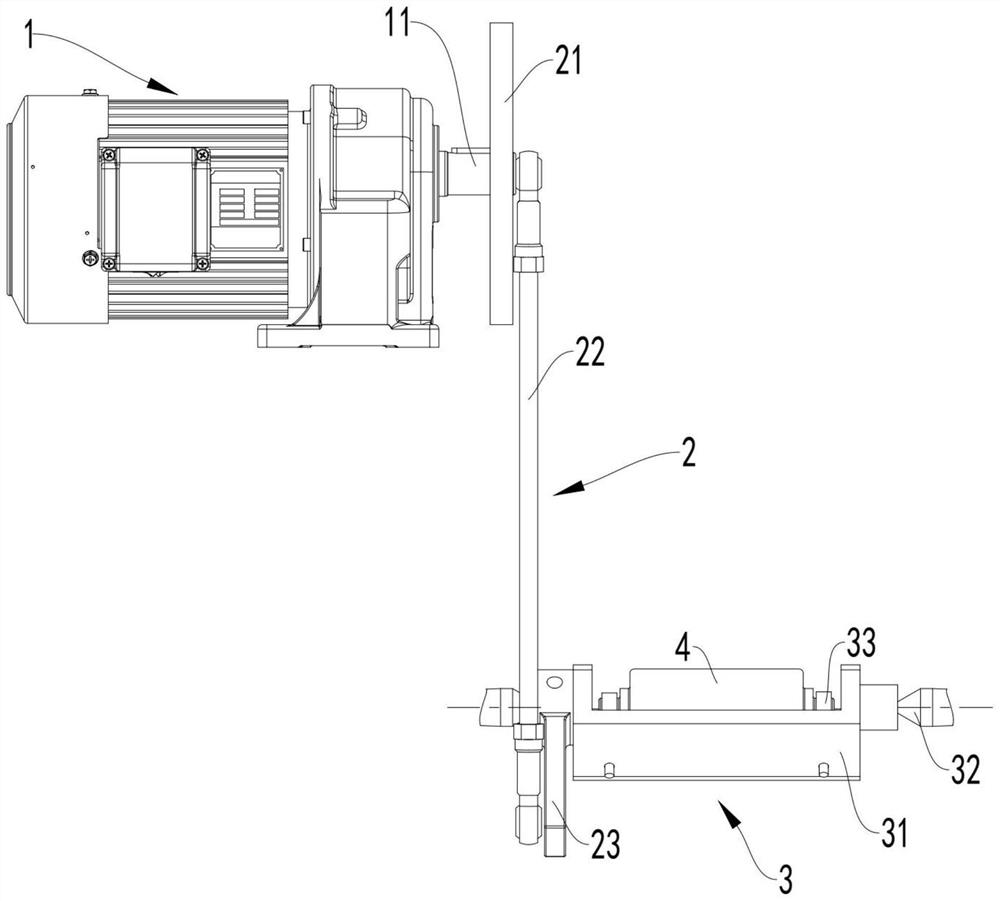

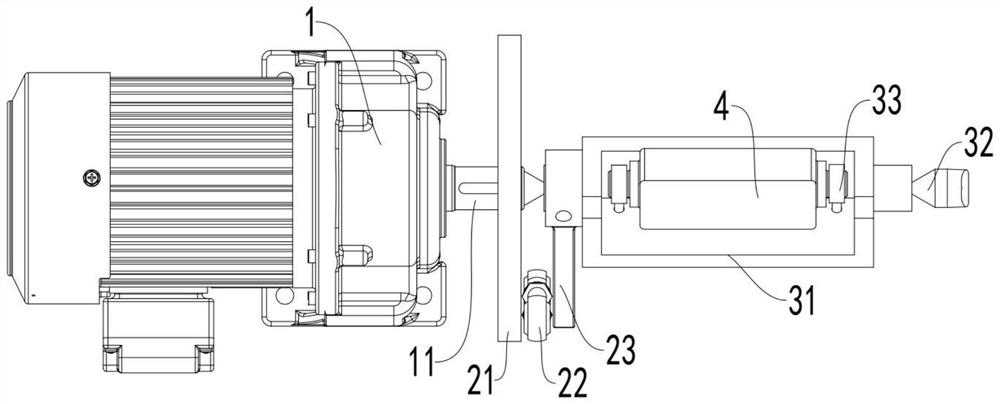

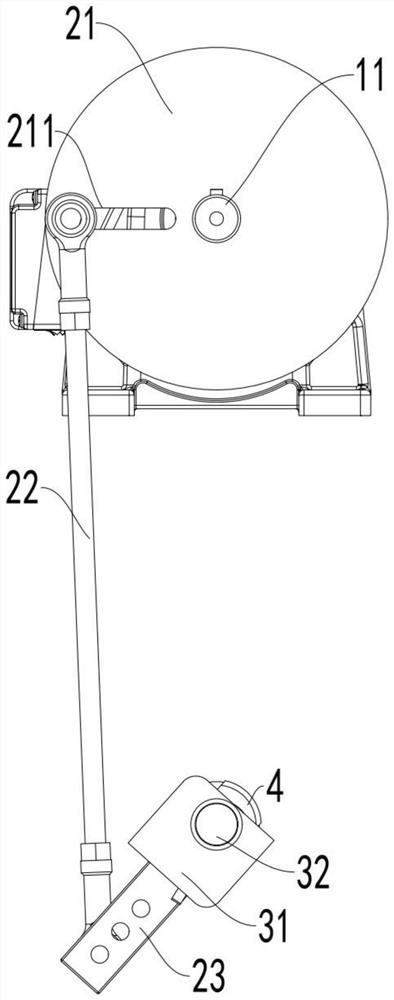

[0022] Such as Figures 1 to 3 As shown, an oscillating device for eccentric arc grinding includes a driving member 1, a transmission structure 2 and a oscillating structure 3, and the transmission structure 2 is connected to the driving member 1 and the oscillating structure 3;

[0023] The transmission structure 2 includes a transmission wheel 21, a transmission rod 22 and a connecting rod 23; the transmission wheel 21 is sleeved on the output shaft 11 of the drive member 1, and the transmission wheel 21 has a notch 211; One end of the rod 22 is rotatably connected to the notch 211, and the other end of the transmission rod 22 is rotatably connected to one end of the connecting rod 23; and the other end of the connecting rod 23 is connected to the swing structure 3 ;

[0024] The swing structure 3 includes a yaw frame 31, a yaw frame fixing part 32 and a wedge block fixing part 33; one end of the connecting rod 23 is rotatably connected to one end of the yaw frame 31; the y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com