Plastic mold thimble grinding fixture

A technology of plastic molds and thimbles, which is applied in the direction of grinding workpiece supports, etc., can solve the problems of high labor intensity, low processing efficiency, time waste, etc., and achieve the effects of convenient operation, convenient clamping, and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

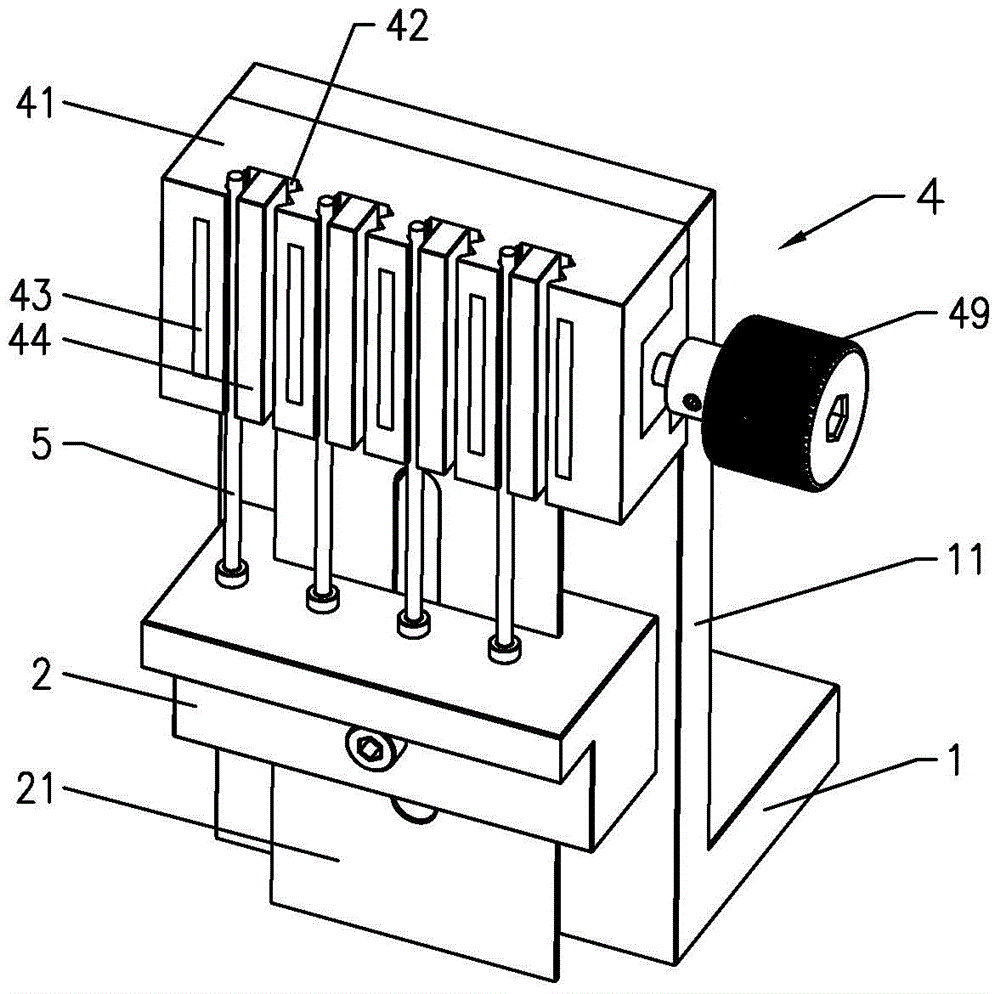

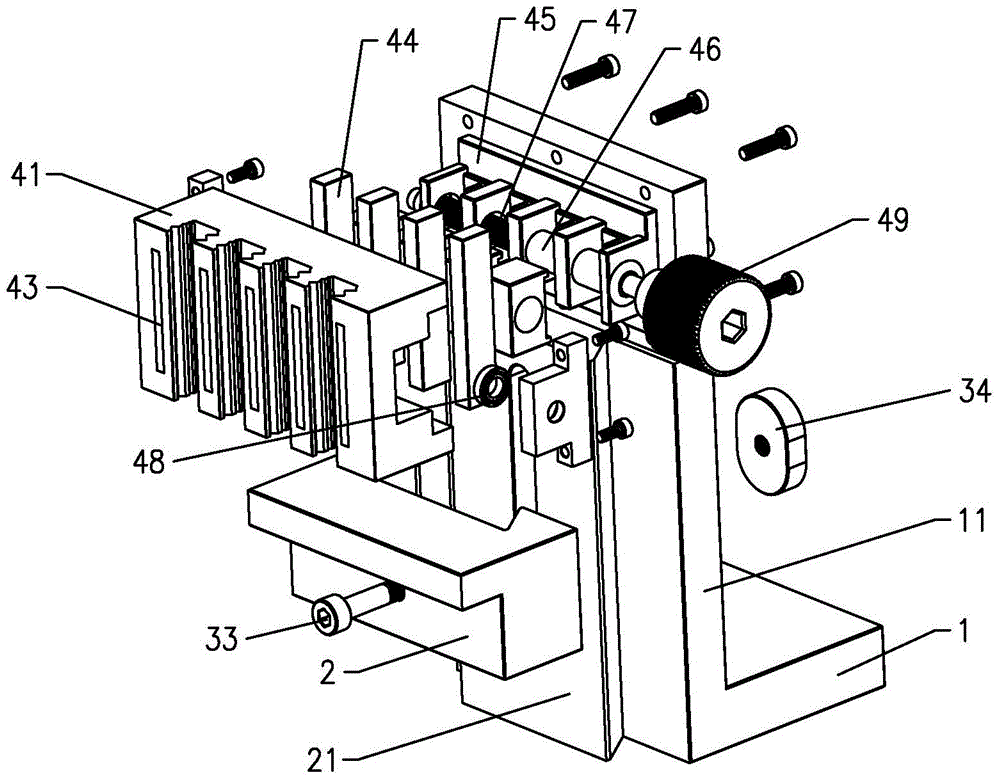

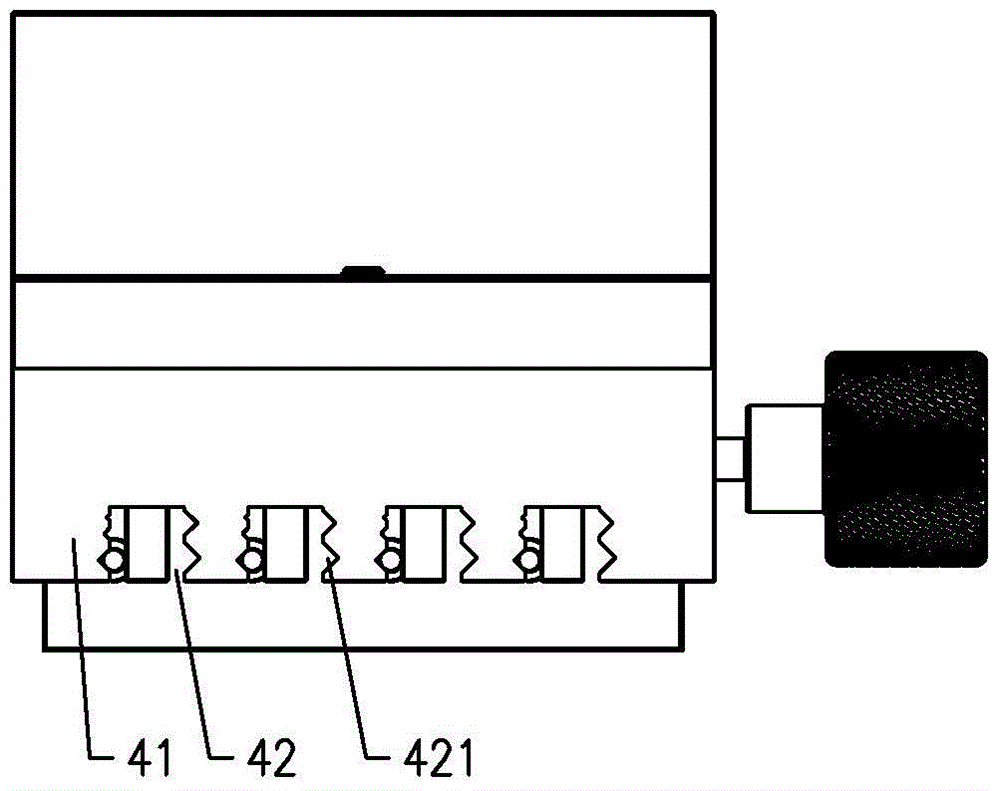

[0025] Such as Figure 1 to Figure 4 As shown, a plastic mold thimble grinding fixture, which includes a base 1, a mounting plate 11 vertically arranged on the base 1, a height adjustment seat 2 located at the bottom of the mounting plate 11, and a thimble located at the top of the mounting plate 11 Clamp 4.

[0026] The mounting plate 11 and the base 1 form an L shape, and the bottom surface of the base 1 is a support plane, which can be installed and adsorbed on the magnetic table of the surface grinder, and the installation is simple and the operation is convenient.

[0027] The height adjustment seat 2 and the mounting plate 11 are slidably assembled to move up and down through the dovetail groove guide rail 21, and a locking mechanism is provided between the height adjustment seat 2 and the mounting plate 11, and the height adjustment seat 2 is fixed by the locking mechanism . The above-mentioned locking mechanism includes: a vertical hole 31 provided on the mounting pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com