Rotary type stone processing equipment

A stone processing and rotary technology, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of low production efficiency and difficult continuous production, achieve high production efficiency, high processing quality, and avoid damage The effect of stone surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

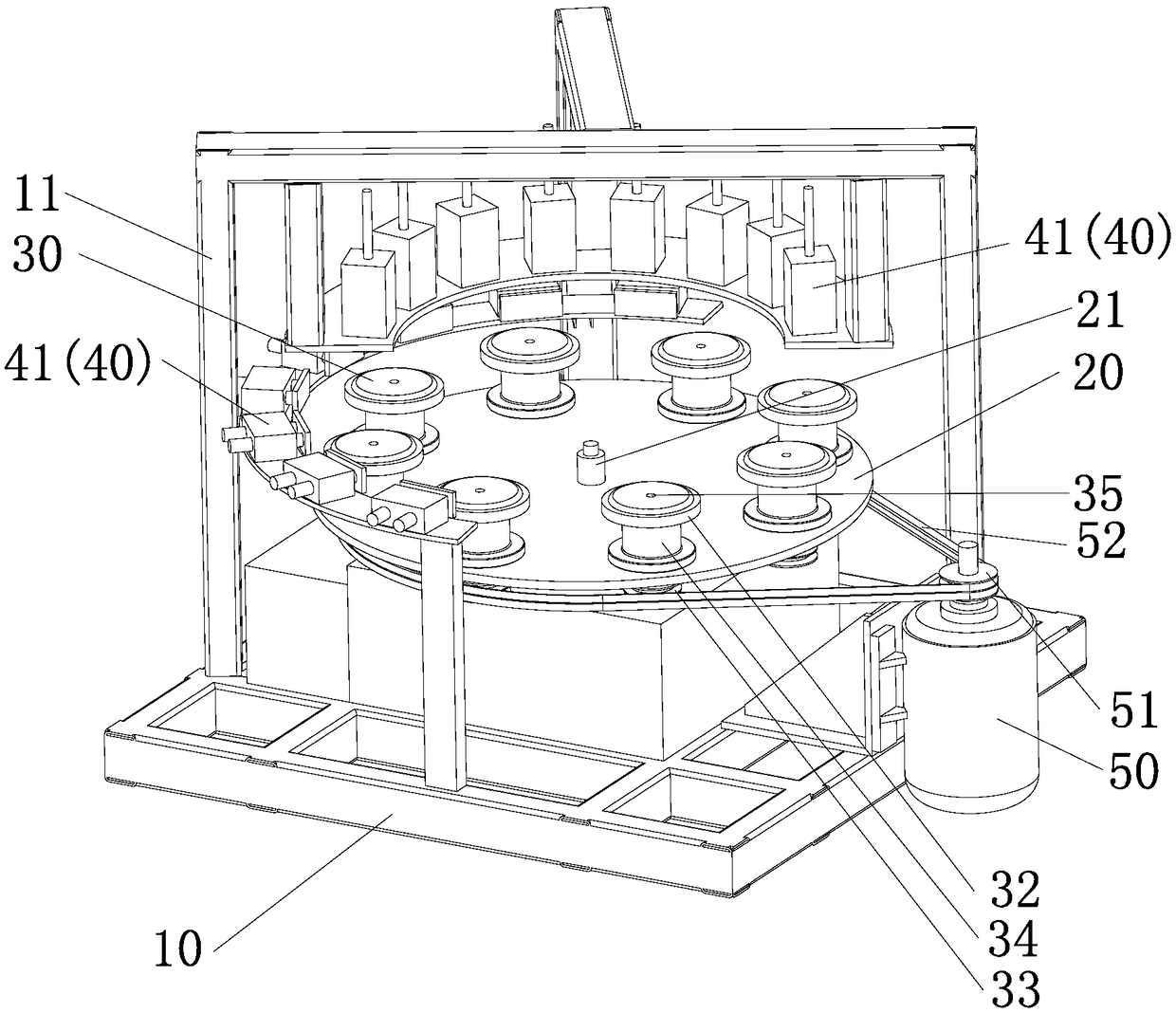

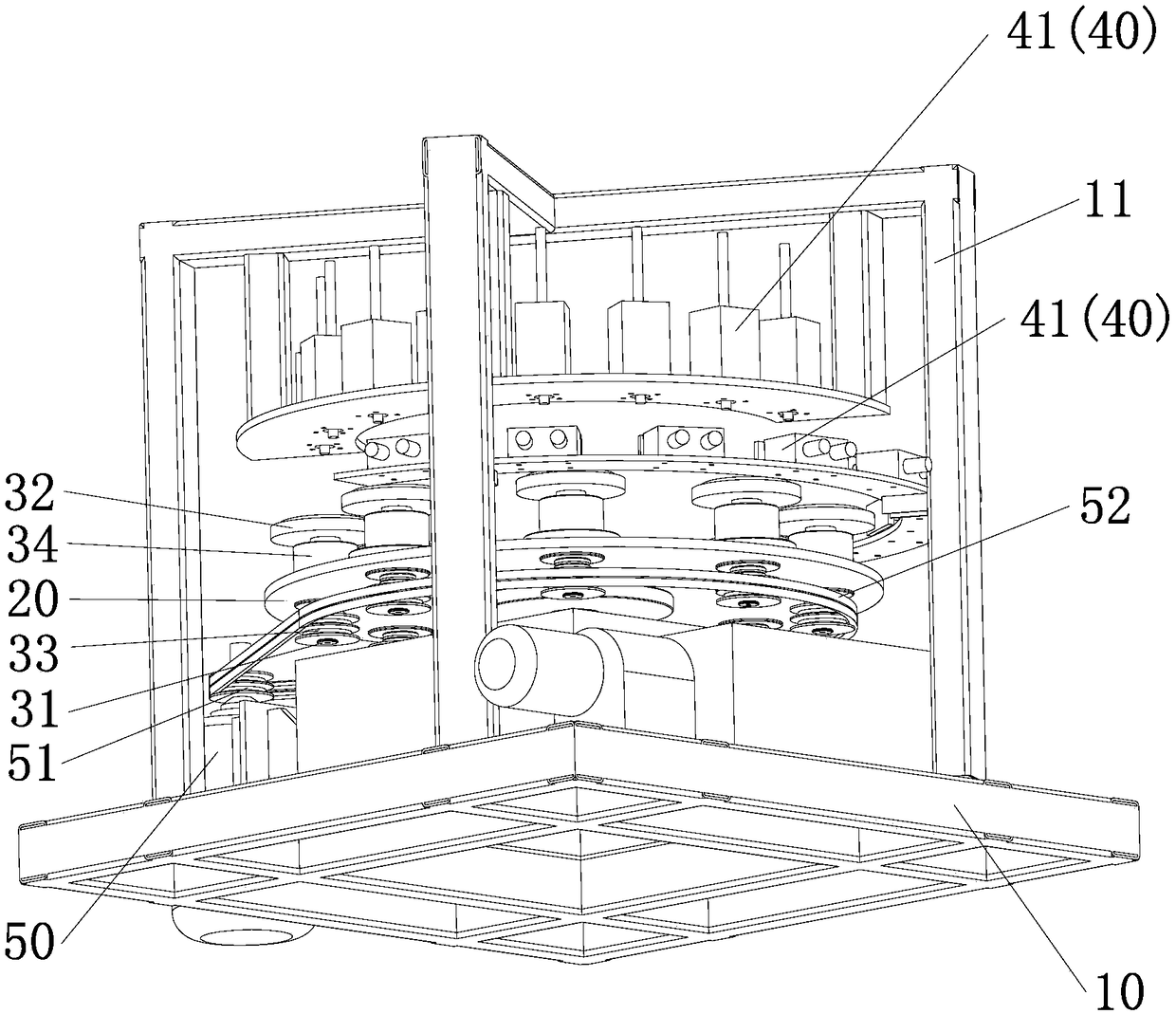

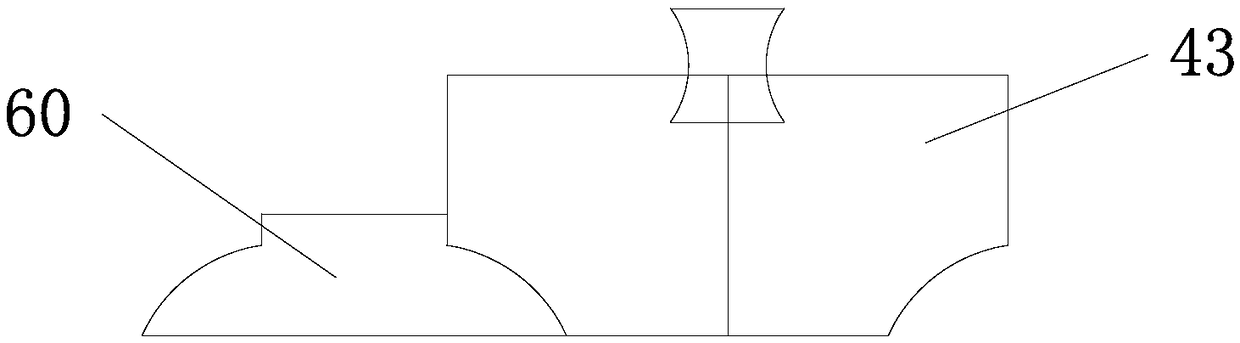

[0037] Such as figure 1 As shown, the rotary stone processing equipment provided in this embodiment includes a base 10, and a turntable 20 is rotatably connected to the base 10. The turntable 20 is arranged horizontally, and the turntable 20 is provided with a rotating motor fixedly connected to the base 10. 50 and a plurality of rotating assemblies 30 evenly distributed around the rotating shaft of the turntable 20. Preferably, the rotary stone processing equipment provided in this embodiment also includes a loading and unloading device arranged on the base 10 or beside the base 10. The manipulator (not shown in the figure), the loading and unloading manipulator is a manipulator that can be directly purchased from the market, such as a multi-joint series manipulator, etc., which are not the focus of this embodiment and will not be described in detail here. In addition, a plurality of grinding assemblies 40 are arranged on the top and / or sides of the turntable 20 to cooperate ...

Embodiment 2

[0049] This embodiment provides a passive grinding device, which includes a frame, and the frame is provided with a rotating assembly 30 and a grinding assembly 40 located above the rotating assembly 30 or on the side

[0050] The structure of the rotating assembly 30 in this embodiment is the same as that in Embodiment 1. The difference is that, since there is no turntable 20, in this embodiment, the rotating rod 31 of the rotating assembly 30 is rotatably connected to the frame, and the rotating assembly 30 also Comprising a rotating motor 50 fixedly connected to the frame, that is, the rotating assembly 30 of this embodiment includes a rotating rod 31 rotatably connected to the frame and a rotating motor 50 fixedly connected to the frame, because in this embodiment, Both the driving pulley 51 and the driven pulley 34 have only one, so the transmission belt 52 is wound between the driven pulley 34 and the driving pulley 51 . In addition, the support base 34 in the rotating a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com