Exterior power source multi-station welding clamp

A welding fixture and multi-station technology, applied in the direction of manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problems that the positioning accuracy cannot meet the technical requirements and low efficiency, and achieve the effect of reducing standby time and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

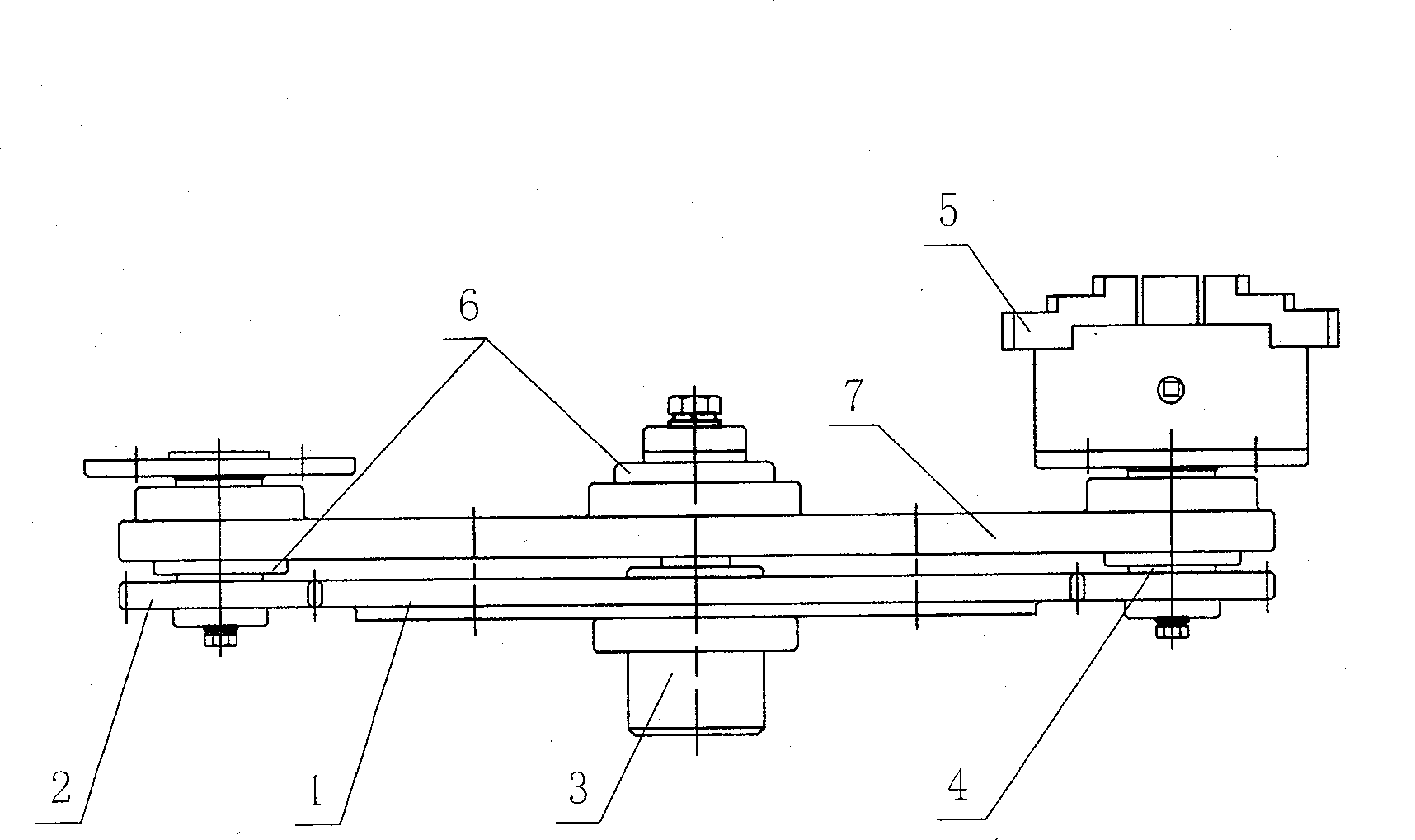

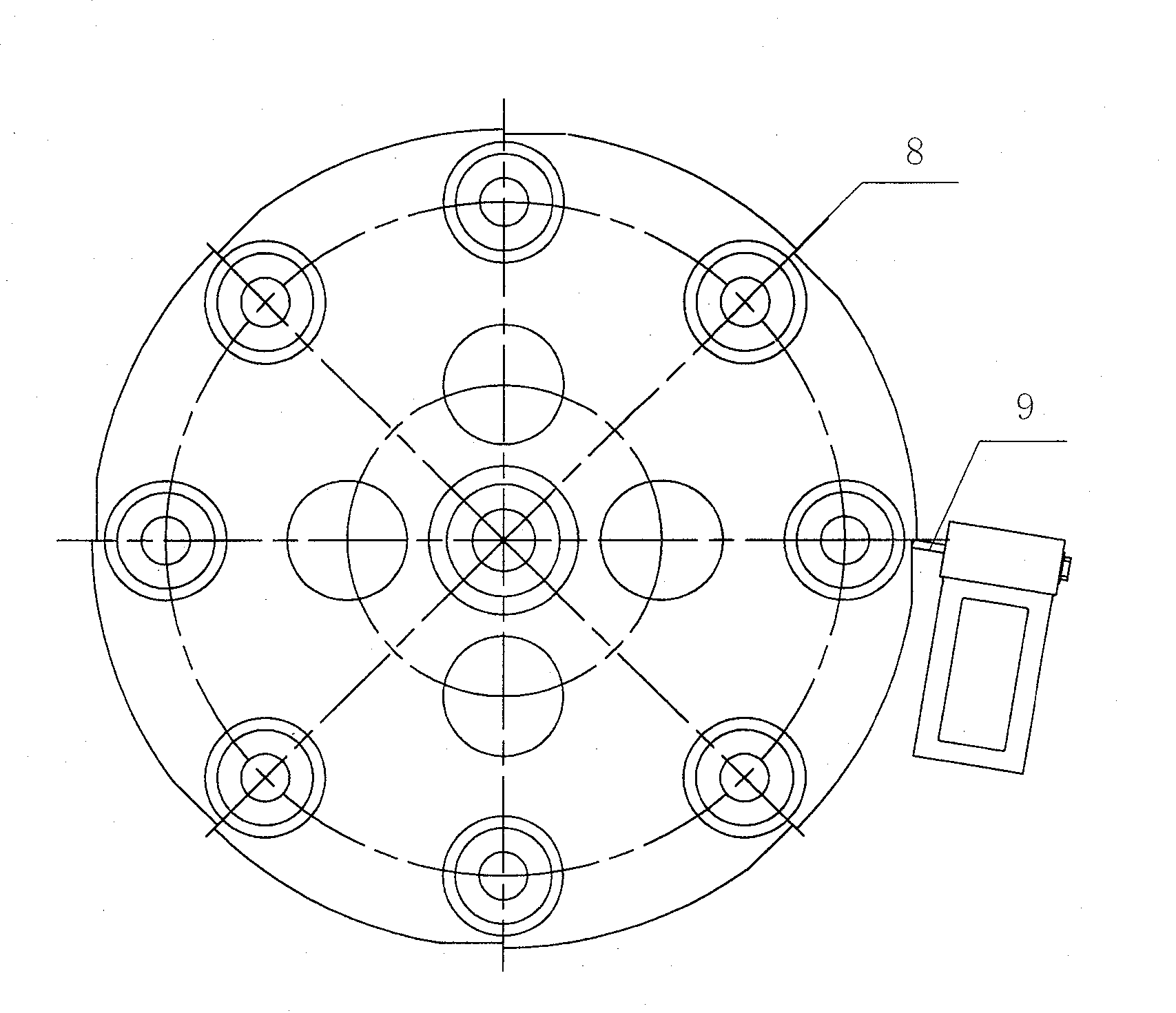

[0011] figure 1 In the shown embodiment, the driving gear 1 meshes with eight driven gears 2; one end of the main shaft 3 is matched with the positioning hole in the center of the equipped turntable, and four sinking grooves are processed on the driving gear 1, and the driving gear 1 is connected to Connect with the positioning T-slot of the turntable. Driving gear 1 meshes with eight driven gears 2. The driven gear 2 is assembled with the three-jaw chuck 5 through the station shaft 4 . The station shaft 4 is evenly installed on eight station holes uniformly distributed on a circular mounting plate 7 through a group of back-to-back thrust bearings 6, and the main shaft 3 passes through the center of the mounting plate 7. On the outer edge of the mounting plate 7, there are eight one-way stop steps 8 at the position where the station axis 4 intersects the radius of the circular mounting plate.

[0012] exist figure 2 In the shown embodiment, that is, in the working state, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com