Two-axis linkage numerical control grinding machine with double spindles

A CNC grinding machine and shaft linkage technology, which is applied in the direction of grinding machines, machine tools suitable for grinding the edge of workpieces, and machine tools designed for grinding the rotating surface of workpieces, etc. Problems such as holes in deep-drawing parts, to achieve the effect of low difficulty, low cost and simple realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

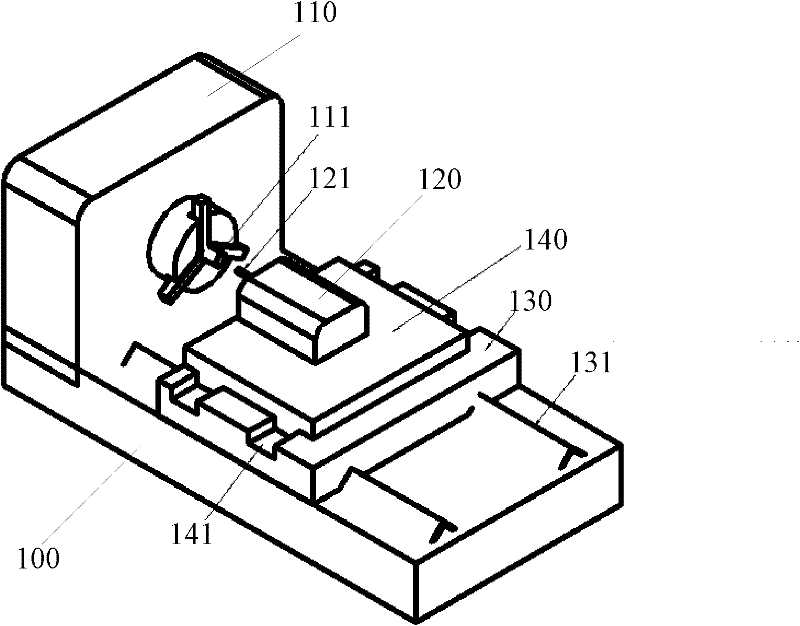

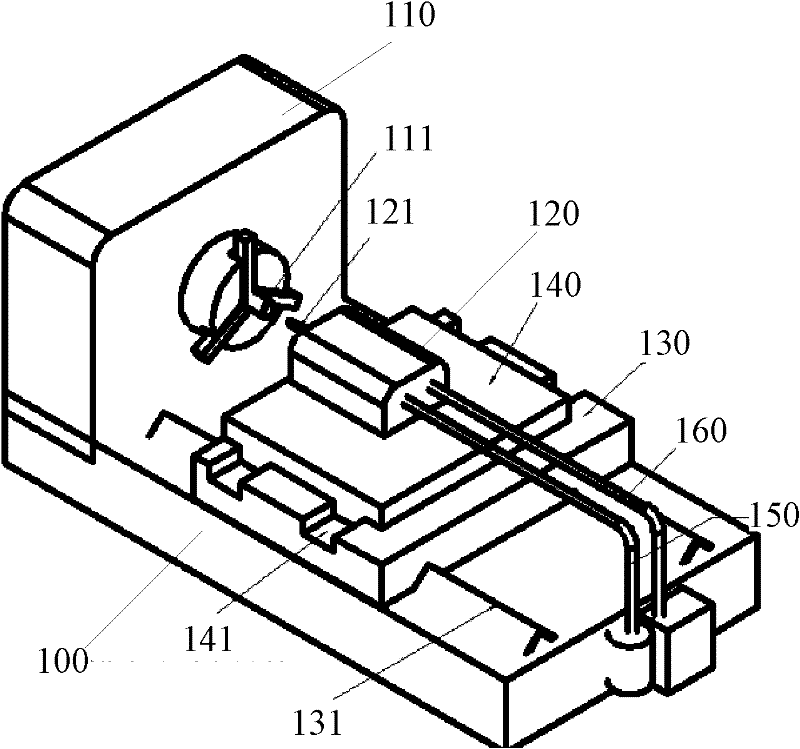

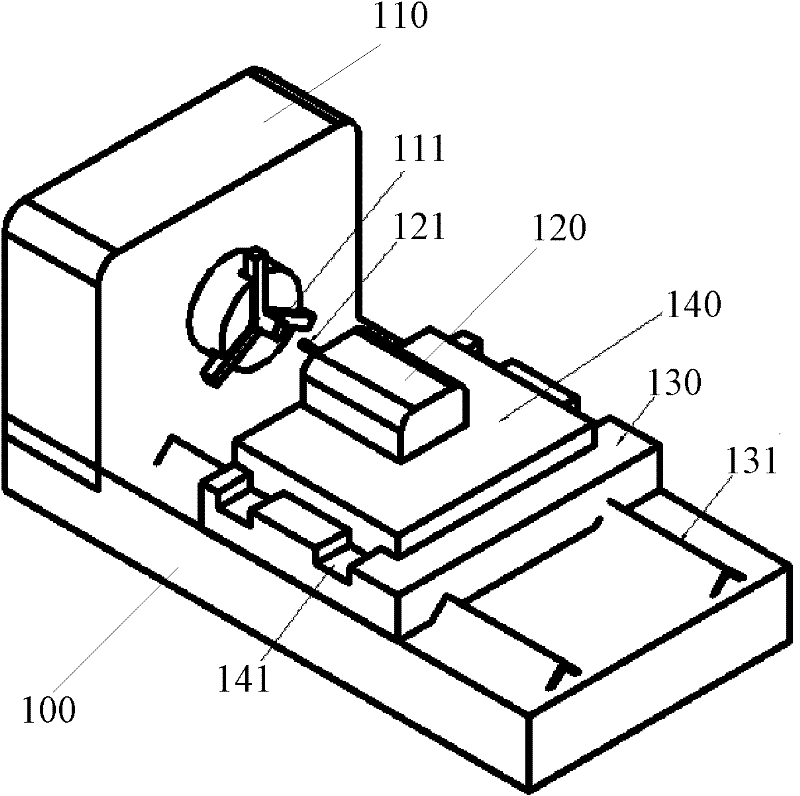

[0017] Please refer to figure 1 , figure 1 It is a schematic structural diagram of a dual-spindle and two-axis linkage CNC grinding machine in a preferred embodiment of the present invention.

[0018] The present invention proposes a double-spindle two-axis linkage CNC grinding machine, including a base 100, and a workpiece spindle box 110 and a grinding head spindle seat 120 arranged on the base 100, wherein the workpiece and the workpiece spindle 111 are arranged on the On the workpiece spindle box 110; the longitudinal supporting plate 130 is arranged on the base 100 through the longitudinal guide rail 131; the transverse supporting plate 140 is arranged on the described longitudinal supporting plate 130 through the transverse guide rail 141; the grinding head spindle seat 120 Set on the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com