Method for comprehensive utilization of high-iron bauxite

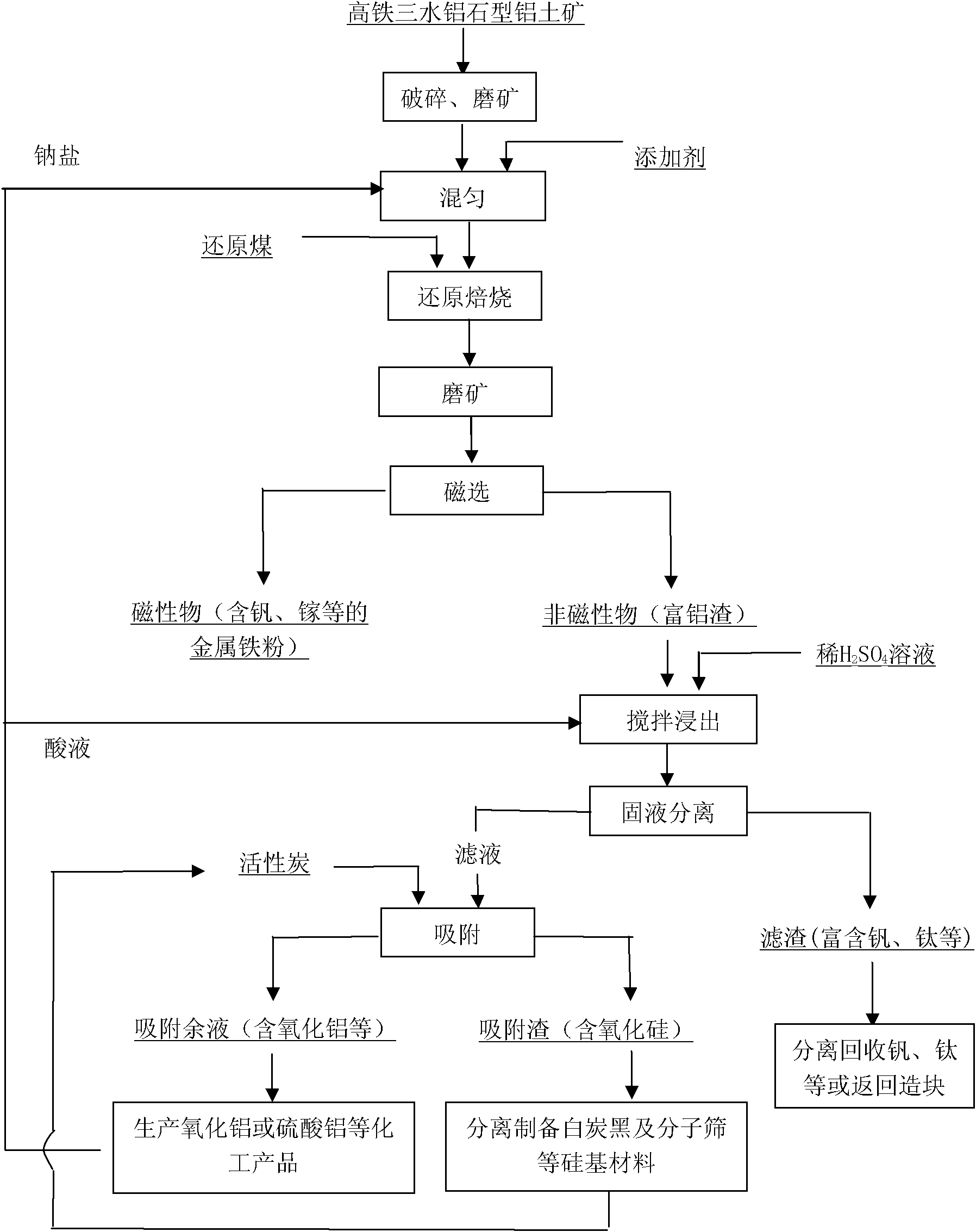

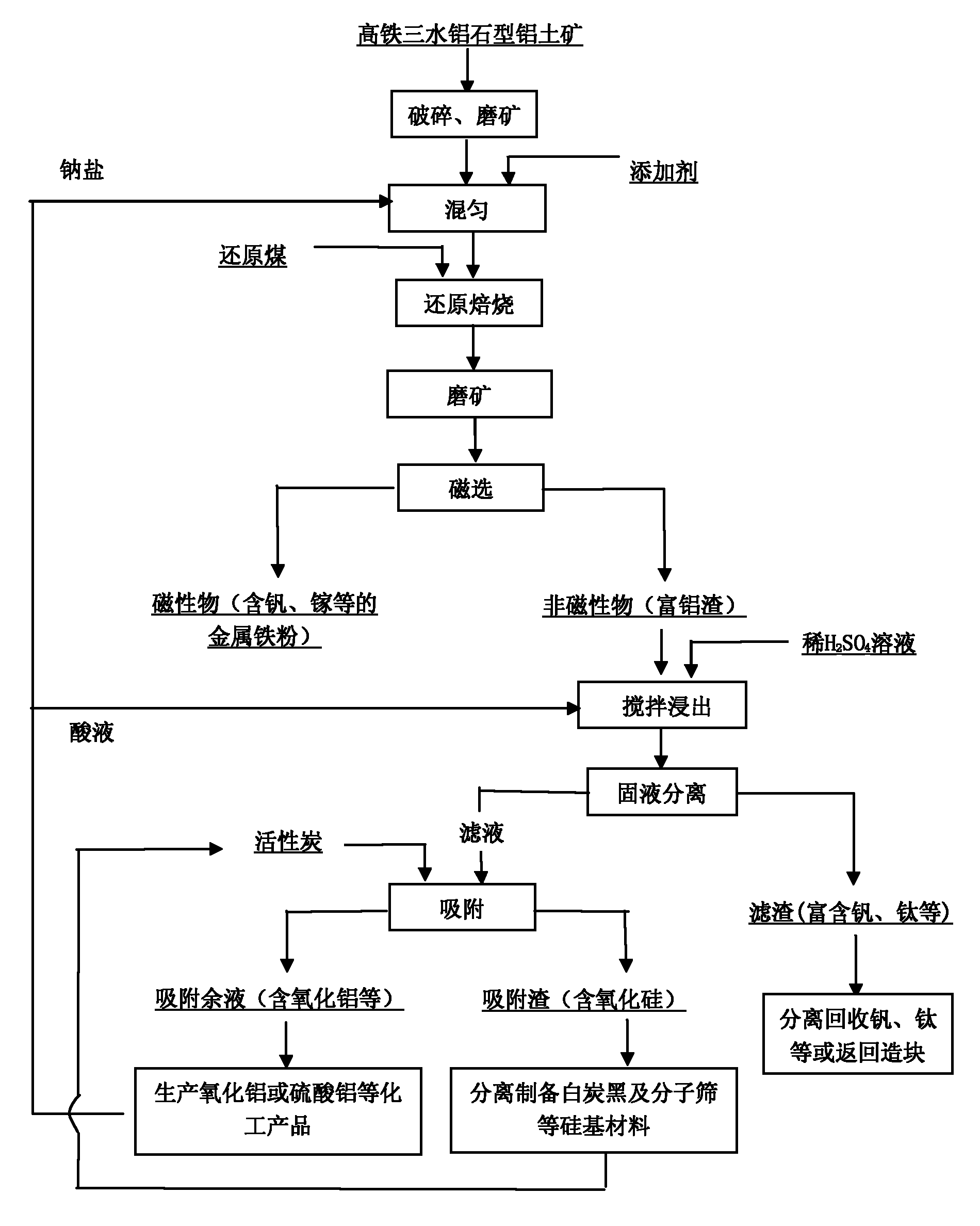

A technology for high-iron bauxite and ore grinding, which is applied in chemical instruments and methods, wet separation, silicon compounds, etc., can solve problems such as inability to desilicate bauxite, difficult monomer dissociation, and complicated relationships. To achieve the effect of comprehensive utilization and value-added processing, good application prospects and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: High-iron bauxite is pre-crushed and ground to a fineness of -0.074mm, and the mass percentage of the particle size is 80%, and then mixed with sodium bicarbonate and sodium citrate in a mass ratio of 95:5 The compounding of additives, the dosage of additives is 17.5% of the mass percentage of dry basis of high-iron bauxite, after mixing, it is reduced and roasted at 1000°C for 90min, and the dosage of reducing agent coal is 0.7% of the dry mass. times, the roasted product is ground to a fineness of -0.074mm, and the mass percentage is 95%, and it is magnetically separated under a magnetic field strength of 97.5mT. The TFe content in the obtained magnetic product metal iron powder is 90.08%, and the Al 2 o 3 Content 1.89%, SiO 2 The content is 1.72%, and the magnetic separation recovery rate of iron is 89.23%. The TFe content of aluminum-rich slag is 5.64%, Al 2 o 3 Content 37.72%, SiO 2Content 11.62%. The aluminum-rich slag is leached with a sulfuri...

Embodiment 2

[0020] Embodiment 2: High-iron bauxite is pre-crushed and ground to a fineness of -0.074mm, and the mass percentage of the particle size is 85%, and then mixed with sodium bicarbonate and sodium citrate in a mass ratio of 92:8. The compounding of the additives, the addition amount of the additive accounts for 25% of the mass percentage of the high-iron bauxite dry basis, after mixing, it is reduced and roasted at a temperature of 1050°C for 90min, and the addition amount of the reducing agent coal is 0.9% of the mass of the dry mass. times, the roasted product is ground to a fineness of -0.074mm and the mass percentage is 95%, and magnetically separated under a magnetic field strength of 125mT, the TFe content in the obtained magnetic product metal iron powder is 92.96%, Al 2 o 3 content of 1.28%, SiO 2 The content is 1.17%, and the magnetic recovery rate of iron is 92.77%. The TFe content of aluminum-rich slag is 3.61%, Al 2 o 3 Content 40.92%, SiO 2 Content 11.65%. The...

Embodiment 3

[0021] Example 3: High-iron bauxite is pre-crushed and ground to a fineness of -0.074mm, the mass percentage of which is 95%, and is mixed with sodium bicarbonate and sodium citrate in a mass ratio of 95:5 Additives, the amount of additives accounted for 22.5% of the dry mass percentage of high-iron bauxite, after mixing, it was reduced and roasted at a temperature of 1100 ° C for 60 minutes, and the amount of reducing agent coal added was 1.2 times the dry mass. , the roasted product is ground to a fineness of -0.074mm, and the mass percentage is 98%. Magnetic separation under a magnetic field strength of 125mT, the TFe content in the obtained magnetic product metal iron powder is 92.23%, Al 2 o 3 Content 1.49%, SiO 2 The content is 1.27%, and the magnetic separation recovery rate of iron is 92.66%. TFe content of aluminum-rich slag is 4.02%, Al 2 o 3 Content 35.28%, SiO 2 Content 12.19%. The aluminum-rich slag is leached with a sulfuric acid solution with a mass percen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com