Method and device based on micro-nano laser-induced shock wave three dimensional lossless makr

A technology of laser shock and shock wave, which is applied in the direction of laser welding equipment, digital marking record carrier, record carrier used by machines, etc. It can solve problems such as unevenness, uneven spatial distribution of pulse laser, liquid crystal absorption spectrum, and inability to mark complex graphics. Achieve the effect of non-destructive and three-dimensional high anti-counterfeiting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

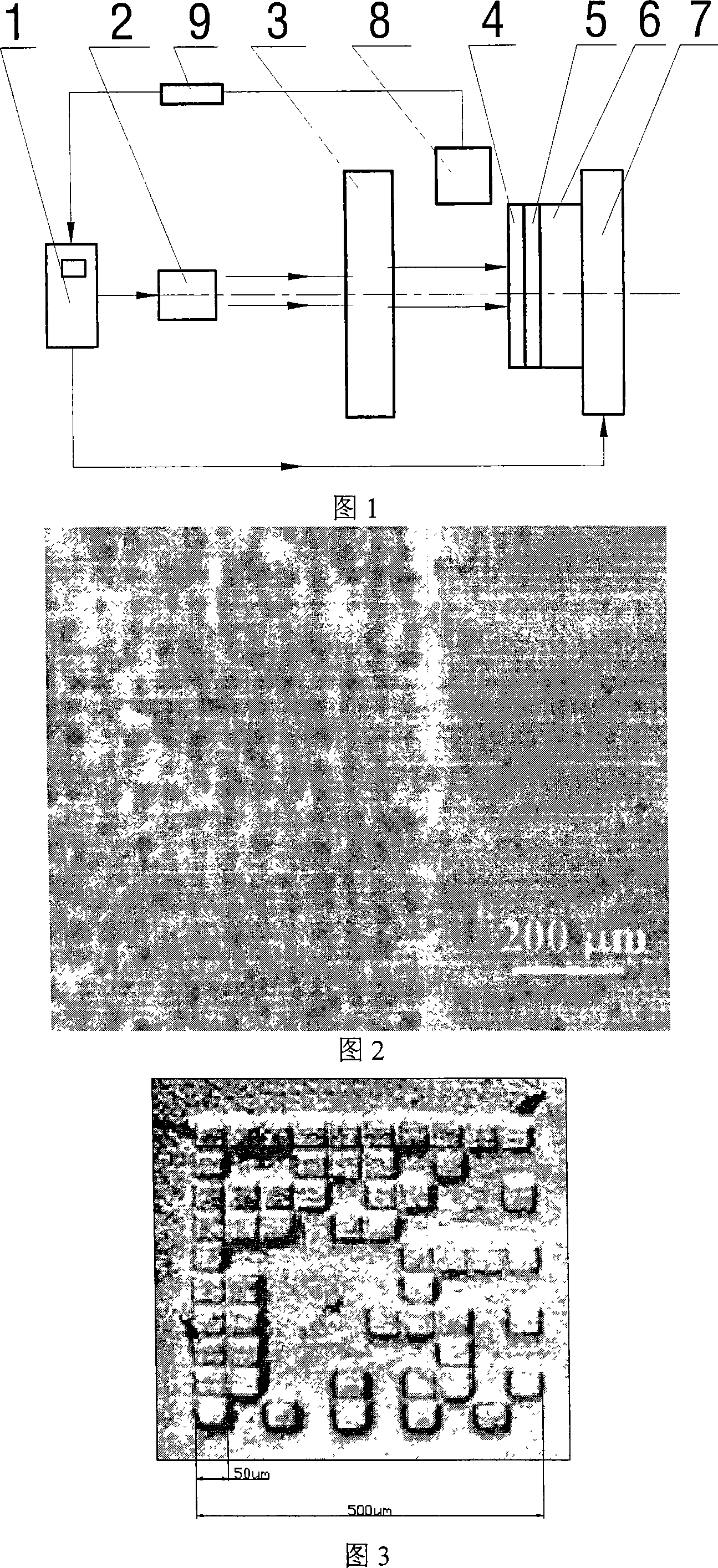

[0025] The details and working conditions of the specific device proposed by the present invention will be described in detail below in conjunction with FIG. 1 .

[0026] The device includes computer control system 1, laser generator 2, beam space modulator 3, constrained layer 4, absorbing layer 5, parts 6, five-axis worktable (including fixture) 7, CCD identification information acquisition device 8 and identification conversion system 9. The spatial modulator is composed of concave lens, convex lens and homogenizer.

[0027] According to the size, pattern and material of the marking area of the part 6, the constraining layer 4 is selected, and the absorbing layer is pasted on the surface of the part 6; according to the requirements of the marking, the trajectory of the laser shock is controlled by a programmable control technology, and controlled by a computer, and According to the complexity of the pattern and the depth of plastic deformation, select the pulse energy, pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com