Measurement and processing integrated laser leveling polishing method

A technology of laser and measuring points, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of no better solution and low precision, and achieve the effect of improving smoothness, processing accuracy and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In this embodiment, the galvanometer scanning system in the integrated measurement and processing device is a one-dimensional galvanometer scanning system, one two-dimensional laser displacement sensor is used, and the displacement stage only supports one-dimensional X-direction movement.

[0048] The invention provides a laser flattening and polishing method integrating measurement and processing, which specifically includes the following steps:

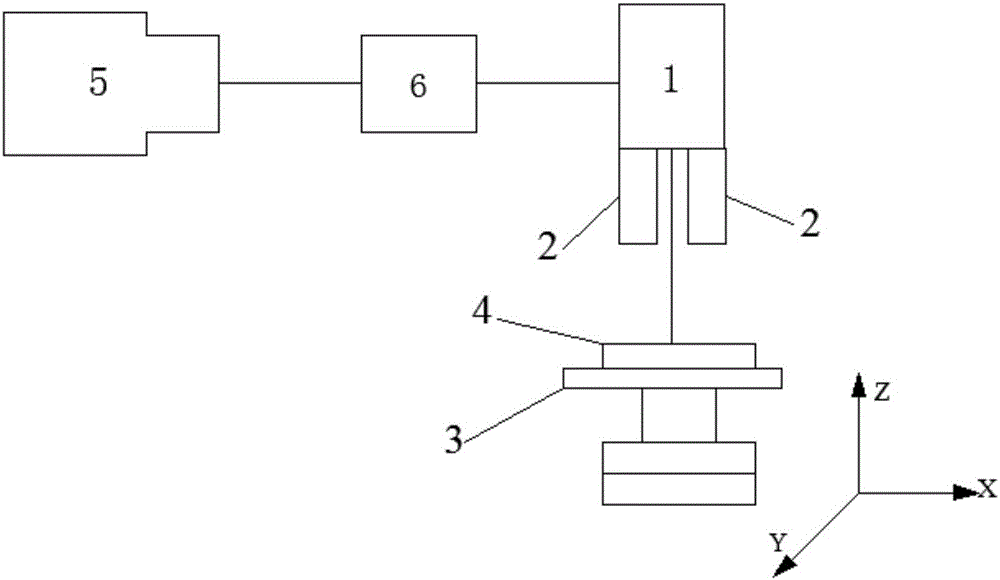

[0049] (1) Clamp the workpiece on figure 2 In the measurement and processing integrated processing device shown, the measurement laser output surface of the two-dimensional laser displacement sensor is parallel to the reference plane, the distance between the two is kept within the range of the two-dimensional laser displacement sensor, and the fluctuation of the workpiece is smaller than that of the two-dimensional laser displacement sensor. The Z vector range of the laser displacement sensor.

[0050] The workpiece is req...

Embodiment 2

[0070]In this embodiment, the galvanometer scanning system in the measurement and processing integrated processing device is a one-dimensional galvanometer scanning system, and there are two two-dimensional laser displacement sensors. The laser processing head and two two-dimensional laser displacement sensors are installed side by side. One-dimensional laser displacement sensor is installed in front of the laser processing head, and another two-dimensional laser displacement sensor is installed behind the laser processing head. The distance between the two two-dimensional laser displacement sensors is an integer multiple of the sampling interval of the two-dimensional laser displacement sensor, so that Ensure that the measurement points of the two two-dimensional laser displacement sensors coincide completely during the scanning of the workpiece.

[0071] The invention provides a laser flattening and polishing method integrating measurement and processing, which specifically i...

Embodiment 3

[0092] This embodiment is the case where the galvanometer scanning system in the measuring and processing integrated processing device is a two-dimensional galvanometer scanning system and one two-dimensional laser displacement sensor.

[0093] The invention provides a laser flattening and polishing method integrating measurement and processing, which specifically includes the following steps:

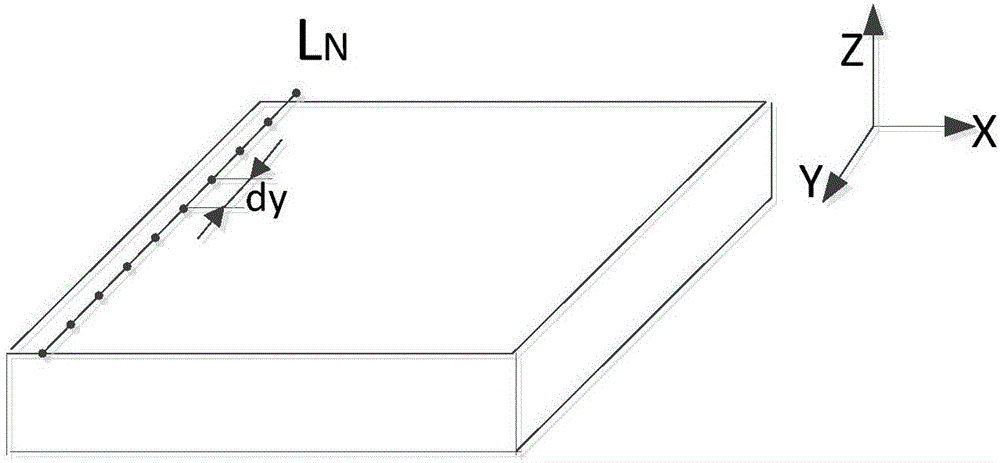

[0094] (1) Clamp the workpiece on figure 2 In the measurement and processing integrated processing device shown, the measurement laser output surface of the two-dimensional laser displacement sensor is parallel to the reference plane, and the distance between the two is kept within the distance measurement range of the two-dimensional laser displacement sensor. The measurement width of LN is larger than the surface of the workpiece The width of the part to be polished and the undulation of the workpiece are smaller than the Z vector range of the two-dimensional laser displacement sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com