Patents

Literature

65results about How to "Eliminate traces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

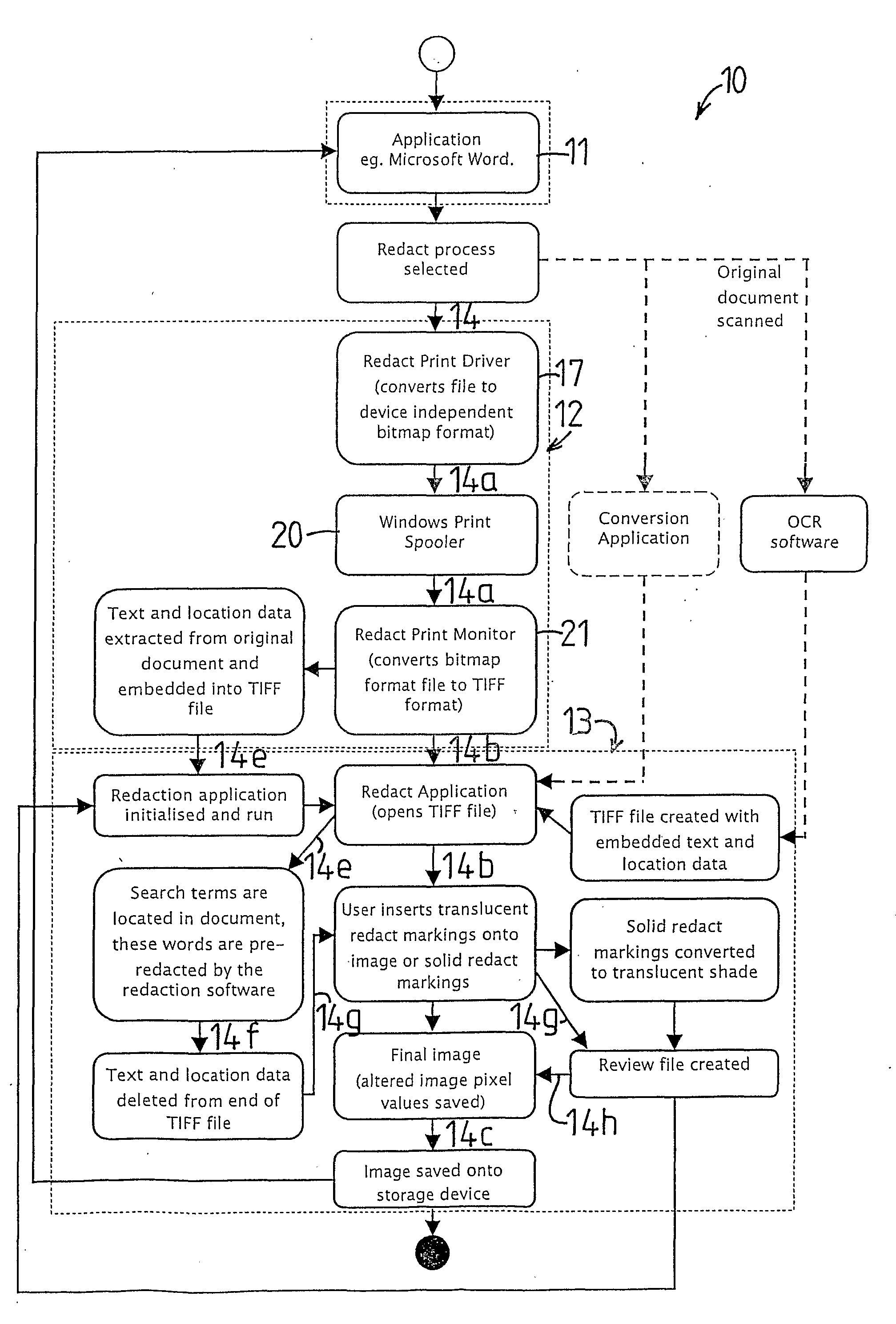

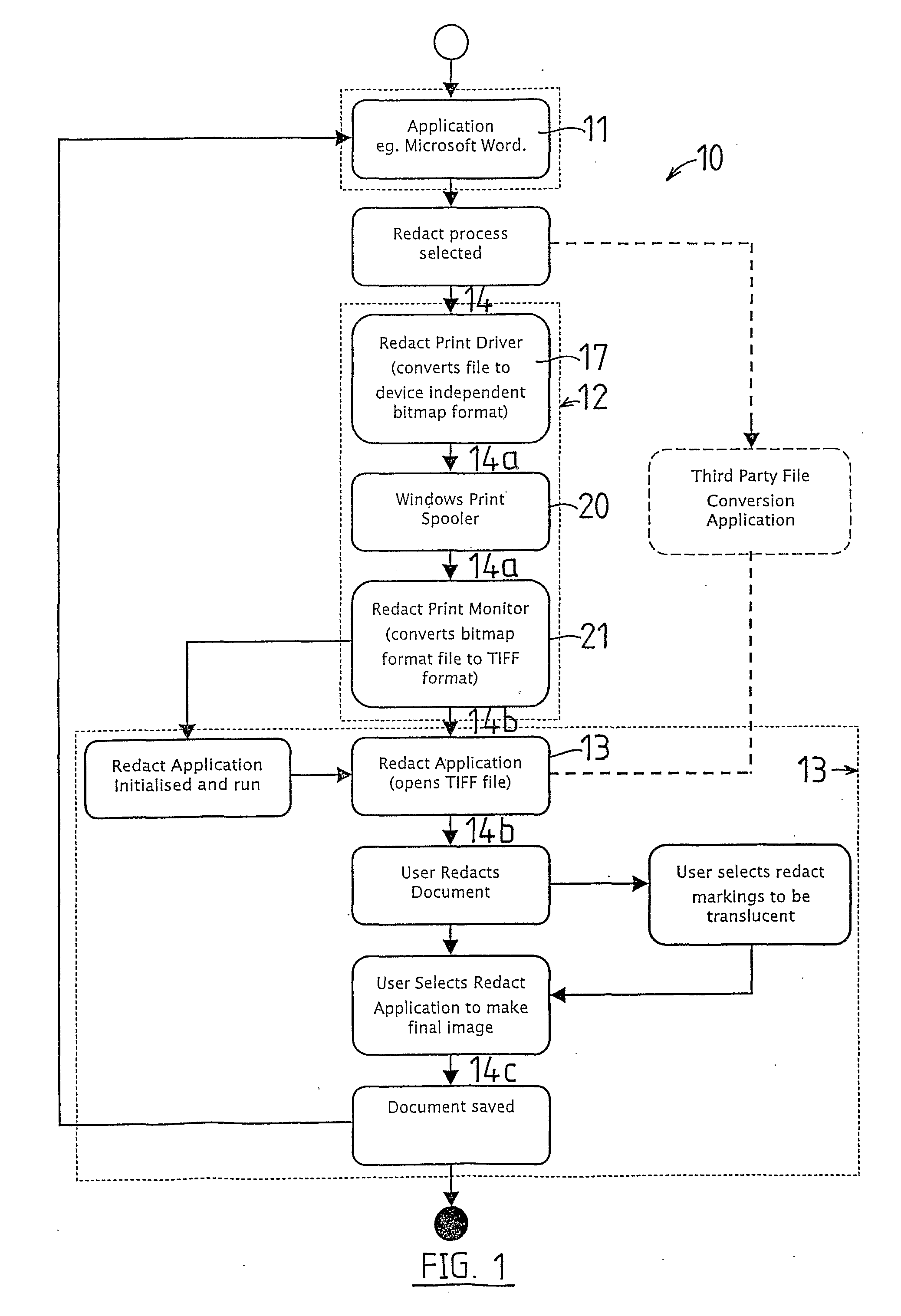

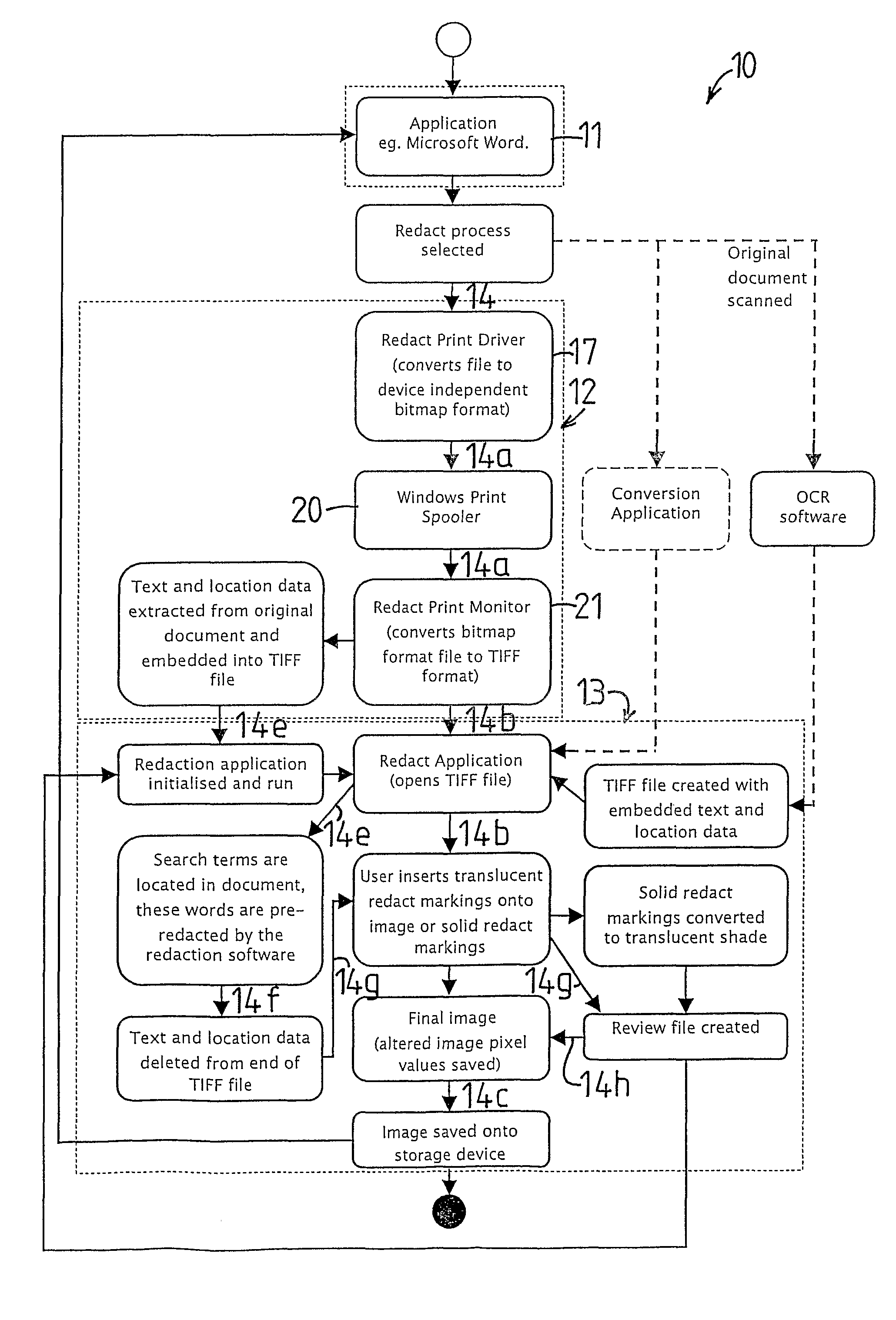

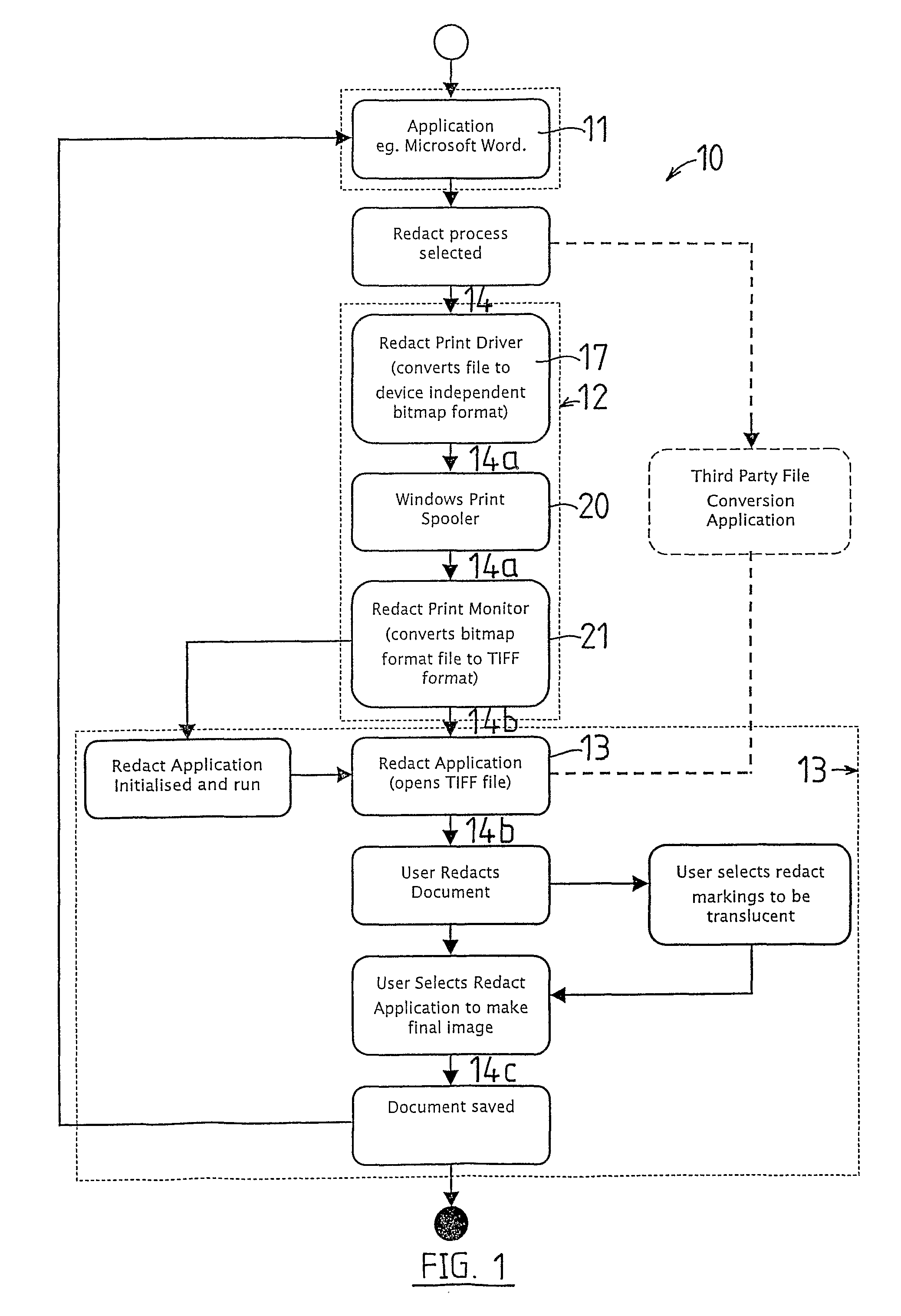

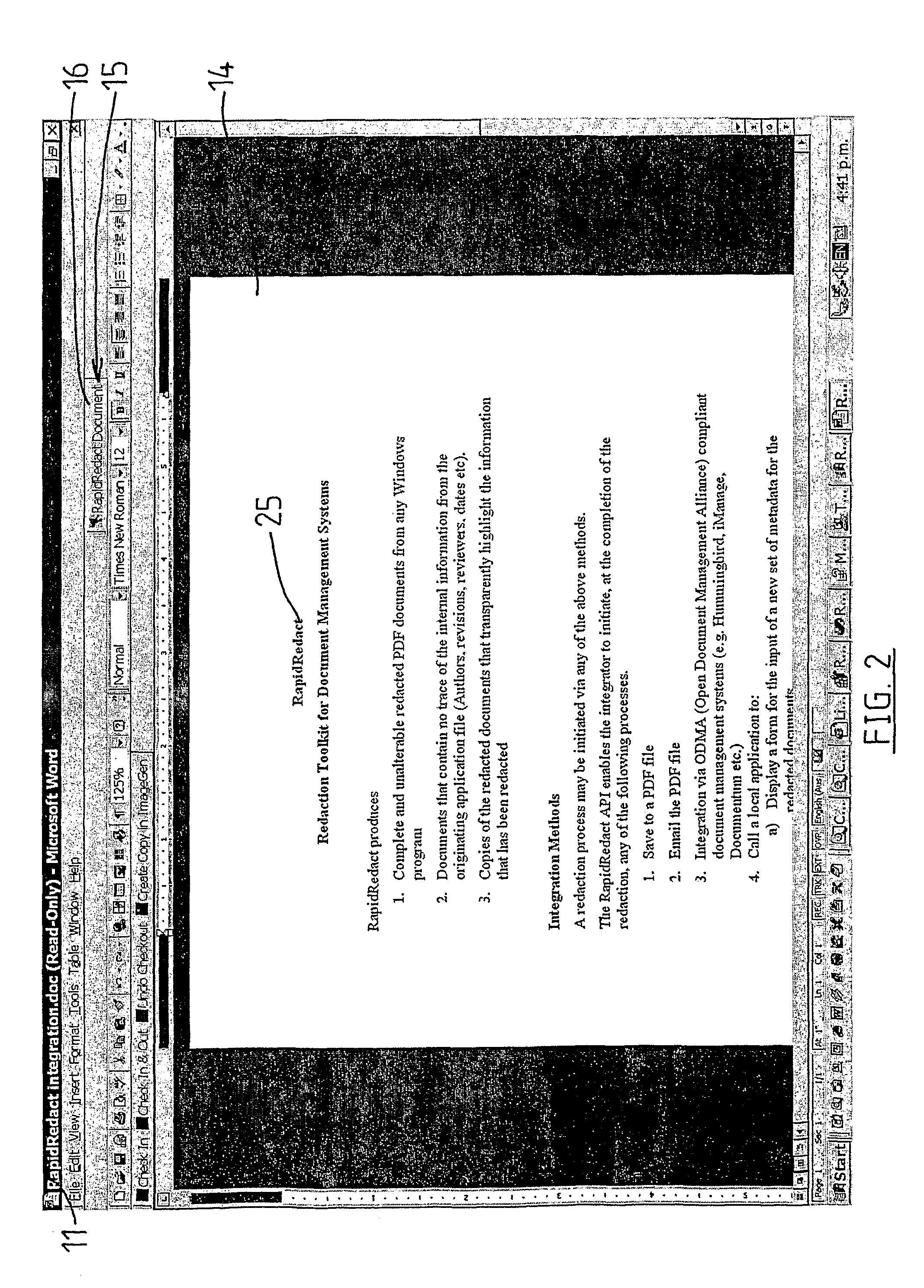

Process for Electronic Document Redaction

ActiveUS20080204788A1Eliminate tracesDigitally marking record carriersDigital computer detailsElectronic documentDocumentation

A redaction process (10) to enable a user to redact an electronic document on a computer. The redaction process (10) includes the steps of converting a copy of the original electronic document file (14) from its native format into the format of an electronic image file. The user may redact sections of the electronic image file, and save the redacted electronic image file in electronic file format.

Owner:OBJECTIVE CORP SOLUTIONS NZ LTD

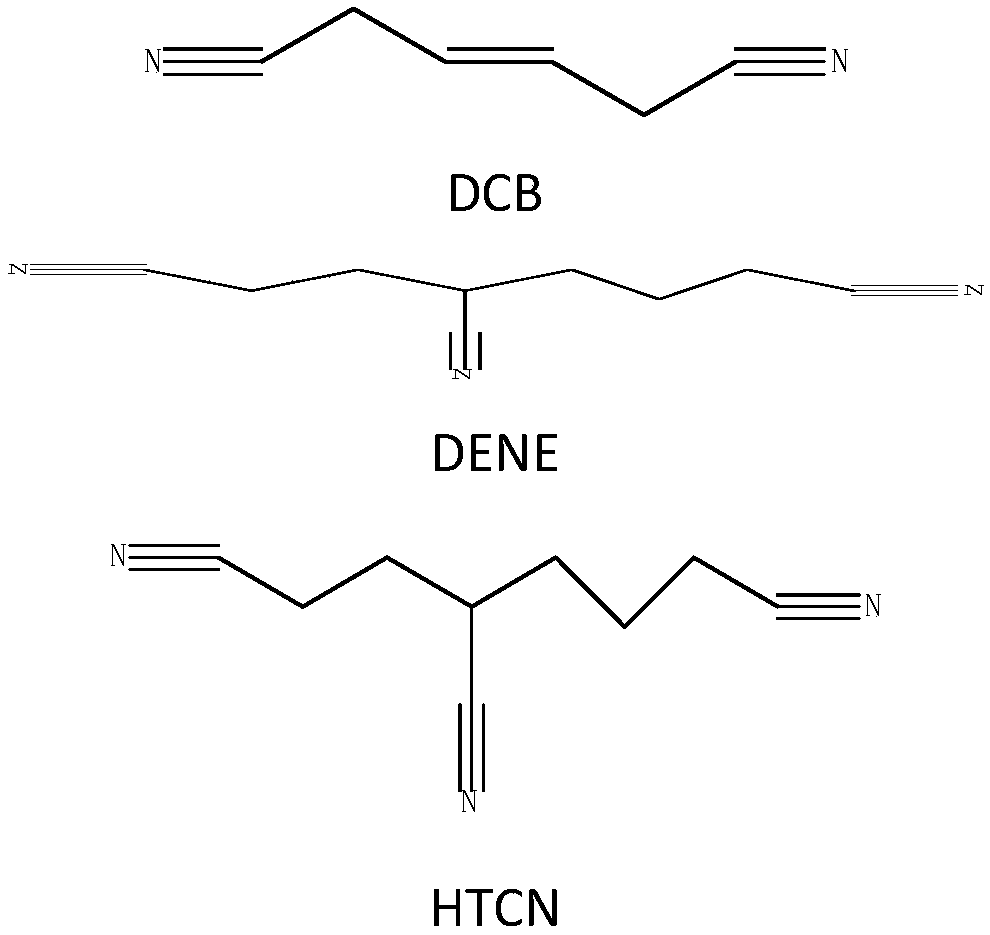

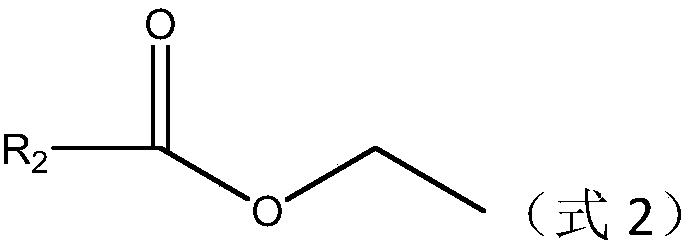

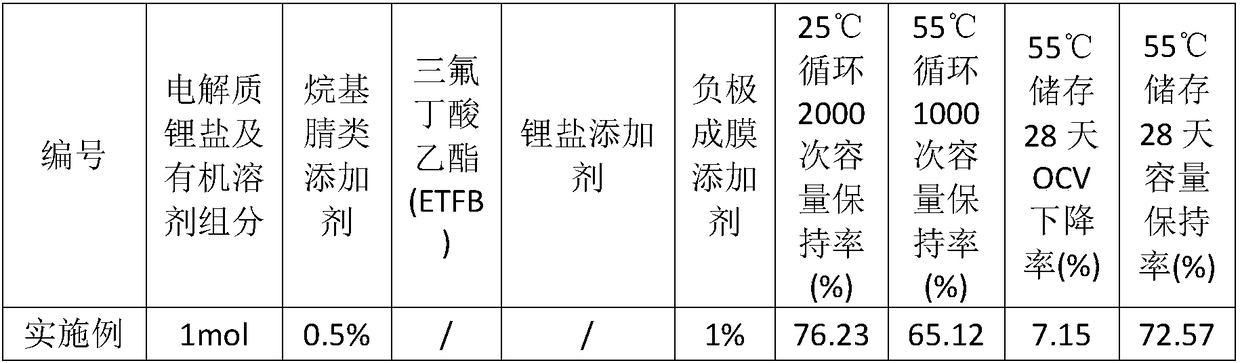

Nickelic ternary anode material power lithium ion battery electrolyte and preparation method thereof

InactiveCN109461967AImprove cycle performanceImprove thermal stabilityFinal product manufactureElectrolyte accumulators manufactureHigh temperature storageCarboxylic salt

The invention belongs to the technical field of lithium ion battery preparation, and specifically relates to nickelic ternary anode material power lithium ion battery electrolyte and a preparation method thereof. The electrolyte consists of electrolyte lithium salt, a non-aqueous organic solvent and functional additives, wherein the functional additives comprise an alkyl nitrile additive, fluorinated chain carboxylate, a lithium salt additive and a cathode film forming additive; and the content of the functional additives is 0.5-10% of the weight of the electrolyte. The electrolyte provided bythe invention interacts with transition metal in a nickelic ternary anode material through the functional additives and is decomposed on the surfaces of the anode and cathode to form stable interfacefilms, so as to inhibit the metal ionic catalysis activity and decrease battery side reactions, so that the electrolyte has favorable anti-oxidant and film forming characteristics, is capable of effectively improving the high-temperature storage performance, safety performance and cycle life of nickelic ternary anode material power lithium ion batteries, effectively inhibiting the generation of battery expansion and ensuring the high power characteristic of the batteries at the same time.

Owner:JIANGXI YOULI NEW MATERIALS

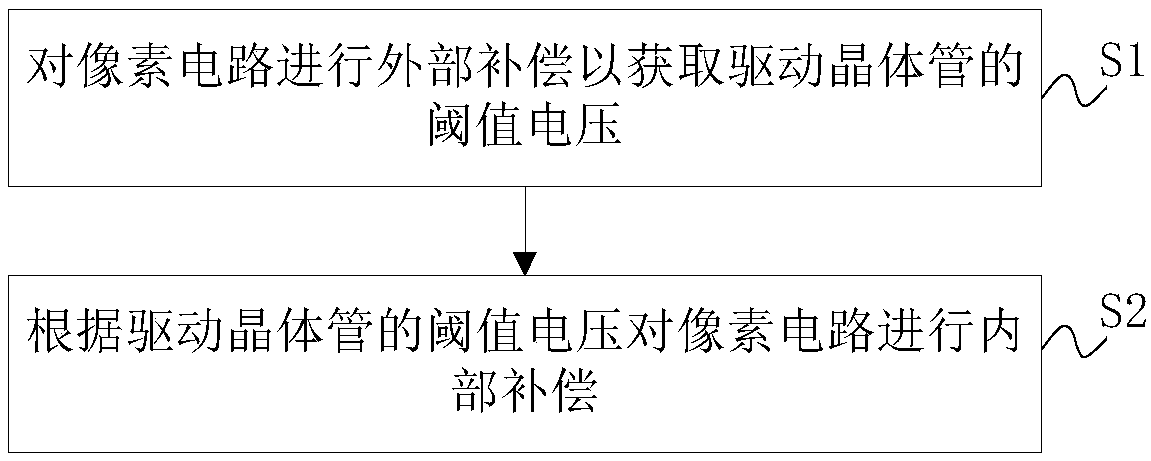

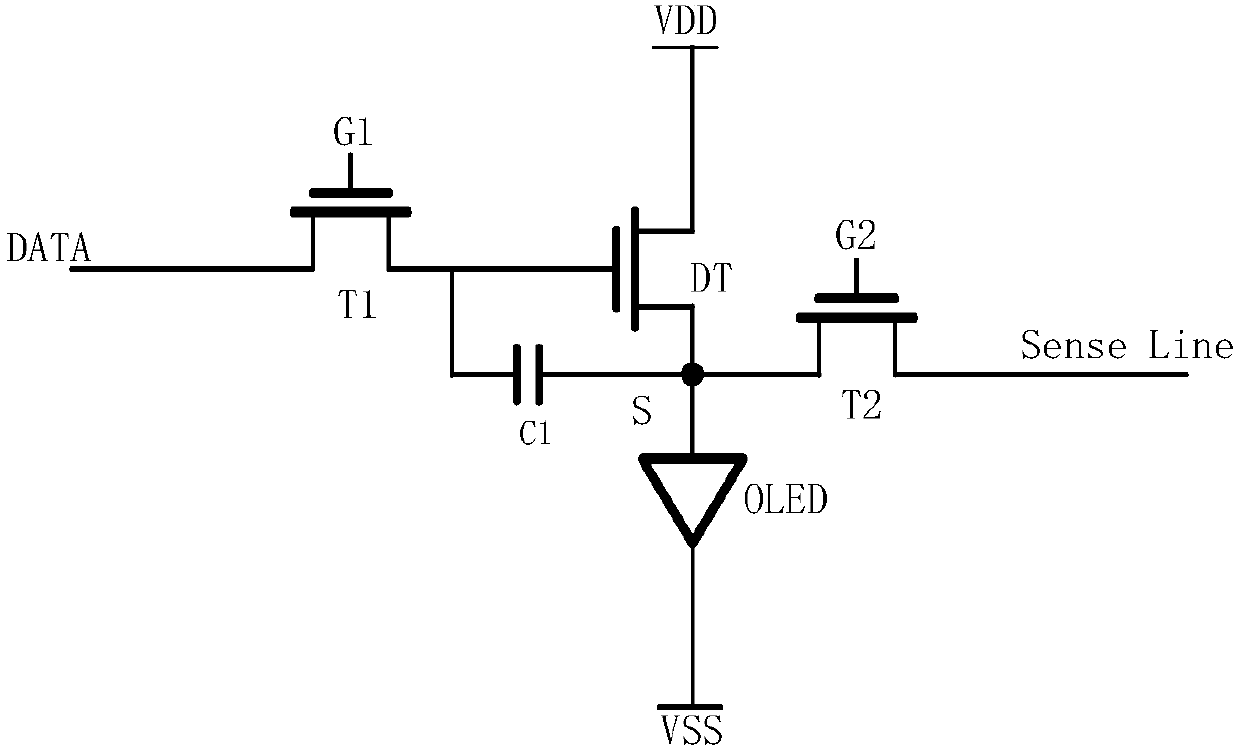

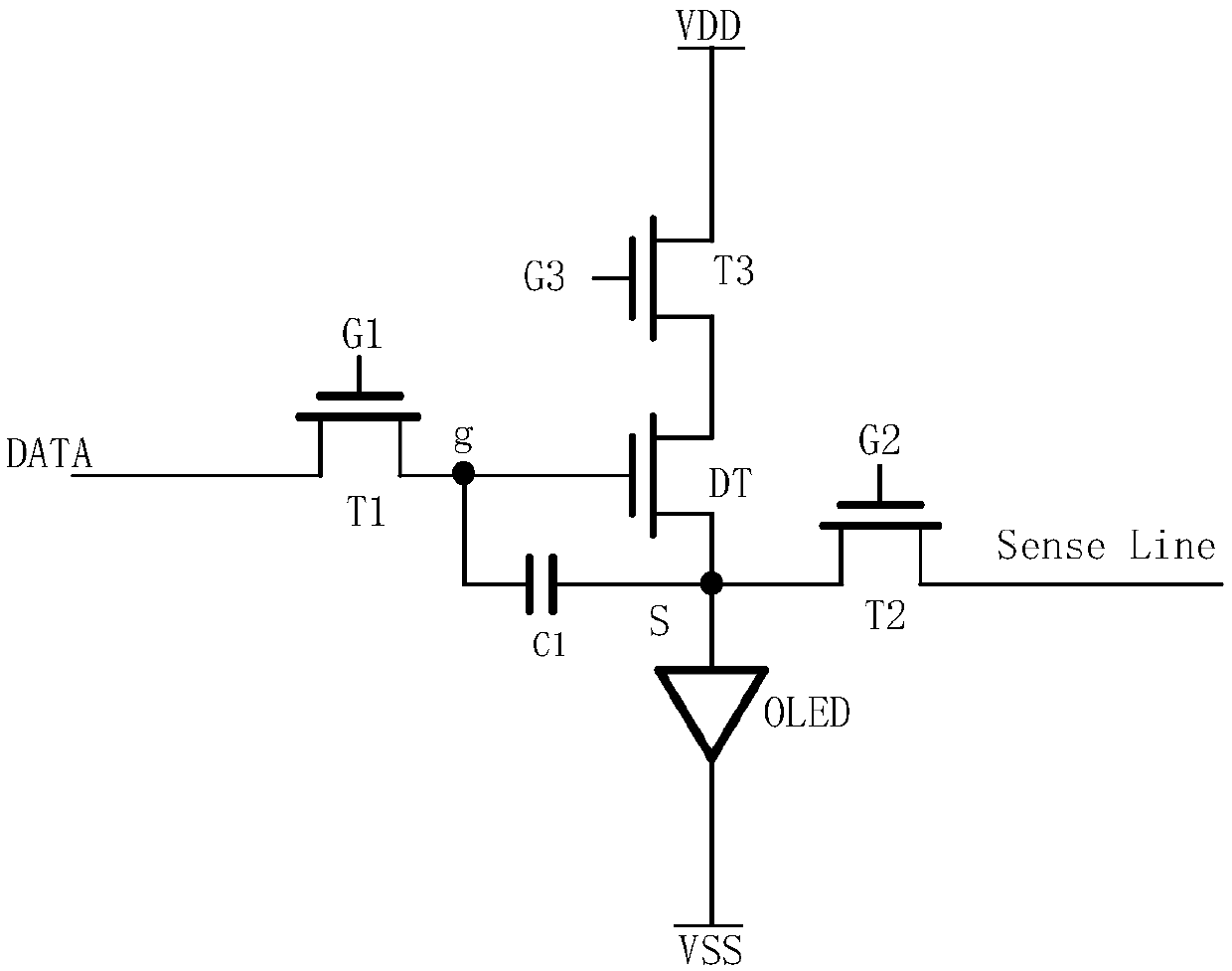

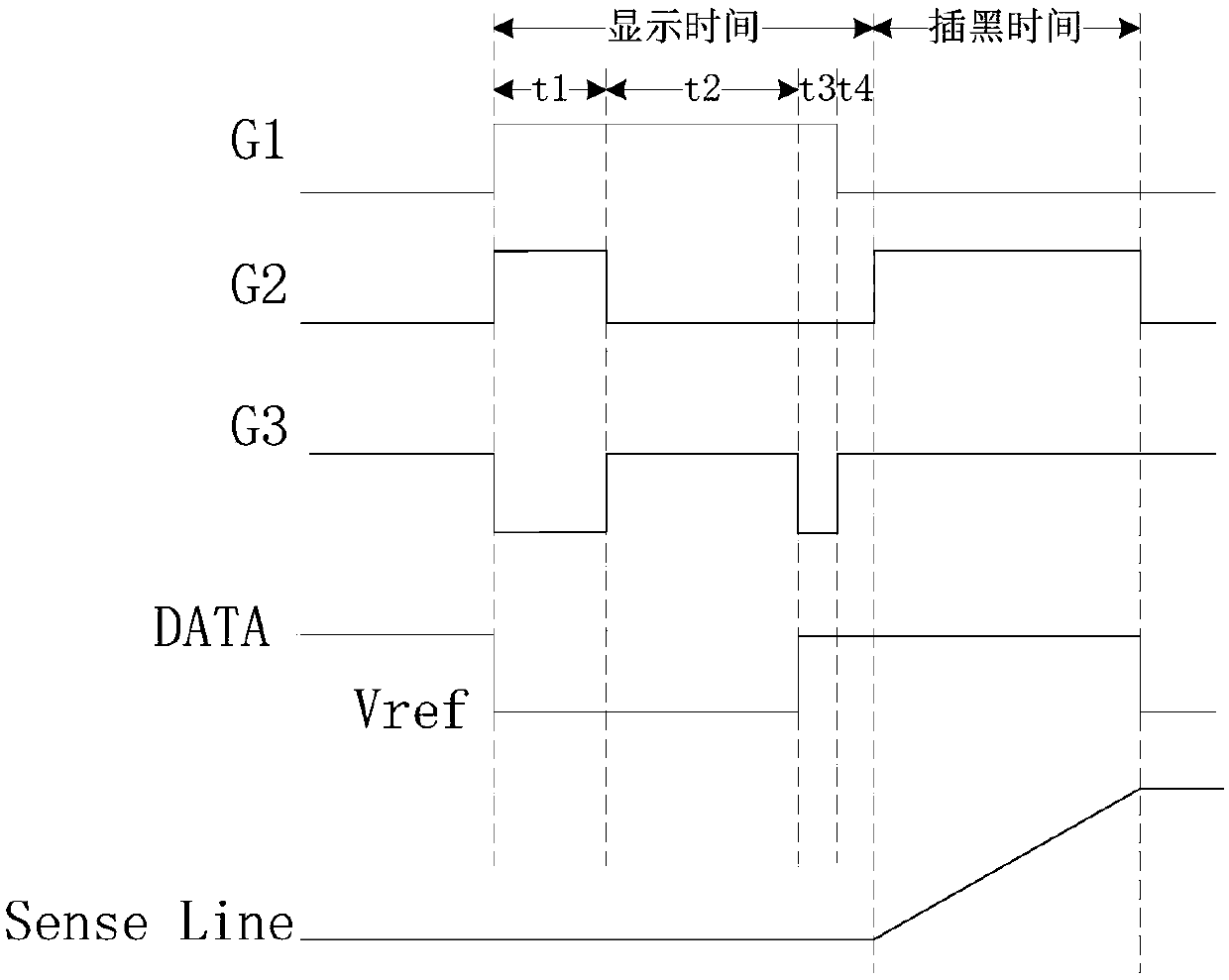

Display device, pixel circuit, compensation method and compensation device

InactiveCN107863067AAvoid compensating hysteresisEliminate tracesStatic indicating devicesHysteresisDisplay device

The invention discloses a display device, a pixel circuit, a compensation method and a compensation device. The pixel circuit comprises drive transistors, data lines and detection signal lines. The method includes the steps: externally compensating the pixel circuit to acquire threshold voltage of the drive transistors; internally compensating the pixel circuit according to the threshold voltage of the drive transistors. Therefore, the threshold voltage of the drive transistors can be compensated, large characteristic change of the drive transistors can be covered, the characteristic change ofthe drive transistors are compensated in real time, compensation hysteresis is effectively avoided, marks and the like generated by external compensation can be eliminated, and display effects are better.

Owner:BOE TECH GRP CO LTD

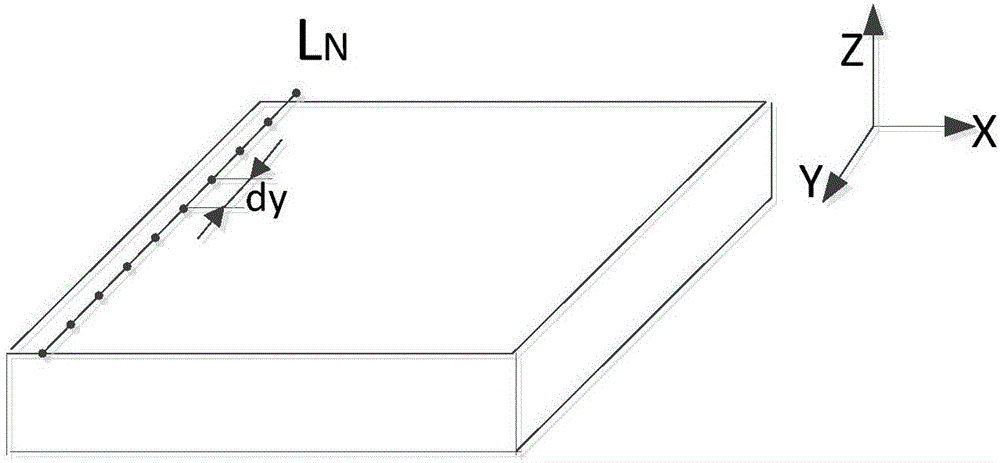

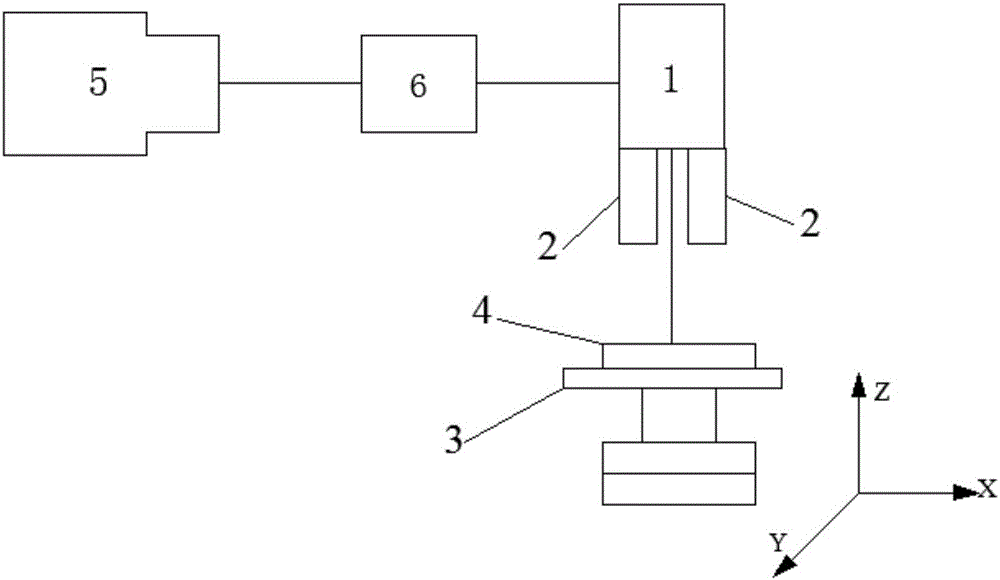

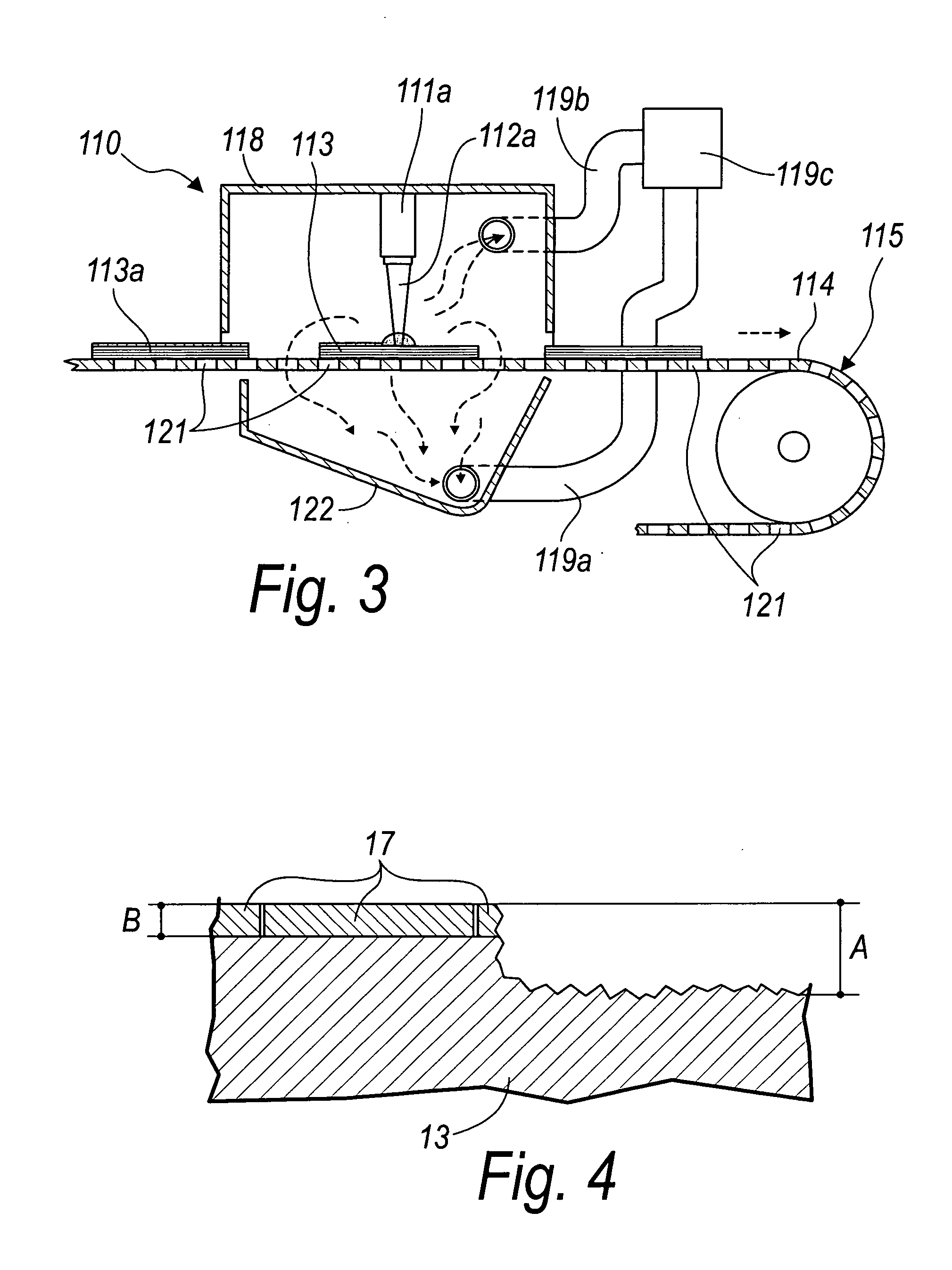

Measurement and processing integrated laser leveling polishing method

ActiveCN106001927ARealize dynamic adjustmentReduce thicknessLaser beam welding apparatusMeasurement pointLaser scanning

The invention provides a measurement and processing integrated laser leveling polishing method which comprises the steps that a workpiece is clamped; a two-dimensional laser displacement sensor and the workpiece are controlled to make relative translation movement, and a coordinate matrix of uniform measurement points is obtained; a galvanometer scanning system is controlled to scan a to-be-polished part of the surface of the workpiece according to the set scanning speed, and a new coordinate matrix of the uniform measurement points of the to-be-polished part of the surface of the workpiece is obtained after laser scanning; delta is calculated according to the function that delta is equal to z'max-z'min, if delta is less than or equal to the target smoothness of the workpiece, the operation is completed; otherwise, a laser scanning grid chart of the surface of the workpiece is constructed, and each grid in the laser scanning grid chart is endowed with a weight number k; the galvanometer scanning system is controlled to carry out k times of scanning processing on each grid in the laser scanning grid chart according to weight number k. Dynamic adjustment of processing parameters is realized and different processing parameters are used in different stages, so that the thickness of a material removed by laser scanning at every time can be increased, the leveling speed can be increased, and the processing efficiency and the processing precision can be improved.

Owner:JIANGSU KERUIXIN MACHINERY

Process for electronic document redaction

ActiveUS8456654B2Eliminate tracesDigitally marking record carriersDigital computer detailsElectronic documentDocumentation

A redaction process (10) to enable a user to redact an electronic document on a computer. The redaction process (10) includes the steps of converting a copy of the original electronic document file (14) from its native format into the format of an electronic image file. The user may redact sections of the electronic image file, and save the redacted electronic image file in electronic file format.

Owner:OBJECTIVE CORP SOLUTIONS NZ LTD

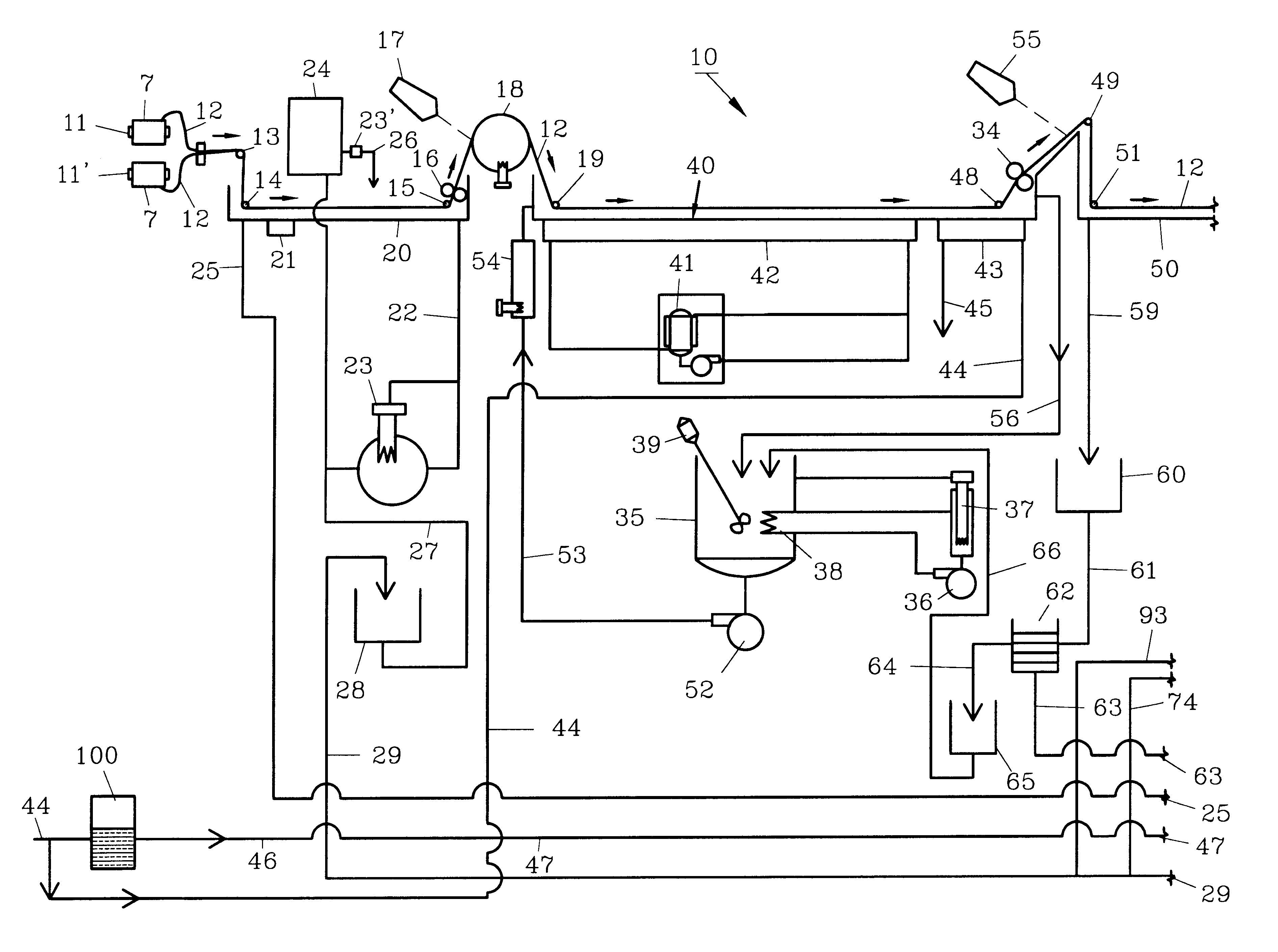

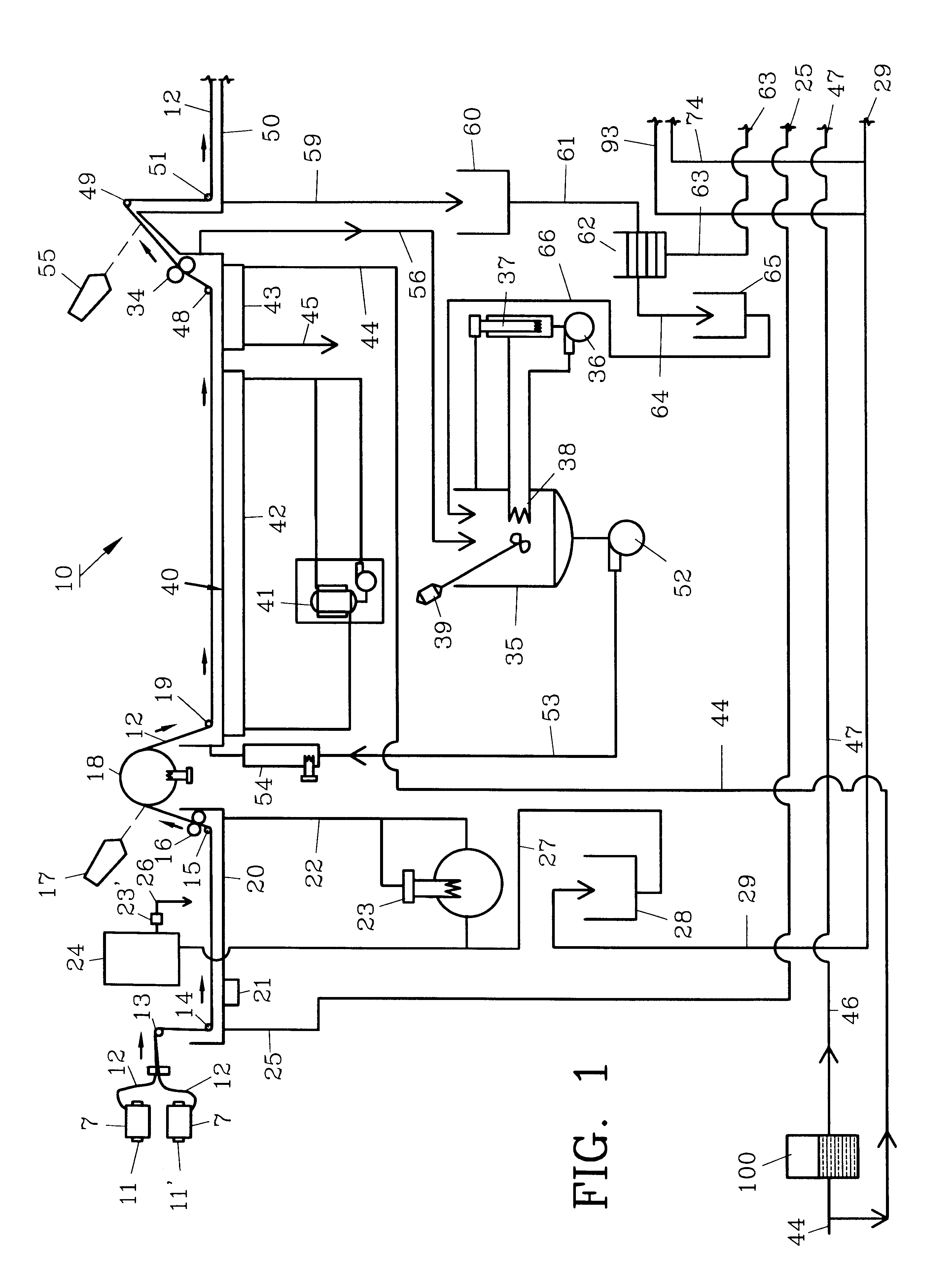

Dye composition, dyeing apparatus and dyeing method

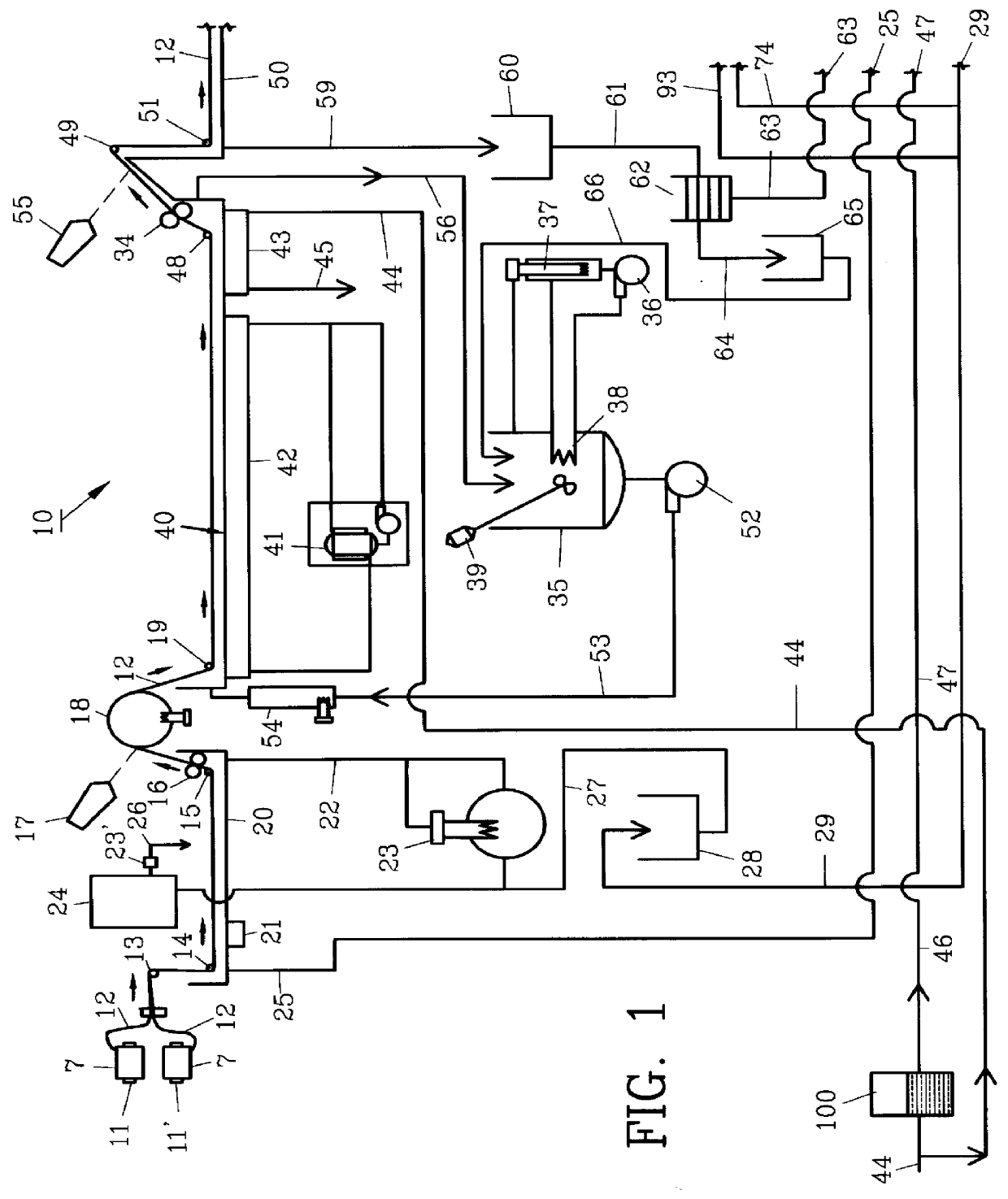

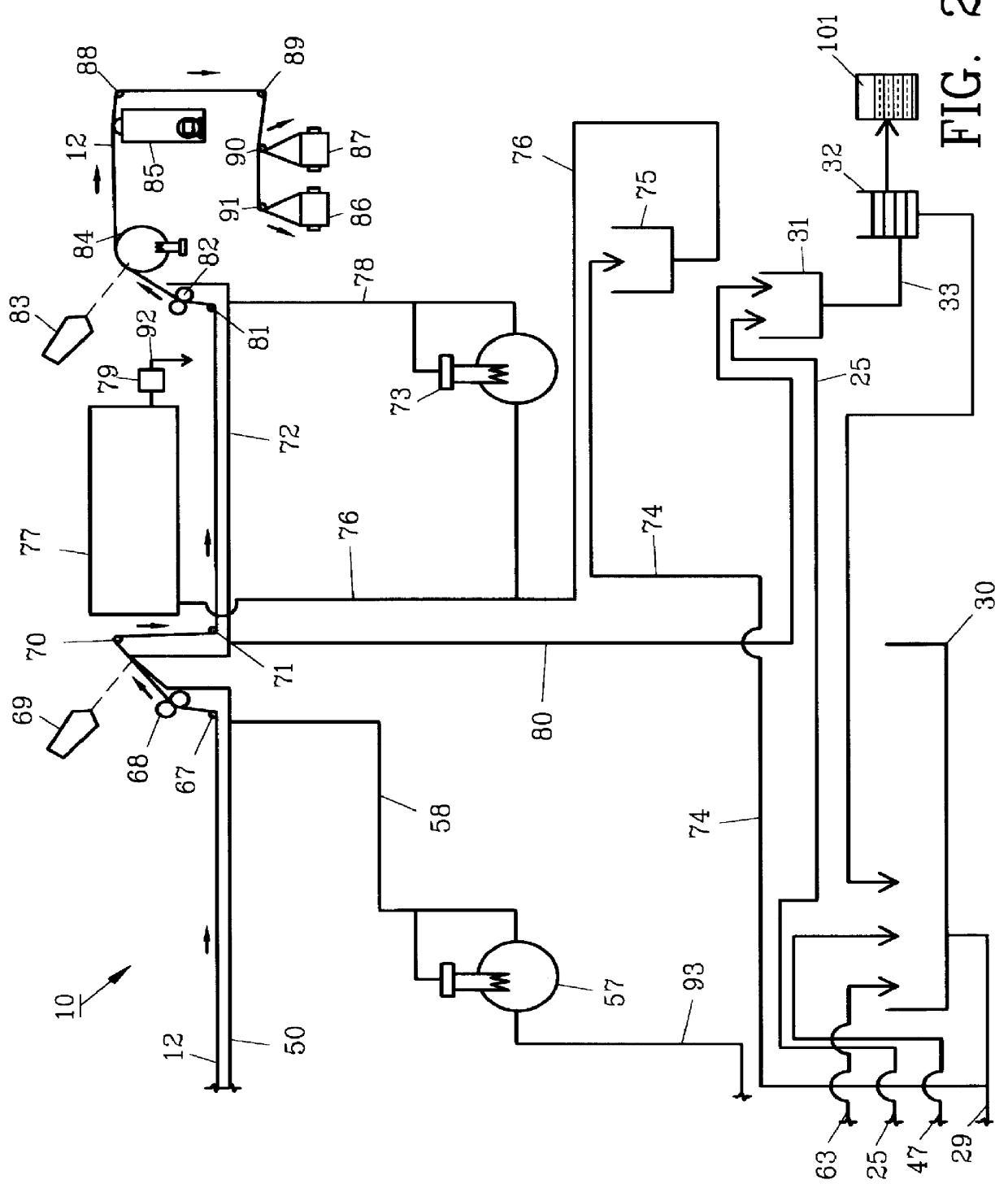

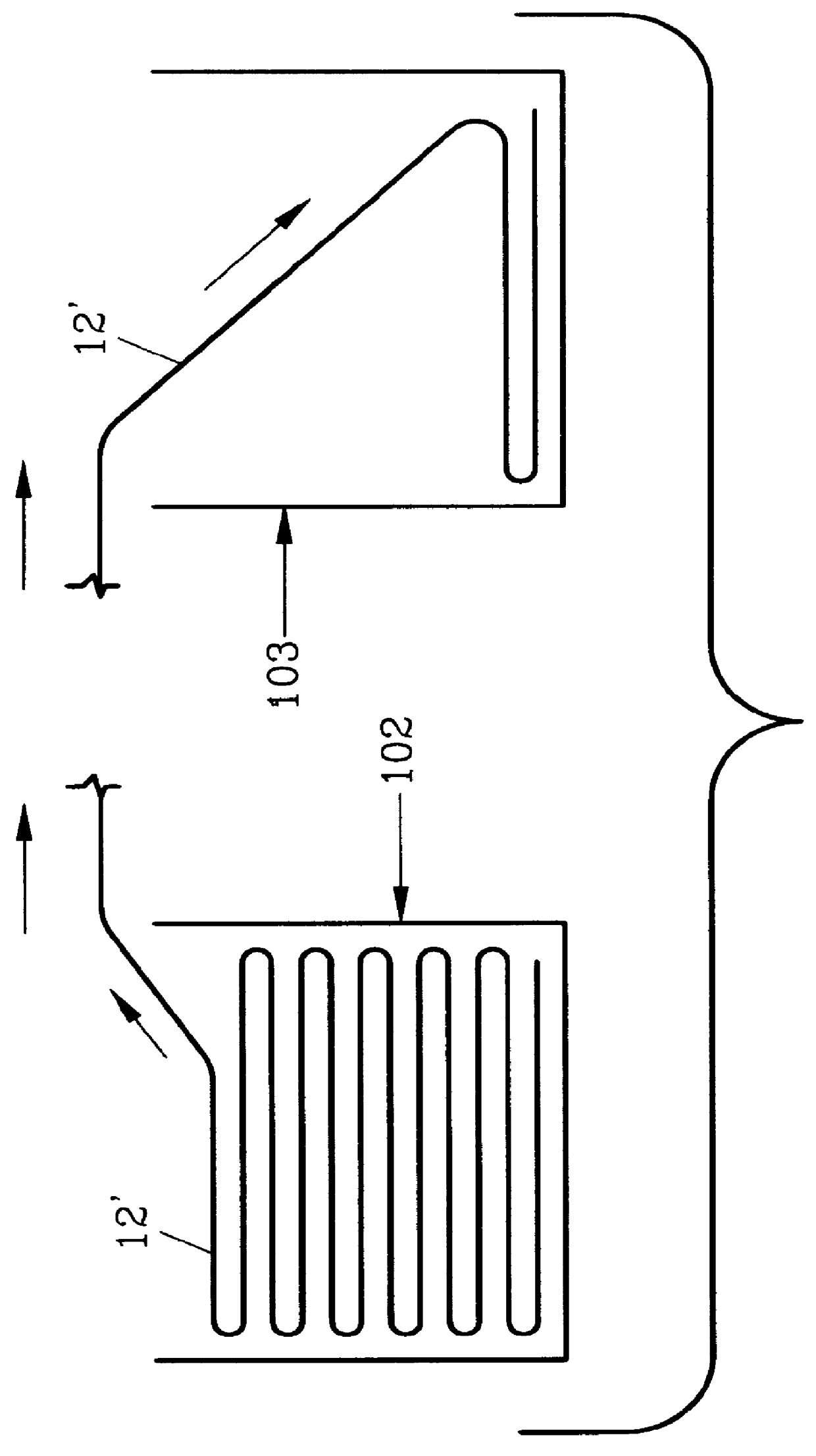

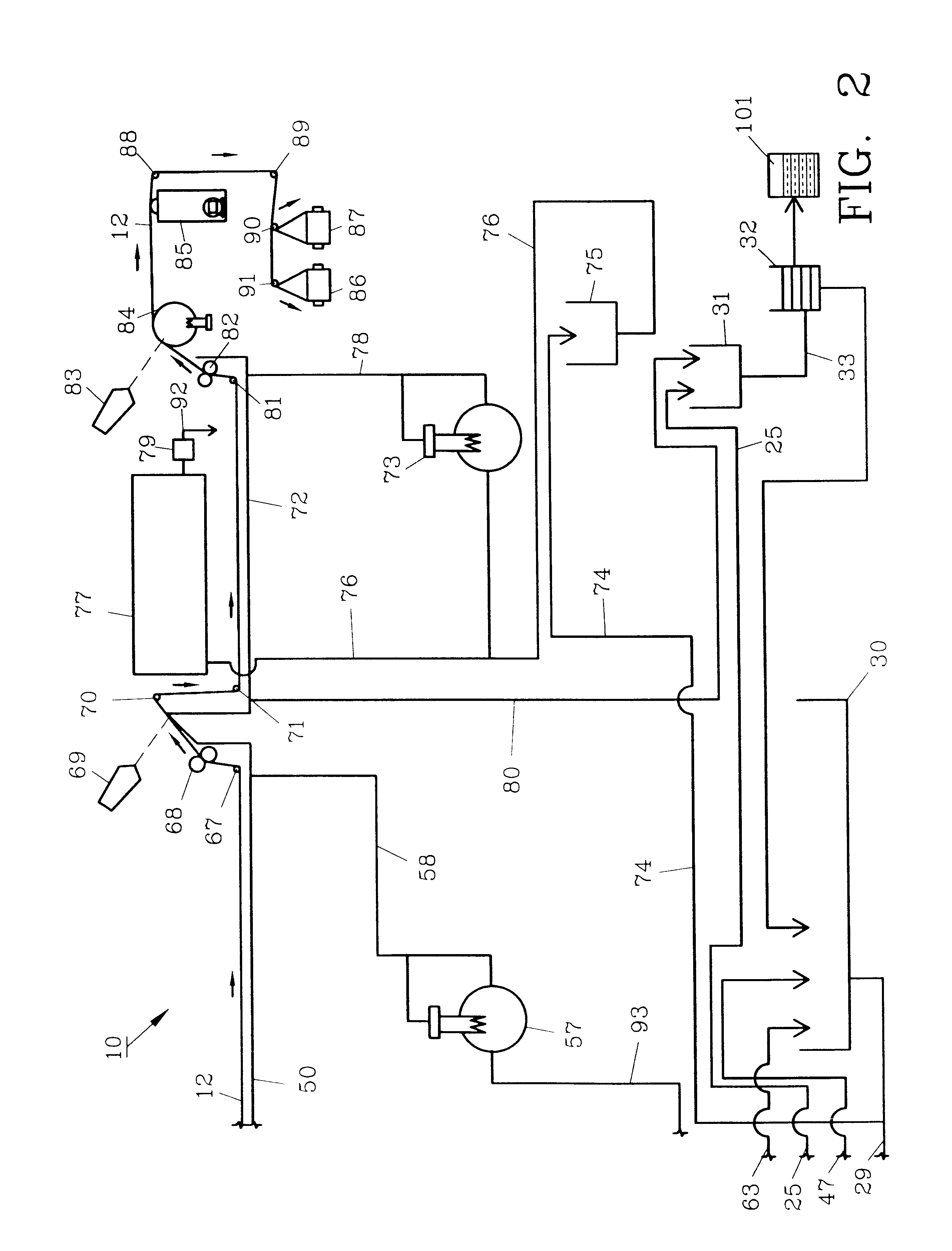

InactiveUS6117192ANo crocking problemsEliminate tracesSucessive textile treatmentsSolvent treatment with solvent recoveryPolyesterYarn

A dye composition of 99.7% pure glycerin and press cake dye is provided along with an apparatus and method of use for the same. The apparatus sets the dye composition into polyester yarns by heating the composition to 160-190 DEG C. and then cooling the composition to 100-140 DEG C. Prescour, dye scour and post scour vessels are provided to facilitate the dyeing process. The fluids used in the apparatus and process are recycled by recycling units.

Owner:TATECRAFT INDS

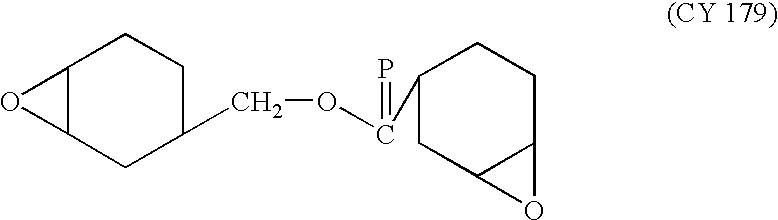

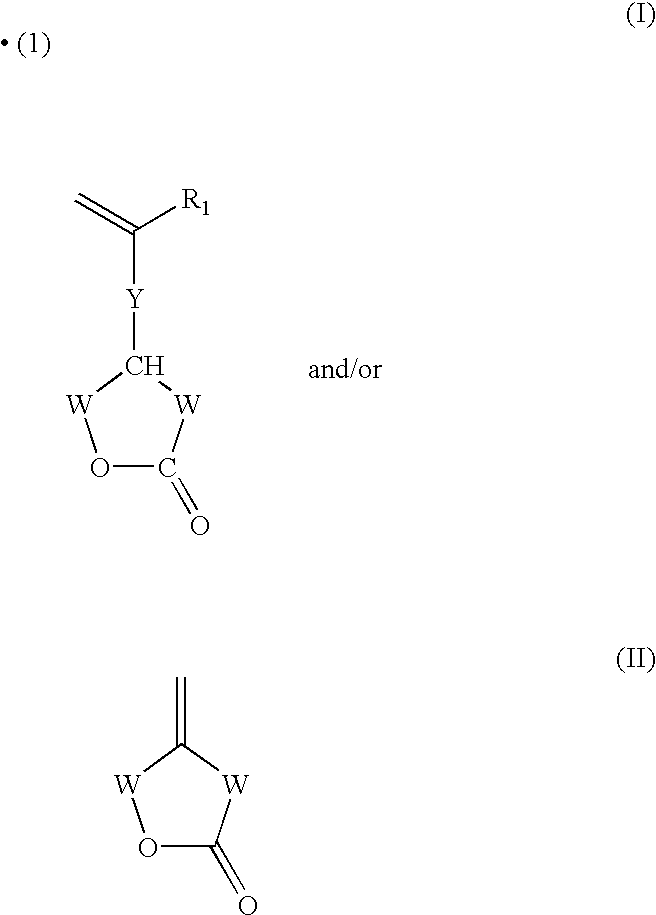

Composition (e. g. ink or varnish) which can undergo cationic and/or radical polymerization and/or crosslinking by irradiation, based on an organic matrix, a silicone diluent and a photoinitiator

InactiveUS6864311B2Lower performance requirementsEliminate tracesGroup 4/14 element organic compoundsInksEpoxyOnium

The invention aims at improving such compositions by proposing a non-toxic diluent harmless to reactivity and by making these compositions translucent, free from metallic impurities and capable of constituting light-polymerisable varnish with good properties of ductility for leveling and surface coating. This aim is achieved by the invention which proposes a composition comprising an organic polymerisable matrix A, containing cyclo-aliphatic epoxide resins or not, acrylates, alkenyl-ethers or polyols, a silicon diluent B with viscosity less than 100 MPa's, a radical and / or cationic (onium salt) photoinitiator C, optionally a light-sensitising material D, a pigment E and another additive F; provided that when A is a cyclo-aliphatic epoxide resin, B has a metal concentration not more than 100 ppm. The invention also concerns the use of the silicon diluent B for preparing a composition crosslinkable by cationic and / or radical process, under UV radiation, in the presence of a photoinitiator (ink or varnish).

Owner:BLUESTAR SILICONES FRANCE SAS

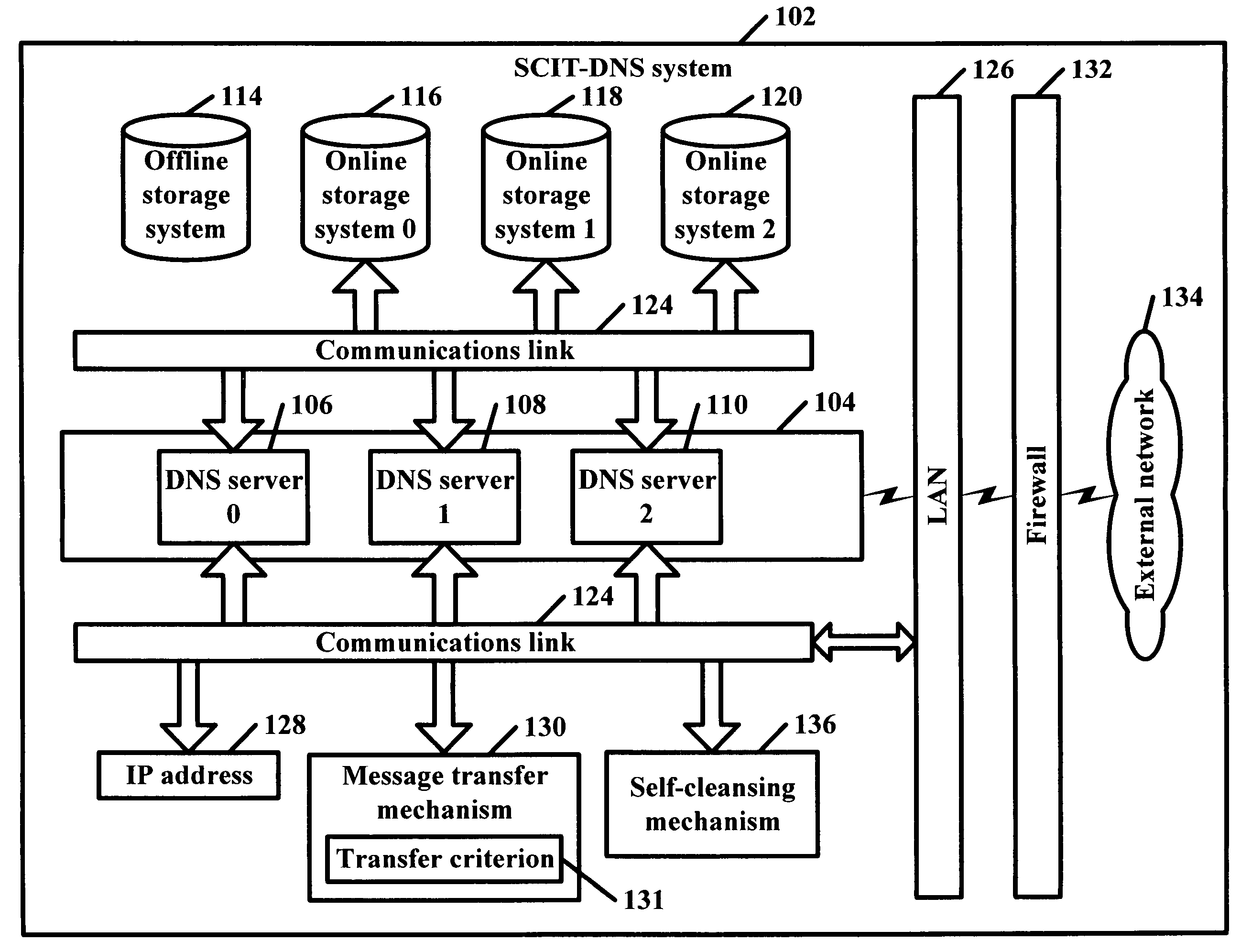

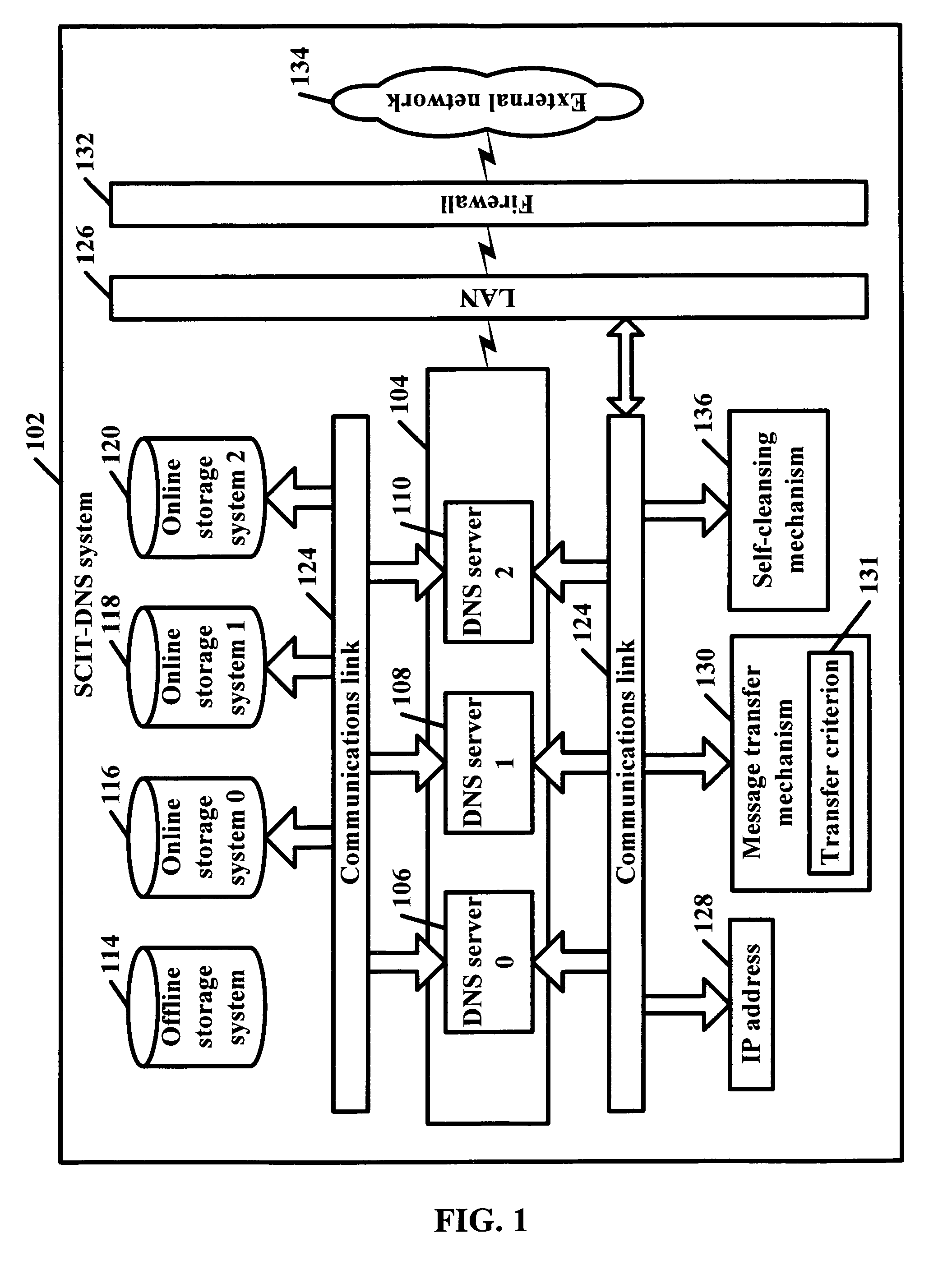

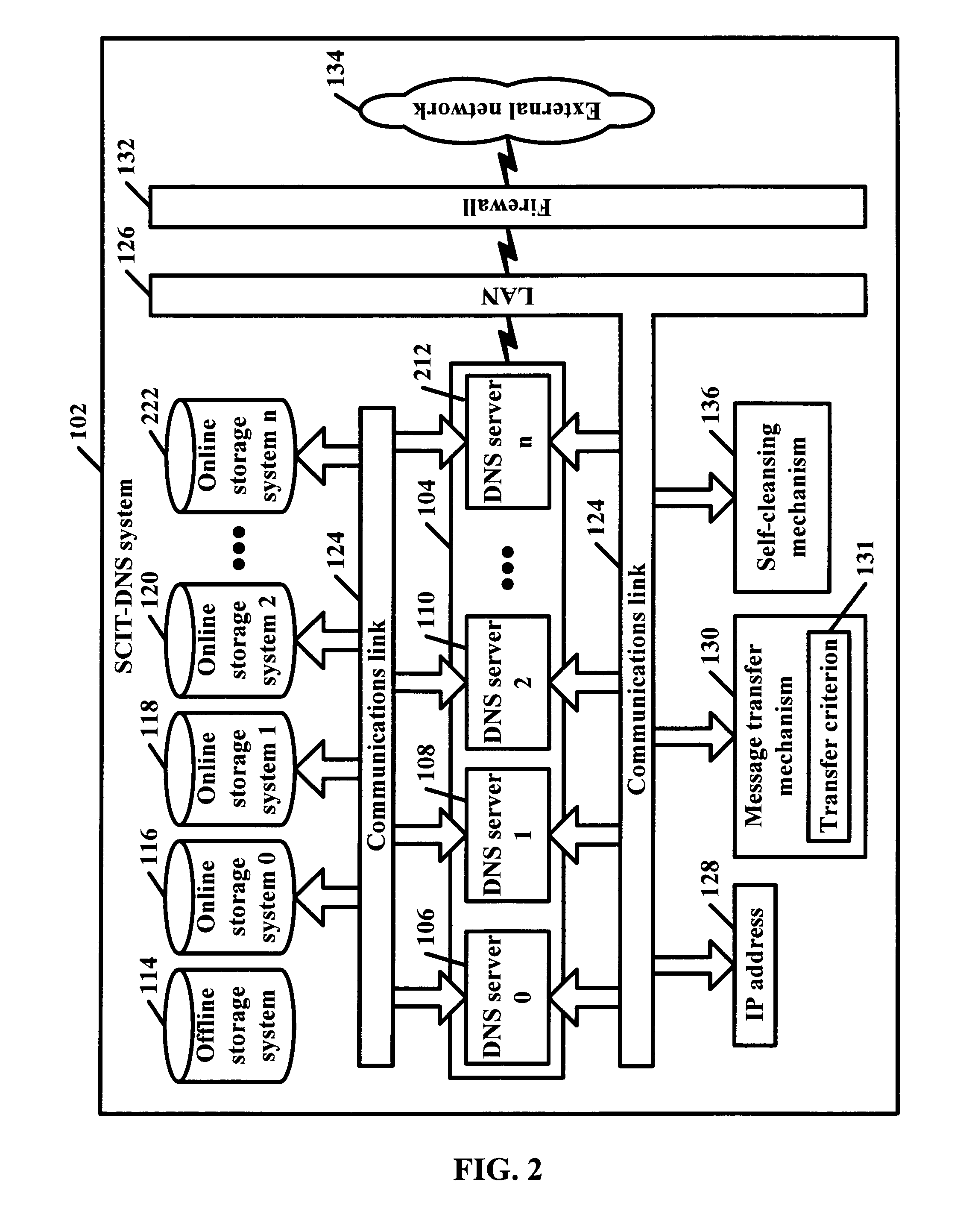

SCIT-DNS: critical infrastructure protection through secure DNS server dynamic updates

ActiveUS7680955B2Eliminate tracesMemory loss protectionError detection/correctionDomain nameTelecommunications link

Disclosed is a self-cleansing intrusion tolerance-domain name systems system comprising at least three DNS servers, at least four storage systems accessible by the DNS servers, a communications link, a message transfer mechanism, and a self-cleansing mechanism. The storage systems include at least three online storage systems and at least one offline storage system. The communications link can connect the DNS servers with the storage systems, as well as connect the DNS servers with a local area network, which can connect the DNS servers with an external network. The message transfer mechanism can rotate the DNS servers into a plurality of roles, including a primary role, a secondary role, a designated role, and a self-cleansing role. The self-cleansing mechanism can be used to perform the self-cleansing role.

Owner:GEORGE MASON INTPROP INC

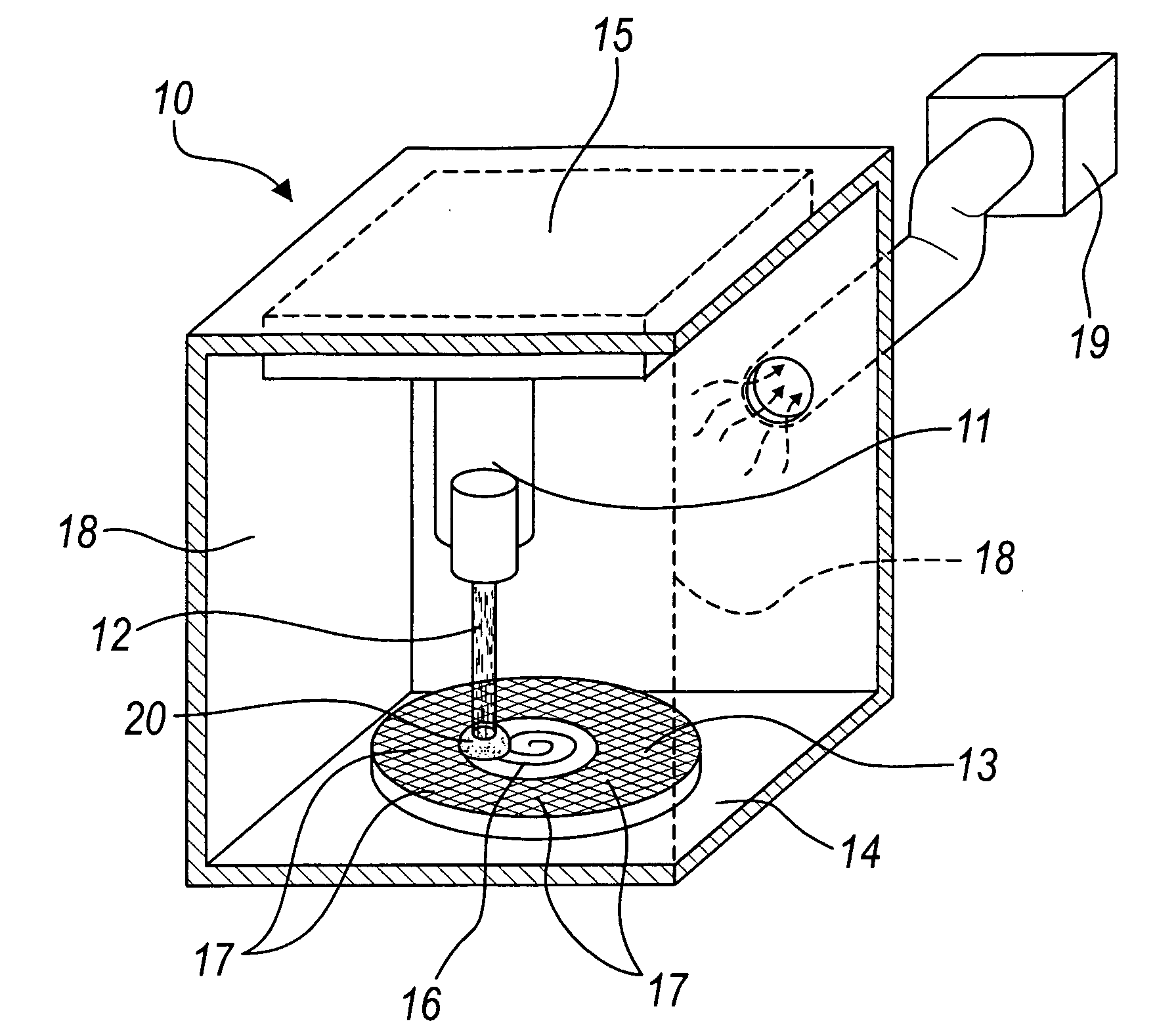

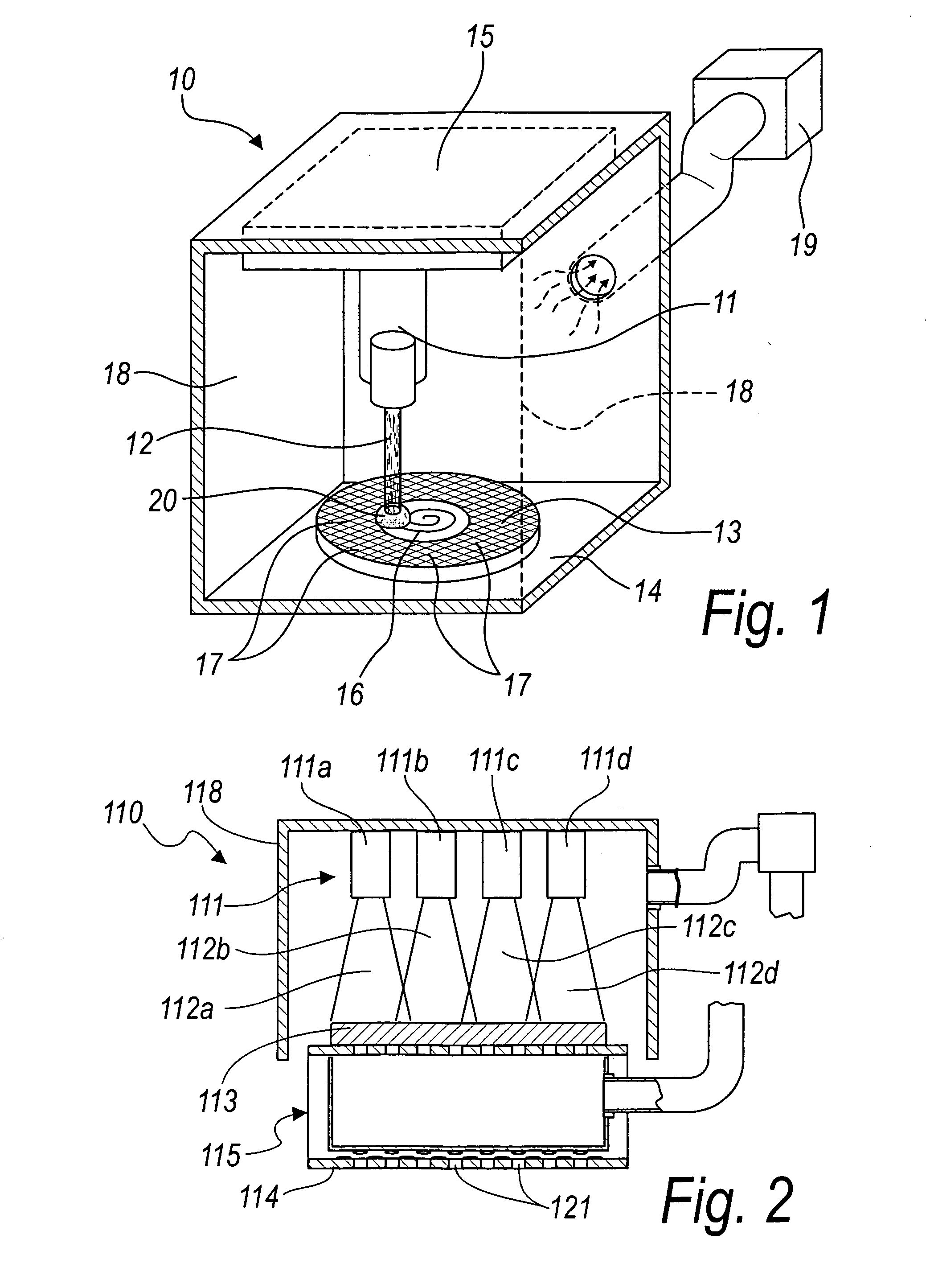

"Machine for removing surfaces of semiconductors and particularly surfaces with integrated circuits"

InactiveUS20080302770A1Drawback can be obviatedEliminate tracesSemiconductor/solid-state device manufacturingDirt cleaningLaser transmitterSurface layer

A machine for removing surfaces of semiconductors with integrated circuits, comprising laser emitters, at least one beam of which strikes at least one semiconductor wafer or at least one fragment thereof, for ablation of a surface layer of preset thickness, supports for the at least one wafer or fragment thereof, and movers for the relative movement of the emitters with respect to the at least one wafer or fragment thereof, the movers being adapted to make the emitters follow a path such that the at least one beam emitted thereby travels over the entire surface to be removed of the at least one wafer or fragment thereof.

Owner:HELIOS TECH

Increase in the melting point and the enthalpy of melting of polyamides by a water treatment

ActiveUS7468405B2Eliminate tracesAdditive manufacturing with solidsPolyamideCrystallization temperature

A method for increasing at least one of the following two parameters of a polyamide: (I) its melting point and (ii) its enthalpy of melting ΔHm, in which:this polyamide is brought into contact in the solid state with water or with steam at a temperature close to its crystallization temperature Tc for a time long enough to effect this increase;then, the water (or steam) is separated from the polyamide and the polyamide is dried.

Owner:ATOFINA

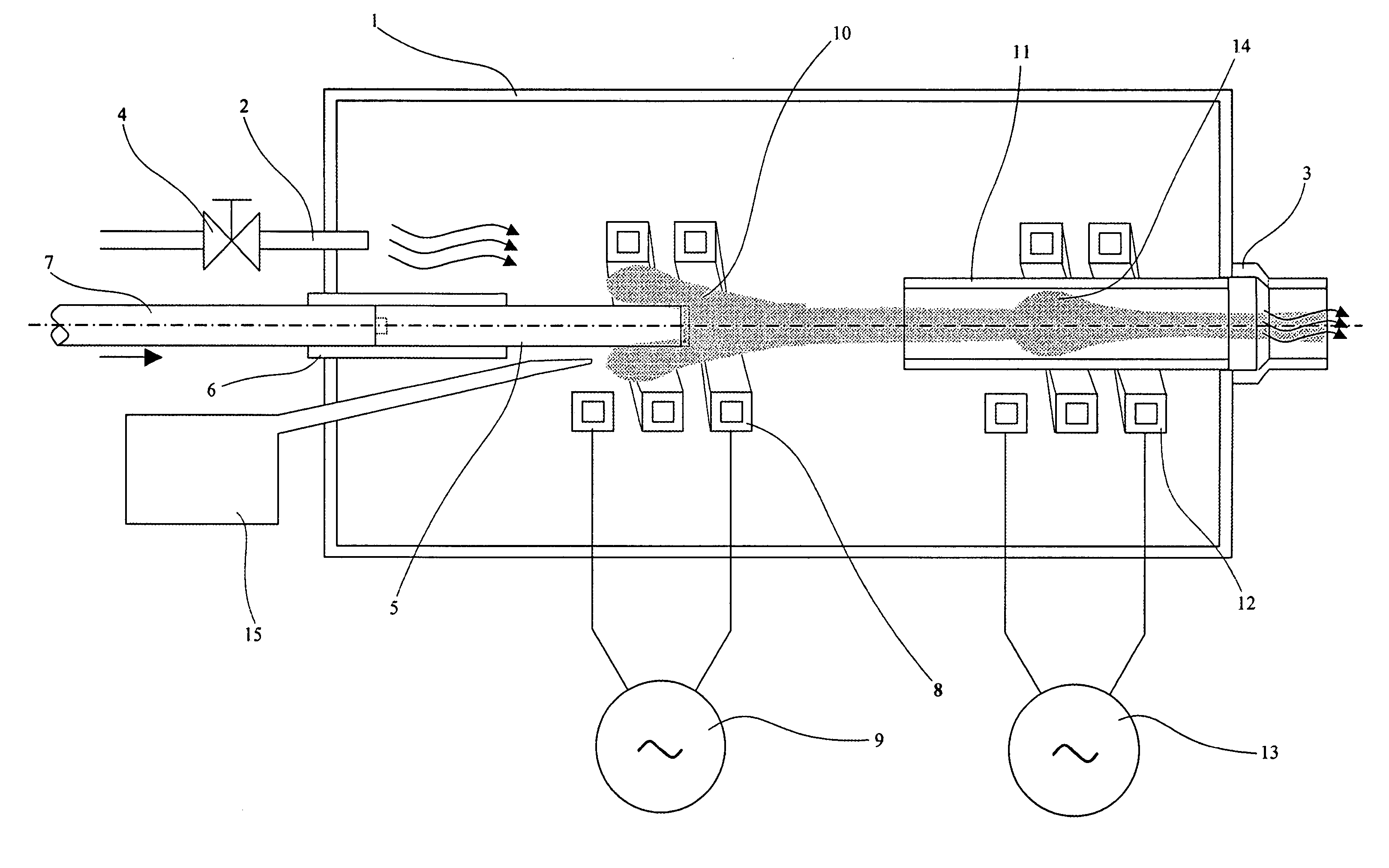

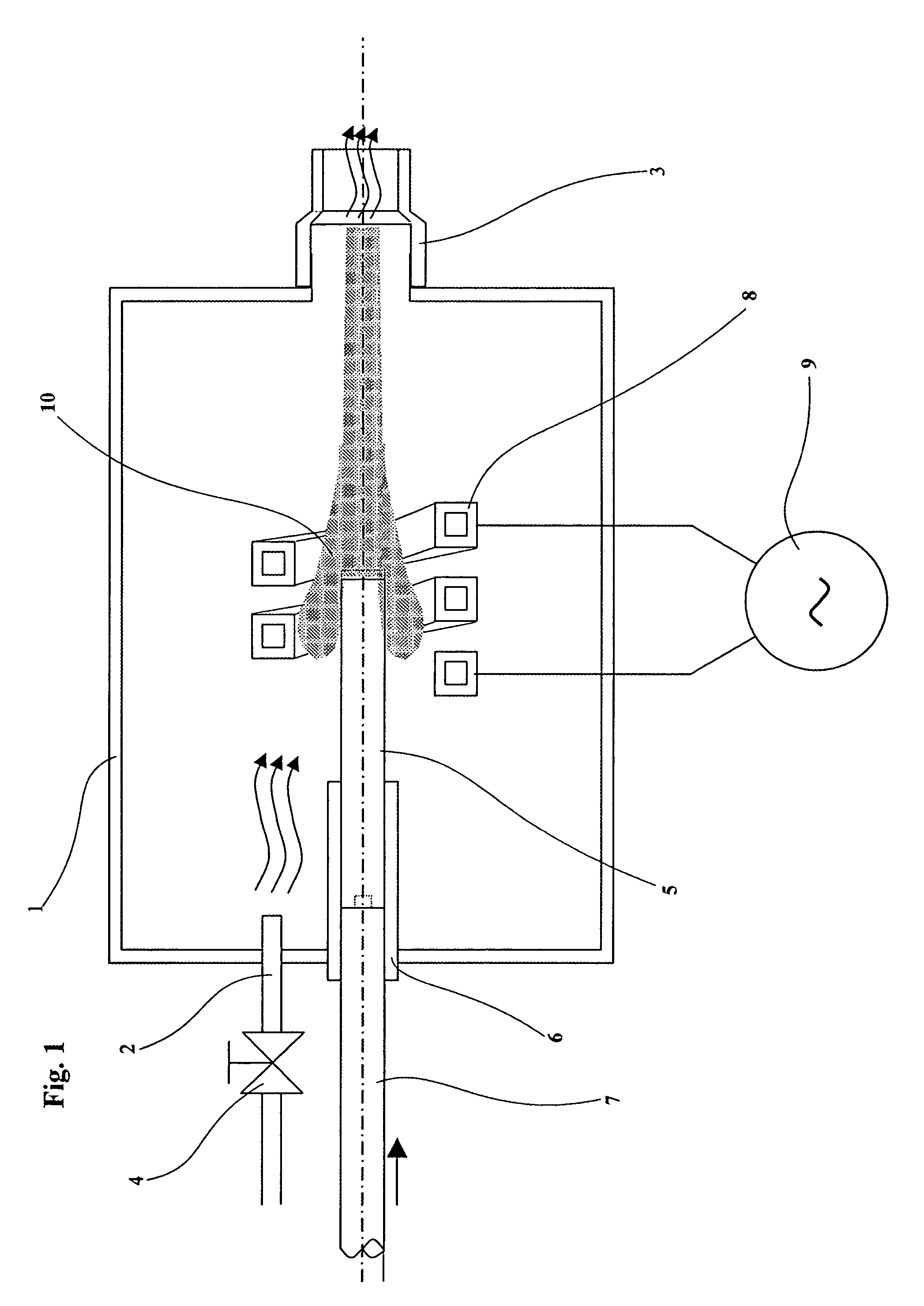

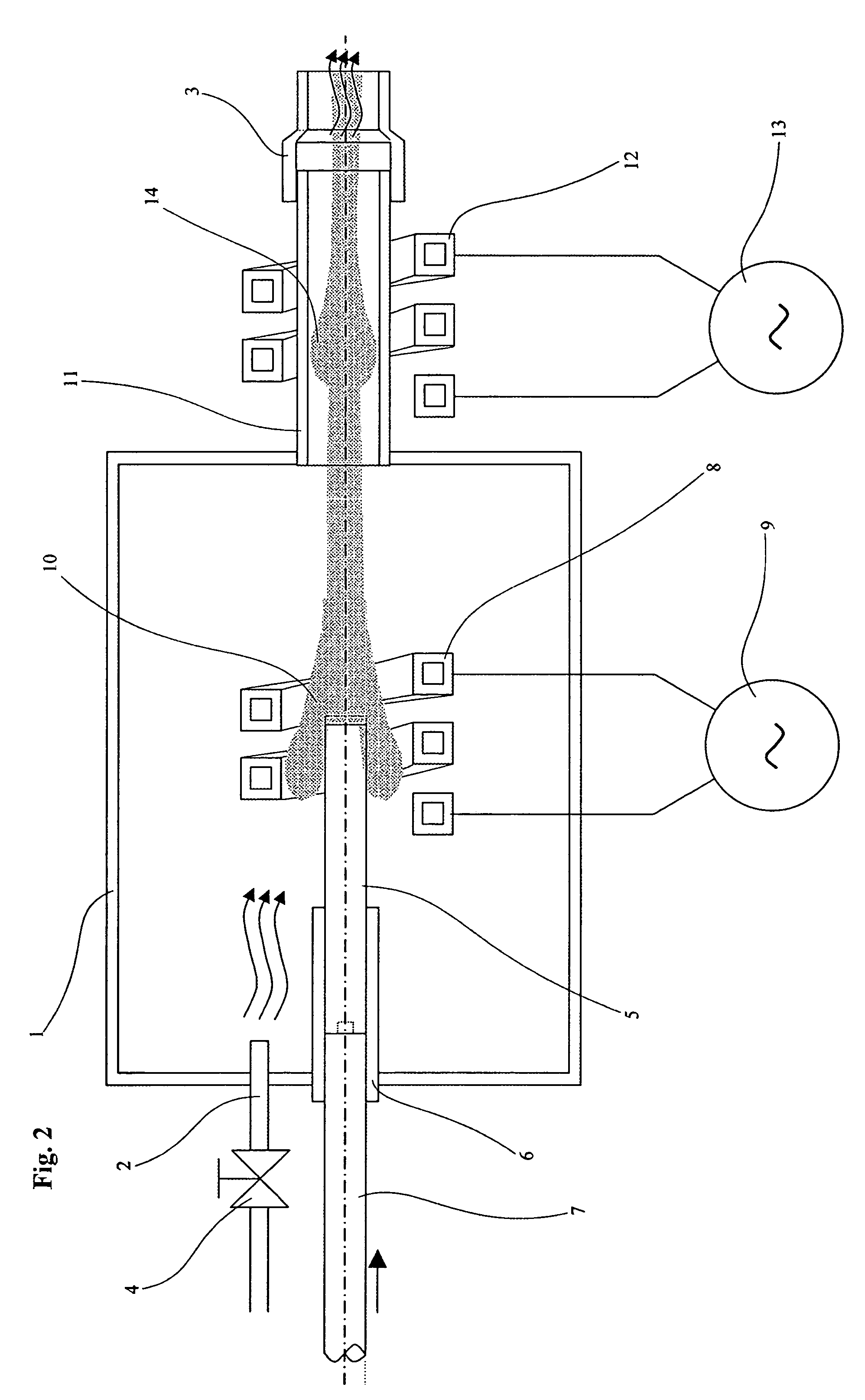

Device and method for production of carbon nanotubes, fullerene and their derivatives

An apparatus and method for the production of nanotubes, fullerene and their derivatives where, in an environment where an inert gas flows at or below atmospheric pressure, a high frequency electromagnetic field is generated and a pure or doped graphite element is subjected to the electromagnetic field and heated to vaporization to form a plasma.

Owner:CARBONIUM

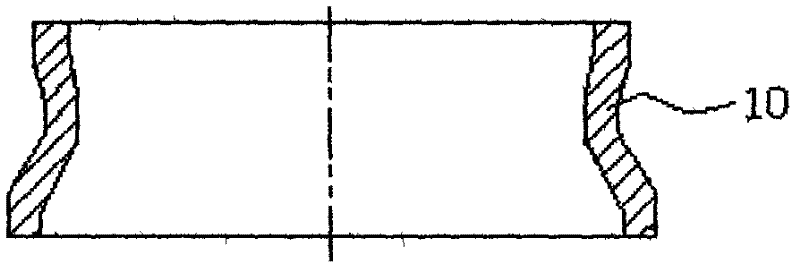

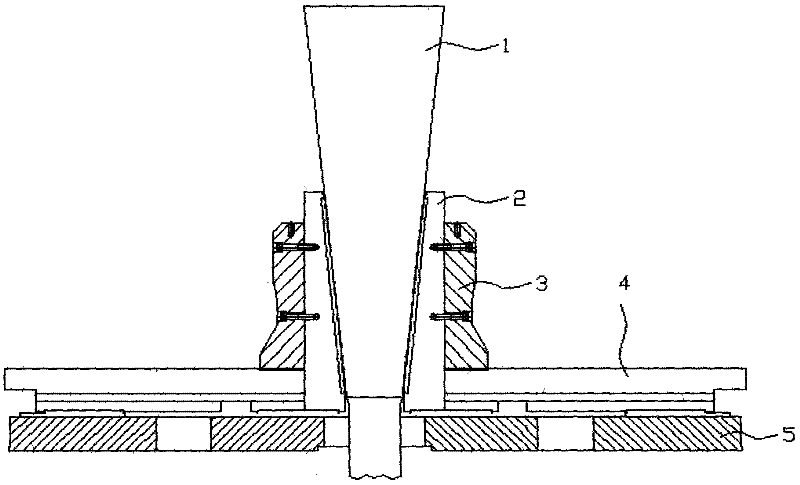

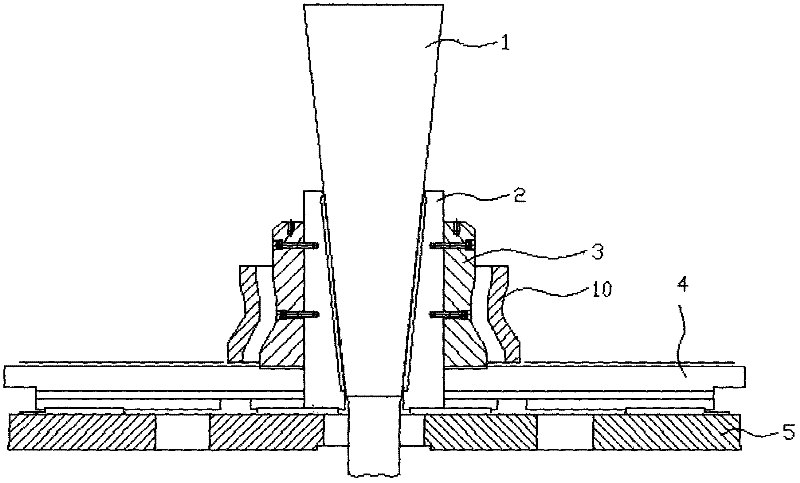

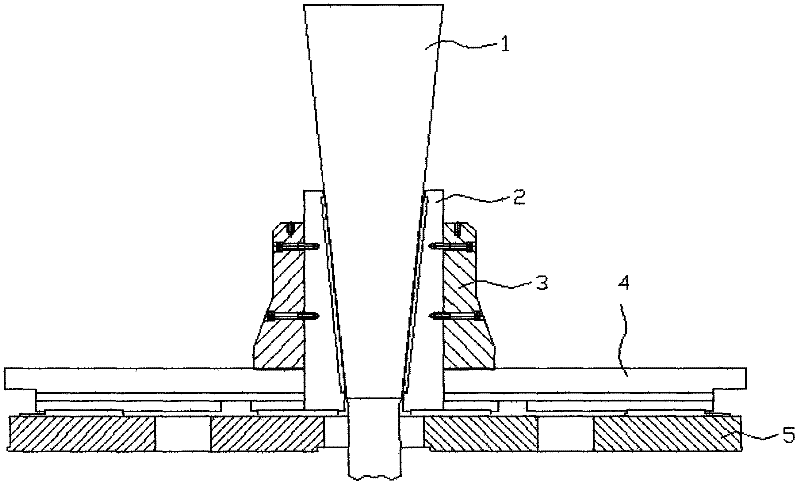

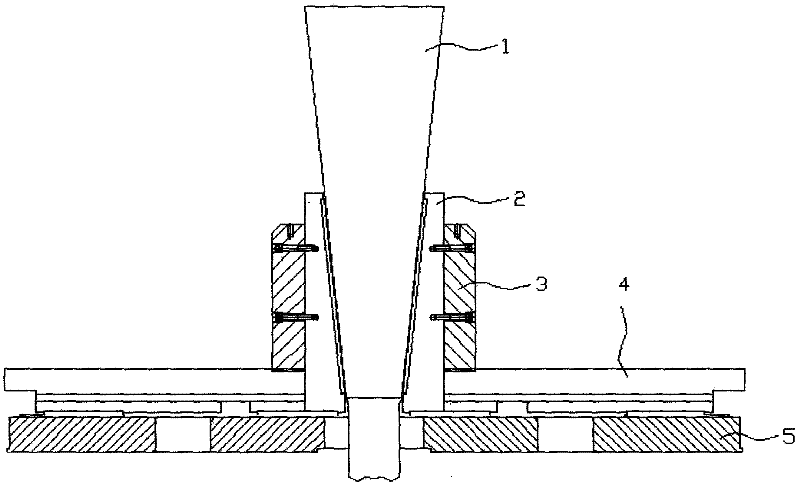

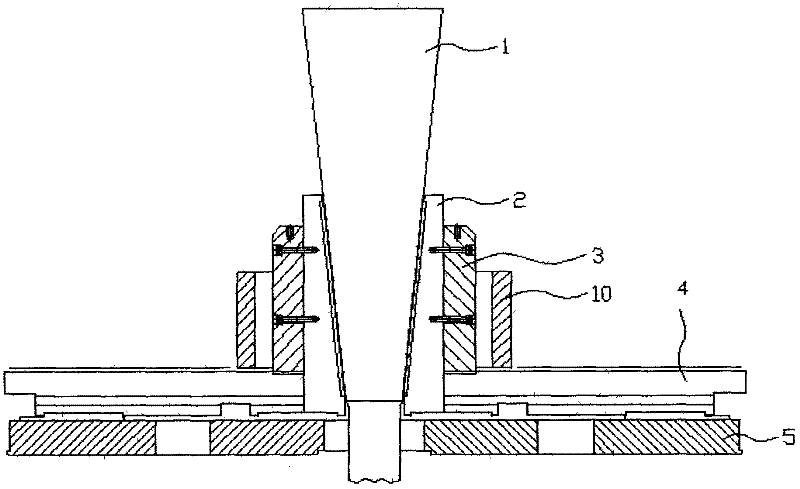

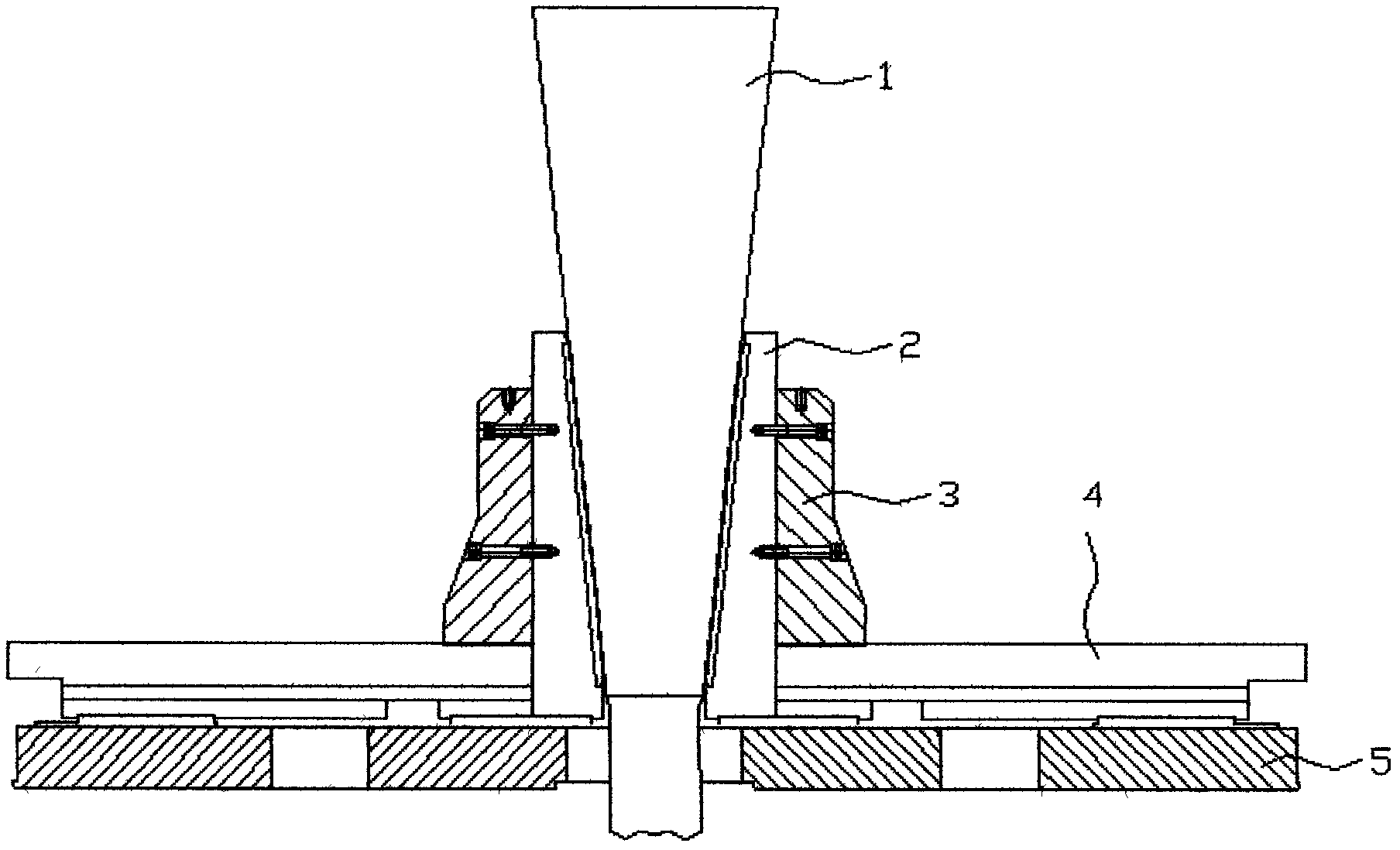

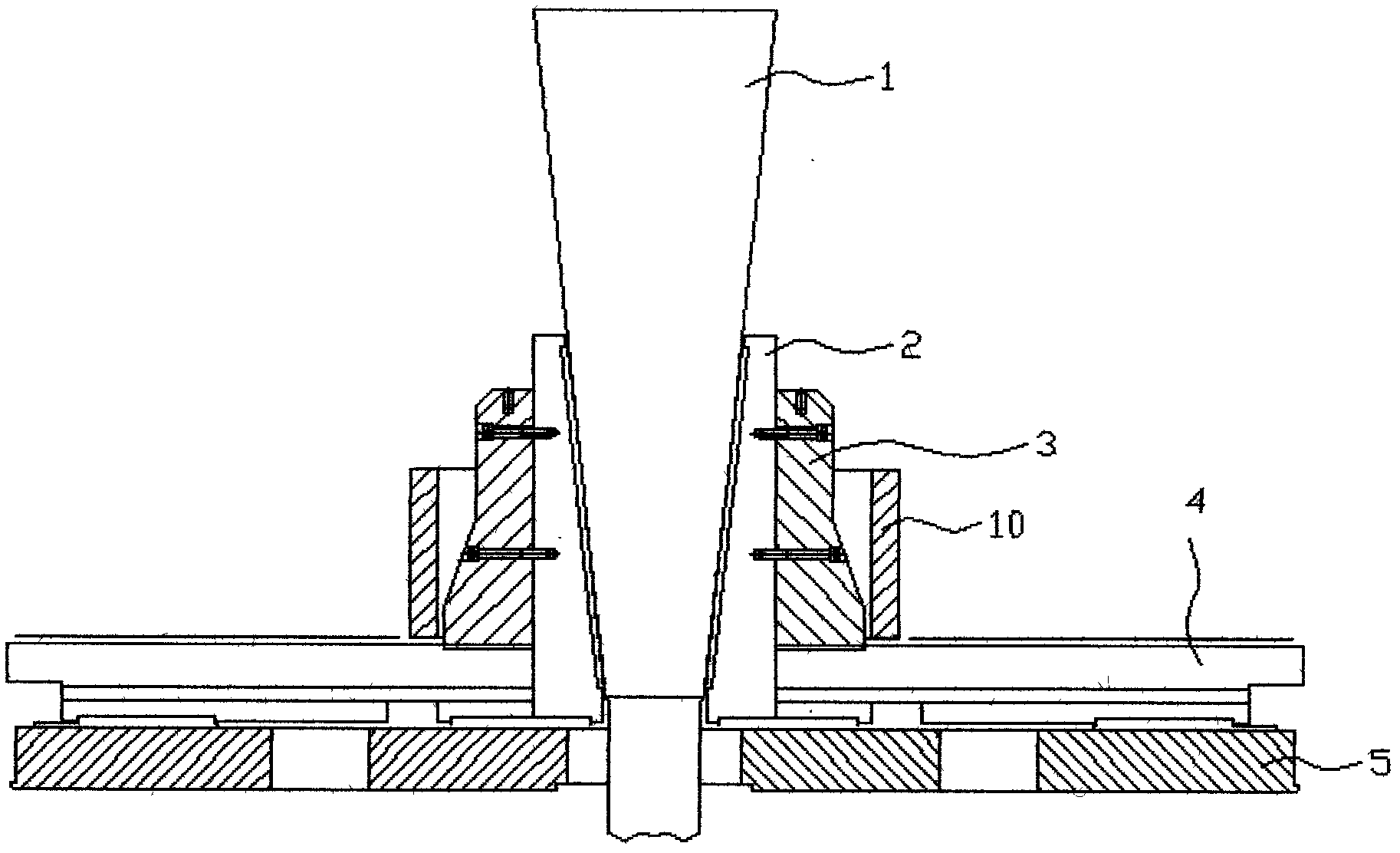

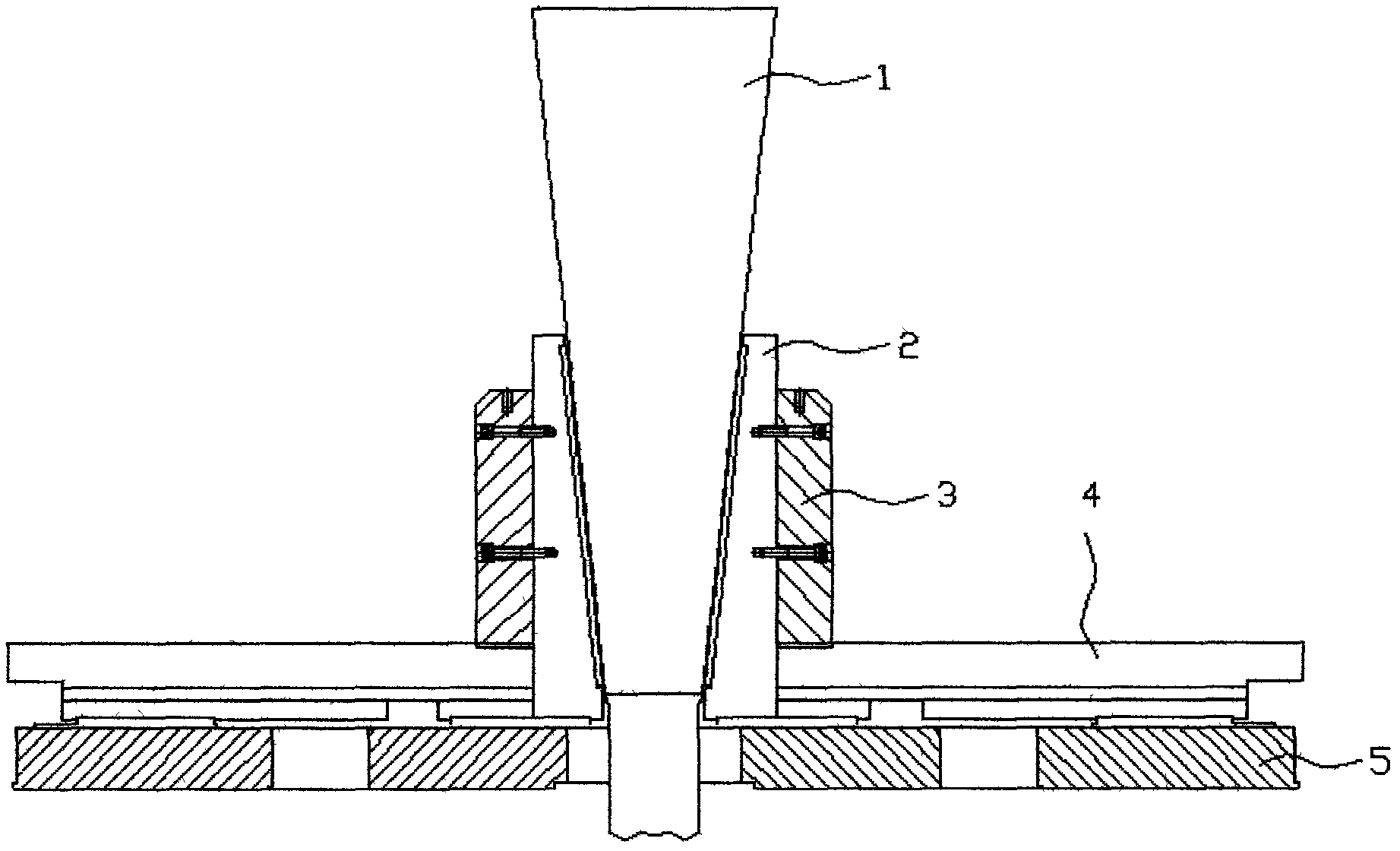

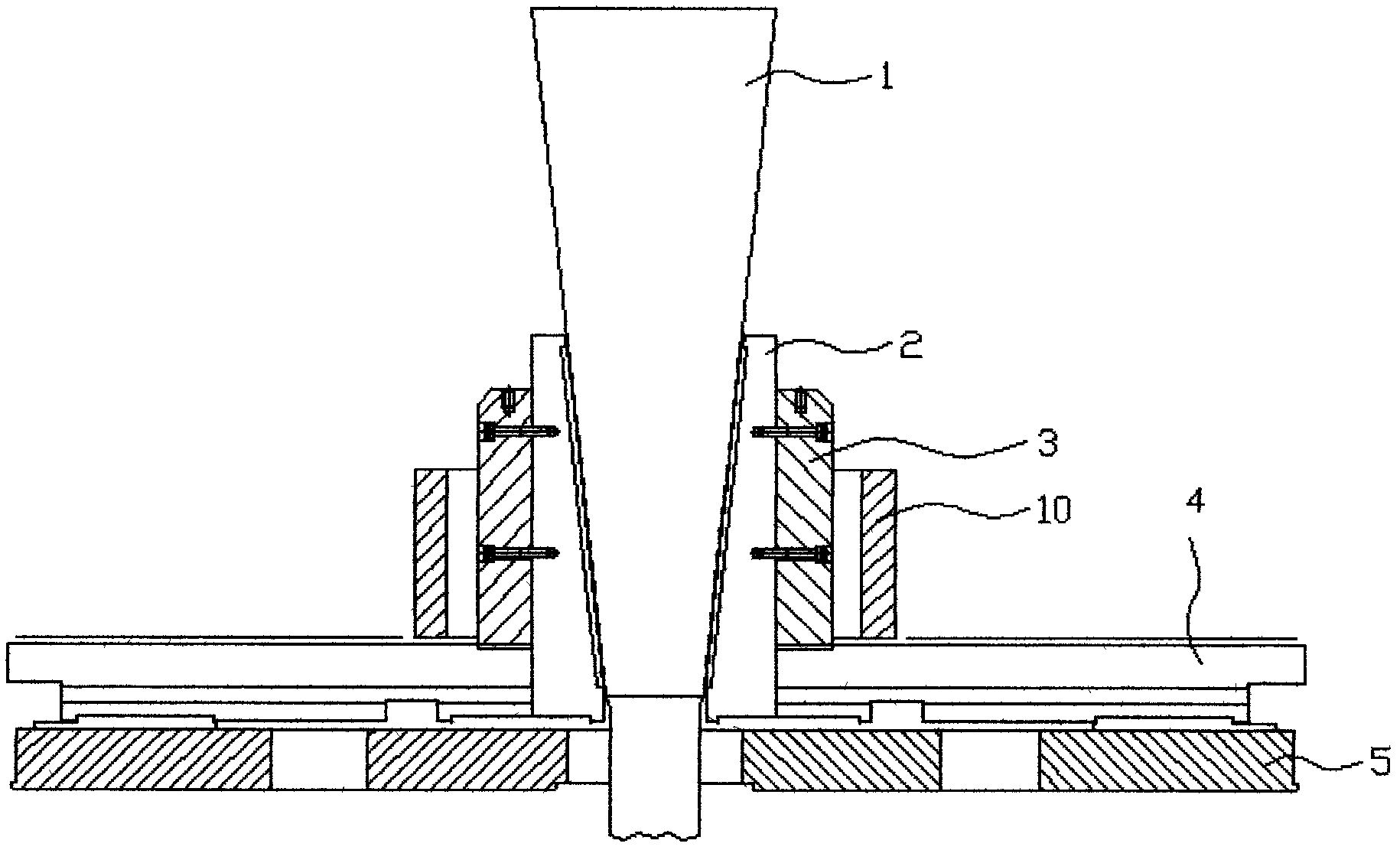

Thermal bulging process for special-shaped high-temperature-alloy rolled ring workpieces

The invention discloses a thermal bulging process for special-shaped high-temperature-alloy rolled ring workpieces, which includes steps of primary bulging; primary rotation; secondary rotation; secondary bulging and tertiary bulging. In the primary bulging, a special-shaped high-temperature-alloy rolled ring workpiece which is treated by thermal rolling is sleeved on the periphery of a preheated bulging block in a bulging machine, and the bulging block squeezes the ring workpiece axially along the inner circumference of the rolled ring workpiece after the bulging machine is started so that the primary bulging is completed, wherein the bulging temperature ranges from 820 DEG C to 860 DEG C, the bulging time ranges from 20s to 30s, the pressure holding time ranges from 10s to 11s, and the deflection ranges from 0.7% to 0.9%. The primary rotation is completed by rotating the rolled ring workpiece along the center axis by 45 degrees. The secondary bulging is completed by processes of the primary bulging, wherein the bulging temperature ranges from 790 DEG C to 830 DEG C, the bulging time ranges from 20s to 30s, the pressure holding time ranges from 16s to 18s, and the deflection ranges from 0.8% to 1 %. The second rotation is completed by rotating the ring workpiece again along the direction the same with that of the primary rotation. The tertiary bulging is completed by the processes of the primary bulging again, wherein the bulging temperature ranges from 760 DEG C to 800 DEG C, the bulging time ranges from 30s to 40s, the pressure holding time ranges from 25s to 28s, and the deflection ranges from 0.9% to 1.1%. The dimensional precision of the rolled ring workpiece can be 1%. to 2%. of the corresponding precision after the rolled ring workpiece is bulged, and the rolled ring workpiece is mainly used for the fields of space navigation and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

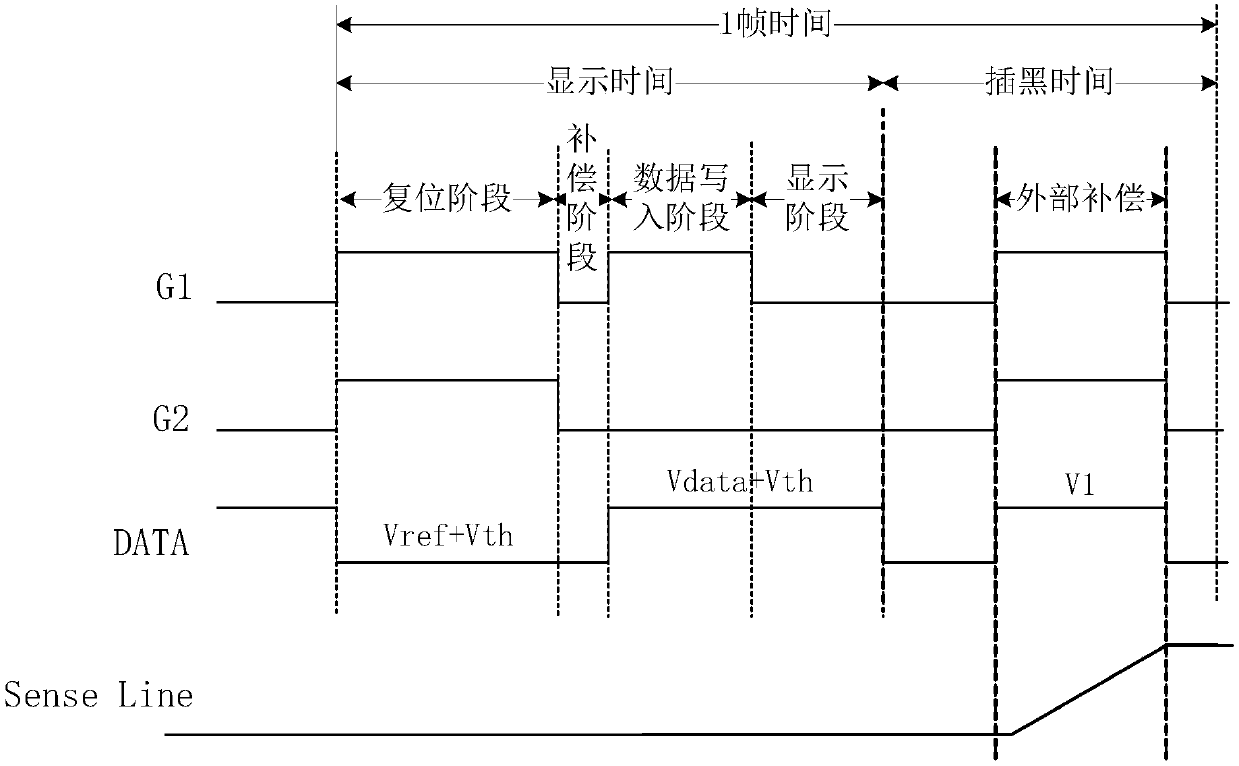

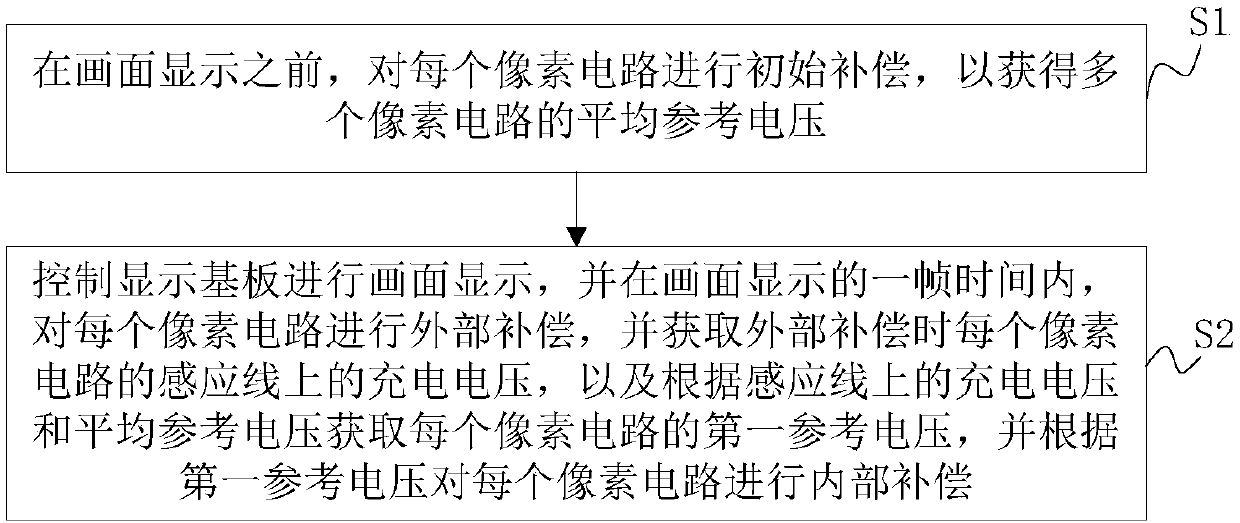

Display device, display substrate and display compensation method and device

ActiveCN108053793AImplement Threshold Voltage CompensationReal-time compensation for characteristic changesStatic indicating devicesDisplay deviceHemt circuits

The invention discloses a display device, a display substrate and a display compensation method and device. The method comprises the following steps: before an image is displayed, performing initial compensation on each pixel circuit to obtain the average reference voltage of a plurality of pixel circuits; controlling the display substrate to display the image, and performing external compensationon each pixel circuit within the display time of a frame of the image, and acquiring the charging voltage of the sensing line of each pixel circuit during the external compensation, acquiring the first reference voltage of each pixel circuit according to the charging voltage of the sensing lines and the average reference voltage, and performing internal compensation on each pixel circuit according to the first reference voltage. Thus, not only can threshold voltage compensation of a driving transistor be realized, but also a large characteristic change of the driving transistor can be covered and real-time compensation is performed on the characteristic change of the driving transistor. Further, traces generated by external compensation can be eliminated so that the display effect can befurther improved.

Owner:BOE TECH GRP CO LTD

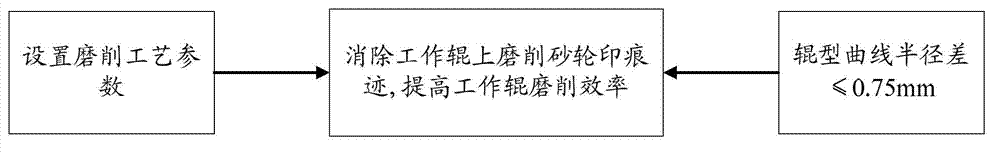

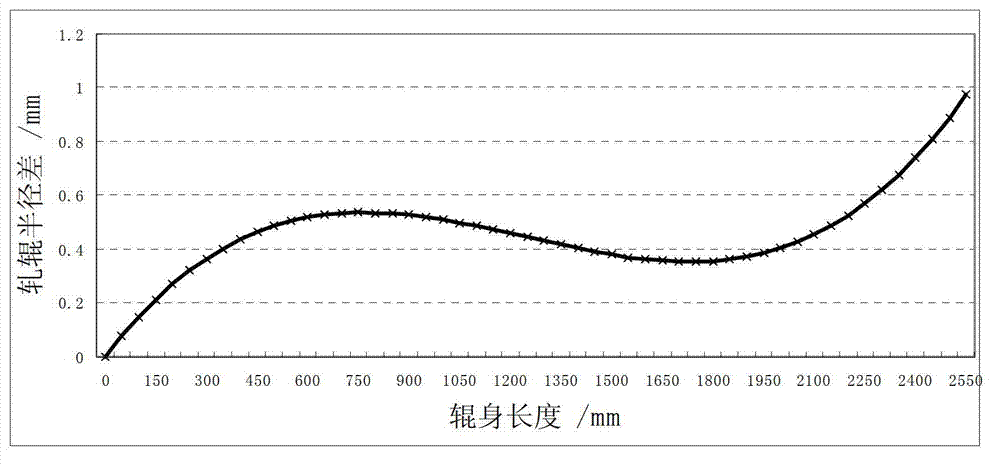

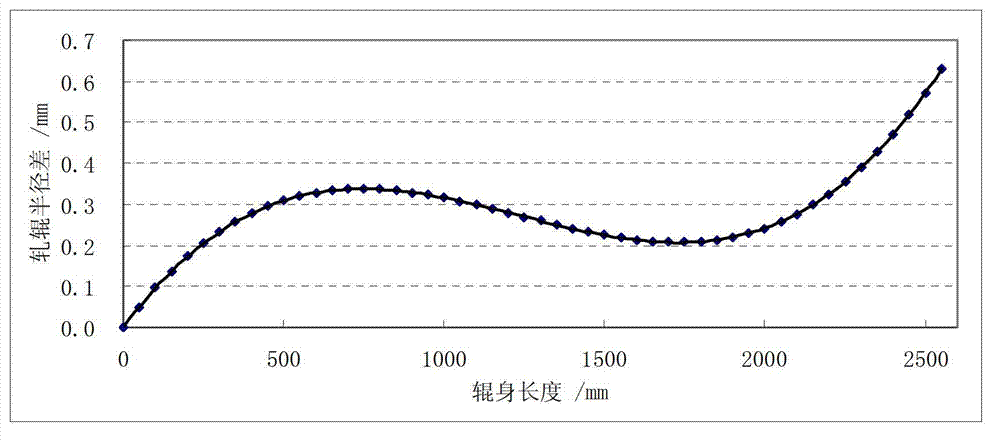

Hot-rolled steel strip vertical stripe defect eliminating method

ActiveCN103240280AImprove grinding efficiencyEliminate contact pressureProfile control deviceContact pressureFrame work

The invention discloses a hot-rolled steel strip vertical stripe defect eliminating method. The method includes reducing the rotary speed of a grinding wheel, increasing the rotary speed of a roller during the process of rough grinding and fine grinding, reducing the rotary speed of the roller during the process of first half fine grinding, reducing the rotary speed of the roller during the processes of second half fine grinding and third half fine grinding, reducing the speed of a layer board, and reducing the contact pressure of the grinding wheel and the roller face and increasing the number of fine grinding passes. By the method, impression traces on a working roller of F4-F6 in the grinding process can be eliminated completely, and good effect can be achieved. Meanwhile, the curve radius difference of a finishing mill group end frame working roller of CVC (continuous variable crown) type is controlled in a range less than or equal to 0.75mm (0.625mm is selectable), and high grinding efficiency is improved. The hot-rolled steel strip vertical stripe defect eliminating method has the advantages of convenience in operation, significance in effect and high accuracy, and qualified raw materials are provided for producing cold rolling products, namely automobile plates, house appliance plates and the like, with high-level surface quality requirements.

Owner:SHOUGANG CORPORATION

Manufacturing method of printed circuit board

ActiveCN106034380APrecise positioningPositioning does not shiftPrinted circuit manufactureEngineeringCopper

The invention relates to a manufacturing method of a printed circuit board. The manufacturing method is applicable to the printed circuit board with no positioning hole designed in the inner side of a technological side or only with non-electroplate-copper hole with the diameter smaller than or equal to 1.5 mm. The manufacturing method comprises the steps that V-cut production is carried out, the technological edge, close to the peripheral edge, of each unit of the printed circuit board is provided with at least two connection places with the length of 1-2 mm, the V-cut line of each connection place exceeds the technological edge by 0.1-0.2 mm, the remaining thickness of each connection place is 0.15-0.25 mm, and peripheral positioning holes are drilled near the connection places. According to the method, V-cut production is carried out on the PCB at first, the technological edge, close to the peripheral edge, of the PCB is provided with the connection places, the peripheral positioning holes are formed in the outer sides of the connection places and used for carrying out cutting operation, and it can be ensured that positioning is accurate and displacement is avoided.

Owner:AOSHIKANG TECH CO LTD

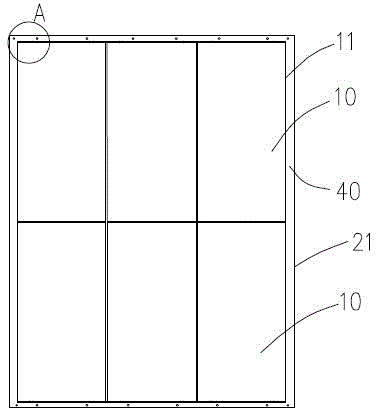

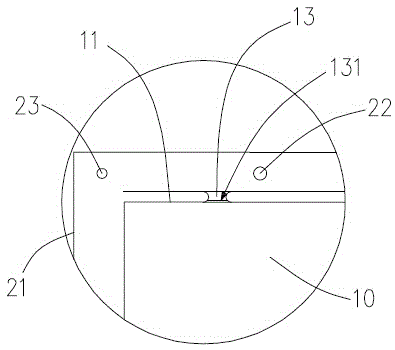

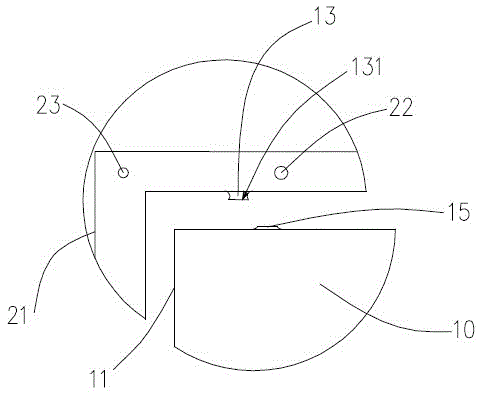

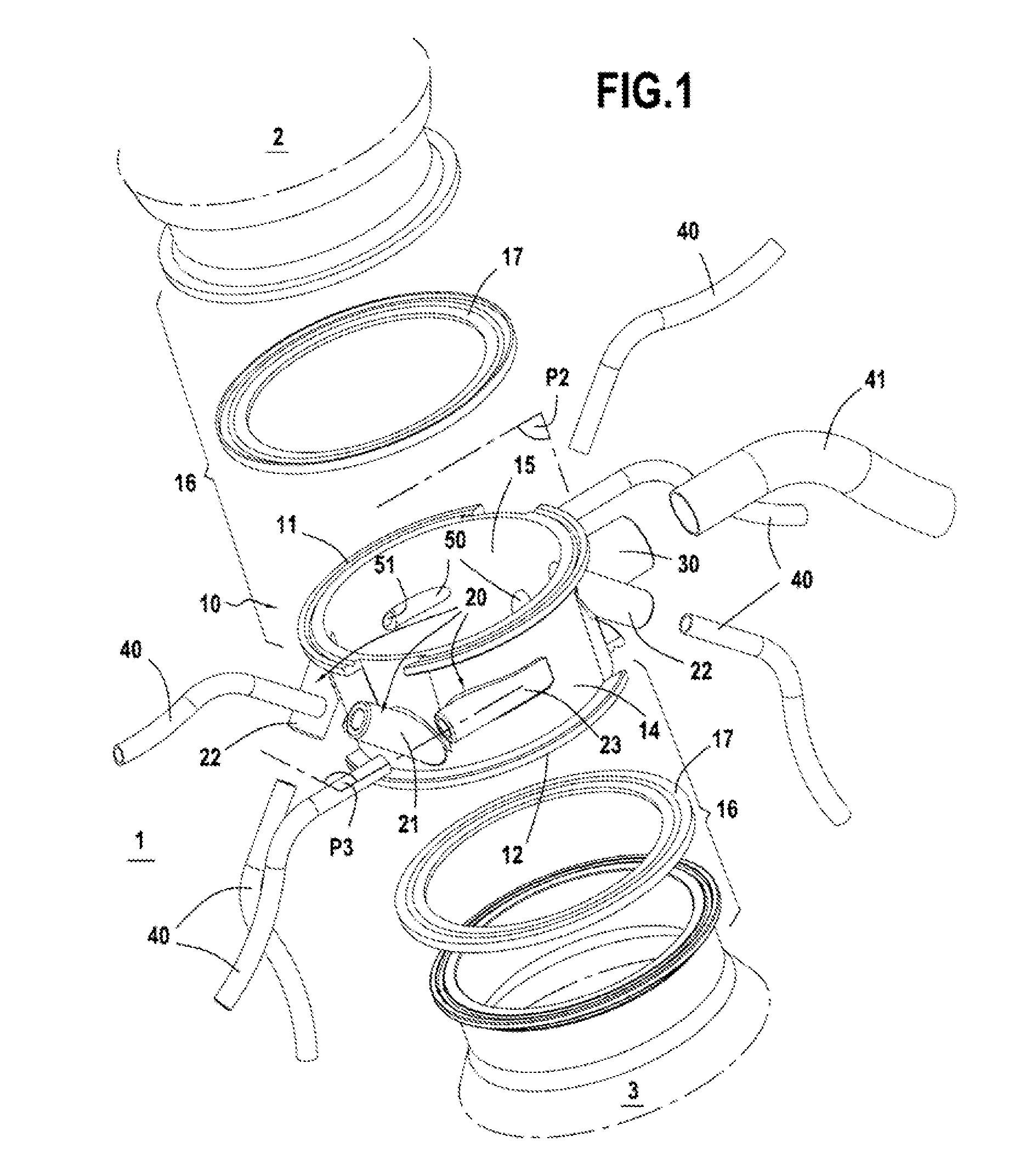

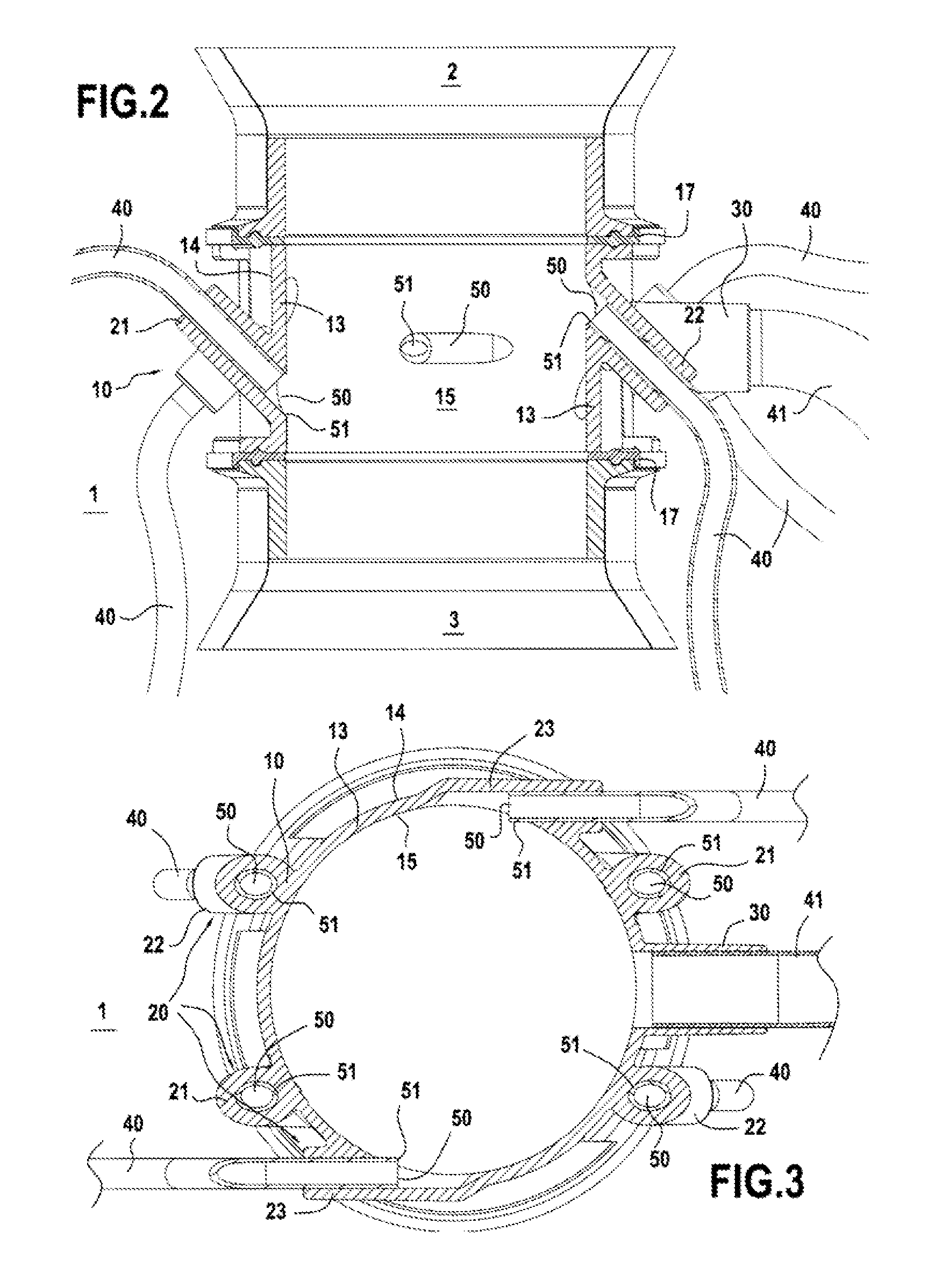

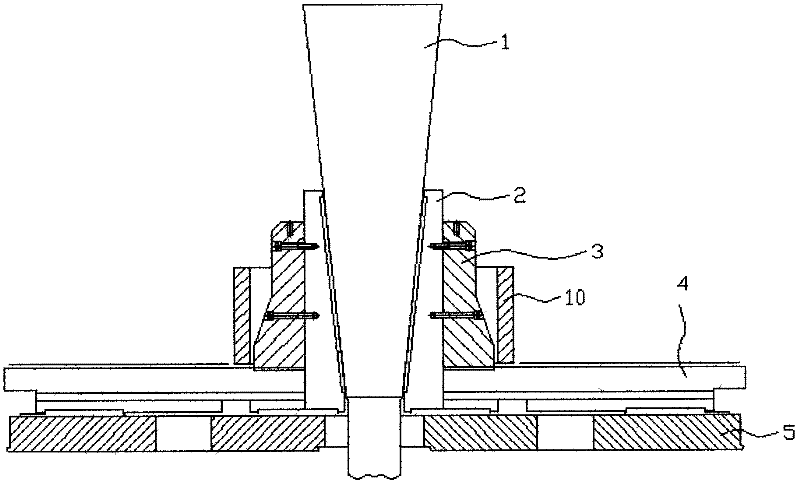

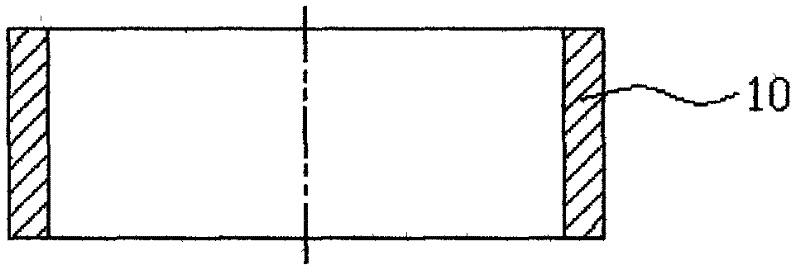

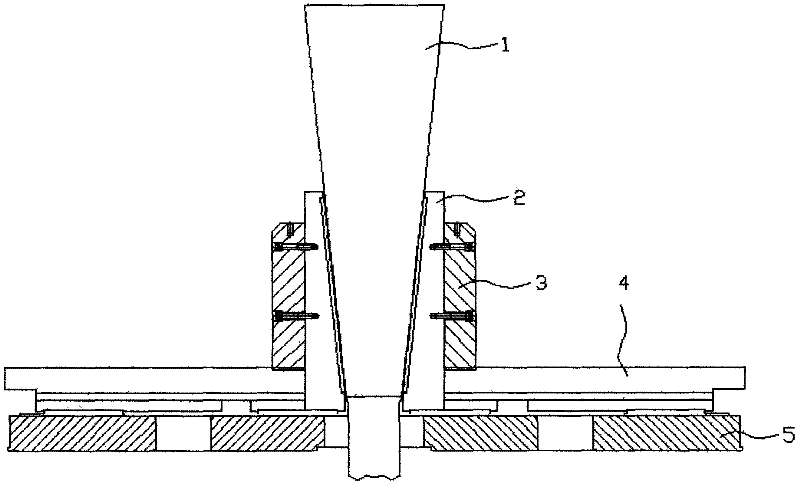

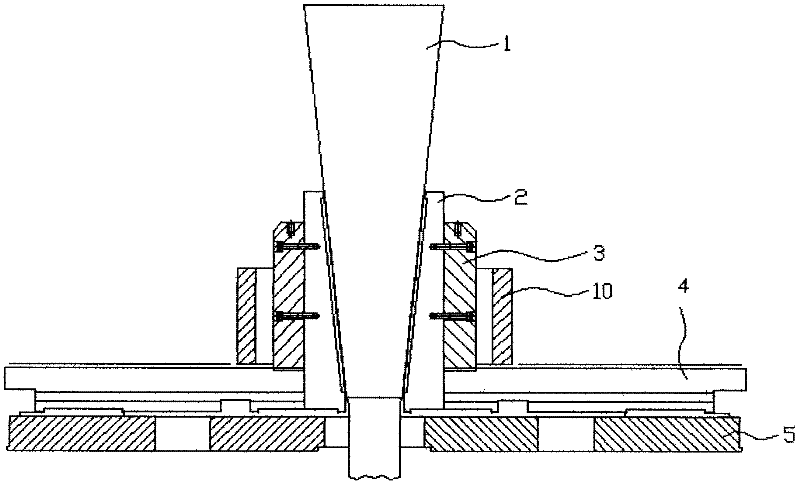

Dust extractor, in the context of the transfer of powdery products, installation, dust extraction method, transfer method, and sterilization method using said device

ActiveUS20110100397A1Strict requirementsEliminate tracesSuction cleanersHollow article cleaningPhencycloneEngineering

The invention relates to a device (1) for extracting dust in the context of the transfer of pulverulent products from a first container (2) to a second container (3), the combination of the first container and of the second container forming, with the dust extraction device, a closed containment volume comprising, by way of means of connection between the two containers (2), (3), a hollow connector (10) having an open top end (11) and an open bottom end (12), comprising a side wall (13) between its two ends, said side wall (13) defining an external wall (14) and an internal wall (15), characterized in that said connector (10) is pierced with several inlet pipes (20) connected to hoses (40) fed with a stream of pressurized fluid and also pierced with at least one fluid discharge pipe (30), said pipes projecting from said external wall (14) of said connector (10), and opening onto said internal wall (15) via orifices (50) that allow the fluid to be introduced, said orifices (50) being oriented relative to one another in such a way as to cause said fluid to flow in a cyclone within said connector (10), carrying with it any pulverulent product that remains on the internal wall (15) and / or upstream and / or downstream of said connector (10).The invention also relates to an installation comprising said device and to a method of extracting dust, a method of transferring at least one pulverulent product, and a method of sterilizing using said device.

Owner:CHANGEXPLORER PRODN

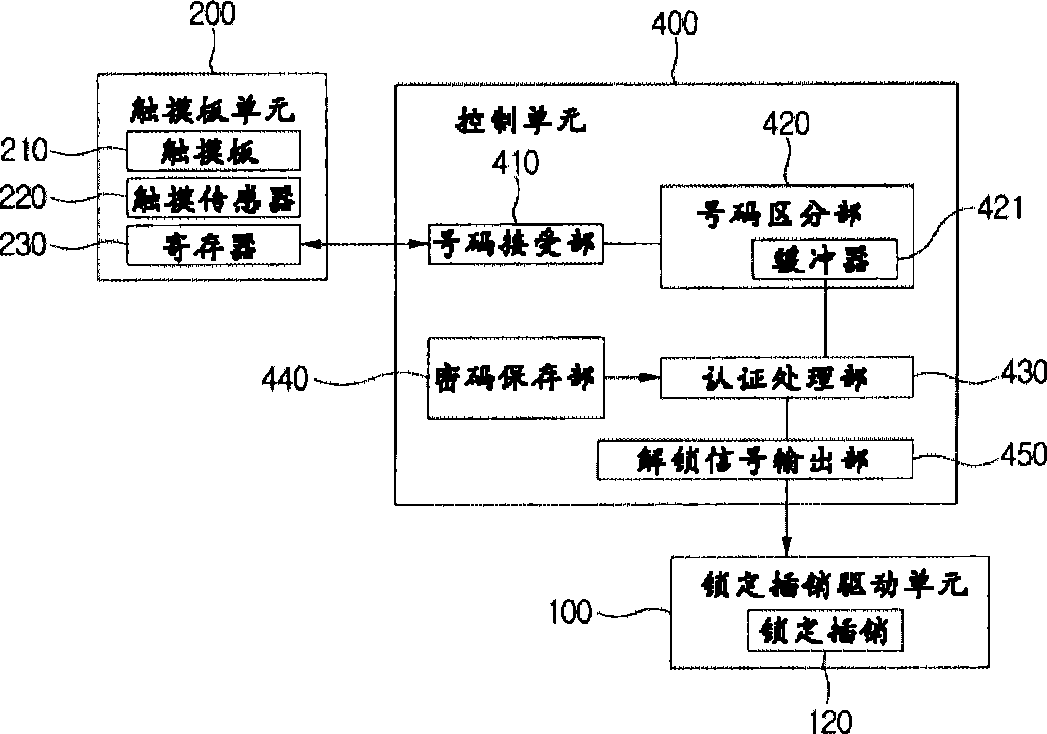

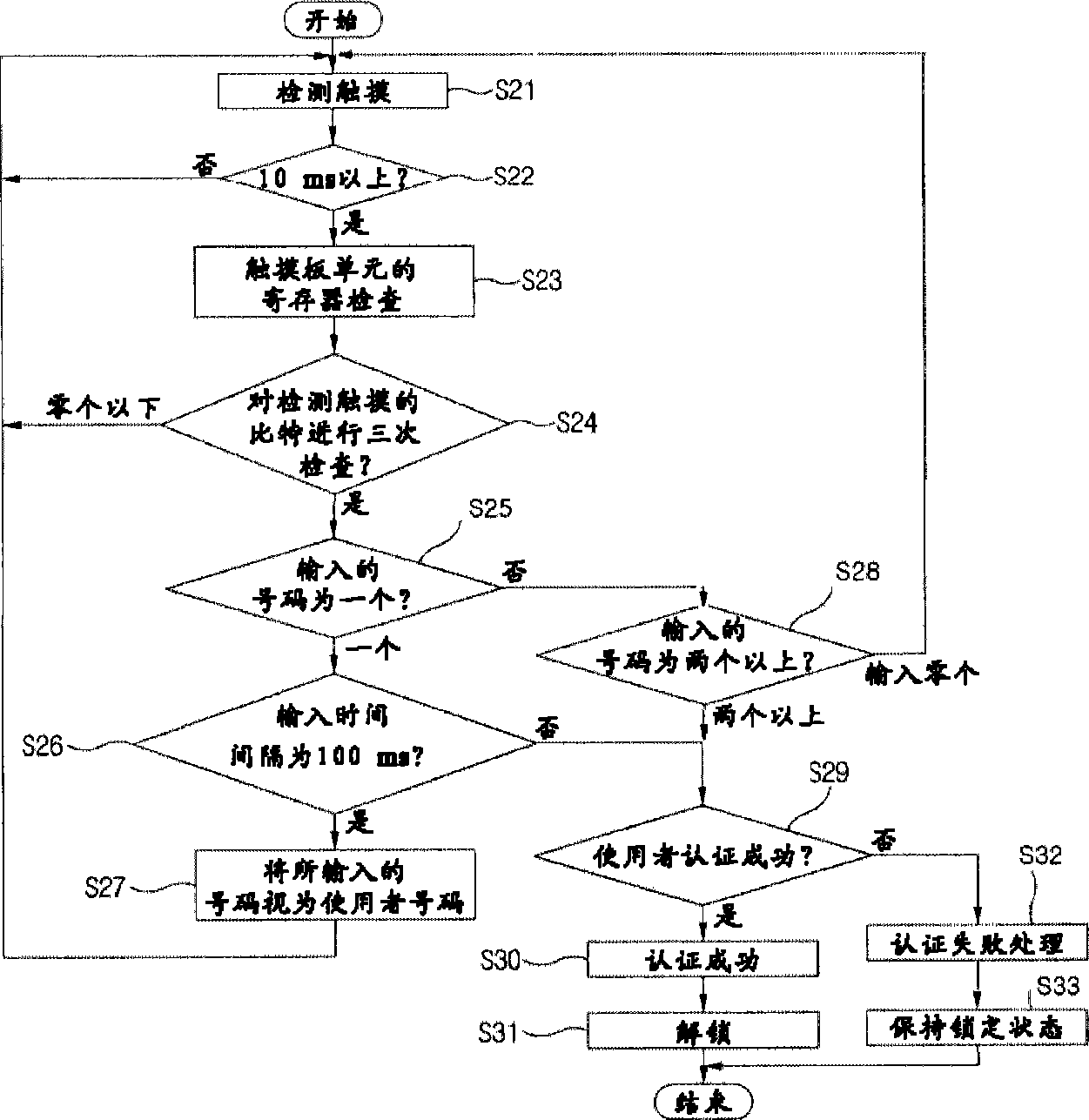

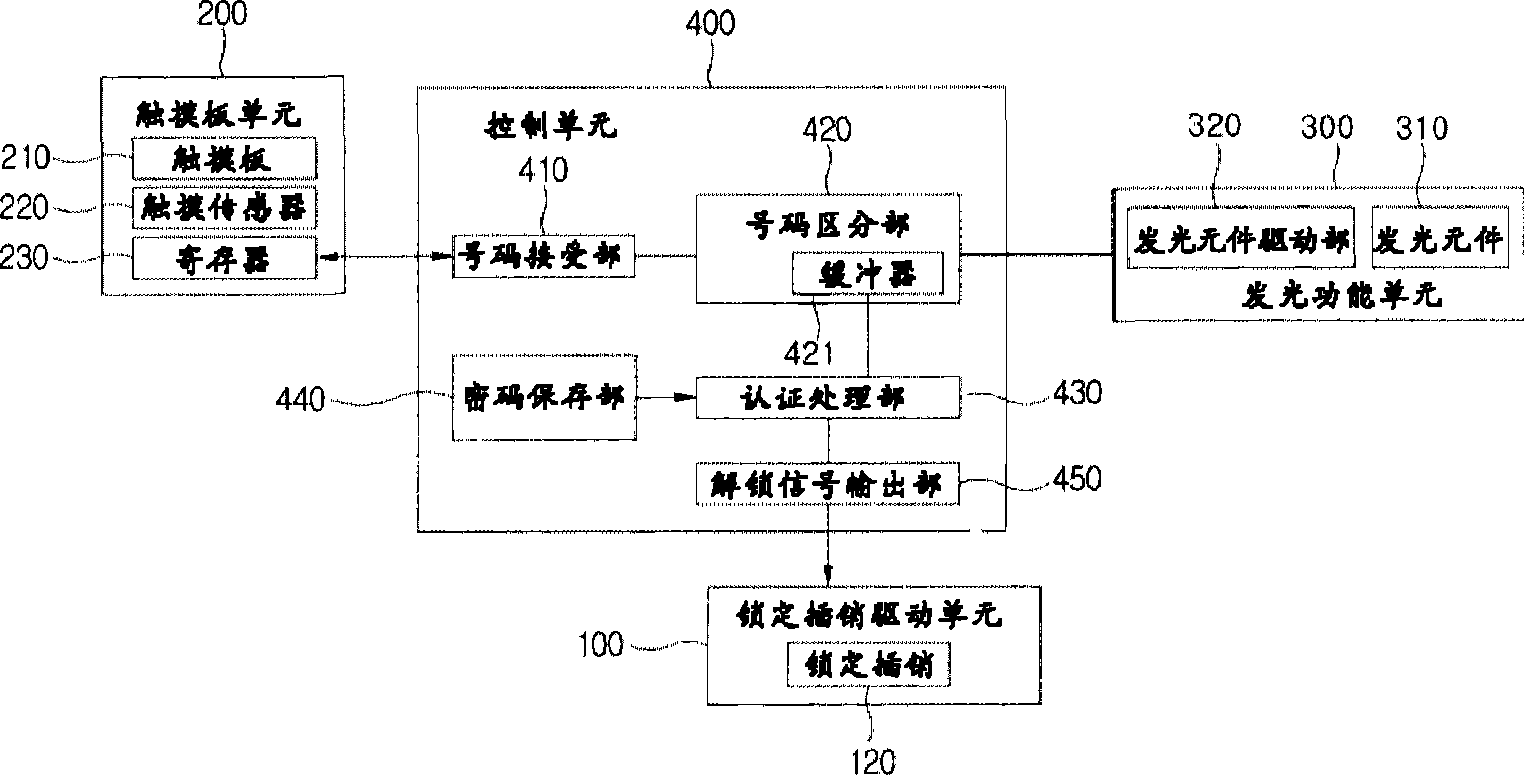

Door lock system with touch pad unit and control method thereof

ActiveCN101532353AEliminate tracesSimple designElectric permutation locksIndividual entry/exit registersPasswordTouchpad

The invention provides a lock system of door. The lock has a dead bolt drive unit for operating a dead bolt; a touch pad unit sensing electrostatic capacity of a touch pad, and outputting a contact number corresponding to a contact point; a control unit, after the touch pad unit inputs the number corresponding to the preset password, if inputting the second contact number is input within predetermined base time after inputting the first contact number, judging that an input of the number corresponding to the password is terminated, and comparing the input number and the password, if the input number and the password are accordant, outputting an unlocking signal to the dead bolt drive unit.

Owner:IREVO INC

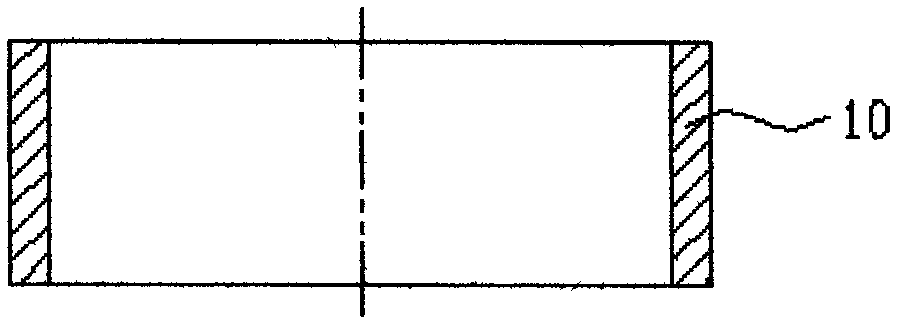

Method for forming irregular ring piece by utilizing stainless-steel rectangular ring rolled piece through thermal bulging

ActiveCN102513457AHigh dimensional accuracyPrecise control of bulge sizeShaping toolsAbnormal shapedAerospace

The invention discloses a method for forming an irregular ring piece by utilizing a stainless-steel rectangular ring rolled piece through thermal bulging, comprising the following steps of: sleeving the heated stainless-steel rectangular ring rolled piece on the periphery of a pre-heated bulging blockin a bulging machine; starting the bulging machine so that the ring rolled piece is squeezed by the bulging block in a radial direction along the inner circumference surface of the ring rolled piece and becomes the irregular ring blank after being deformed for 11-13%, thus completing primary bulging; rotating the irregular ring blank for 45 degrees along an center axis, thus completing primary rotation; carrying out secondary bulging with the deformation amount of 1.8-2% and secondary rotation on the irregular ring blank according to the previous steps; carrying out tertiary bulging with the deformation amount of 1.4-1.6% and tertiary rotation on the irregular ring blank according to the previous steps; and carrying out quartus bulging with the deformation amount of 1.2-1.4% and quartus rotation on the irregular ring blank according to the previous steps, so as to obtain the irregular ring piece. The size precision of the irregular ring piece can reach 0.1-0.2% of the corresponding size. The irregular ring piece formed by using the method disclosed by the invention is mainly used for fields of aerospace and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

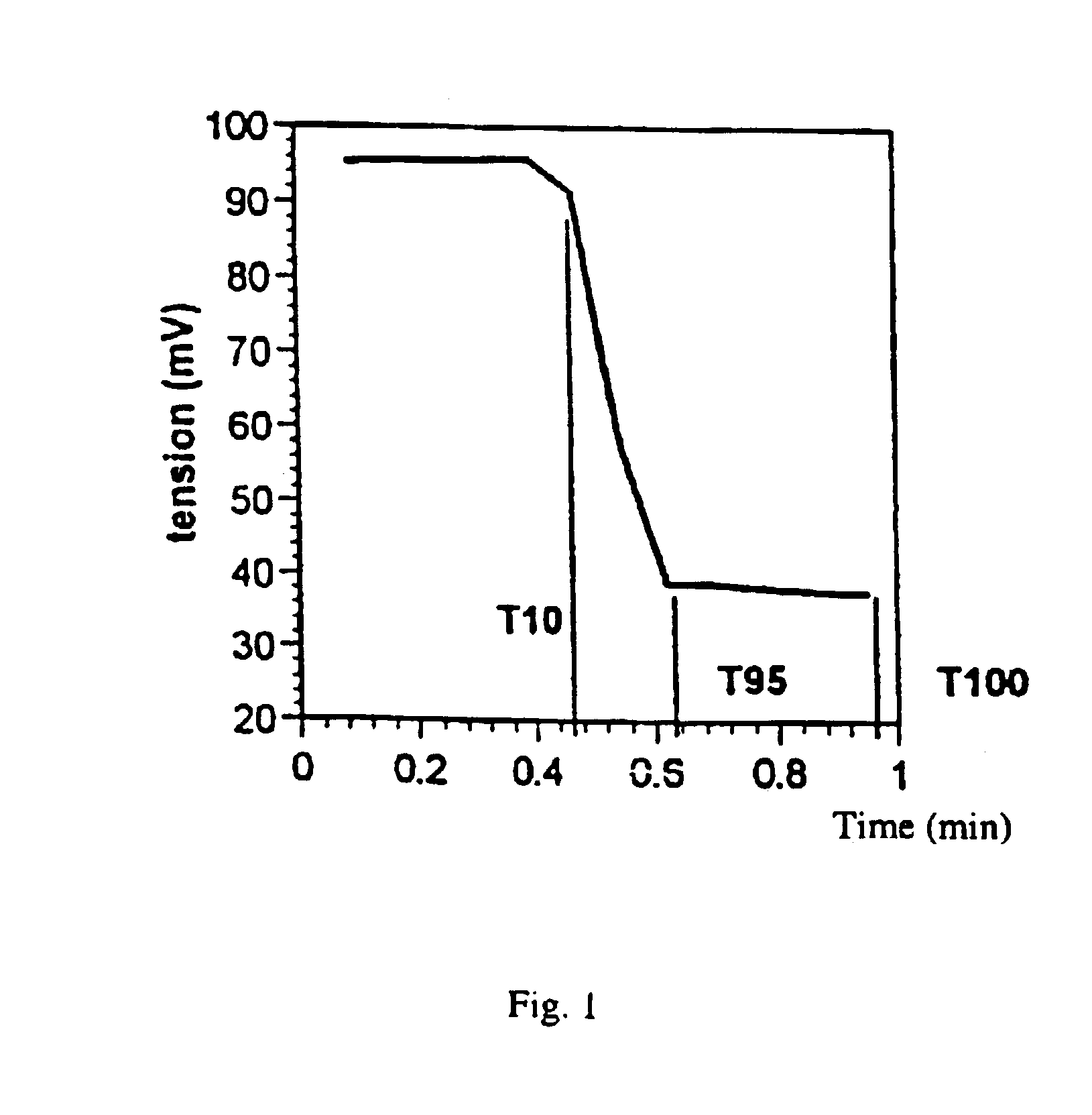

Testing method for determining quenching speeds through thermal simulation test

InactiveCN106248715AConvenient inspectionEliminate tracesMaterial thermal analysisStrength of materialsThermal treatment

The invention discloses a testing method for determining quenching speeds through a thermal simulation test and belongs to the technical field of thermal simulation. The testing method includes the following steps that A, multiple sets of samples made of the same material are kept in a thermal simulation tester for heating and heat holding at the same quenching temperature for the same heat holding time; B, different quenching speeds are set for quenching of the samples; C, the same tempering process is set for tempering of the samples; D, the multiple sets of samples obtained after thermal treatment are subjected to an impulse test at the required temperature, and respective shock absorption energy is obtained; E, a curve is drawn with the quenching speeds as transverse coordinates and the shock absorption energy as longitudinal coordinates, and the critical quenching speeds meeting the use requirement under the condition of the quenching temperature and the heat holding time are obtained. A reliable basis is provided for thermal treatment process parameter selection by determining the critical quenching speeds, meeting qualified material mechanical performance, of the samples.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Thermal bulging process for flash-welded stainless steel ring workpieces

The invention discloses a thermal bulging process for flash-welded stainless steel ring workpieces, which includes steps of primary bulging; primary rotation; secondary rotation; secondary bulging and tertiary bulging. In the primary bulging, a flash-welded stainless steel ring workpiece which is annealed is sleeved on the periphery of a preheated bulging block in a bulging machine after being heated, and the bulging block squeezes the ring workpiece axially along the inner circumference of the ring workpiece after the bulging machine is started so that the primary bulging is completed, wherein the bulging temperature ranges from 950 DEG C to 1040 DEG C, the bulging time ranges from 22s to 28s, the pressure holding time ranges from 18s to 20s, and the bulging deflection ranges from 0.12% to 0.15%. The primary rotation is completed by rotating the ring workpiece along the center axis by 45 degrees. The secondary bulging is completed by processes of the primary bulging, wherein the bulging temperature ranges from 920 DEG C to 1010 DEG C, the bulging time ranges from 20s to 25s, the pressure holding time ranges from 16s to 18s, and the deflection ranges from 0.08% to 0.09%. The second rotation is completed by rotating the ring workpiece again along the direction the same with that of the primary rotation. The tertiary bulging is completed by the processes of the primary bulging again, wherein the bulging temperature ranges from 890 DEG C to 980 DEG C, the bulging time ranges from 25s to 30s, the pressure holding time ranges from 21s to 23s, and the deflection ranges from 0.09% to 1%. The dimensional precision of the ring workpiece can be 1%. to 2%. of the corresponding precision after the ring workpiece is bulged, and the ring workpiece is mainly used for the field of space navigation.

Owner:GUIZHOU ANDA AVIATION FORGING

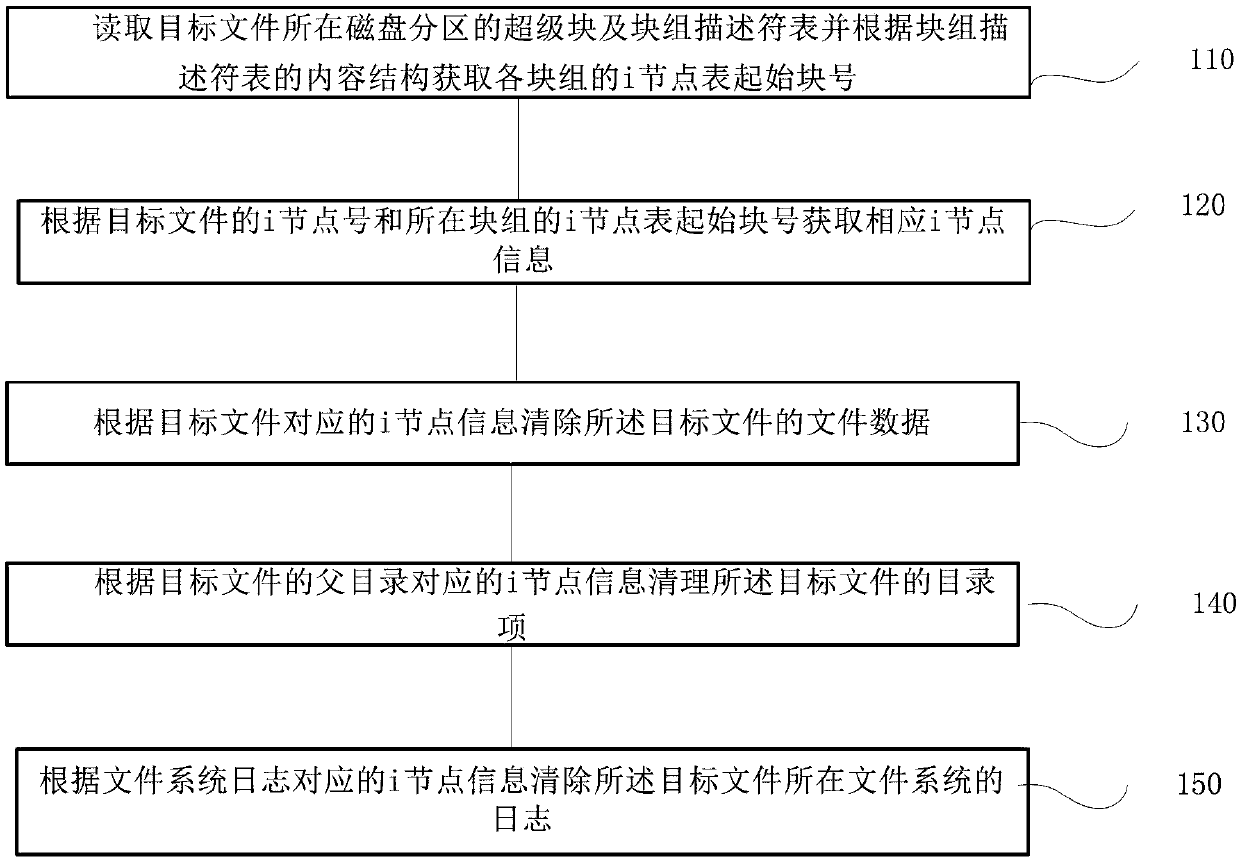

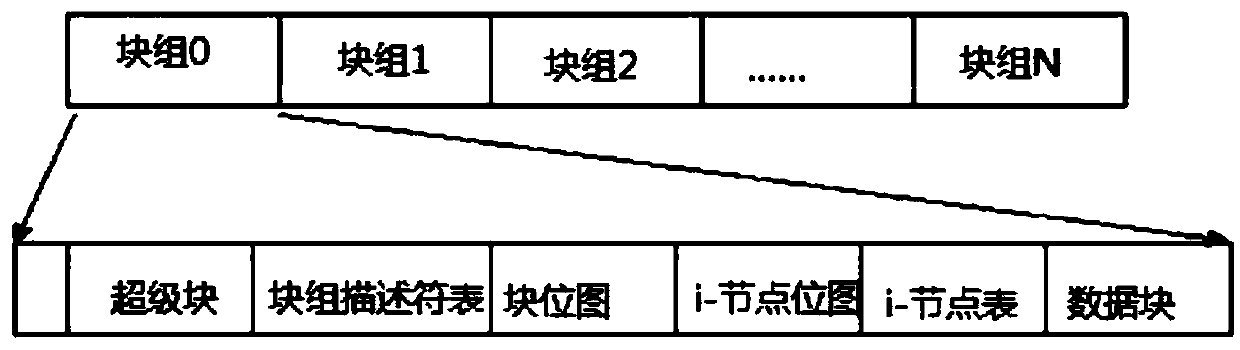

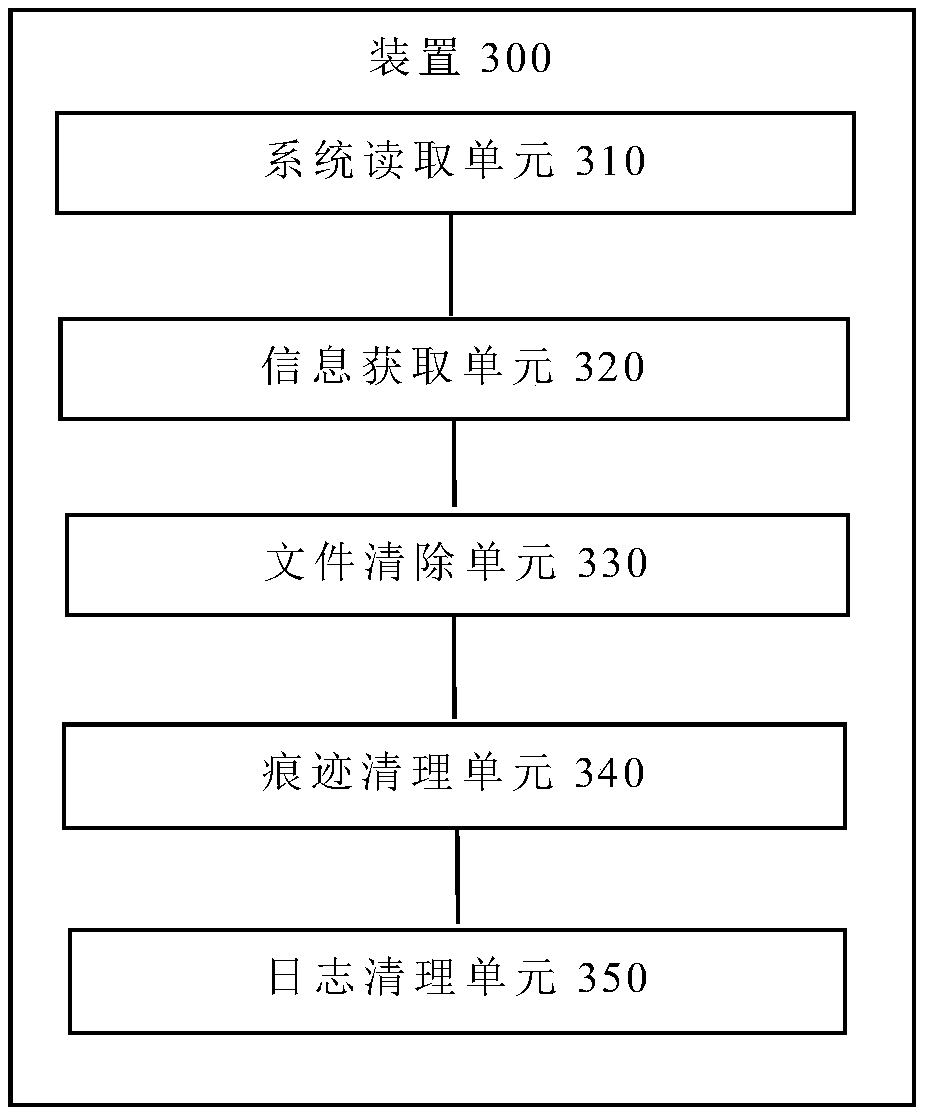

Linux file system-based file complete deletion method and device

InactiveCN109656888AErase disk data and tracesAvoid data recoveryFile/folder operationsFile systemBlock number

The invention provides a linux file system-based file thorough deletion method and apparatus. The method comprises the steps of reading a block group descriptor table of a disk partition where a target file is located, and obtaining an i node table initial block number of each block group according to a content structure of the block group descriptor table; Obtaining corresponding i node information according to the i node number of the target file and the i node table starting block number of the block group; Clearing file data of the target file according to the i node information corresponding to the target file; Cleaning the directory entry of the target file according to the i node information corresponding to the directory entry of the parent directory of the target file; And clearing the log of the file system where the target file is located according to the i node information corresponding to the file system log. According to the method, it can be guaranteed that disk data andtraces of the target file are thoroughly eliminated, logs are deleted, and data recovery through technical means is avoided.

Owner:中孚安全技术有限公司 +2

Process for forming special-shaped ring workpieces from aluminum alloy rectangular rolled ring workpieces by hot bulging

ActiveCN102500707AHigh dimensional accuracyPrecise control of bulge sizeShaping toolsMaterials scienceAerospace

The invention discloses a process for forming special-shaped ring workpieces from aluminum alloy rectangular rolled ring workpieces by hot bulging, which includes: sleeving a heated aluminum alloy rectangular rolled ring workpiece onto the periphery of a preheated bulging block in a bulging machine, squeezing the rolled ring part by the bulging block radially from the inner circumference surface of the rolled ring part after starting the bulging machine, completing the primary bulging after the rolled ring part is deformed by 10%-18% to form a special-shaped ring blank, completing the primary rotation by rotating the special-shaped ring blank around the center axis by 45 degrees; completing the secondary bulging by repeating the above steps to deform the specials-shaped ring blank by 1.3%-2% and completing the secondary rotation; completing the tertiary bulging with deformation of 1.3%-2% and completing the tertiary rotation; completing the fourth bulging with deformation of 0.8%-1%; and finally obtaining the special-shaped ring workpiece. The dimension precision of the special-shaped ring workpiece can be 1%.-2%. of the corresponding dimension, and is mainly used for making rotor parts such as cylindrical casings and the like in the aerospace field.

Owner:GUIZHOU ANDA AVIATION FORGING

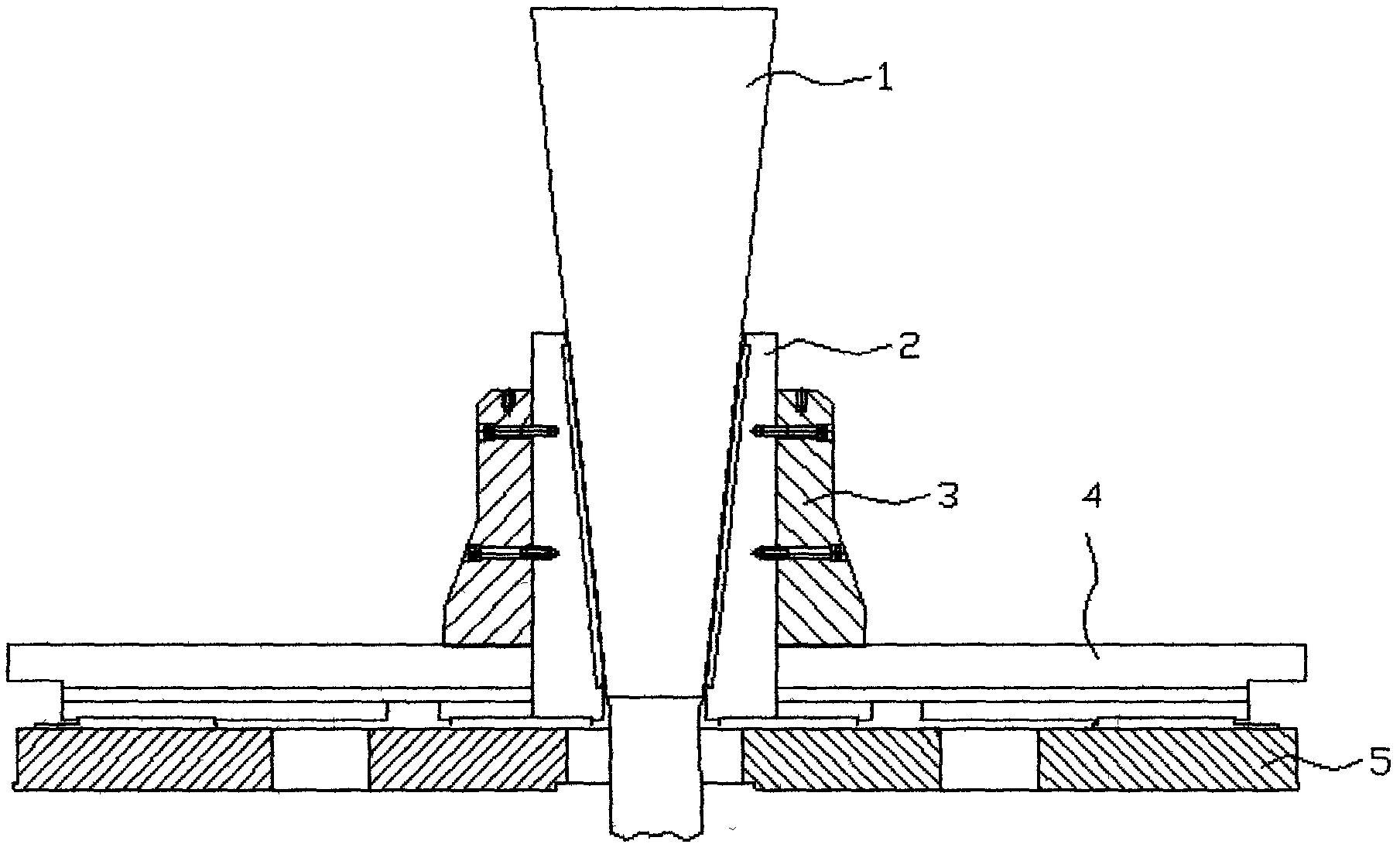

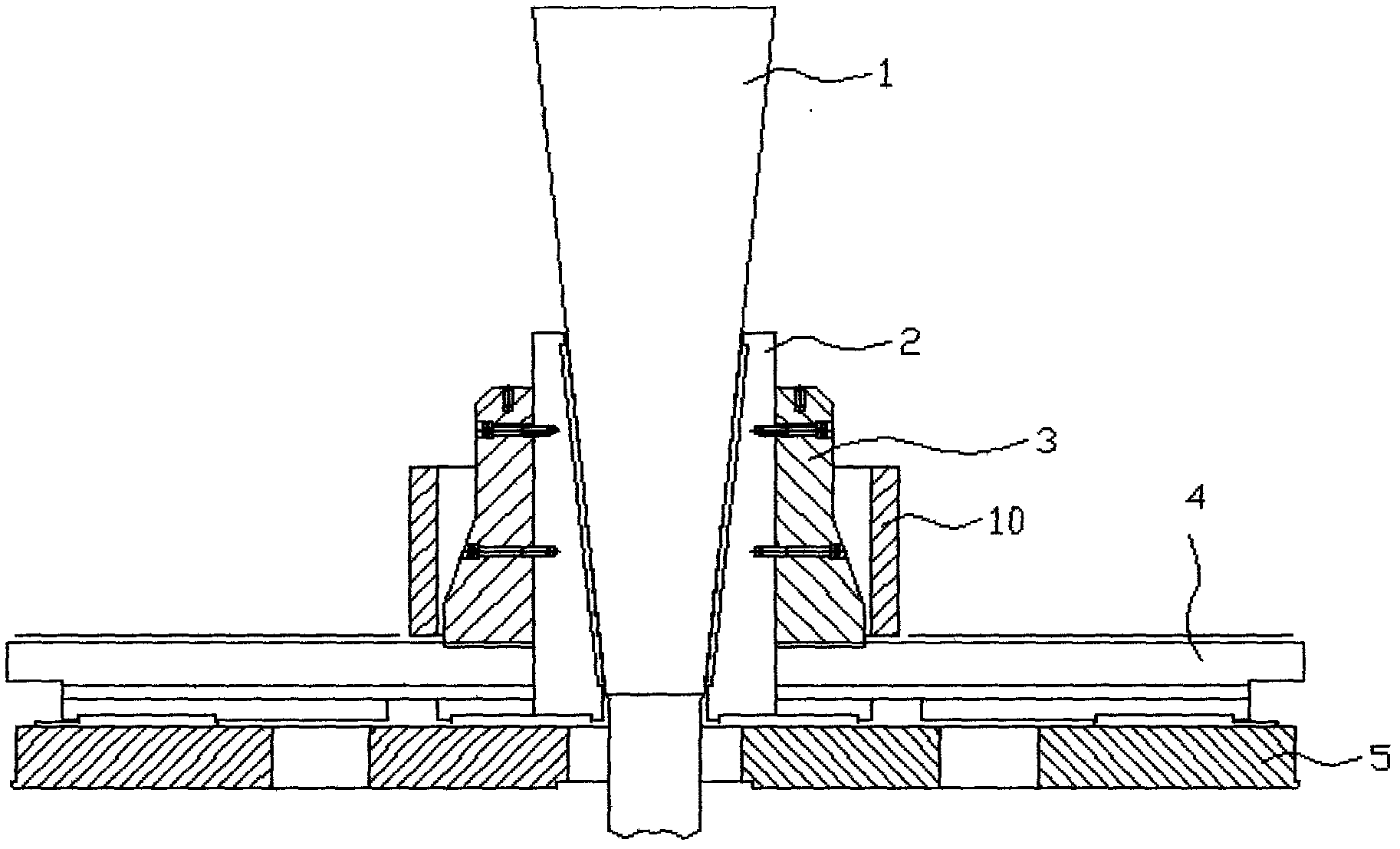

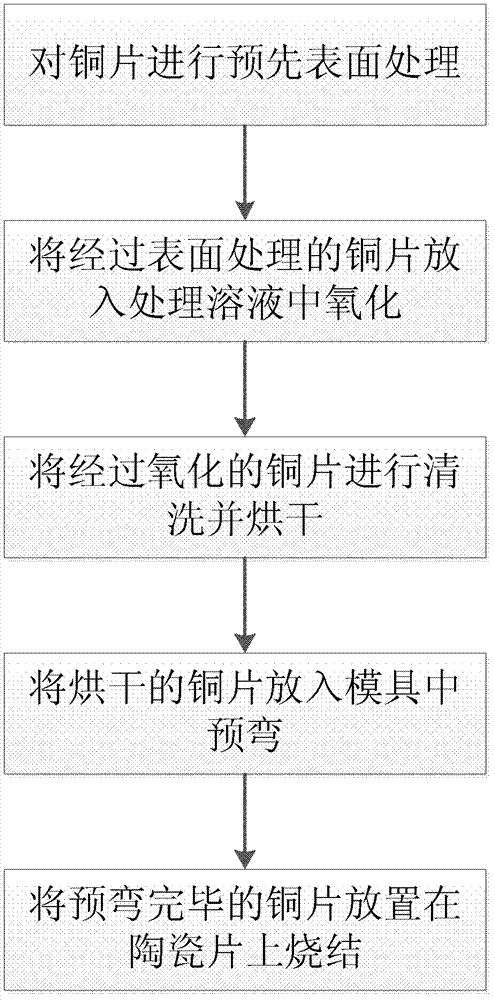

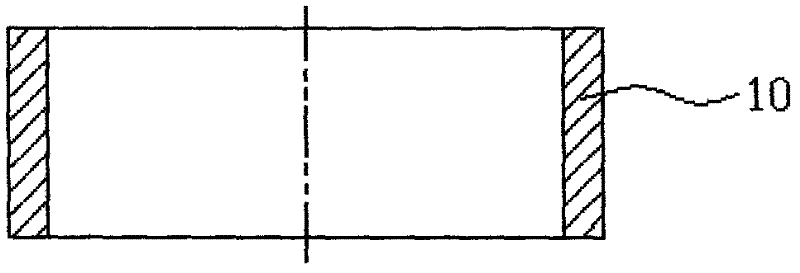

Method for directly cladding copper by sintering wet-method copper oxide piece

The invention discloses a method for directly cladding copper by sintering a wet-method copper oxide piece. The method comprises the following steps of: step one, carrying out surface pretreatment on the copper piece; step two, putting the copper piece subjected to surface treatment into a treatment solution to oxidize; step three, washing and drying the oxidized copper piece; step four, putting the dried copper piece into a mold to pre-bend; and step five, putting the pre-bent copper piece on a ceramic piece to sinter. Compared with the high-temperature annealing and oxidation, the wet-method oxidation is beneficial for shorting the procedure time, saves the energy, lowers the cost and needs no equipment such as an annealing furnace. Compared with high-temperature annealing and oxidation, the copper surface of a DBC (Database Computer) produced by wet-method oxidation is fine in grain, the improvement of the mechanical properties of the copper piece is facilitated, and the trace of a conveyer belt is eliminated.

Owner:SHANGHAI SHENHE THERMO MAGNETICS ELECTRONICS CO LTD

Whitening health tablets and preparation method thereof

InactiveCN105106795ARemove tracesEliminate tracesPill deliveryDermatological disorderSide effectAsiatic pennywort

The invention discloses whitening health tablets and a preparation method thereof. The whitening health tablets comprise, by weight, 3 to 10 parts of giant Typhonium rhizome, 3 to 9 parts of Nardostachys rhizome, 10 to 20 parts of Rhodiola root, 10 to 20 parts of Japanese Ampelopsis root, 2 to 10 parts of divaricate Saposhnikovia root, 3 to 9 parts of common Bletilla tuber, 2 to 10 parts of Kaempferia rhizome, 3 to 12 parts of paper mulberry fruit, 5 to 10 parts of Cimicifuga rhizome, 3 to 9 parts of common selfheal fruit-spike, 4 to 8 parts of Asiatic pennywort herb, 5 to 10 parts of Cinnamomum camphora leaf, 2 to 8 parts of dwarf Lilyturf tuber, 5 to 10 parts of wild ginger, 10 to 15 parts of xylitol, 5 to 15 parts of starch, and 70 to 90 parts of water. The whitening health tablets are made with multiple herbs and is capable of promoting blood circulation in skin tissues, nourishing skin and delaying skin ageing, is effective in moisturizing, whitening, nourishing and skin rejuvenating, and is natural, green and free of any toxic or side effect owing to containing no chemical additives such as antibacterial agent and preservative.

Owner:俸莲英

Whitening health beverage and preparation method thereof

InactiveCN105077480AReasonable compositionPromote blood circulationFood ingredient functionsFood preparationRHODIOLA ROSEA ROOTSide effect

The invention discloses a whitening health beverage and a preparation method thereof. The whitening health beverage is prepared from the following raw materials in parts by weight: 3-10 parts of rhizoma typhonii, 3-9 parts of rhizoma nardostachyos, 10-20 parts of rhodiola rosea, 10-20 parts of radix ampelopsis, 2-10 parts of radix saposhnikoviae, 3-9 parts of bletilla striata, 2-10 parts of rhizoma kaempferiae, 3-12 parts of fructu broussonetiae, 5-10 parts of rattletop, 3-9 parts of selfheal, 4-8 parts of centella, 5-10 parts of yellow cinnamon leaf, 2-8 parts of radix ophiopogonis, 5-10 parts of asarum, and 2400-6400 parts of water. According to the invention, rhizoma typhonii, rhizoma nardostachyos, rhodiola rosea, radix ampelopsis, radix saposhnikoviae, bletilla striata, rhizoma kaempferiae, fructu broussonetiae, rattletop, selfheal, centella, yellow cinnamon leaf, radix ophiopogonis and asarum are taken as the raw materials, so that the whitening health beverage can promote blood circulation of the skin tissue, nourish the skin, and delay the skin ageing, has the efficacies of preserving moisture, whitening, nourishing and tendering skin, does not contain the chemical addition agents such as antibacterial agents and preservatives, and is natural and environmentally friendly without any toxic or side effect.

Owner:俸莲英

Hot bulge forming method for aluminum-alloy flash buttwelding ring components

ActiveCN102489593AHigh dimensional accuracyReduced dimensional accuracyMarine navigationMaterials science

The invention discloses a hot bulge forming method for aluminum-alloy flash buttwelding ring components, which comprises the following steps of: after heating an aluminum-alloy flash buttwelding ring component subjected to annealing treatment, sleeving the aluminum-alloy flash buttwelding ring component on the periphery of a bulge forming block (subjected to preheating) in a bulge forming machine, and starting the bulge forming machine, so that the bulge forming block extrudes the ring component along the radial direction from the interior circumferential surface of the ring component so as to complete the first bulge forming, wherein the bulge forming temperature is 420-470 DEG C, the bulge forming time is 12-15s, the dwell time is 7-8s, and the deflection is 0.08-0.09%; rotating the ring component at an angle of 45 degrees along a central axis so as to complete the first rotation; then, performing the second bulge forming according to the operations above, wherein the bulge forming temperature is 390-440 DEG C, the bulge forming time is 20-35s, the dwell time is 15-16s, and the deflection is 0.7-0.8%; rotating the ring component again along the direction of the first rotation so as to complete the second rotation; and performing the third bulge forming according to the operations above, wherein the bulge forming temperature is 360-410 DEG C, the bulge forming time is 20-25s, the dwell time is 20-22s, and the deflection is 0.9-1%. The size precision of a ring component subjected to bulge forming can reach 0.1-0.2% of a corresponding size, and the method is mainly used in the field of space navigation.

Owner:GUIZHOU ANDA AVIATION FORGING

Dye composition, dyeing apparatus and dyeing method

InactiveUS6582479B1No crocking problemsEliminate tracesSucessive textile treatmentsSolvent treatment with solvent recoveryYarnPolyester

Owner:TATE JOHN E

Pockmark removal mask

InactiveCN105687065ARemove tracesEliminate tracesCosmetic preparationsToilet preparationsWrinkle skinSmilax scobinicaulis

A facial mask for removing acne scars consists of: 20-30 parts of Angelica dahurica, 40-50 parts of Bletilla striata, 40-50 parts of Bai Poria, 40-50 parts of Radix Sinensis, 35-45 parts of white silkworm, 40-50 parts of Atractylodes macrocephala, 40-50 parts of cloves, 20-30 parts of mung beans, 10-15 parts of chrysanthemums, 15-20 parts of pearl powder, 40-50 parts of coix seed. The advantages are: heat-clearing and damp-drying, sterilizing, lightening and whitening, moisturizing and wrinkle-removing, softening the skin, and eliminating the marks left by acne on the face.

Owner:WUHAN HONGXINGJIANG TECH CO LTD

Hot bulging method for forming rectangular titanium alloy rolled ring into special-shaped ring

ActiveCN102489596BHigh dimensional accuracyPrecise control of bulge sizeTitanium alloyMaterials science

The invention discloses a hot bulging method for forming a rectangular titanium alloy rolled ring into a special-shaped ring; the hot bulging method comprises the following steps of: sleeving a heated rectangular titanium alloy rolled ring at the periphery of a preheated bulging block of a bulging machine, starting the bulging machine so that the bulging block extrudes the rolled ring along the radial direction on the surface of the inner circumference of the rolled ring till the deformation amount of the rolled ring is 10%-12%, and the rolled ring is formed into a special-shaped ring blank, thereby completing primary bulging, and then leading the special-shaped ring blank to rotate by 45 degrees along a central axis to complete primary rotation; and afterwards, according to the operation, carrying out secondary bulging with 0.9%-1.5% of deformation amount and secondary rotation, third bulging with 0.9%-1.5% of deformation amount and third rotation, and fourth bulging with 0.5%-1% of deformation amount on the special-shaped ring blank, thereby obtaining the special-shaped ring. The dimensional accuracy of the special-shaped ring can reach 0.1%-0.2% of the corresponding dimension; and the special-shaped ring is mainly applied to the fields of aerospace and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

Thermal bulging process for flash-welded stainless steel ring workpieces

The invention discloses a thermal bulging process for flash-welded stainless steel ring workpieces, which includes steps of primary bulging; primary rotation; secondary rotation; secondary bulging and tertiary bulging. In the primary bulging, a flash-welded stainless steel ring workpiece which is annealed is sleeved on the periphery of a preheated bulging block in a bulging machine after being heated, and the bulging block squeezes the ring workpiece axially along the inner circumference of the ring workpiece after the bulging machine is started so that the primary bulging is completed, wherein the bulging temperature ranges from 950 DEG C to 1040 DEG C, the bulging time ranges from 22s to 28s, the pressure holding time ranges from 18s to 20s, and the bulging deflection ranges from 0.12% to 0.15%. The primary rotation is completed by rotating the ring workpiece along the center axis by 45 degrees. The secondary bulging is completed by processes of the primary bulging, wherein the bulging temperature ranges from 920 DEG C to 1010 DEG C, the bulging time ranges from 20s to 25s, the pressure holding time ranges from 16s to 18s, and the deflection ranges from 0.08% to 0.09%. The second rotation is completed by rotating the ring workpiece again along the direction the same with that of the primary rotation. The tertiary bulging is completed by the processes of the primary bulging again, wherein the bulging temperature ranges from 890 DEG C to 980 DEG C, the bulging time ranges from 25s to 30s, the pressure holding time ranges from 21s to 23s, and the deflection ranges from 0.09% to 1%. The dimensional precision of the ring workpiece can be 1%. to 2%. of the corresponding precision after the ring workpiece is bulged, and the ring workpiece is mainly used for the field of space navigation.

Owner:GUIZHOU ANDA AVIATION FORGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com