Nickelic ternary anode material power lithium ion battery electrolyte and preparation method thereof

A technology of lithium ion battery and positive electrode material, which is applied in the field of power lithium ion battery electrolyte and its preparation of high nickel ternary positive electrode material system, and can solve the problem of capacity attenuation, surface activity enhancement, and safety performance deterioration of power lithium ion battery, etc. problems, to achieve the effect of improving cycle stability, improving high temperature performance, and inhibiting battery flatulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

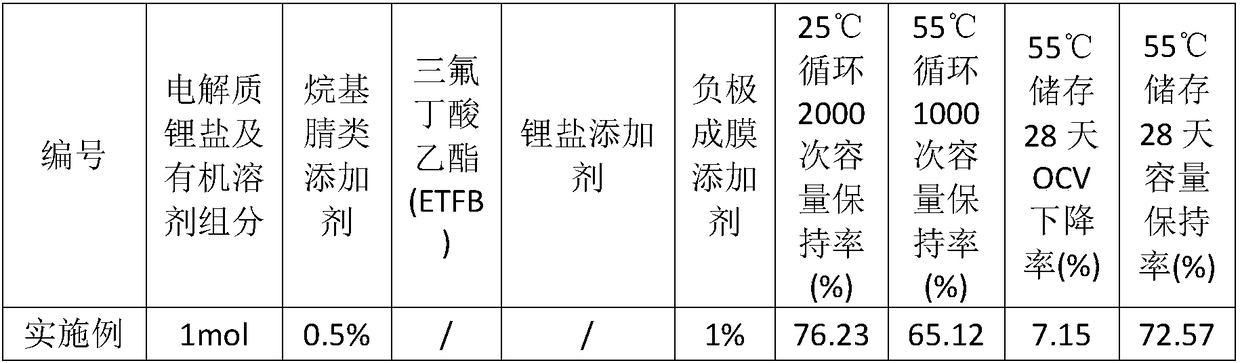

Examples

Embodiment 1

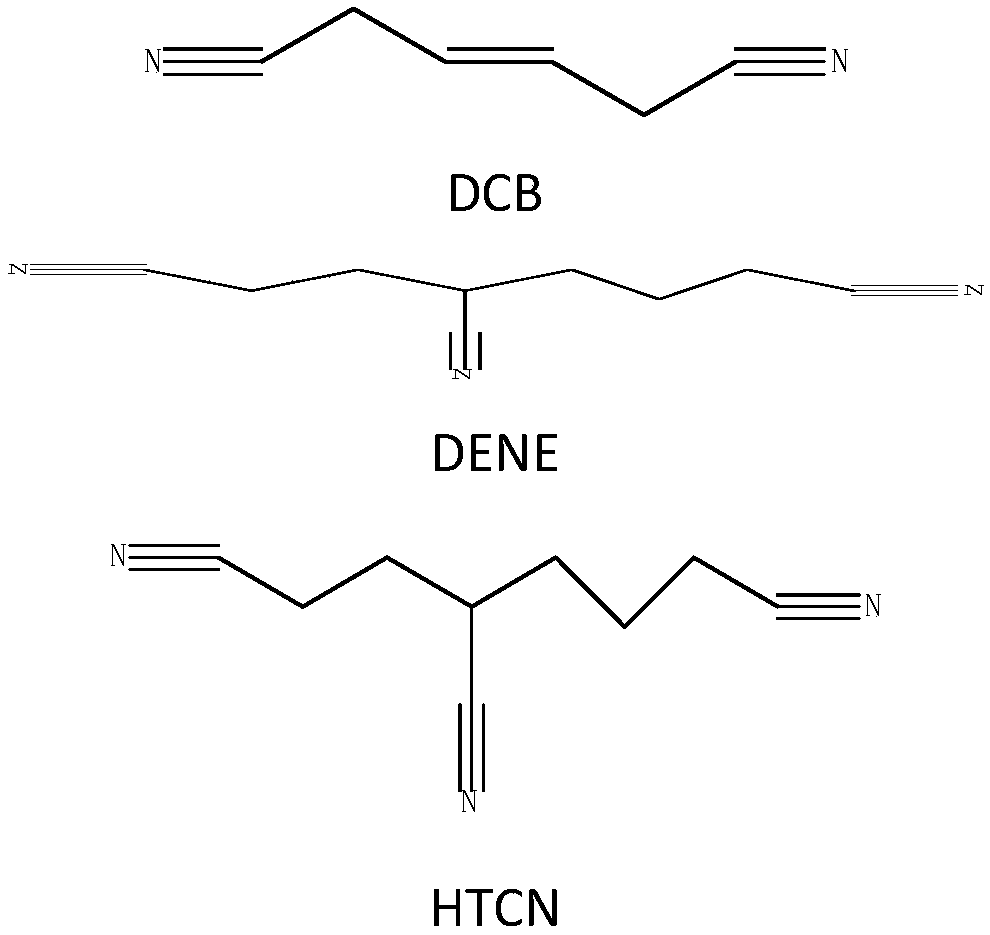

[0045] A high-nickel ternary positive electrode material power lithium-ion battery electrolyte, its functional additives include: ① alkyl nitrile additive: trans-3-hexenedicyanide (DCB), ② negative electrode film-forming additive: fluoroethylene carbonate ester (FEC).

[0046] The preparation method of the electrolyte: in the glove box (H 2 O2 6 ), make it reach the concentration of 1M, add functional additive 0.5% DCB, 1% FEC, after stirring and mixing, be packed in the fluorinated bottle, obtain the electrolytic solution of embodiment 1.

Embodiment 2

[0048] A high-nickel ternary positive electrode material power lithium-ion battery electrolyte, its functional additives include: ① alkyl nitrile additive: trans-3-hexenedicyanide (DCB), ② lithium salt additive: LiN(CF 3 SO 2 ) 2 (LiTFSI), ③ negative electrode film-forming additive: fluoroethylene carbonate (FEC).

[0049] The preparation method of the electrolyte: in the glove box (H 2 O2 6 ), make it reach the concentration of 1M, add functional additives 0.5% DCB, 1% LiTFSI, 1% FEC, stir and mix and put in the fluorinated bottle, obtain the electrolyte of embodiment 2.

Embodiment 3

[0051] A high-nickel ternary positive electrode material power lithium-ion battery electrolyte, its functional additives include: ① alkyl nitrile additive: trans-3-hexenedicyanide (DCB), ② lithium salt additive: LiN(CF 3 SO 2 ) 2 (LiTFSI), ③ negative electrode film-forming additive: fluoroethylene carbonate (FEC).

[0052] The preparation method of the electrolyte: in the glove box (H 2 O2 6 ), make it reach the concentration of 1M, add functional additives 1% DCB, 1% LiTFSI, 1% FEC, stir and mix and put in the fluorinated bottle, obtain the electrolyte of embodiment 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com