Method for directly cladding copper by sintering wet-method copper oxide piece

A technology of copper oxide sheet and wet method, which is applied in the field of semiconductor manufacturing, can solve the problems of copper mechanical properties and surface treatment adverse effects, uneven temperature distribution of copper sheet, large change in peel strength, etc., to shorten the process time and achieve fine grain size , Improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

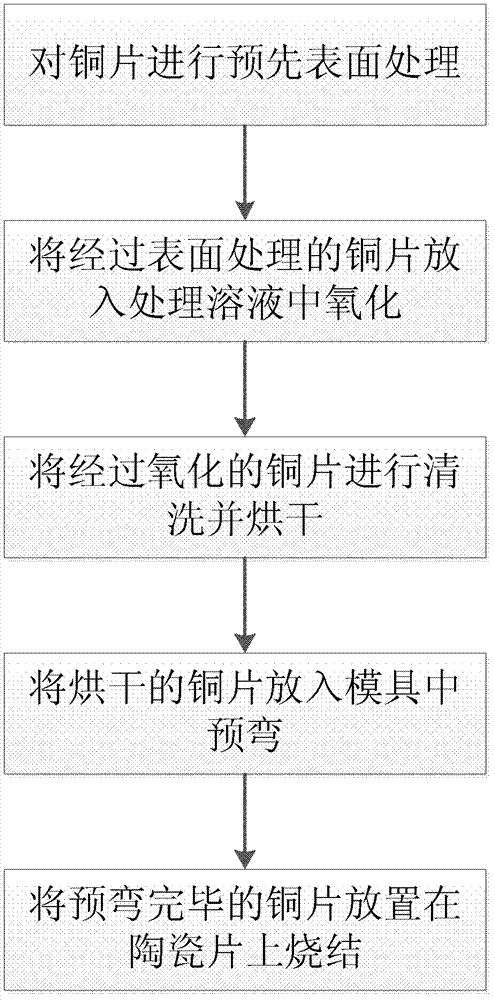

[0016] The method for sintering and direct copper coating of wet-process copper oxide sheets of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0017] Such as figure 1 As shown, the method for direct copper-clad sintering of wet-process copper oxide sheet of the present invention comprises the following steps:

[0018] (1) Cut the copper strip into copper sheets.

[0019] (2) After brushing, micro-etching, air-drying and other processes to remove oxides and roughen the surface of the copper sheet.

[0020] (3) NaOH and K 2 S 2 o 8 According to K 2 S 2 o 8 27g / L~31g / L, NaOH 3g / L~5g / L or K 2 S 2 o 8 83g / L~90g / L, NaOH 22g / L~31g / L, prepare the treatment solution in a glass or plastic container, and preheat to 35℃~45℃ or 30℃~45℃, and then copper The sheet is immersed in the treatment solution for oxidation, and the oxidation time is 2 min to 10 min or 2 min to 5 min.

[0021] (4) After the oxidation is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com