Digitalized thinning machining method for large thin-walled cylinder part

A thin-walled tube and large-scale technology, which is applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve problems such as digital thinning processing methods for large-scale thin-walled tubes, so as to ensure process reliability , reduce manual intervention, control reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

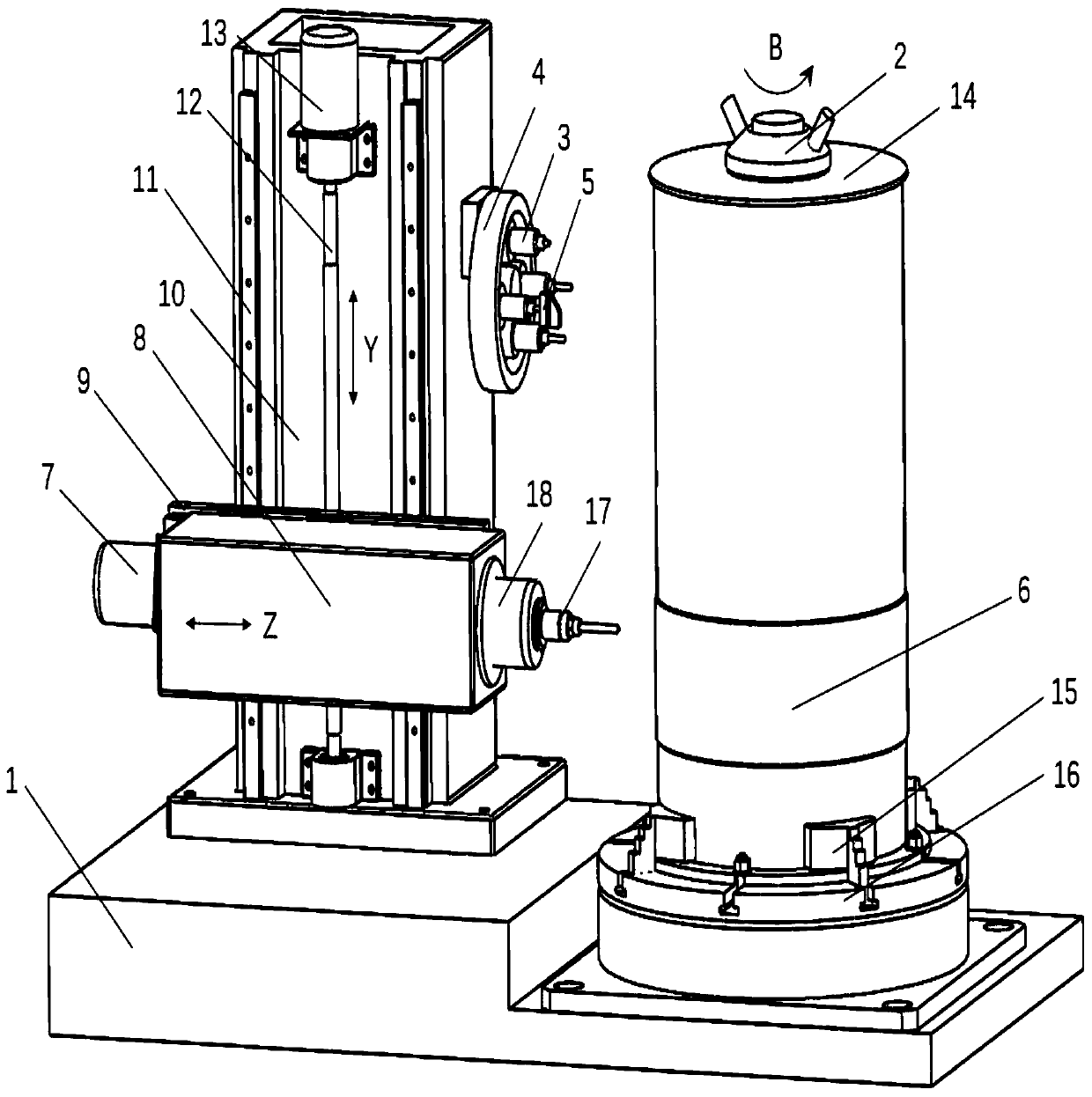

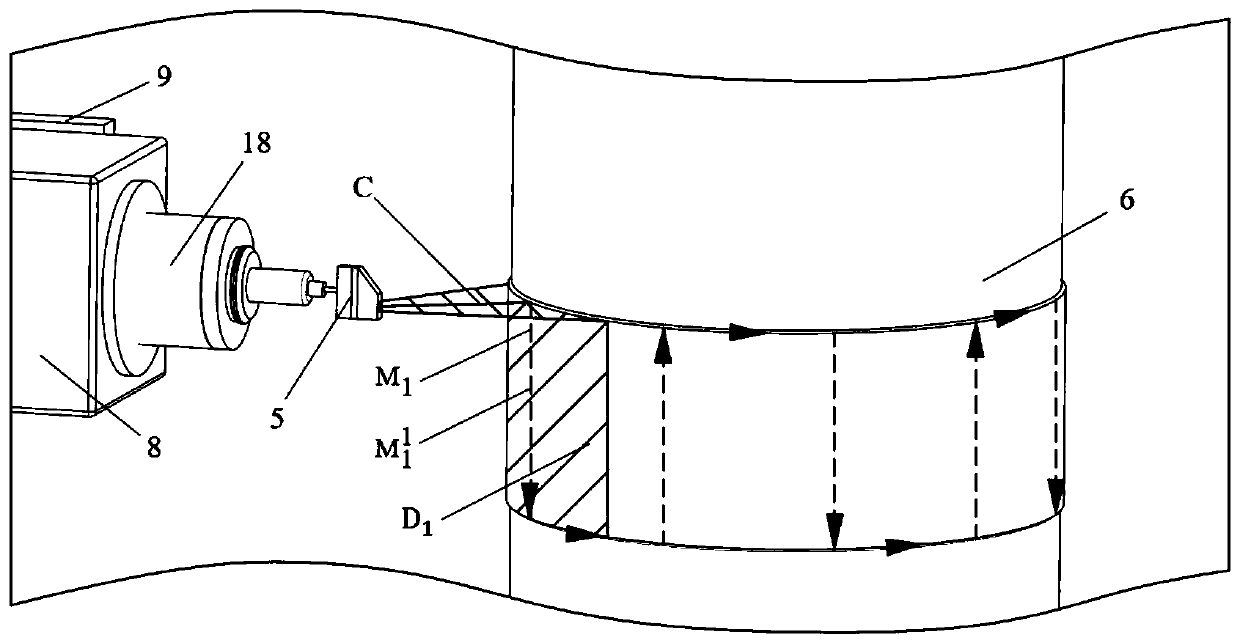

[0045] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions.

[0046] The thin-walled tube 6 to be processed has a diameter of 750-1000 mm, a thinning width of 300-400 mm, a blank wall thickness of 8-12 mm, and a remaining wall thickness of 3-6 mm; the X-axis range of the line laser scanning measuring device is 120 mm; the diameter of the milling cutter is 12 mm.

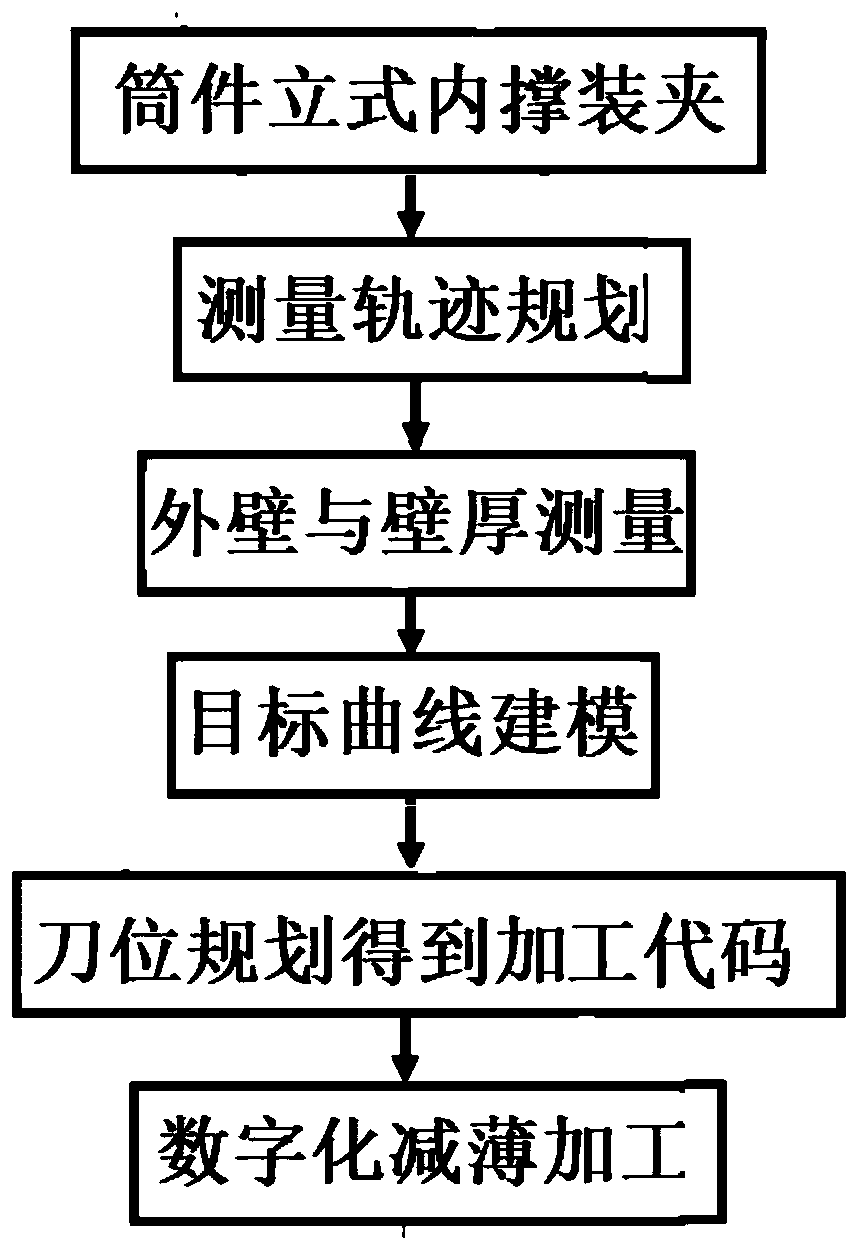

[0047] Processing method flow chart as figure 2 As shown, the specific steps of the method are as follows:

[0048] 1. Vertical inner support clamping of thin-walled tube parts

[0049] The line laser scanning measuring device 5 and the ultrasonic measuring device 3 are pre-installed in the bracket 4 to prevent collisions during clamping. Set the thin-walled tube 6 onto the special inner support fixture, complete the vertical clamping in place, control the special inner support fixture, and automatically complete the inner sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com