Full-automatic plastic bag film multilayer folding machine and method

A fully automated, plastic bag technology, applied to bag making operations, paper/cardboard containers, containers, etc., can solve the problems of inconvenient opening of garbage bags and inconvenient use by users, and achieve high automation and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

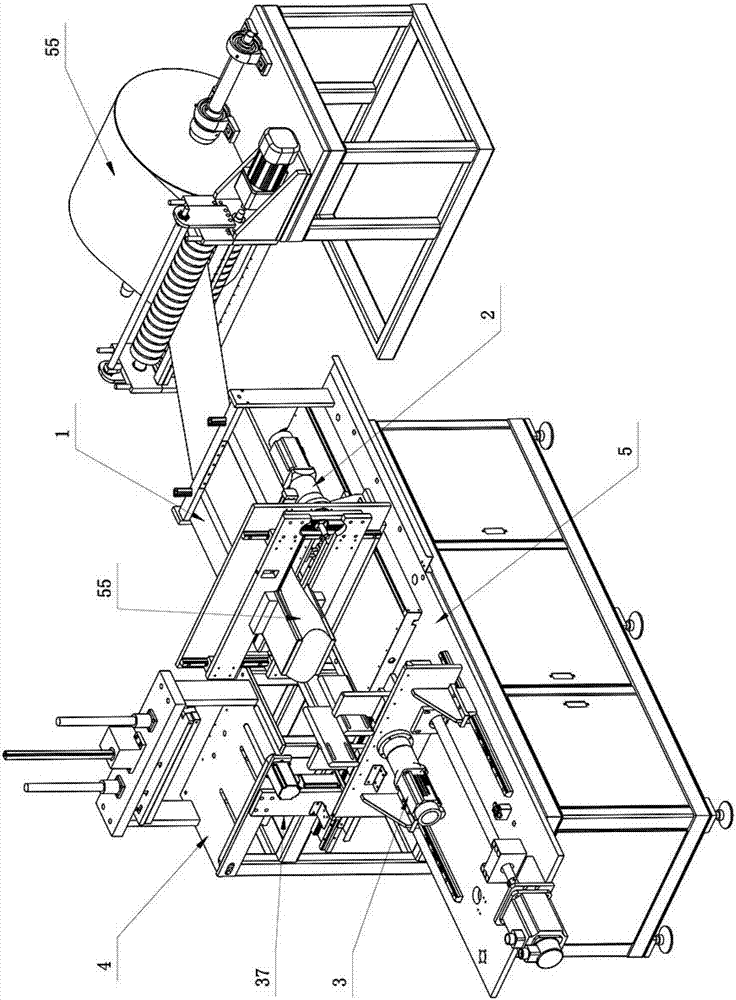

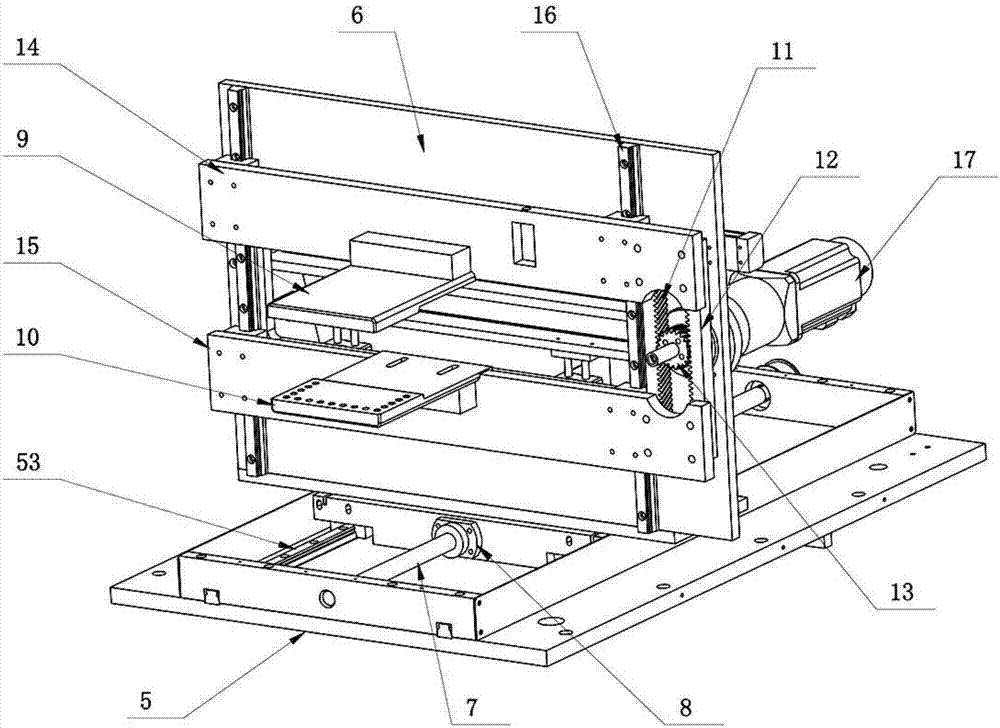

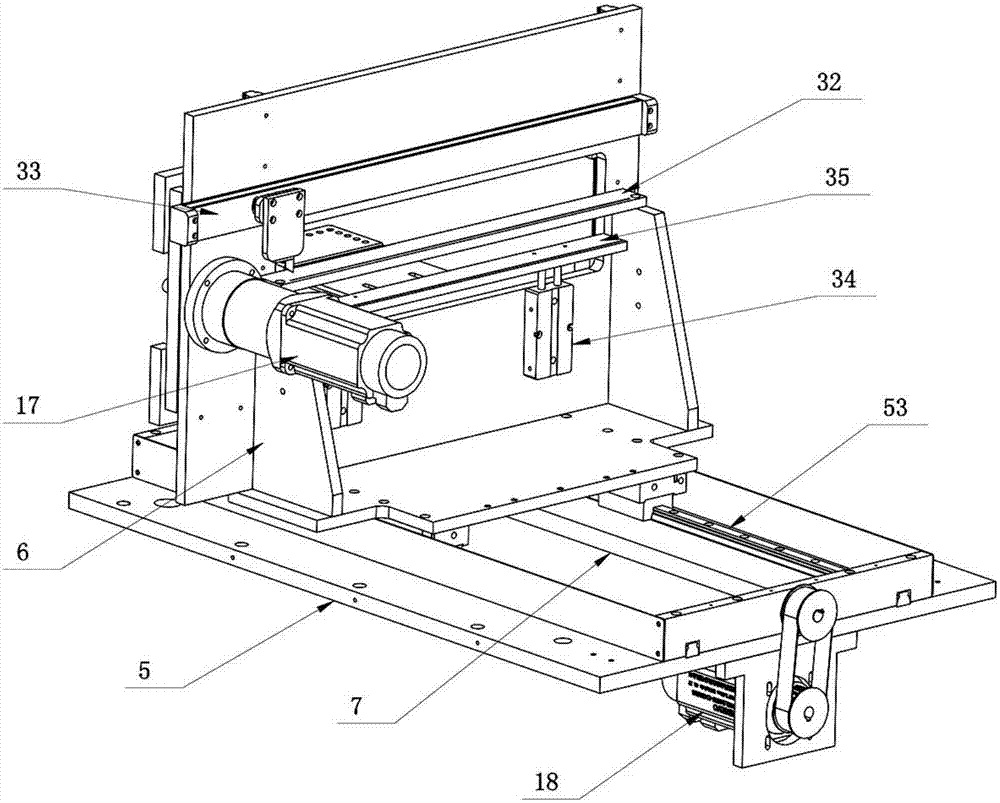

[0033] refer to Figure 1 to Figure 8 , the present invention provides a fully automatic plastic bag film multilayer folding machine, comprising: a feeding plate 1 for placing plastic bag films, a first folding device 2, a second folding device 3, a blanking device 4 and a workbench 5, The feeding plate 1, the first folding device 2 and the second folding device 3 are installed on the workbench 5 respectively; Repeated folding, the blanking device 4 is used to carry out the exhaust extrusion process on the folded film 55; the first folding device 2 includes the first bracket seat 6, the first screw mandrel 7, the first screw mandrel seat 8, the upper splint 9. The lower splint 10, the first rack 11, the second rack 12 and the first gear 13, the first bracket seat 6 is connected with the first screw rod 7 through the first screw seat 8; the upper splint 9 is connected through the first The slide plate 14 is connected with the second rack 12, the lower splint 10 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com