Automatic assembly device for rotating shaft and spiral fan blade wheels of electronic control motor

An automatic assembly and screw fan technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems that are not suitable for assembly line operation, not suitable for mass production, not automatic production, etc., to achieve compact structure, improve rigidity, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

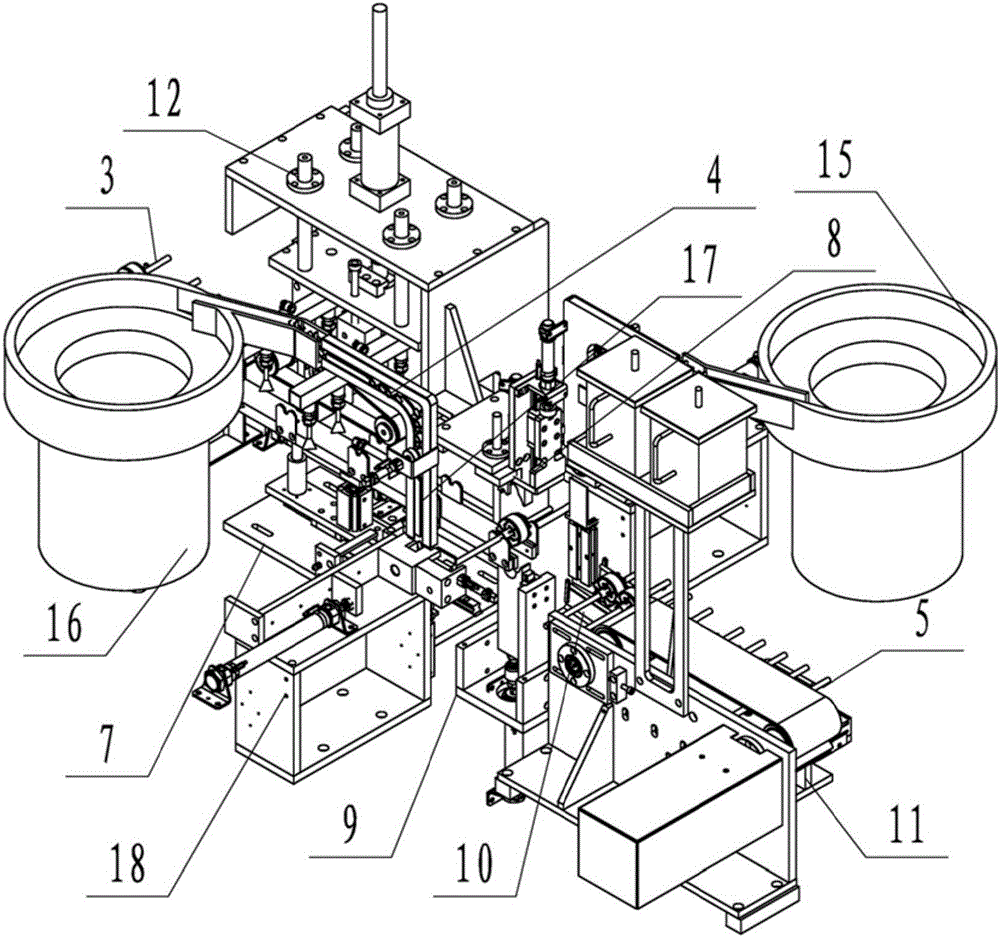

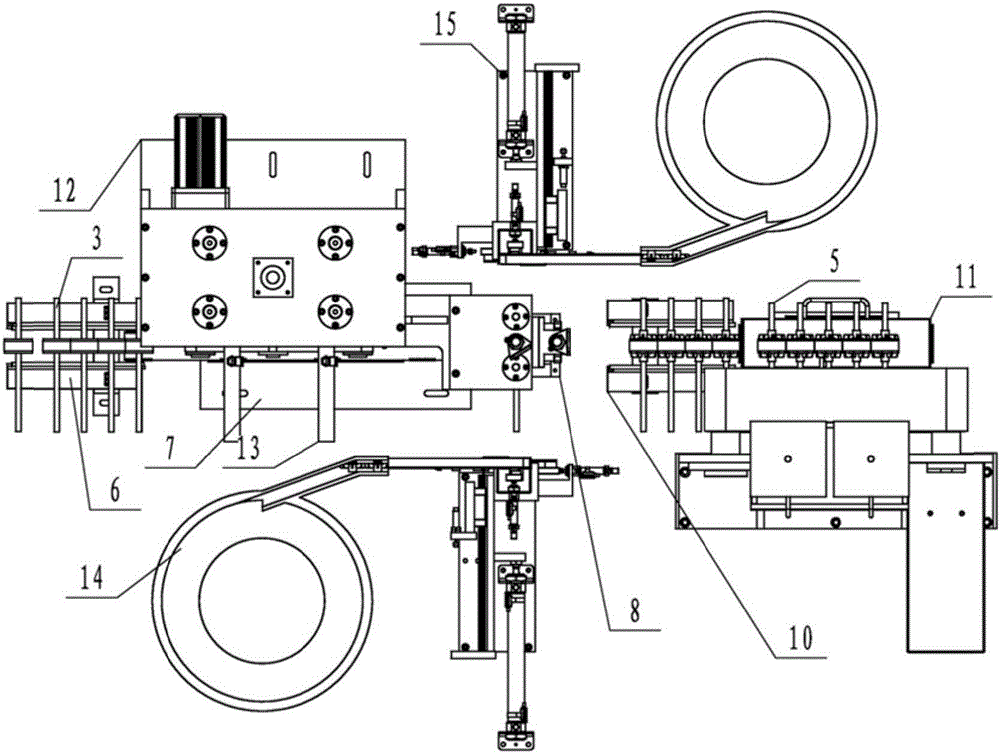

[0046] Such as Figure 1-15 As shown, the automatic assembly device for the rotating shaft of the electronically controlled motor and the spiral fan wheel of this embodiment includes a machine base 1, a working system arranged on the machine base 1, and a shield 2 covering the working system;

[0047] The working system includes the feeding frame group 6 for placing the central spindle 3 to be assembled, the feeding device 7 connected with the feeding device group 6 process, the transition frame group 10 connected with the feeding device 7 process, and the transition frame group 10 process The connected pickling device 11, the rotary drive device 12 arranged on one side of the feeding device 7, the spray frame 13 with the nozzles above the two ends of the central spindle 3 placed on the feeding device 7, and two sets respectively On both sides of the feeding device 7, the first vibrating feeding device 14 and the second vibrating feeding device 15 of the spiral fan wheel 4 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com