Uncoiling blanking production equipment and processing method by adoption of laser cutting technology

A laser cutting, uncoiling and blanking technology, applied in laser welding equipment, other manufacturing equipment/tools, welding equipment, etc., to achieve the effects of rapid product specification conversion, improved material utilization, and reduced equipment costs and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

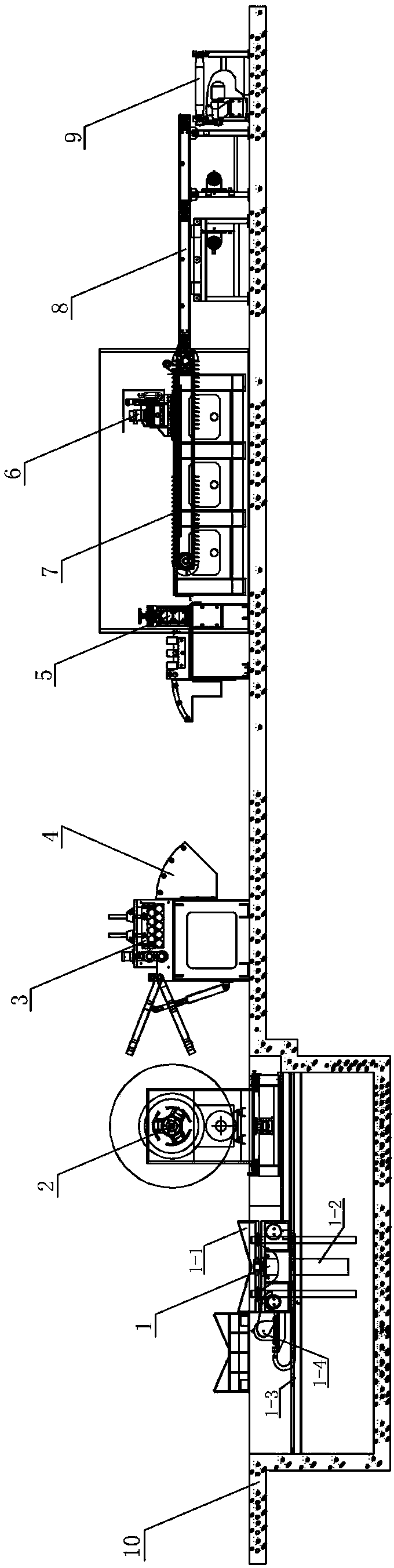

[0030] Such as figure 1 As shown, the structure diagram of the uncoiling blanking production equipment of the present invention is given, which includes a feeding device 1, an uncoiler 2, a leveling machine 3, a looper 4, a servo feeder 5, a laser cutting device 6, a laser cutting The platform 7 , palletizing system 8 , waste material processing system 9 , and each part of the shown uncoiling blanking production equipment are all fixed on the foundation 10 . The feeding device 1 is used to transport the coil material to the uncoiler 2, the uncoiler 2 unrolls the coil material, the leveler 3 levels the unrolled strip material, and the looper 4 is arranged behind the leveler 3, It is used to store the belt material to ensure the smooth operation of the equipment.

[0031] After the tape is leveled by the leveler 3, it enters the servo feeder 5, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com