Rotary tank container end frame welding assembly system

A tank container and assembly system technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of difficult to achieve welding quality, labor and time-consuming, difficult to improve work efficiency, etc., to achieve easy production , Reduce labor intensity and realize the effect of automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

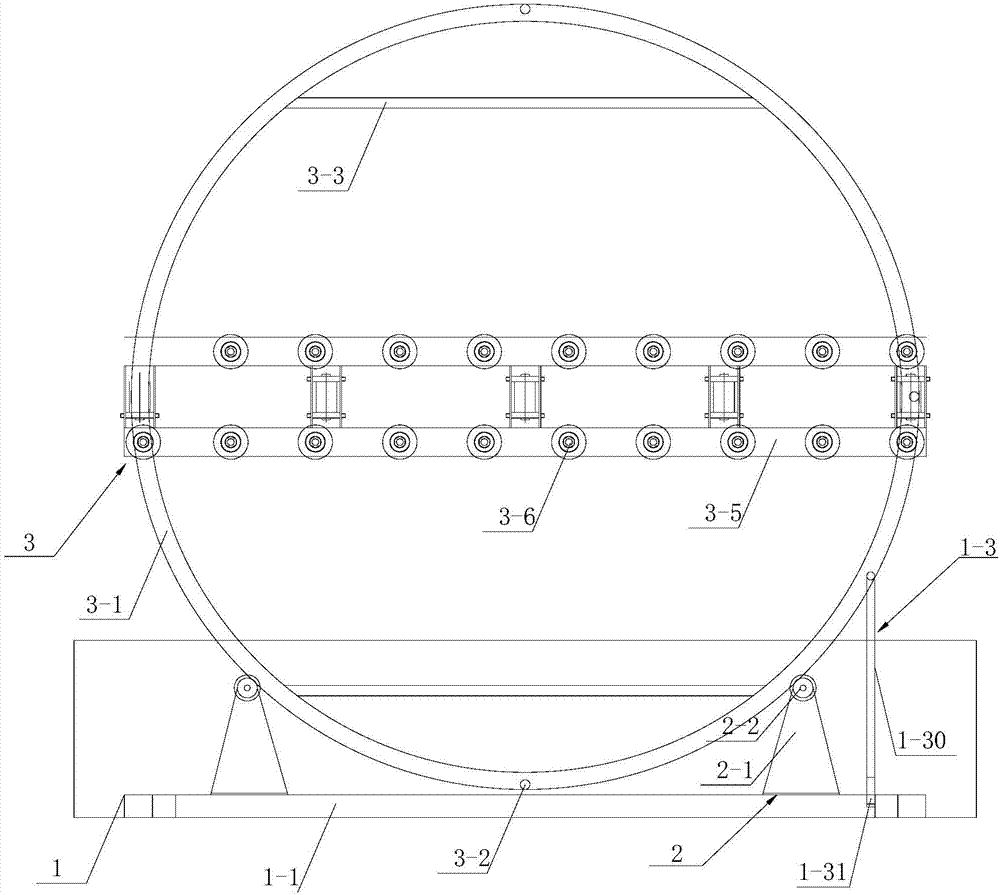

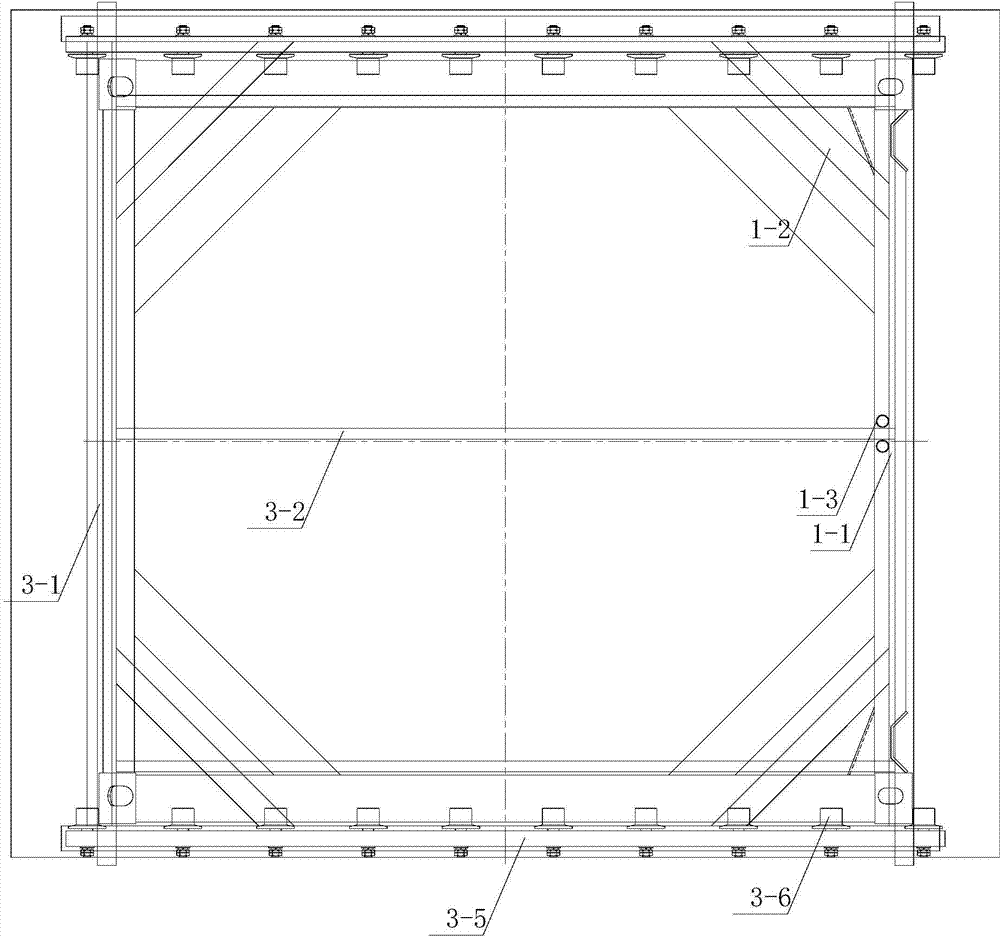

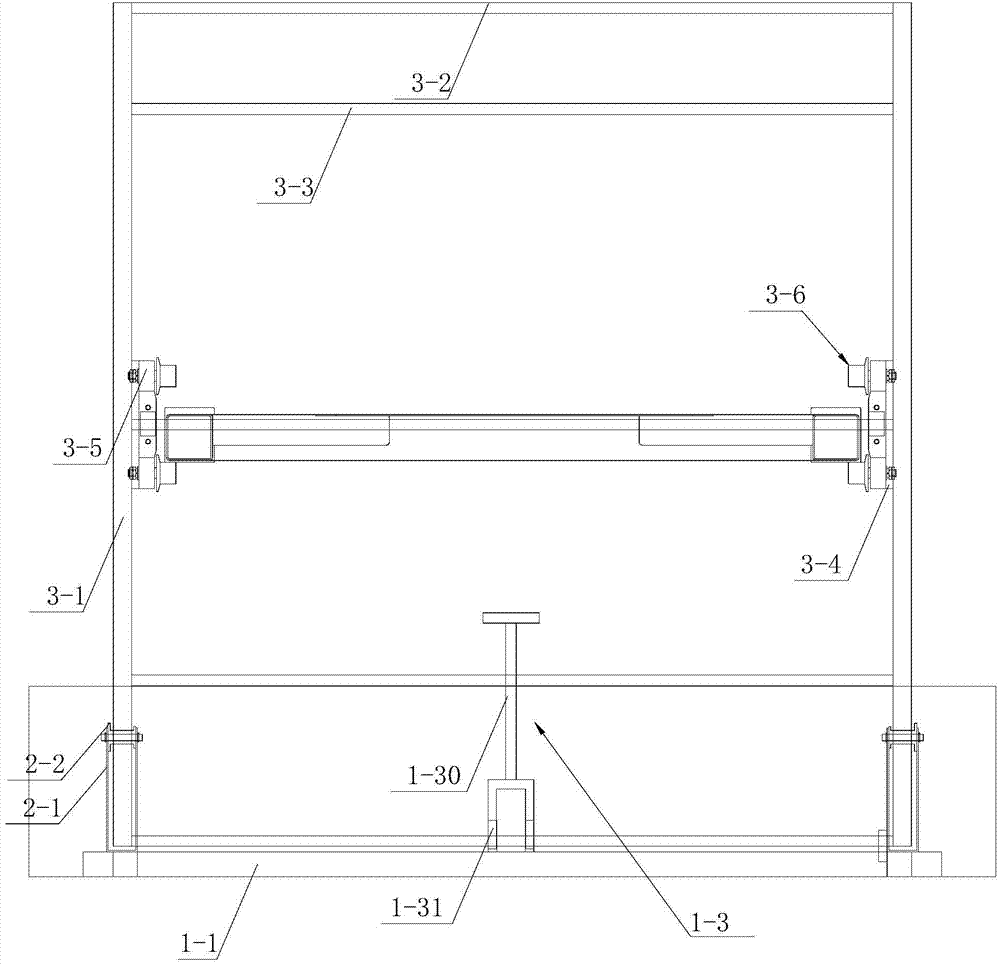

[0020] see Figure 1 to Figure 7 , a rotary tank container end frame welding assembly system, characterized in that: the system mainly includes a foundation beam 1, a support 2, a rotating assembly frame 3, and the foundation beam is welded in a square shape by four beams 1-1, Each crossbeam is connected and reinforced by diagonal braces 1-2, and a locking device 1-3 for fixing the rotating assembly frame is welded on one of the crossbeams. The locking device includes a locking bolt 1-30 and a locking cylinder 1-31, The lock pin is inserted into the lock cylinder.

[0021] The support 2 is distributed at the four corners of the above-mentioned foundation beam 1, and the support 2 is composed of a support 2-1 and a rotating shaft 2-2, wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com