Multi-probe automatic leak detection system and leak detection method

A multi-probe, leak detection technology, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problems of costing a lot of time and manpower, and reducing detection accuracy and accuracy , to achieve the effect of improving sensitivity, detection accuracy and detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

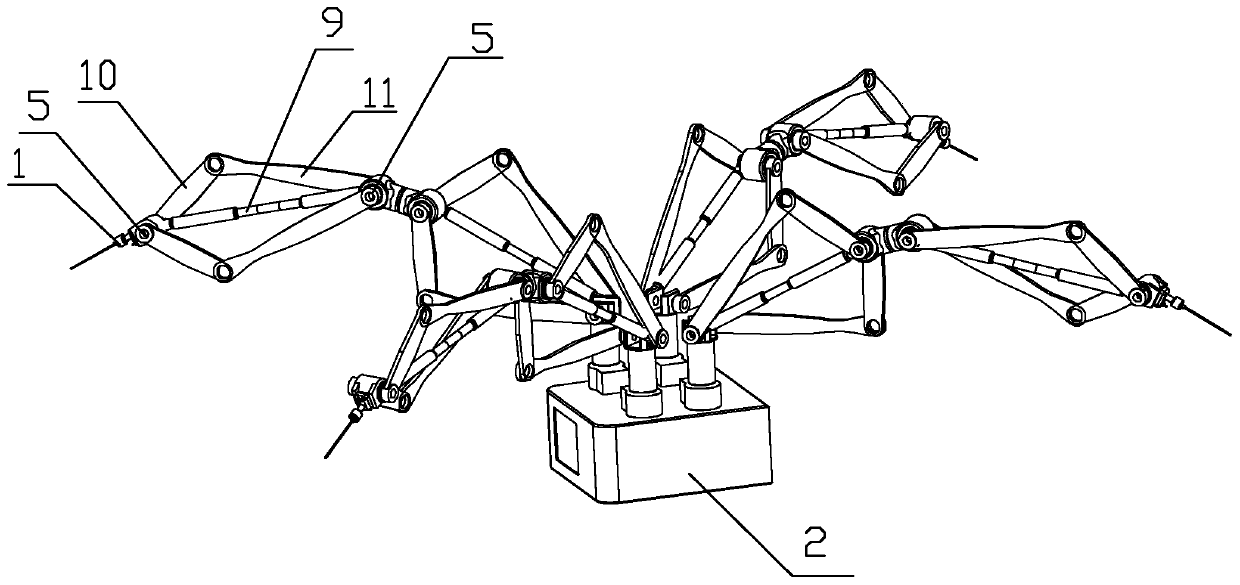

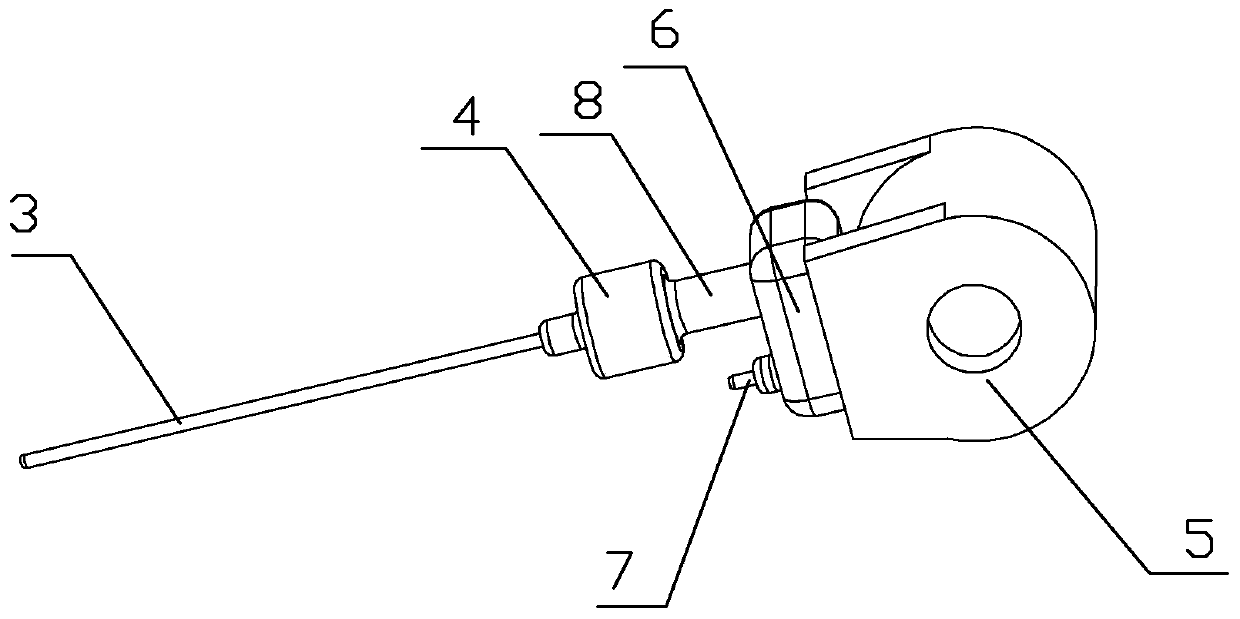

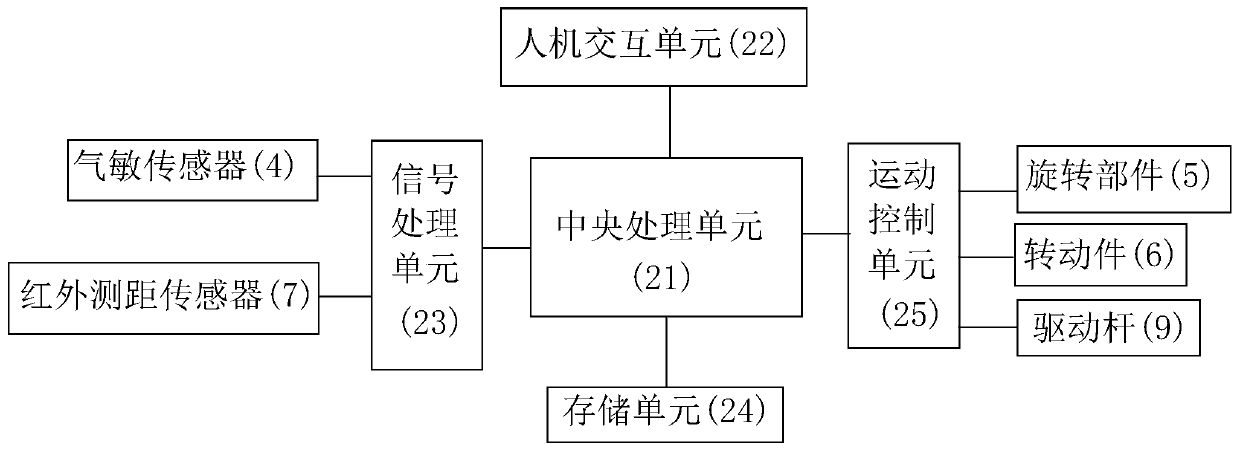

[0020] Embodiment: the multi-probe automatic leak detection system of the present embodiment, such as figure 1 As shown, it includes a leak detection device 1, a mechanical arm and a control platform 2. Four mechanical arms are connected to the control platform, and a leak detection device is installed at the end of the mechanical arm. The leak detection device includes a connected suction pipe 3 and a gas sensor 4, such as figure 2 As shown, the suction pipe is 5cm long, the front end of the suction pipe is the suction end, the rear end of the suction pipe is threaded to the gas sensor, and a dust filter is installed in the suction pipe, which is close to the rear end of the suction pipe to filter and detect dust in the environment. The gas sensor includes a shell and a sensitive layer installed in the shell. The sensitive layer is a palladium alloy layer, which can absorb hydrogen and has good selectivity and responsiveness to hydrogen. The thickness of the sensitive layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com