Patents

Literature

33results about How to "Prevent affecting the welding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

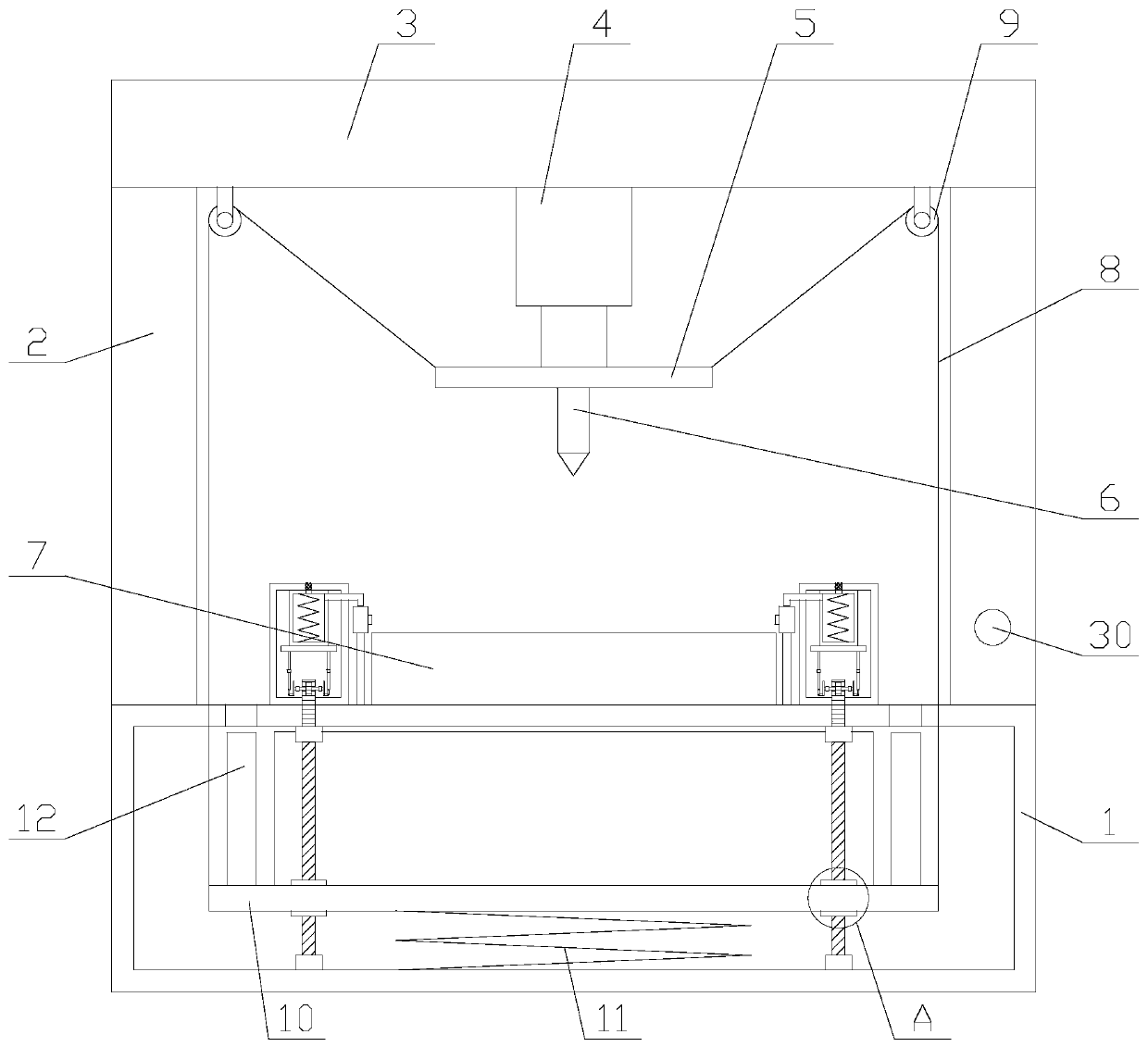

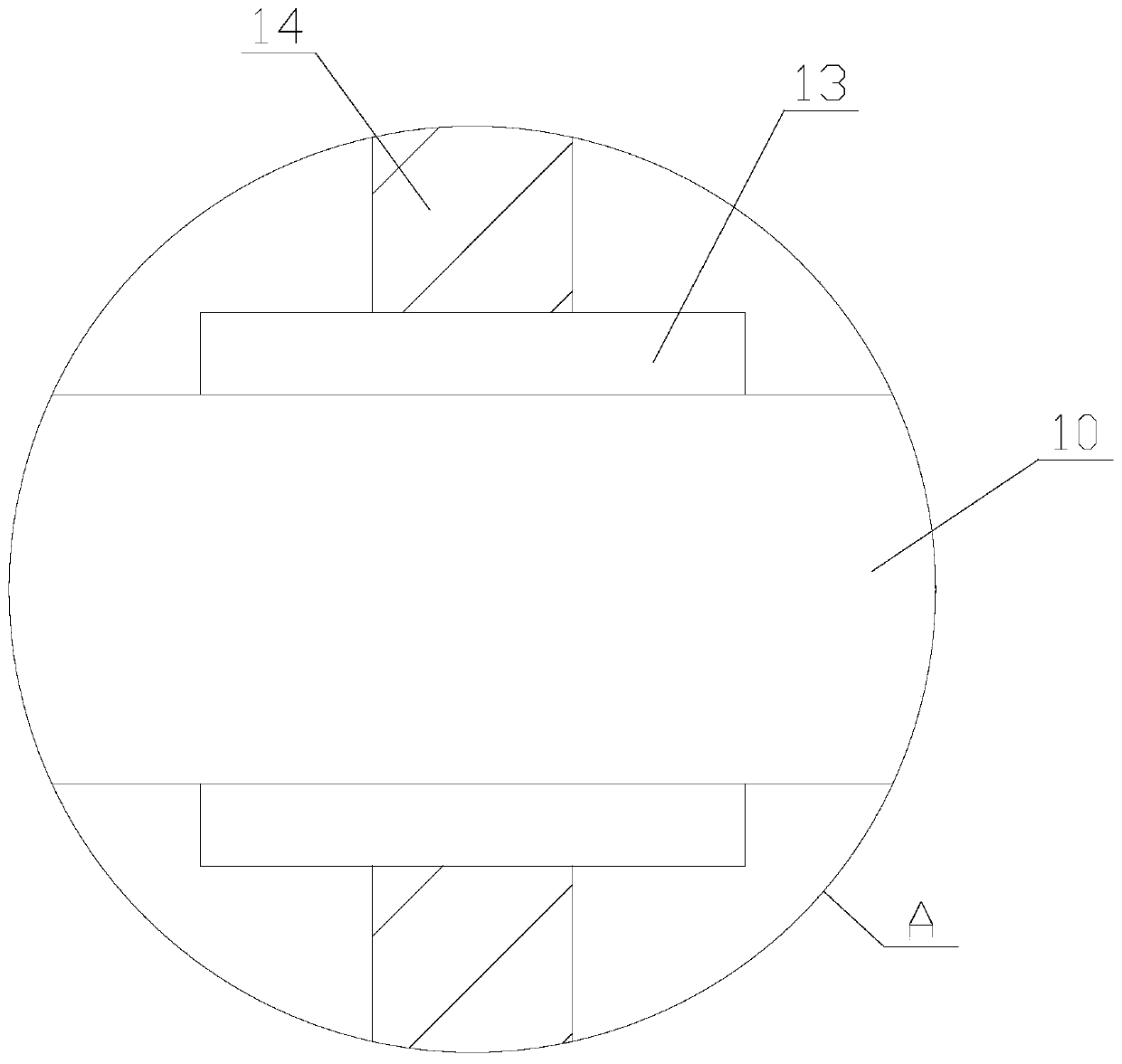

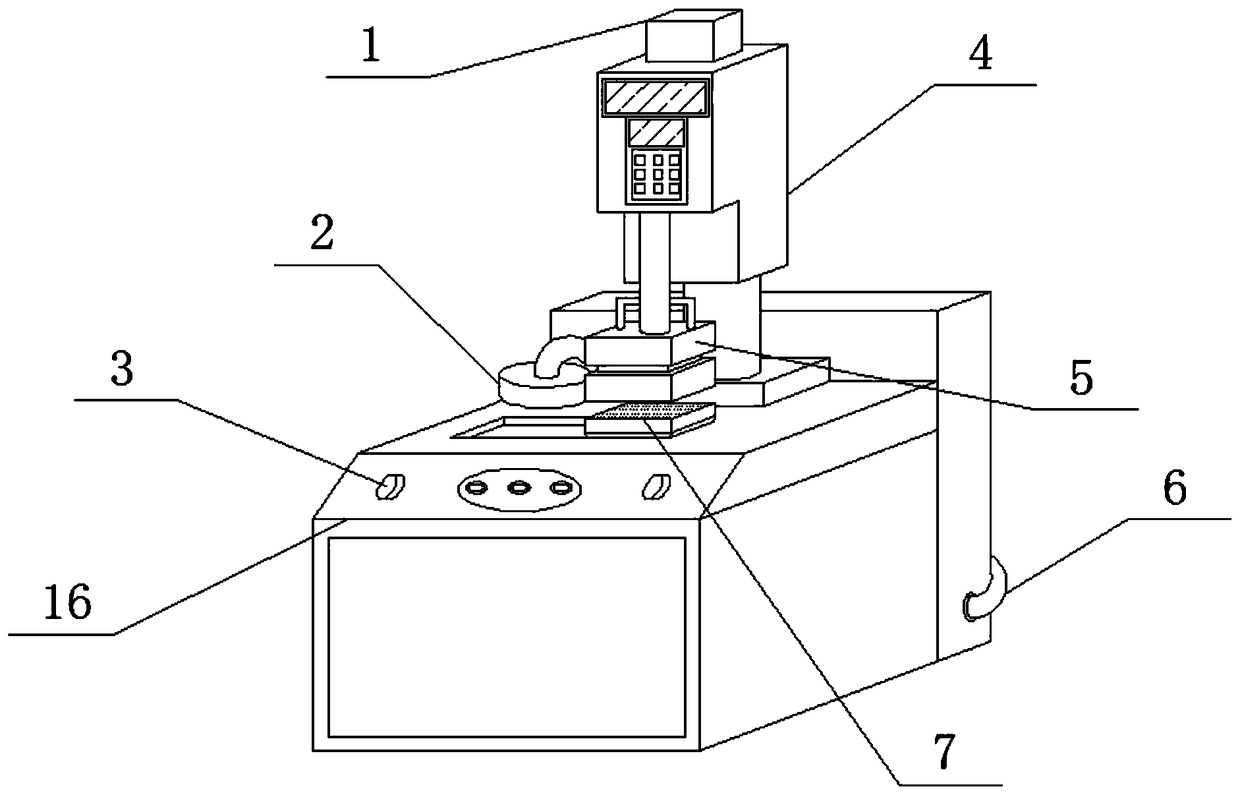

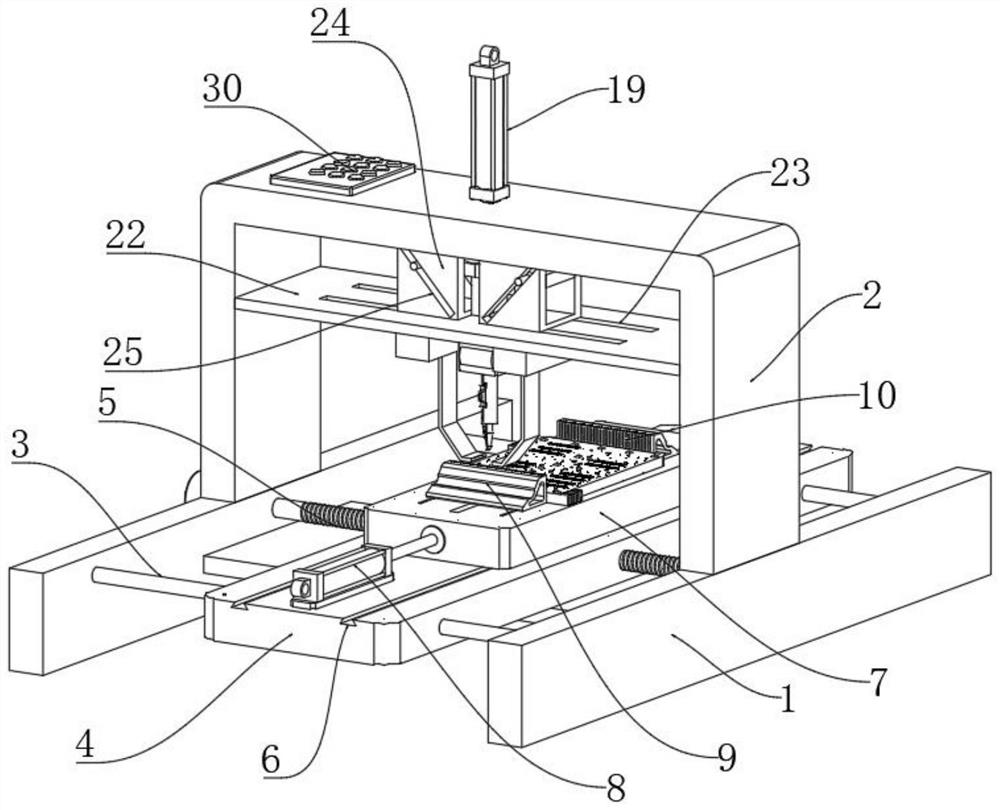

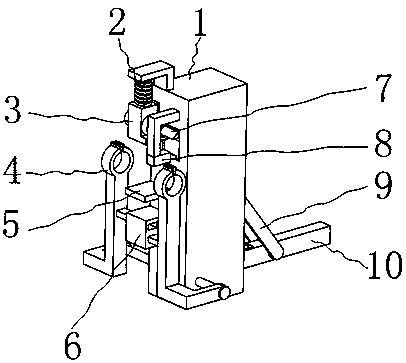

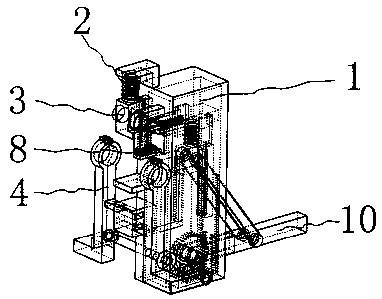

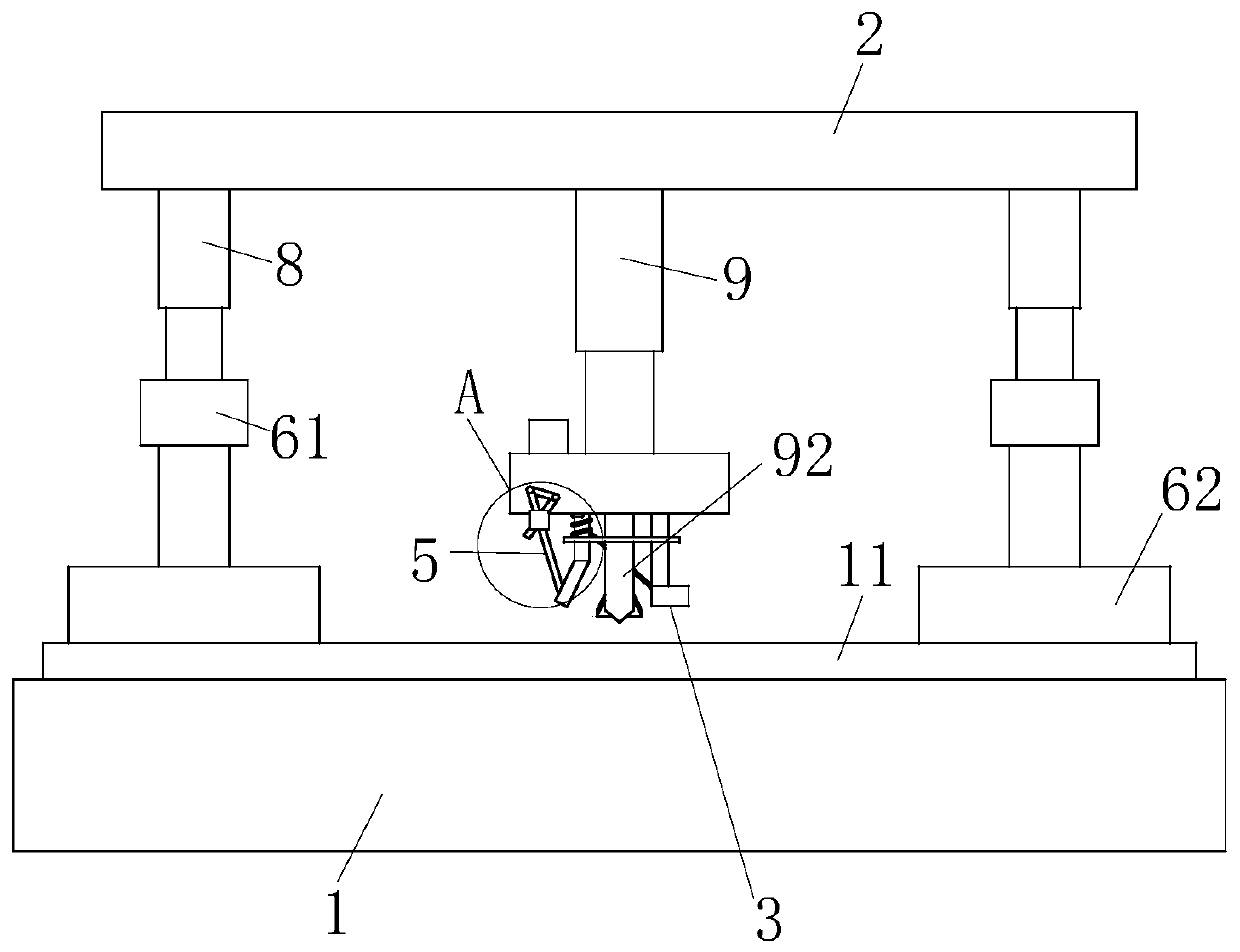

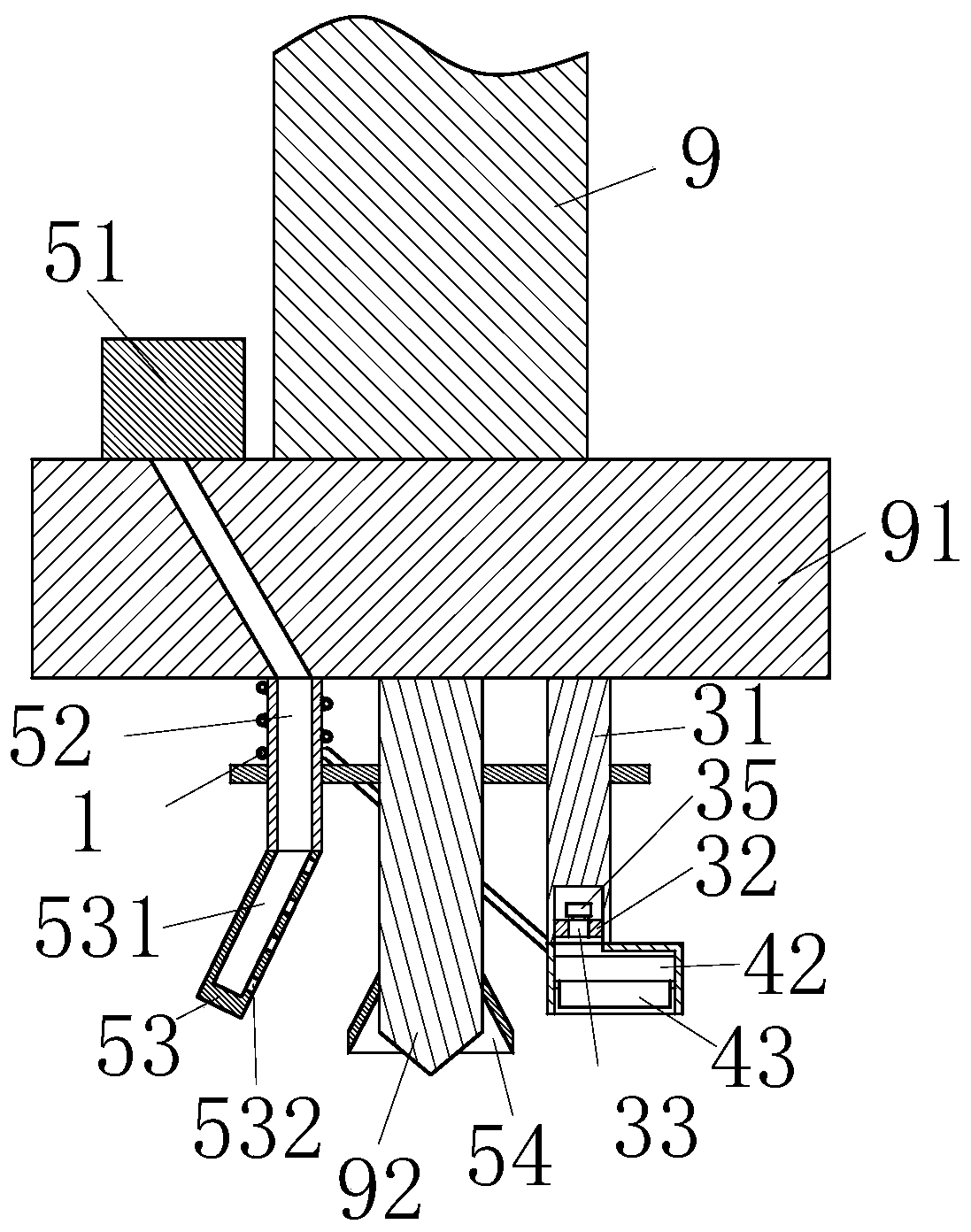

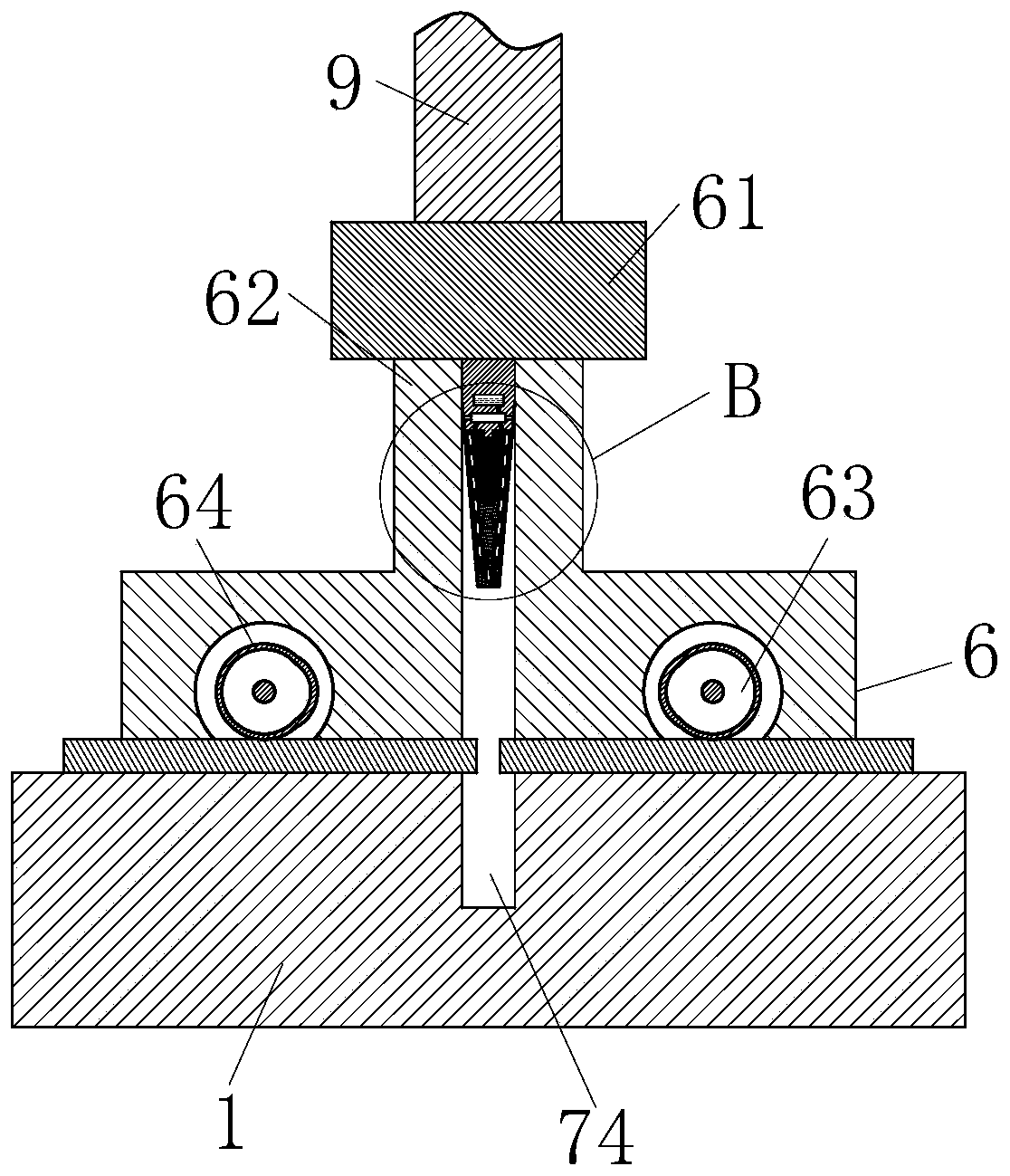

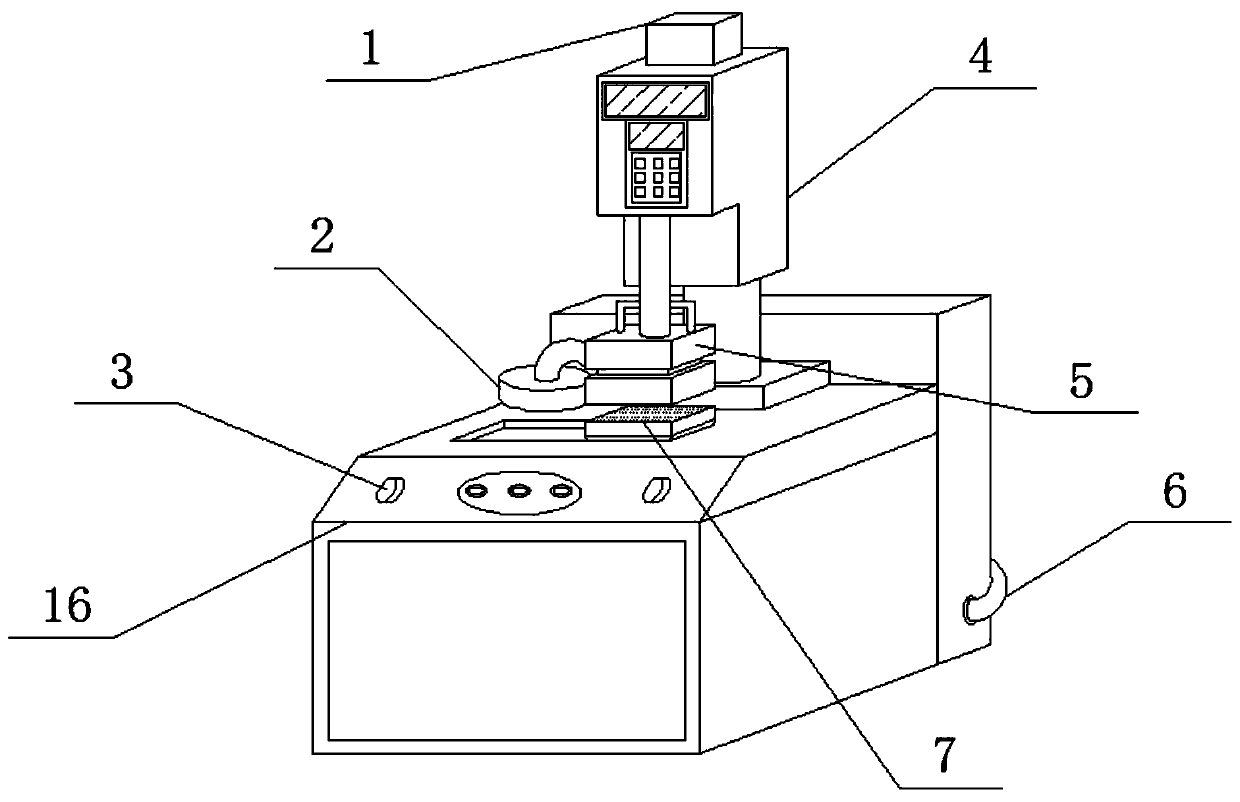

Laser welding equipment with high safety

InactiveCN111451637AImprove securityImprove reliabilityLaser beam welding apparatusLaser solderingStructural engineering

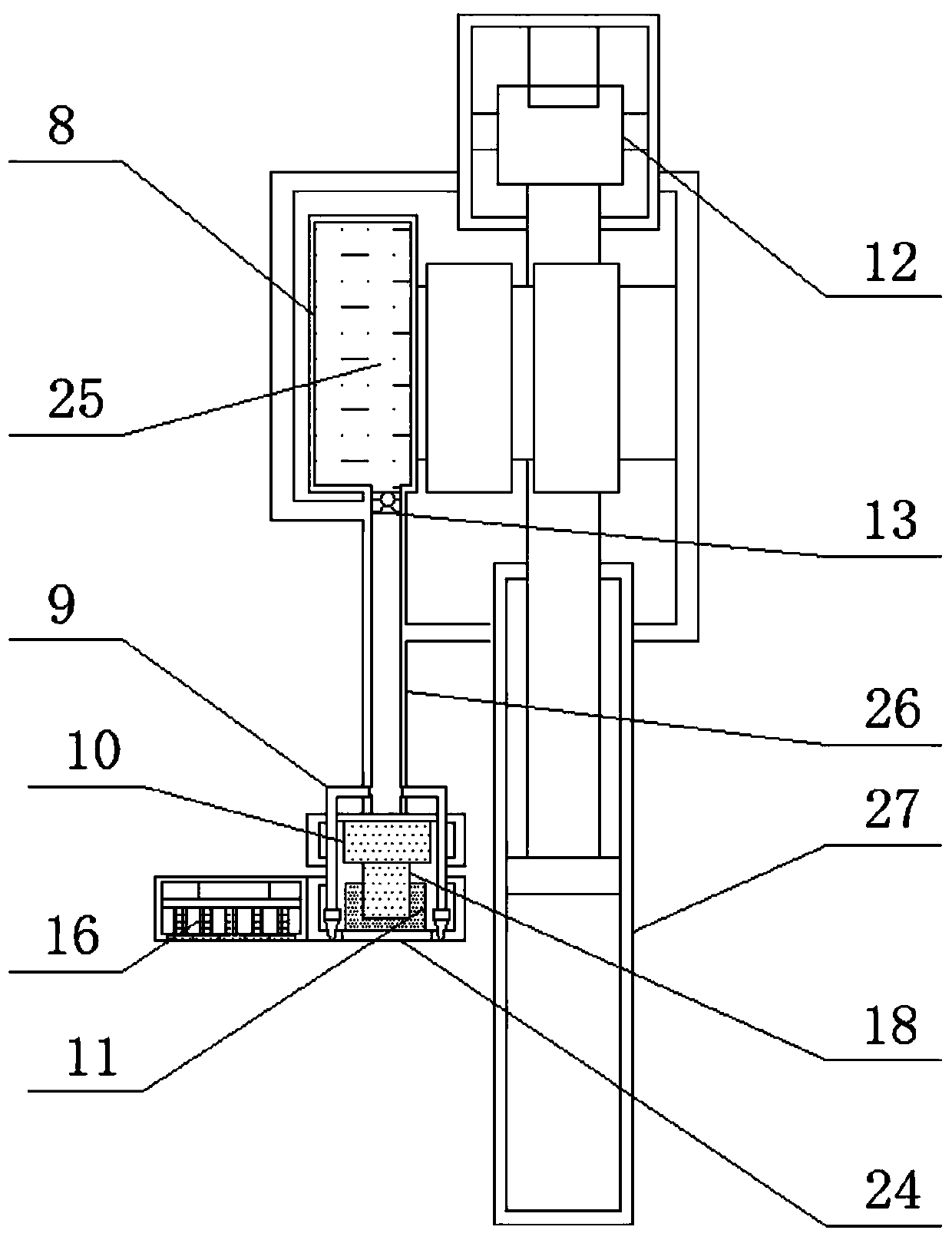

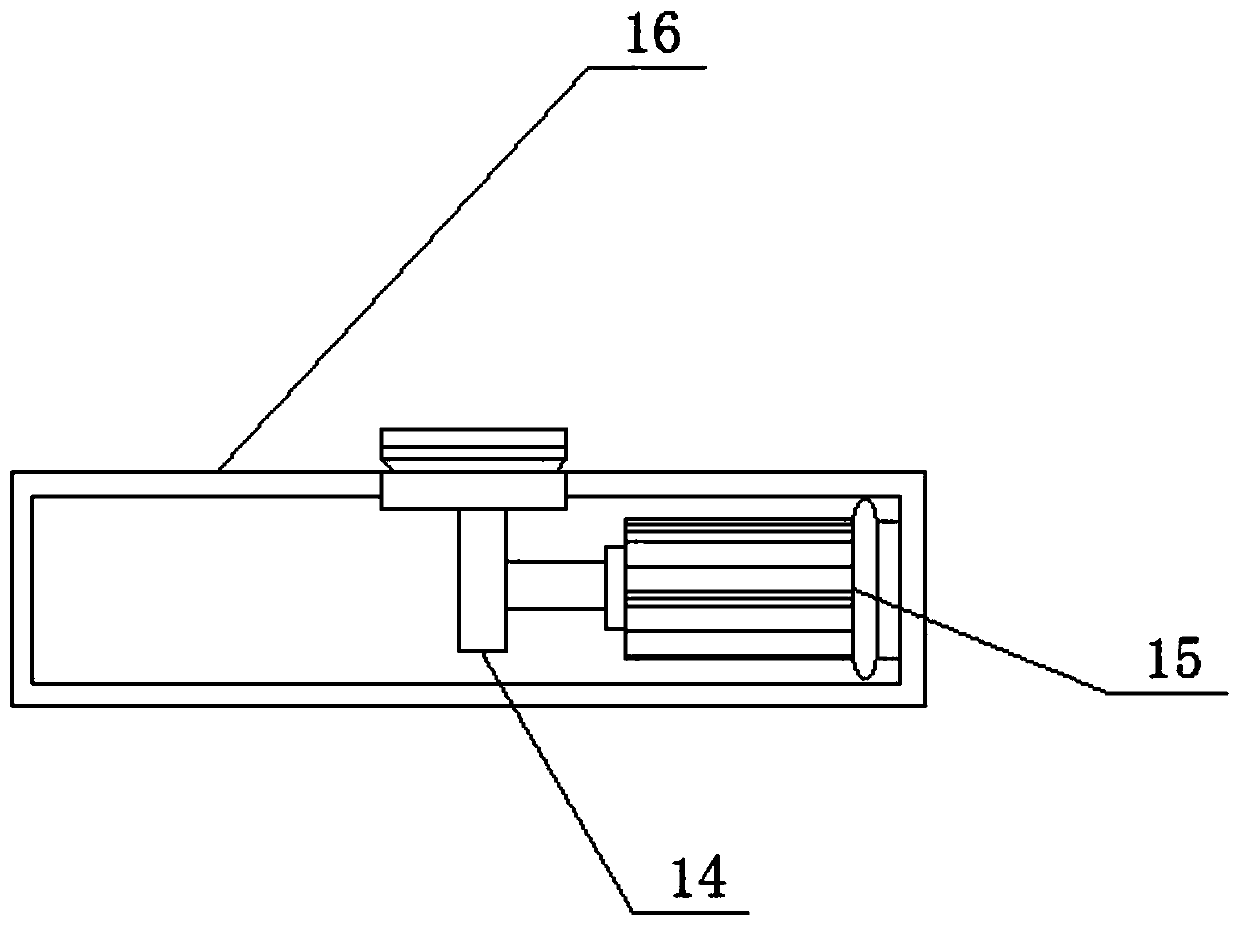

The invention relates to laser welding equipment with high safety. The laser welding equipment comprises a worktable, a base, a top plate, a lifting device, a lifting plate, a welding head and two struts, and further comprises a protection mechanism and two cleaning mechanisms, wherein the protection mechanism comprises a moving plate, a first spring, two connection assemblies, two drive assemblies and four protective plates, each cleaning mechanism comprises a fixed box, an airbag, a pressing plate, a second spring, an air inlet pipe, a connecting pipe, a connecting box, a fixing rod and tworeciprocating assemblies. According to the laser welding equipment with high safety, the protection mechanism is arranged, so that the protective plates can protect the worktable and the welding headfrom the four sides of the worktable during welding, and the sparks generated during welding are prevented from splashing onto users, thus improving the safety of the equipment; and a dust removal mechanism is arranged, dust impurities on workpieces can be blown away, so that the cleaning function is realized, and the impurities on the workpieces is prevented from affecting the welding effect.

Owner:南京捷达威机电科技有限公司

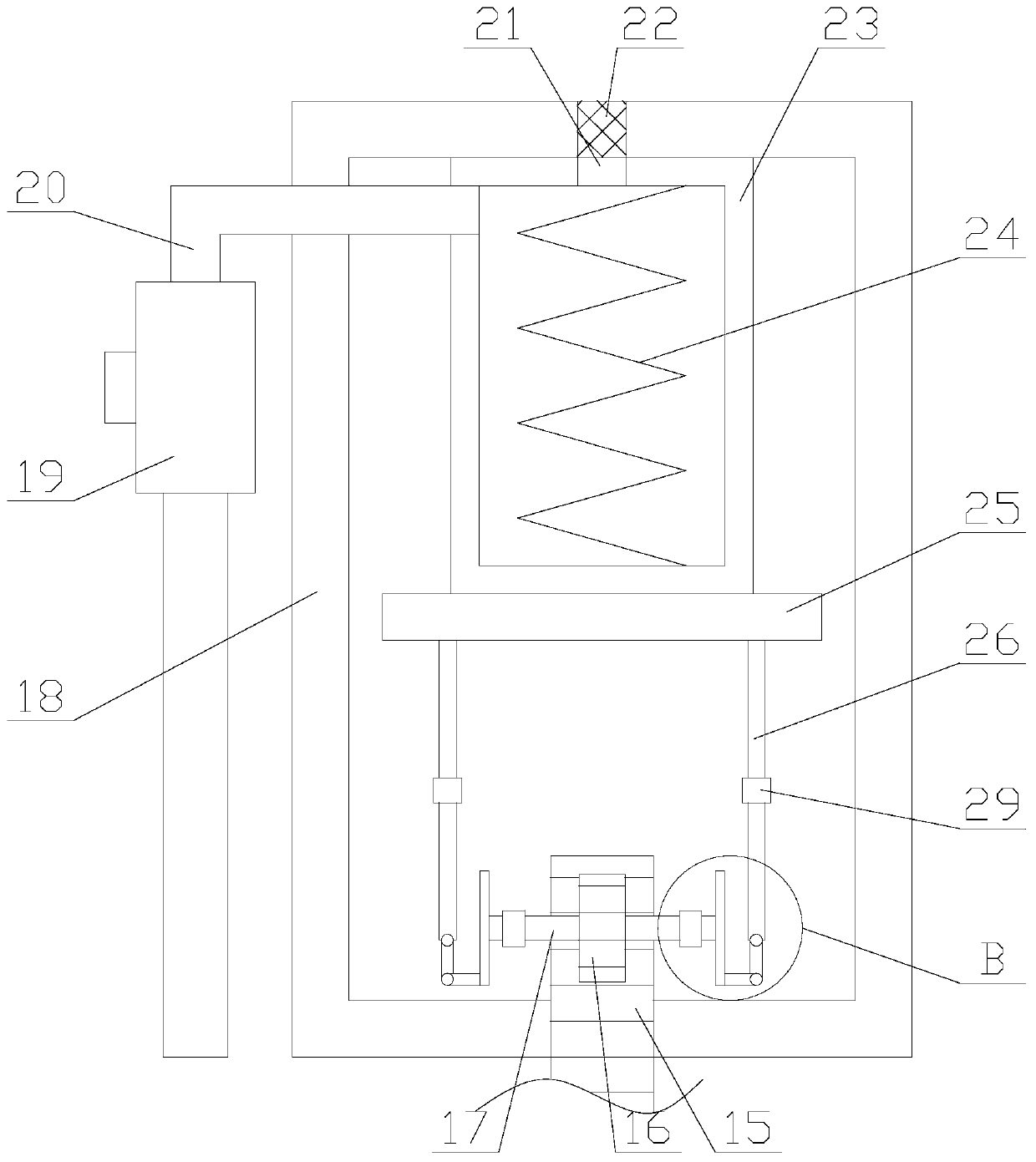

Plastic tube hot-melting welding machine

The invention belongs to the technical field of plastics, and particularly relates to a plastic tube hot-melting welding machine. The plastic tube hot-melting welding machine comprises a mounting shell, a return spring, a hot-melting block, driving arms, a limiting plate, a driving mechanism, a trigger mechanism and a driving swing rod. The plastic water tube welding machine firstly controls the driving swing rod to swing downward so that a fuser can heat two plastic tubes, and then controls the driving swing rod to swing upward so that the two driving arms can drive the plastic tubes to firstmove to both sides, and then the driving swing rod can swing upward to control the hot-melting block to move upward; when the hot-melting block is completely moved to the upper side, the driving swing rod is driven to swing downward again, and the driving swing rod swings to control the two driving arms to drive the plastic tubes to move, and finally the contact pressure is applied to weld the two plastic tubes together; the situation that tube openings cannot be aligned because the two plastic tubes are artificially stressed, the welding effect is influenced, and leakage of the welding is caused is reduced; and meanwhile, the situation that the welding effect is influenced due to the curing of originally heated plastic tubes due to two times of heating is prevented.

Owner:YANCHENG RUITONG PLASTIC CO LTD

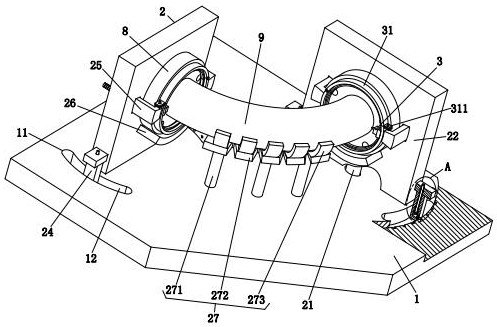

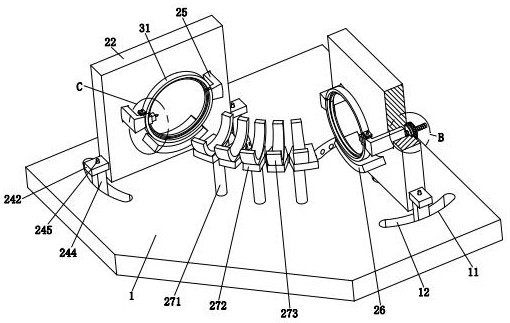

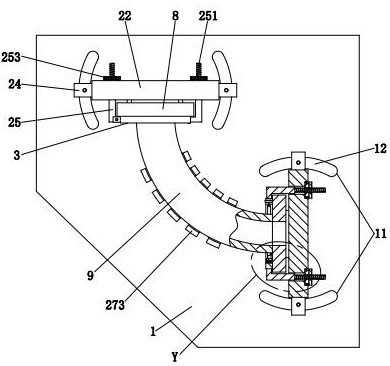

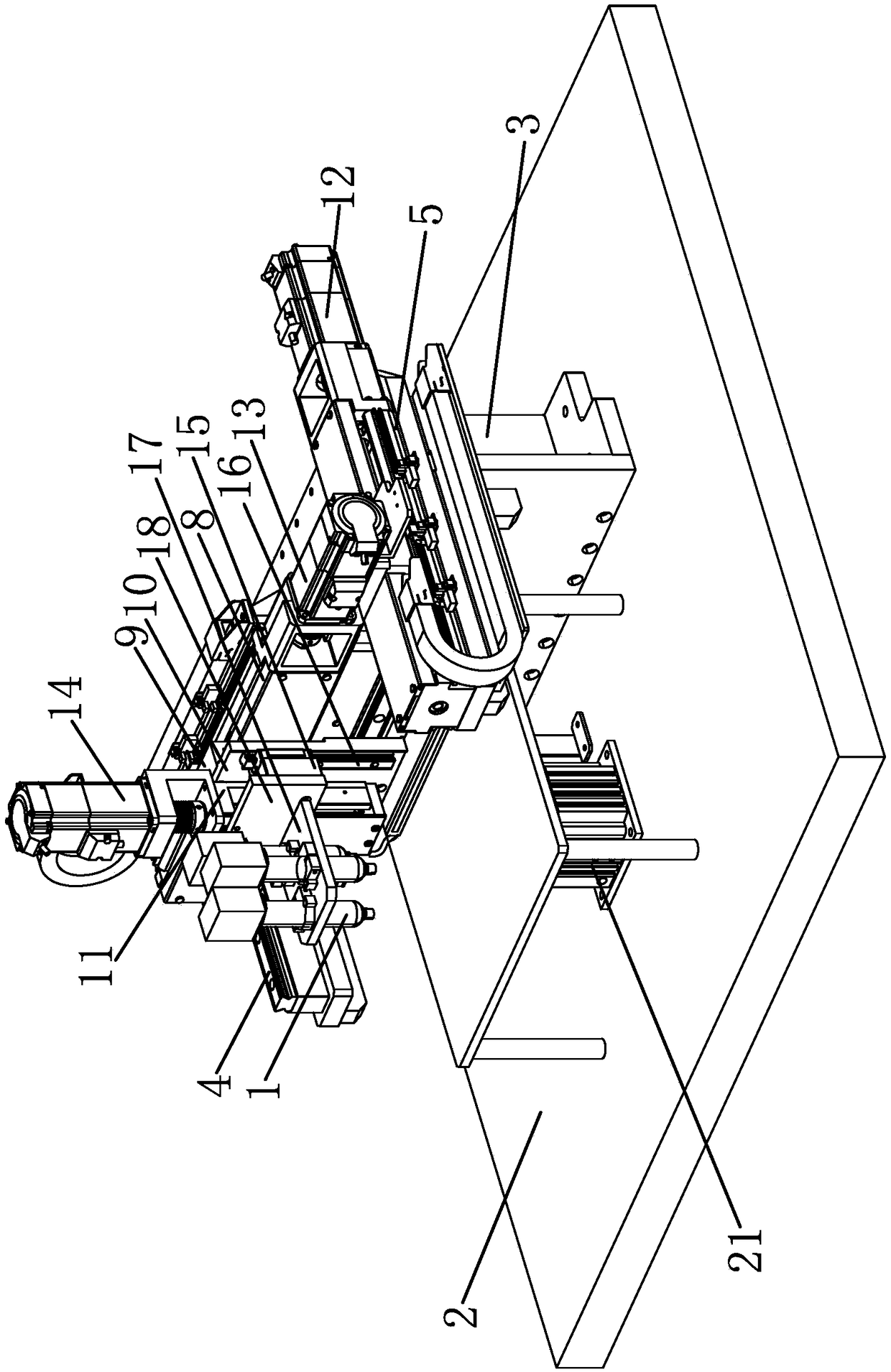

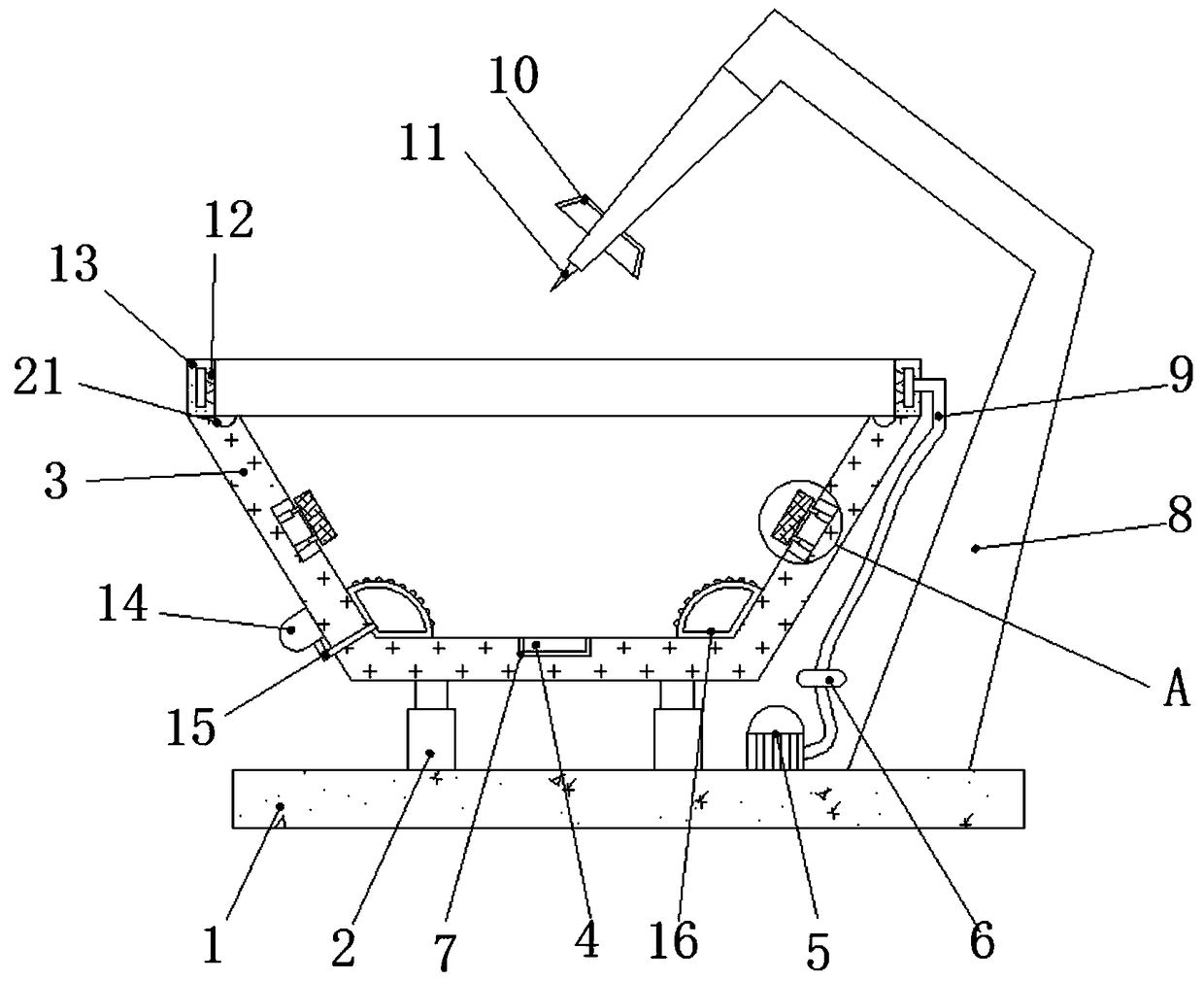

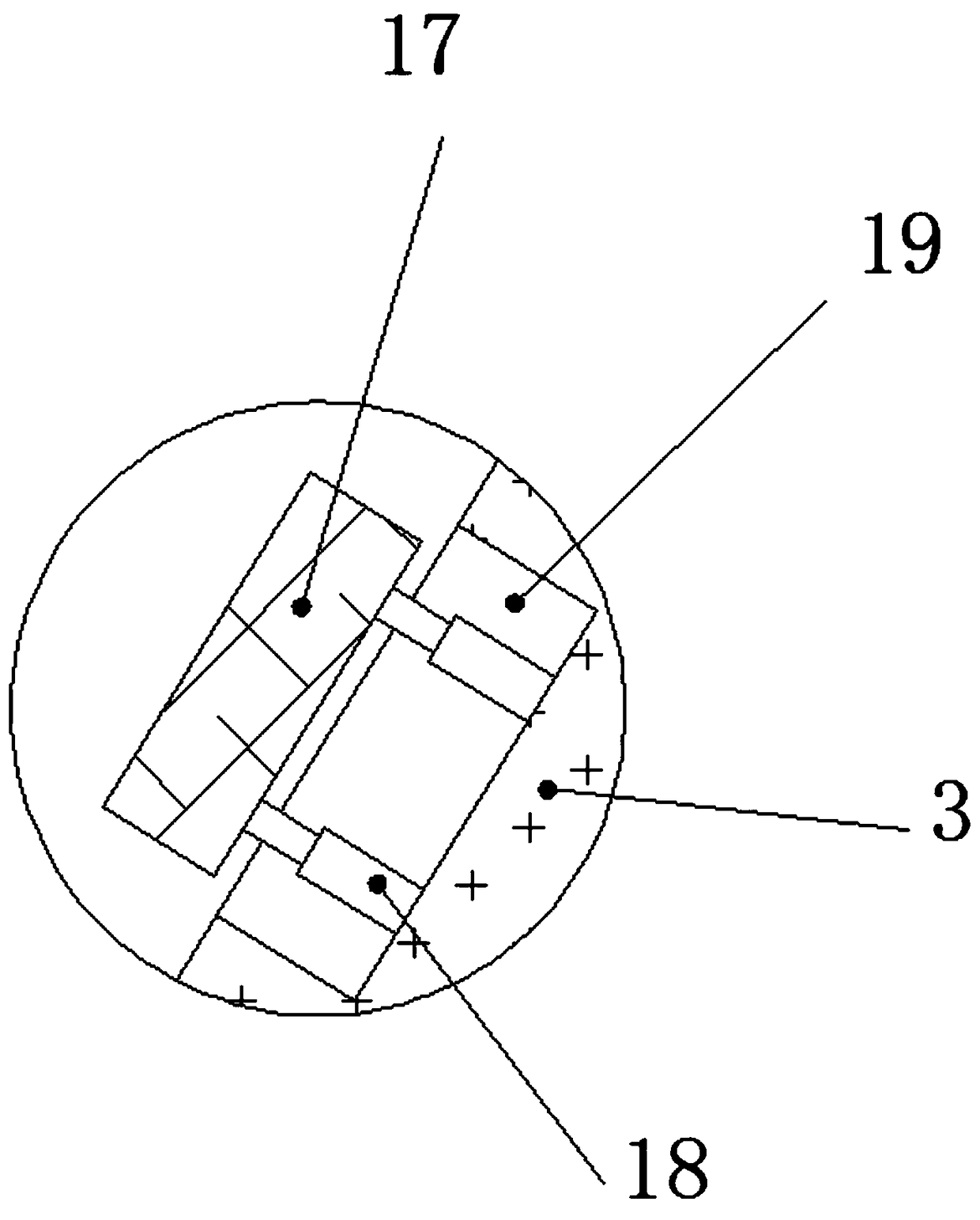

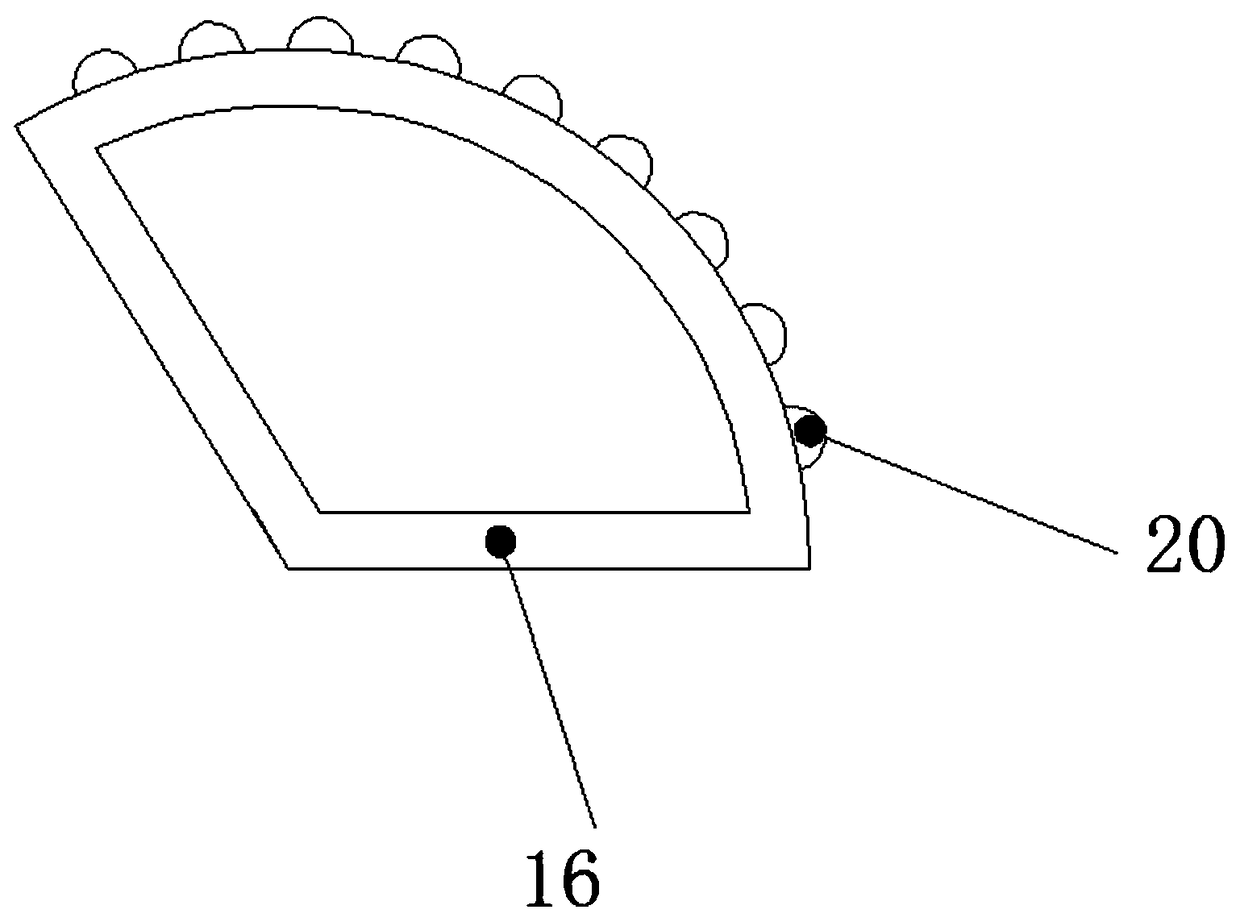

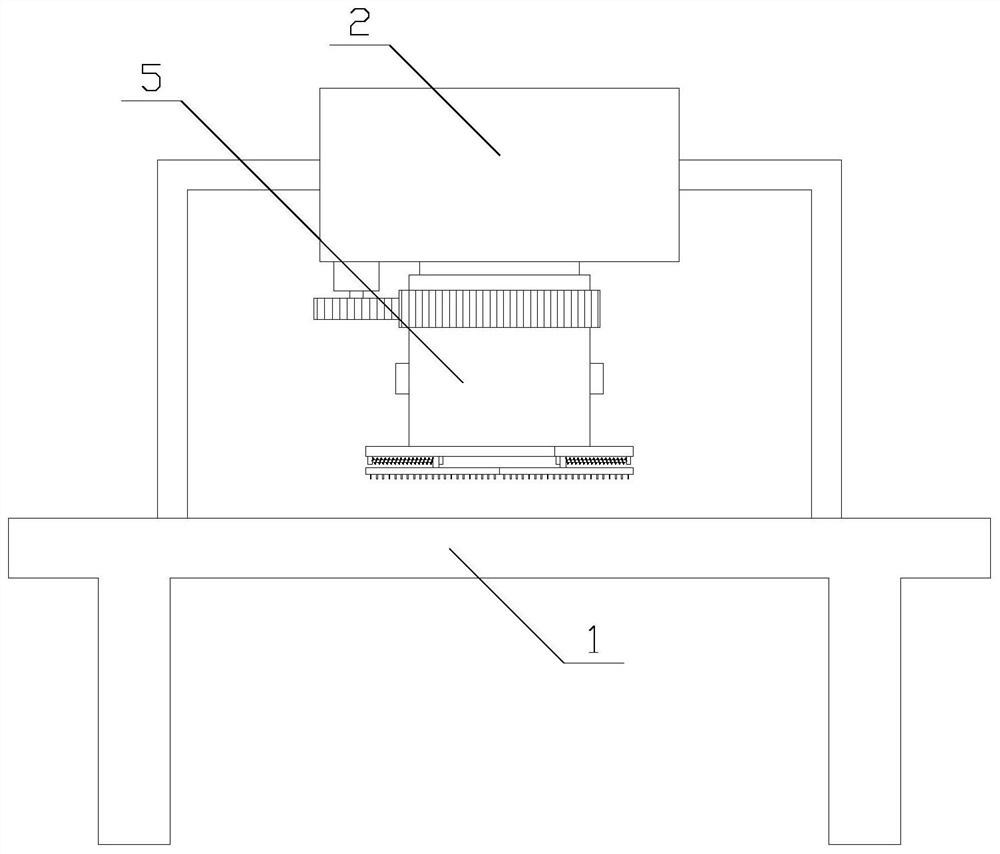

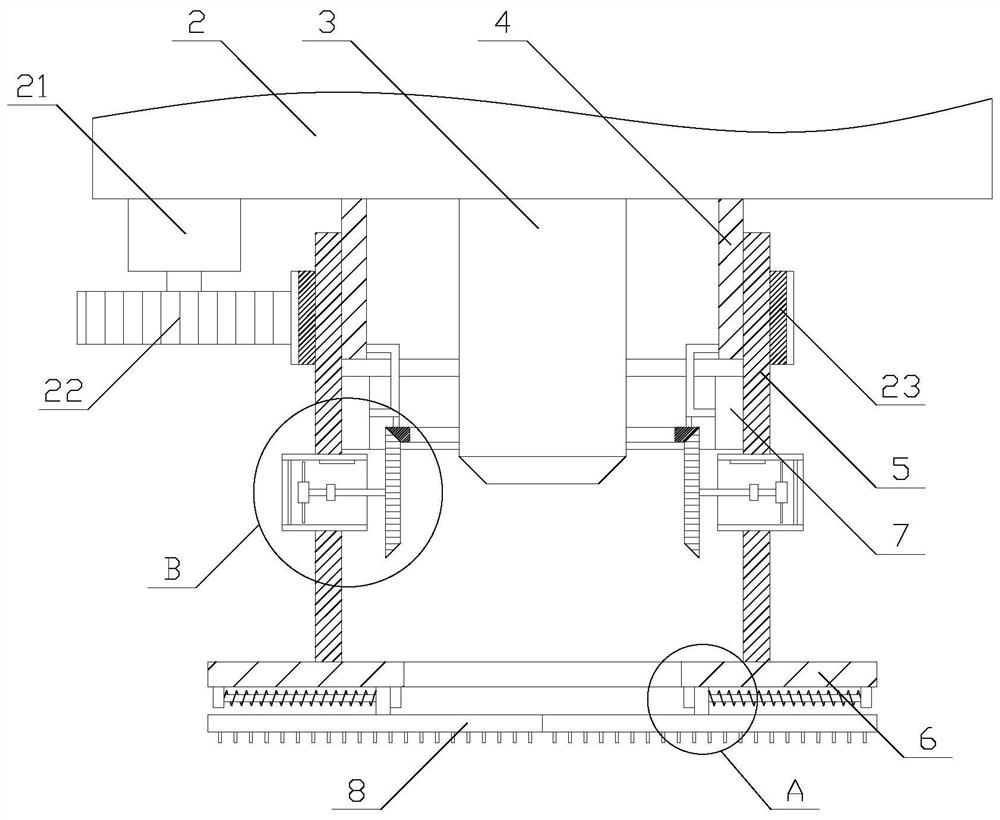

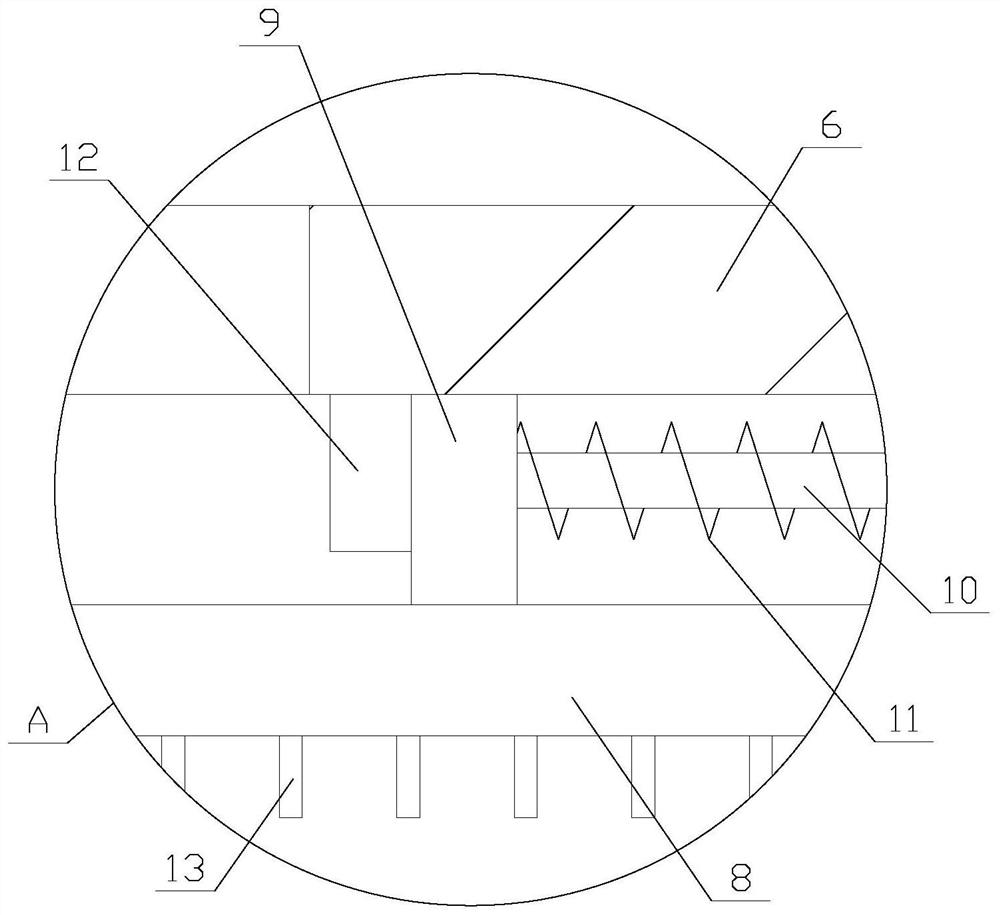

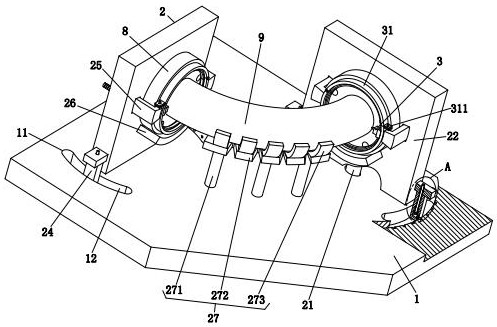

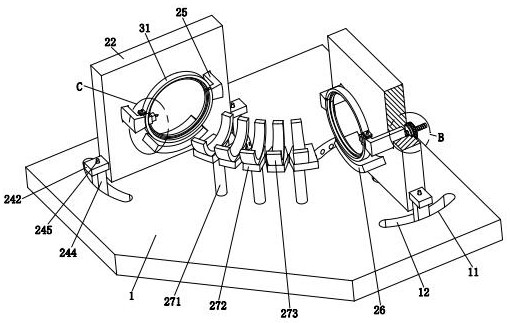

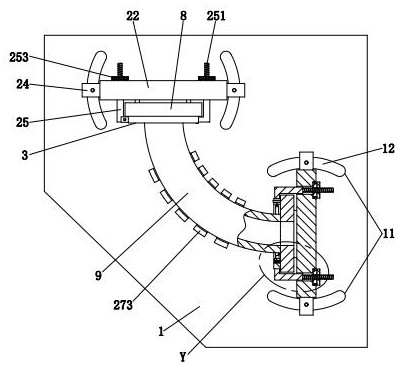

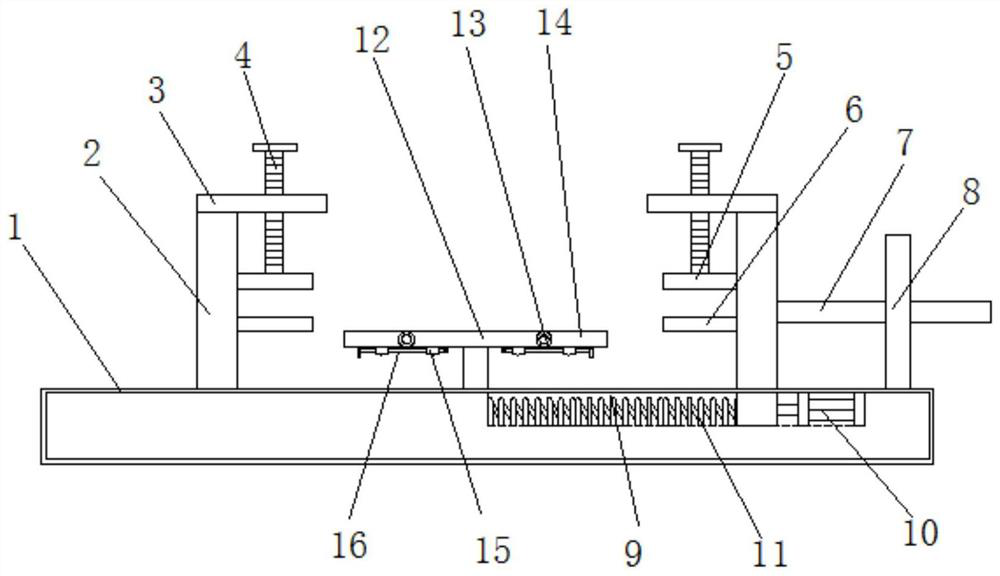

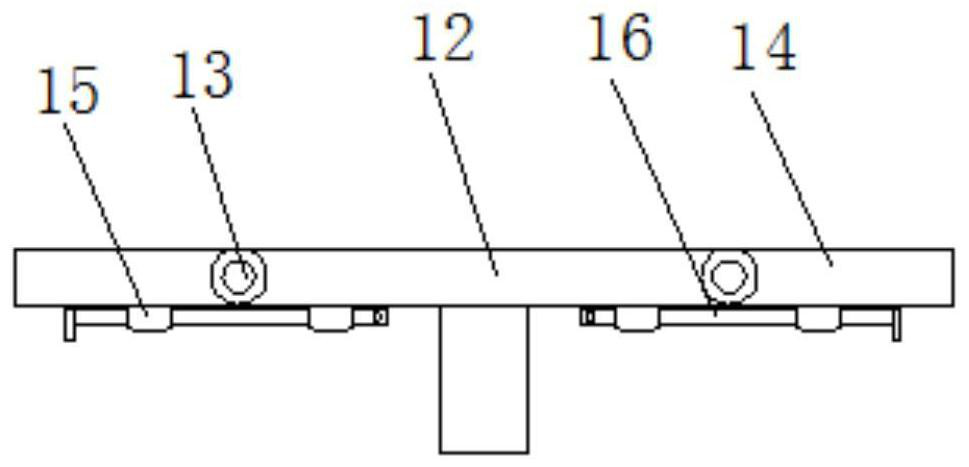

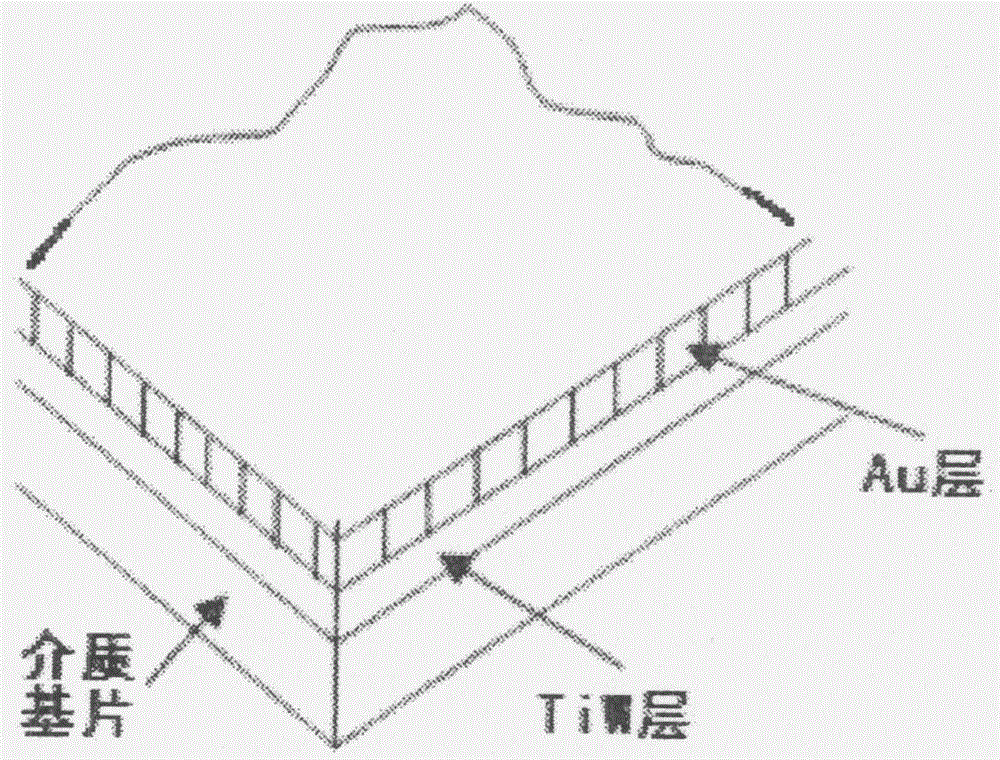

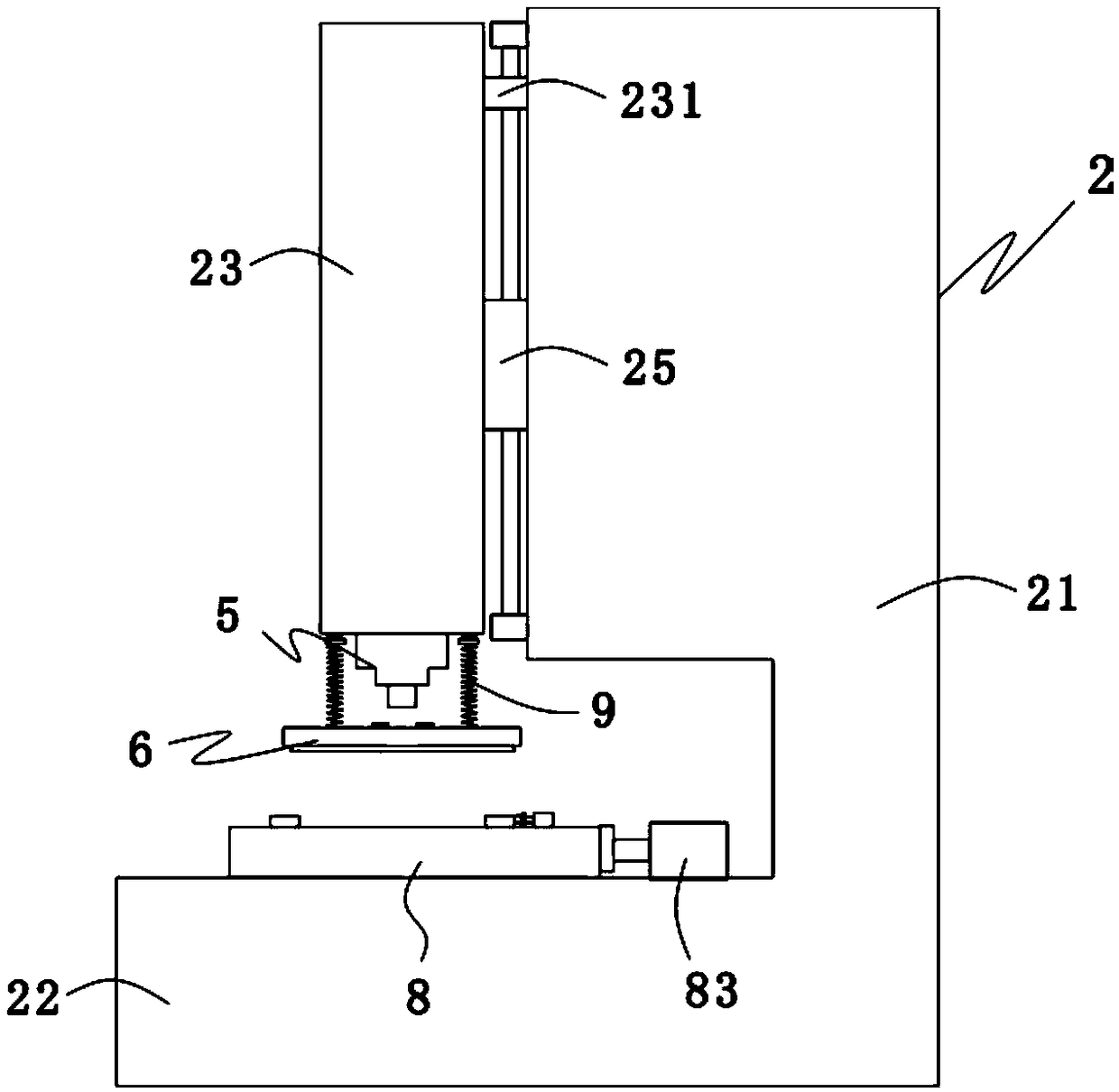

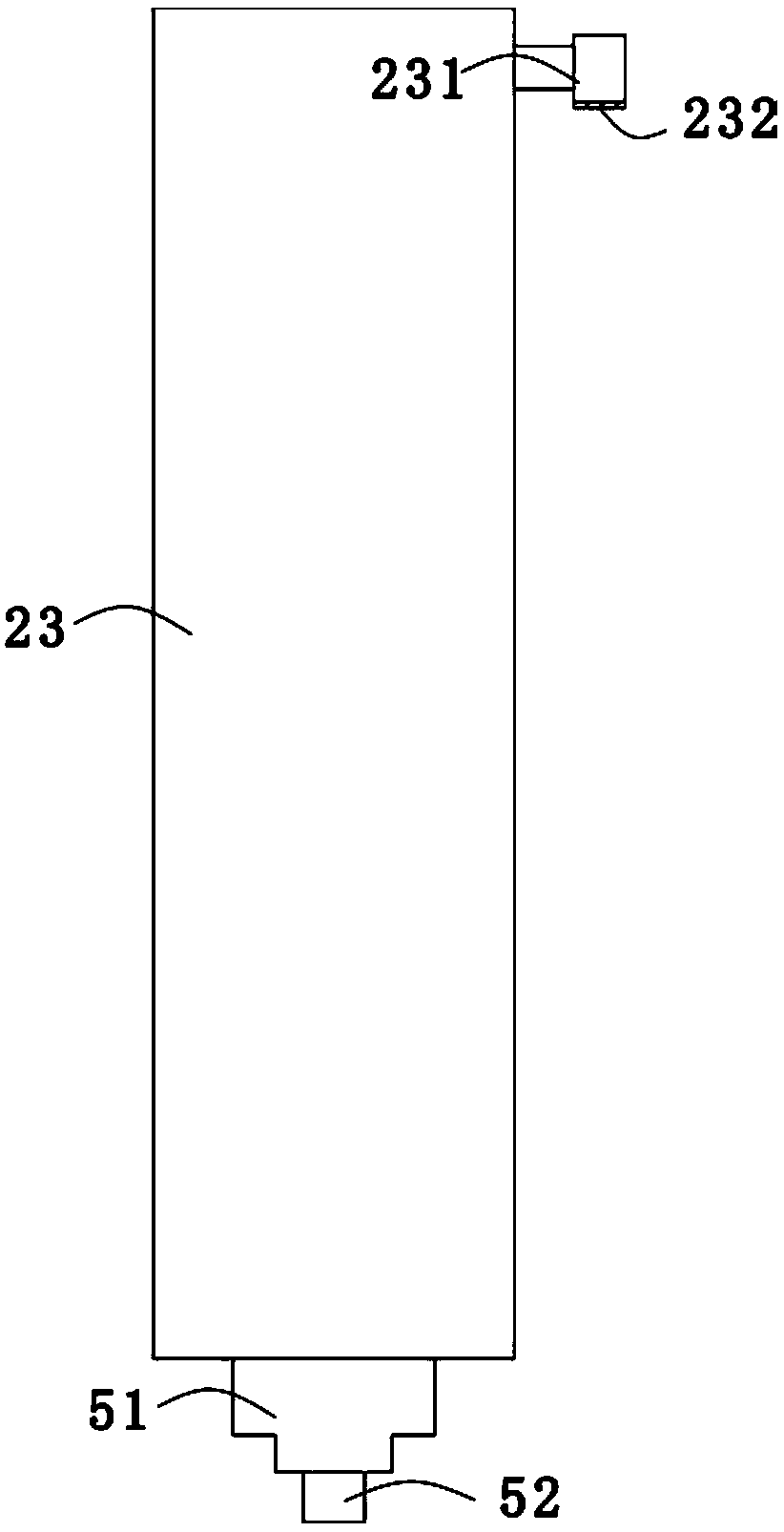

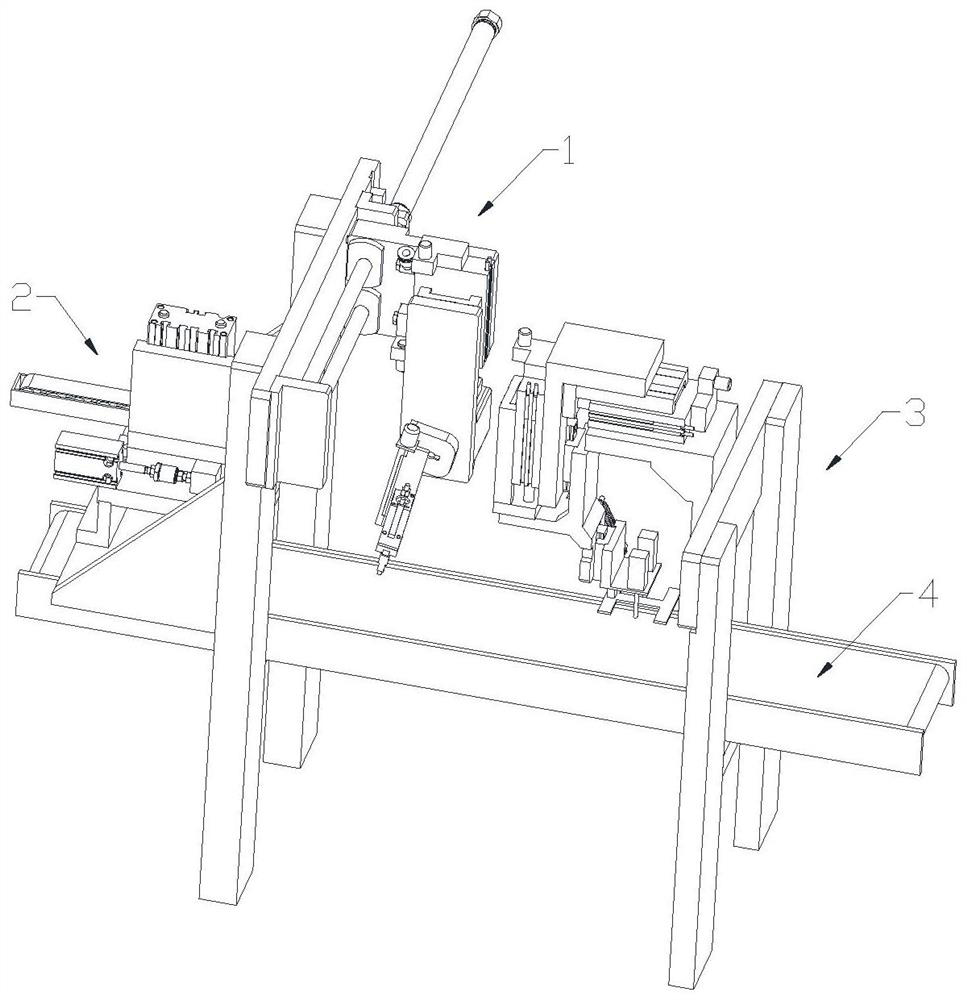

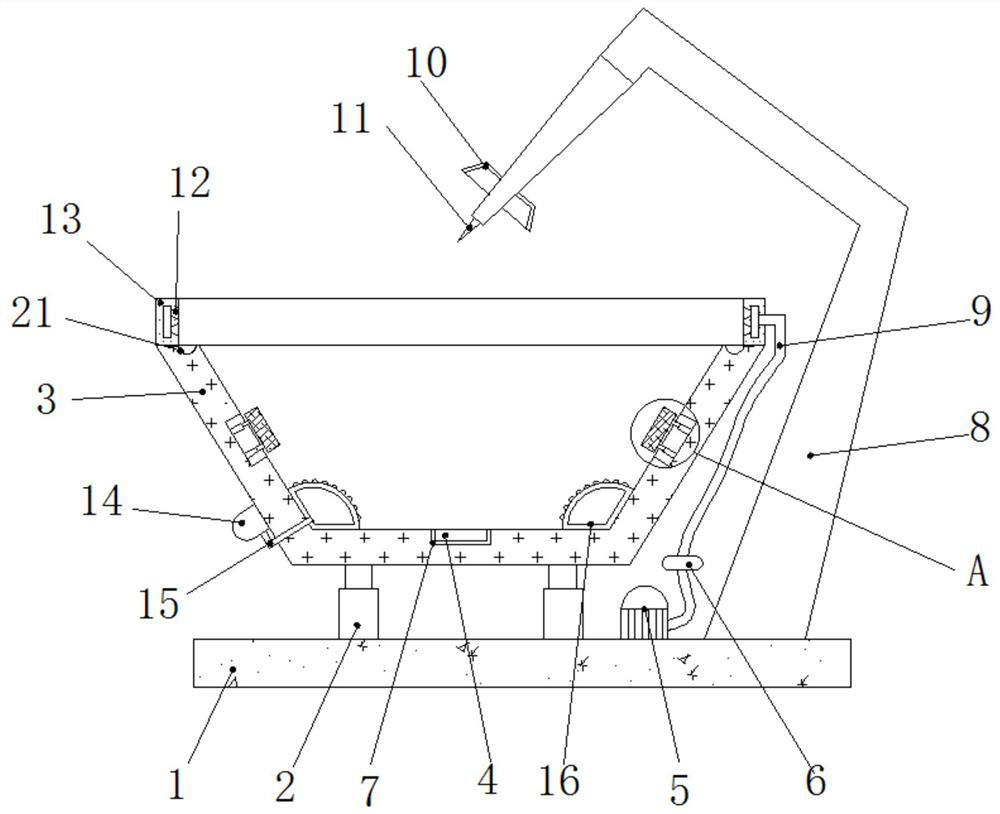

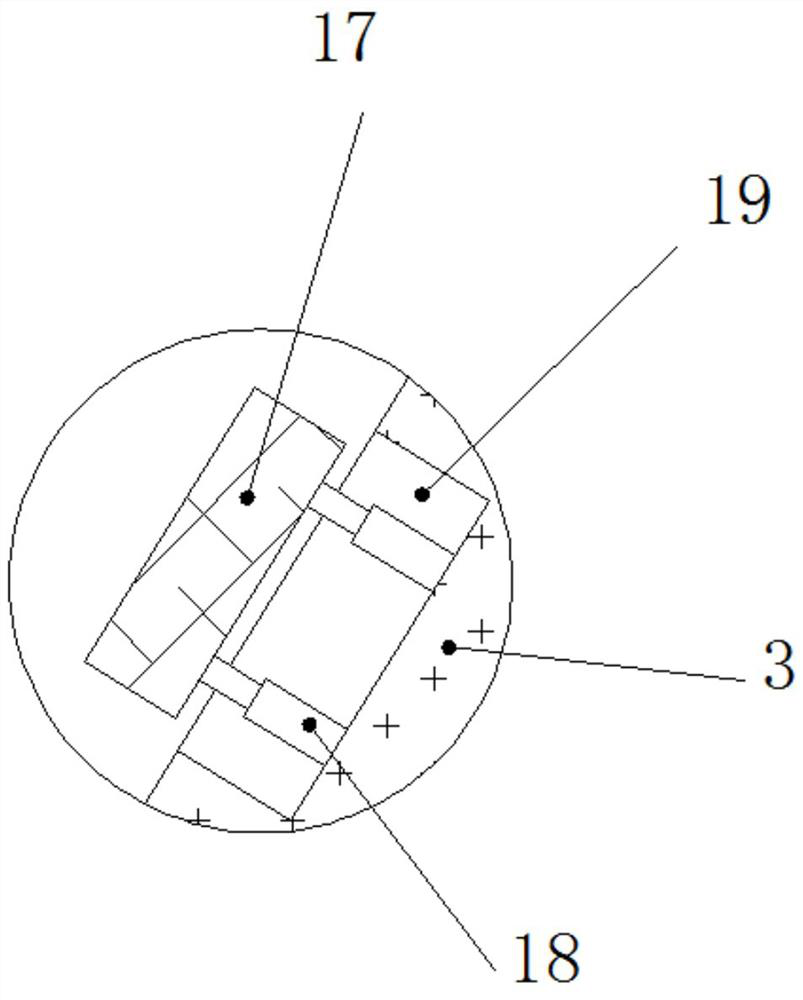

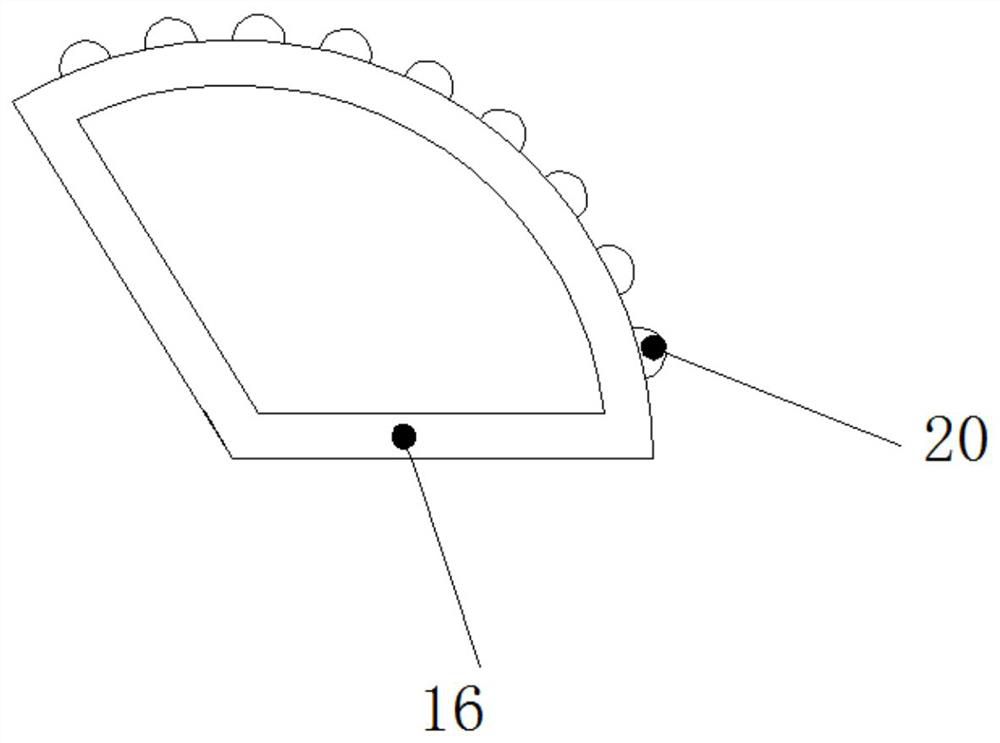

Welding forming machine for bent pipe and flange connection

ActiveCN113601074AEasy alignmentImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesButt jointPipe welding

The invention relates to the technical field of pipeline welding, in particular to a welding forming machine for bent pipe and flange connection. The welding forming machine comprises a bottom plate, a clamping unit and a welding unit. The clamping unit is installed at the upper end of the bottom plate, and the welding unit is arranged on the clamping unit. The welding forming machine has the following problems that an existing clamp cannot adjust the angle between a bent pipe and flanges according to welding requirements, consequently, welding deviation is prone to being generated, circumferential welding cannot be realized when a worker welds the flanges and the bent pipe, the welding efficiency of the flanges and the bent pipe is influenced, and certain potential safety hazards exist when the worker carries out welding. By means of the welding forming machine, the angle between rotating plates and the bent pipe can be adjusted, the bent pipe and the flanges can be aligned conveniently, and therefore deviation generated when the bent pipe and the flanges are welded can be reduced; and by means of the welding forming machine, circumferential welding treatment can be carried out on the butt joint positions of the bent pipe and the flanges, the welding efficiency can be improved, and potential safety hazards existing during manual welding can be avoided.

Owner:徐州市瑞泰钢管有限公司

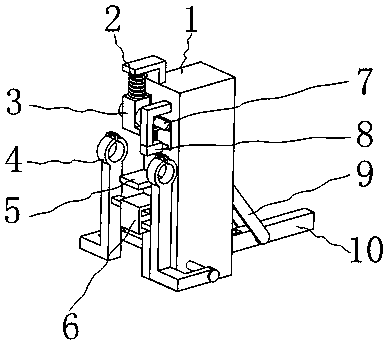

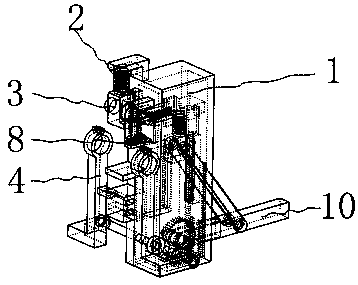

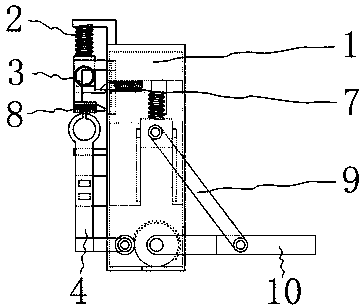

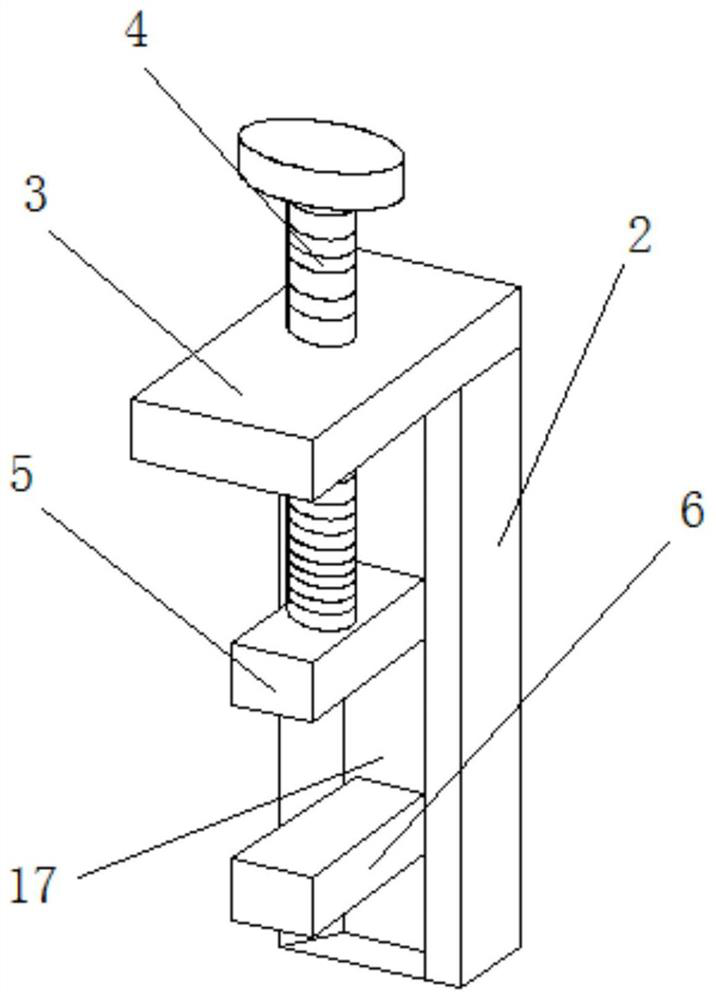

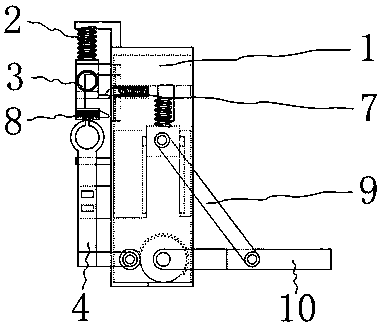

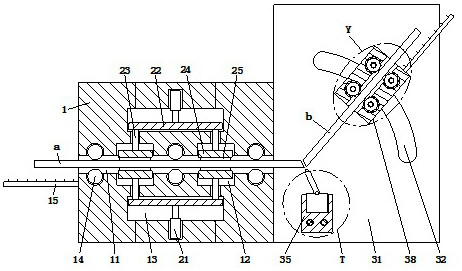

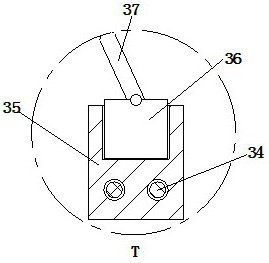

Welding machine

InactiveCN103157925AExtended service lifePrevent affecting the welding effectWelding/cutting auxillary devicesCleaning using toolsSolderingTin

The invention relates to a welding machine. The welding machine comprises a base, a welding part clamping device which is fixed on the base and is used for clamping a welding part, a welding head which is used for welding the welding part, and a cleaning electrode device which is use for cleaning the welding head, wherein the cleaning electrode device comprises a cleaning brush which is used for cleaning the welding head, and a moving device which is used for fixing the cleaning brush and enabling the cleaning brush to be close to or far away from the welding head. According to the welding machine, the cleaning electrode device is arranged to clean the welding head, so that welding effects of next welding are prevented from being affected by residual soldering tin or other dirt produced after the welding head welds, and service life of the welding head is prolonged.

Owner:SIP GOLDWAY TECH

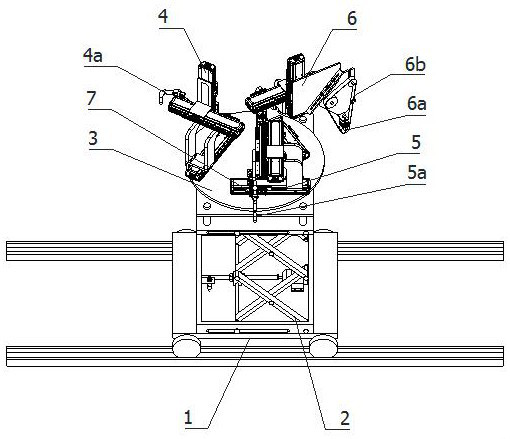

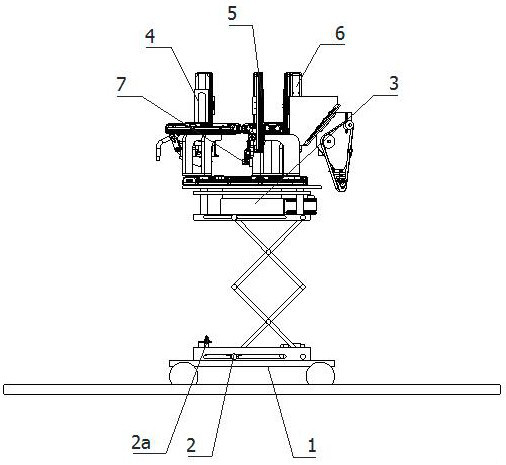

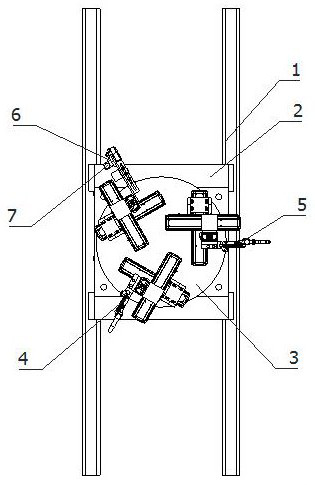

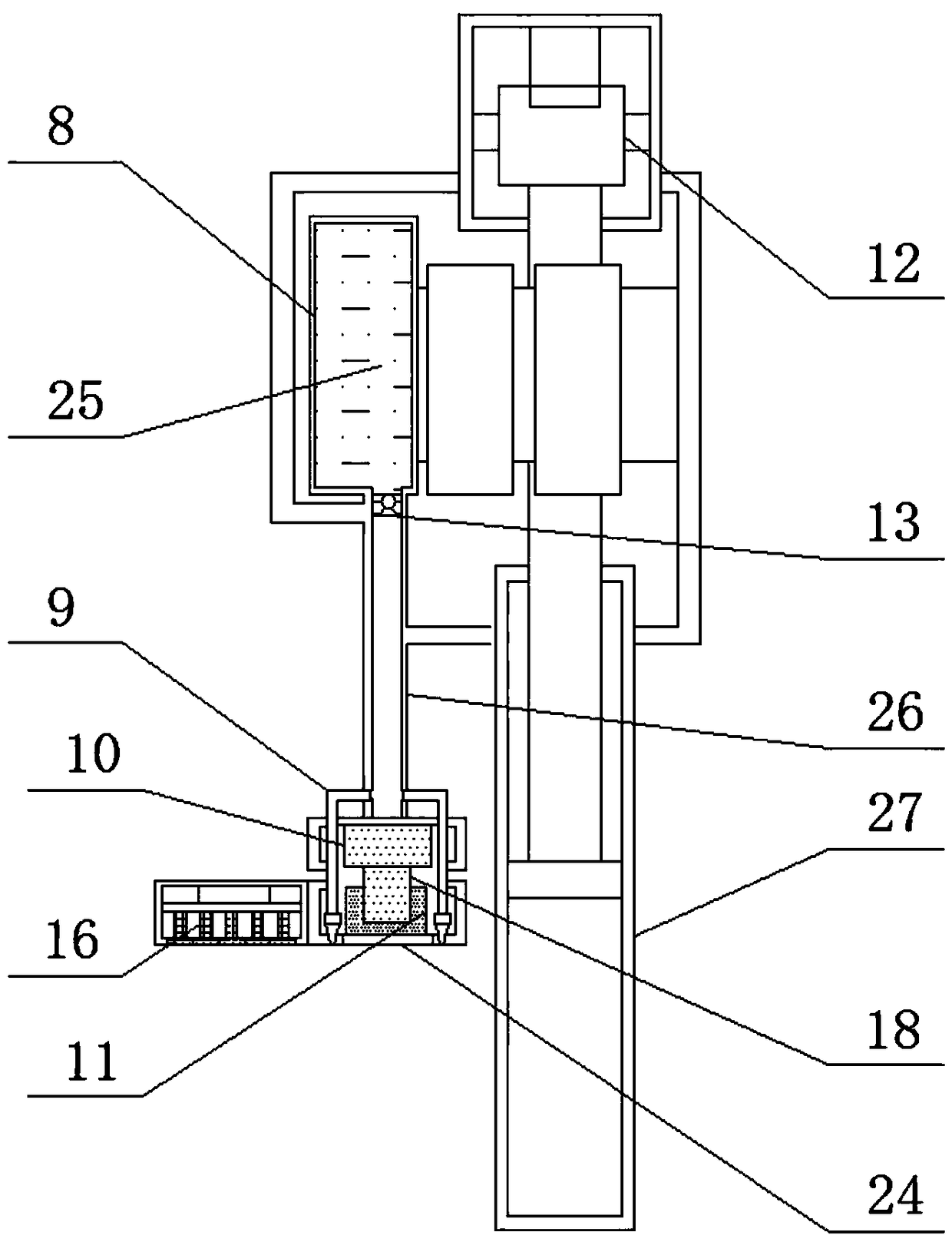

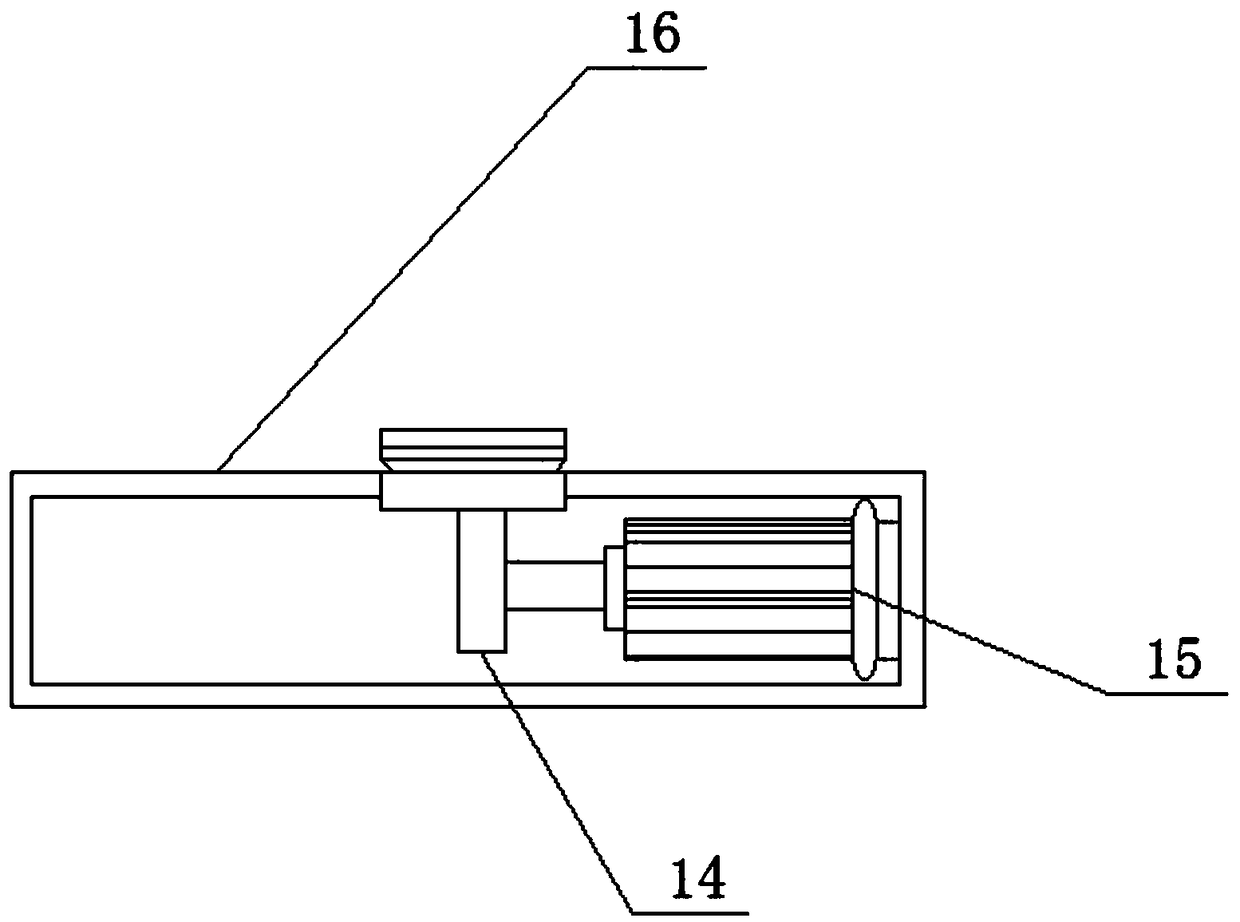

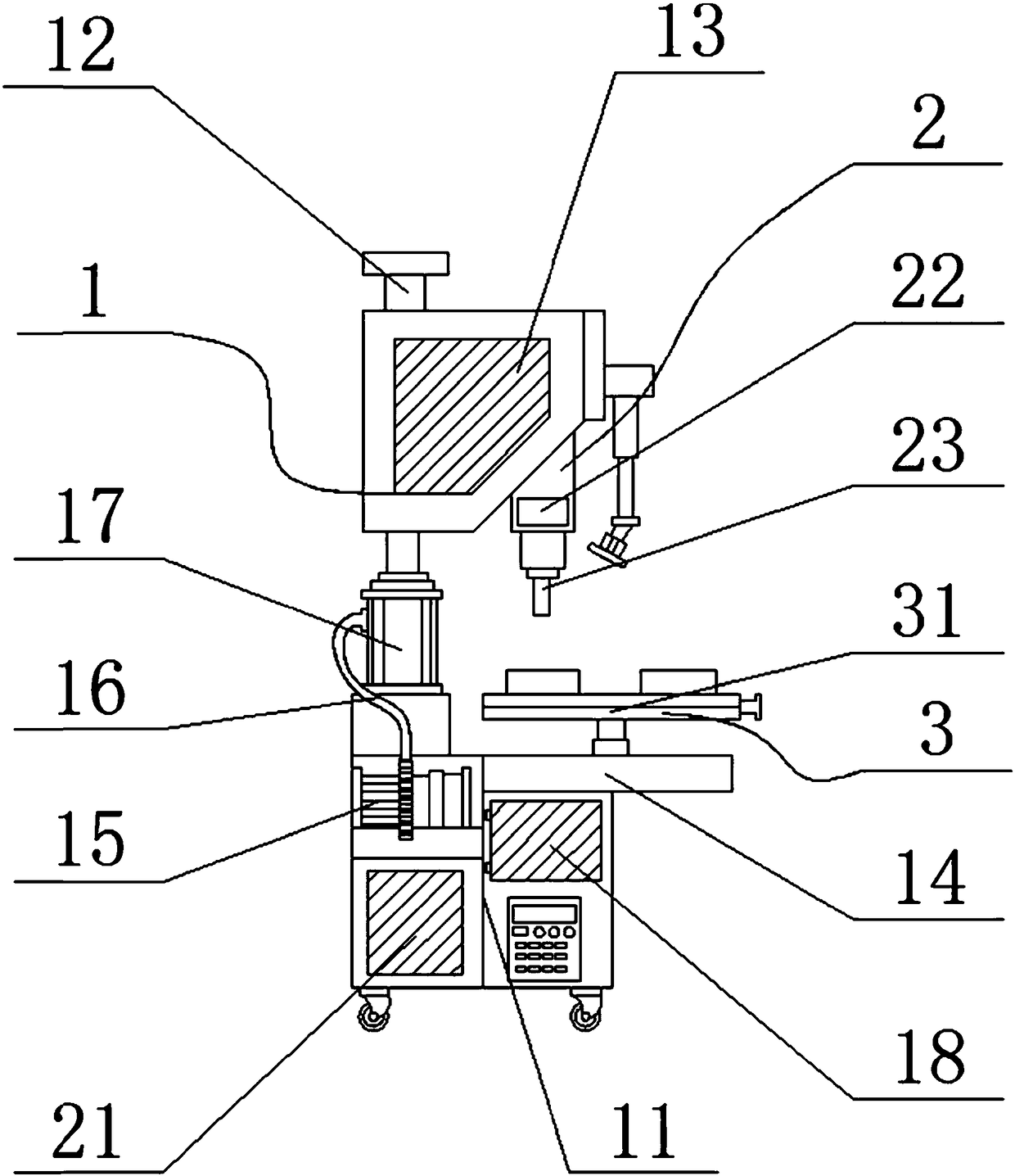

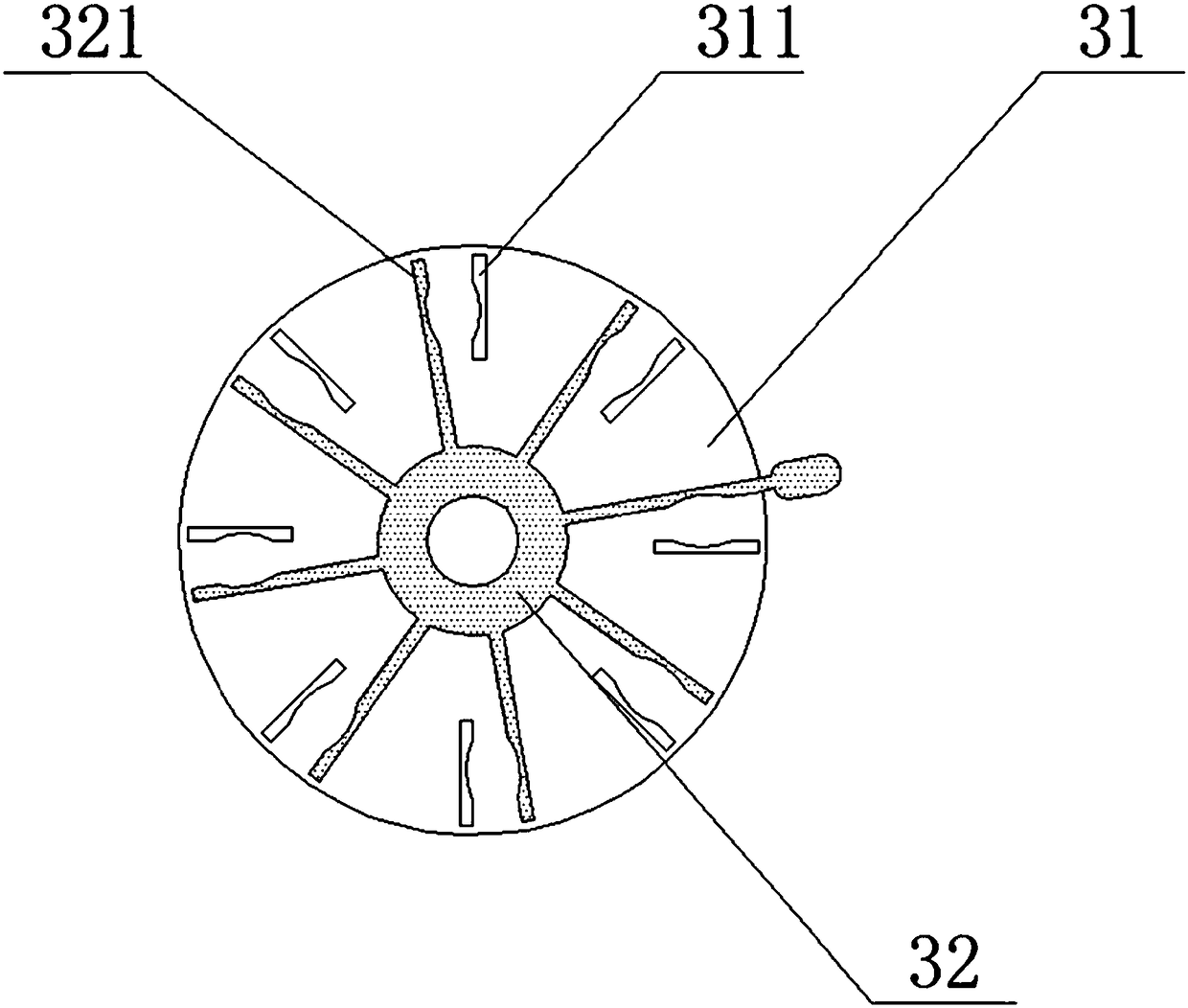

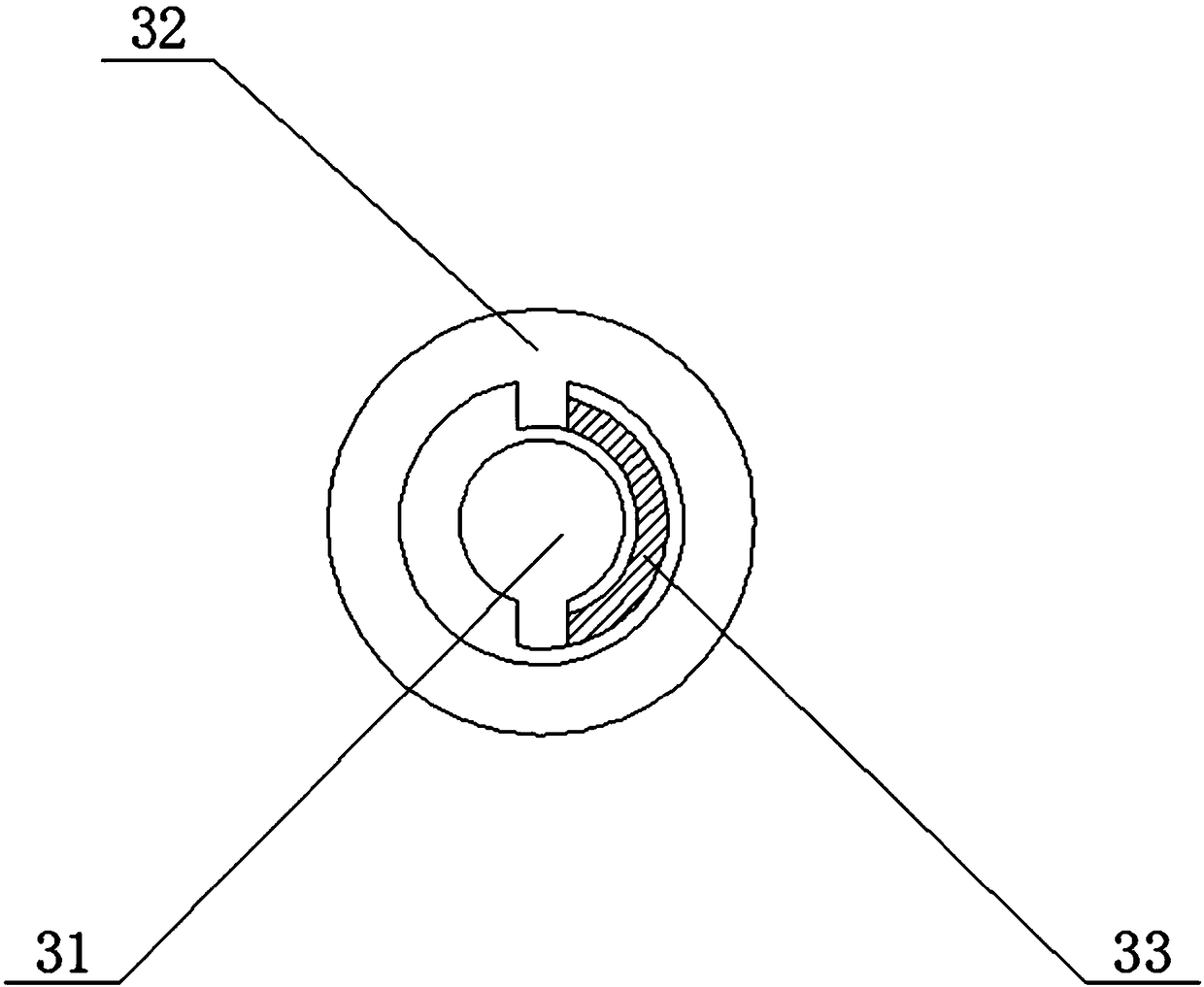

Multifunctional industrial robot for intelligent manufacturing

InactiveCN112518773APrevent affecting the welding effectEasy to blowOther manufacturing equipments/toolsCleaning using gasesEngineeringRotary stage

The invention relates to the technical field of robots, in particular to a multifunctional industrial robot for intelligent manufacturing. The robot comprises a rail car, a scissor lift arranged at the top end of the rail car, a high-precision rotating table arranged at the top end of the scissor lift, a multi-axis blowing mechanism, a multi-axis welding mechanism, a multi-axis polishing mechanismand an industrial camera; the mechanisms are evenly distributed at the working end of the high-precision rotating table in the radial direction; the working end of the multi-axis blowing mechanism comprises a blowing nozzle; the working end of the multi-axis welding mechanism comprises a welding head; the working end of the multi-axis polishing mechanism comprises a flexible abutting wheel whichhas the horizontal axis and can elastically move in the vertical direction and the two side directions; the multi-axis polishing mechanism further comprises a polishing belt arranged on the flexible abutting wheel in a sleeving mode and used for polishing; the working end of the industrial camera obliquely faces the working end of the mechanism and is arranged on the mechanism; and the industrialcamera is electrically connected with a controller. The robot is high in working efficiency and precision.

Owner:丽水市莲都区琼宇服饰加工工作室

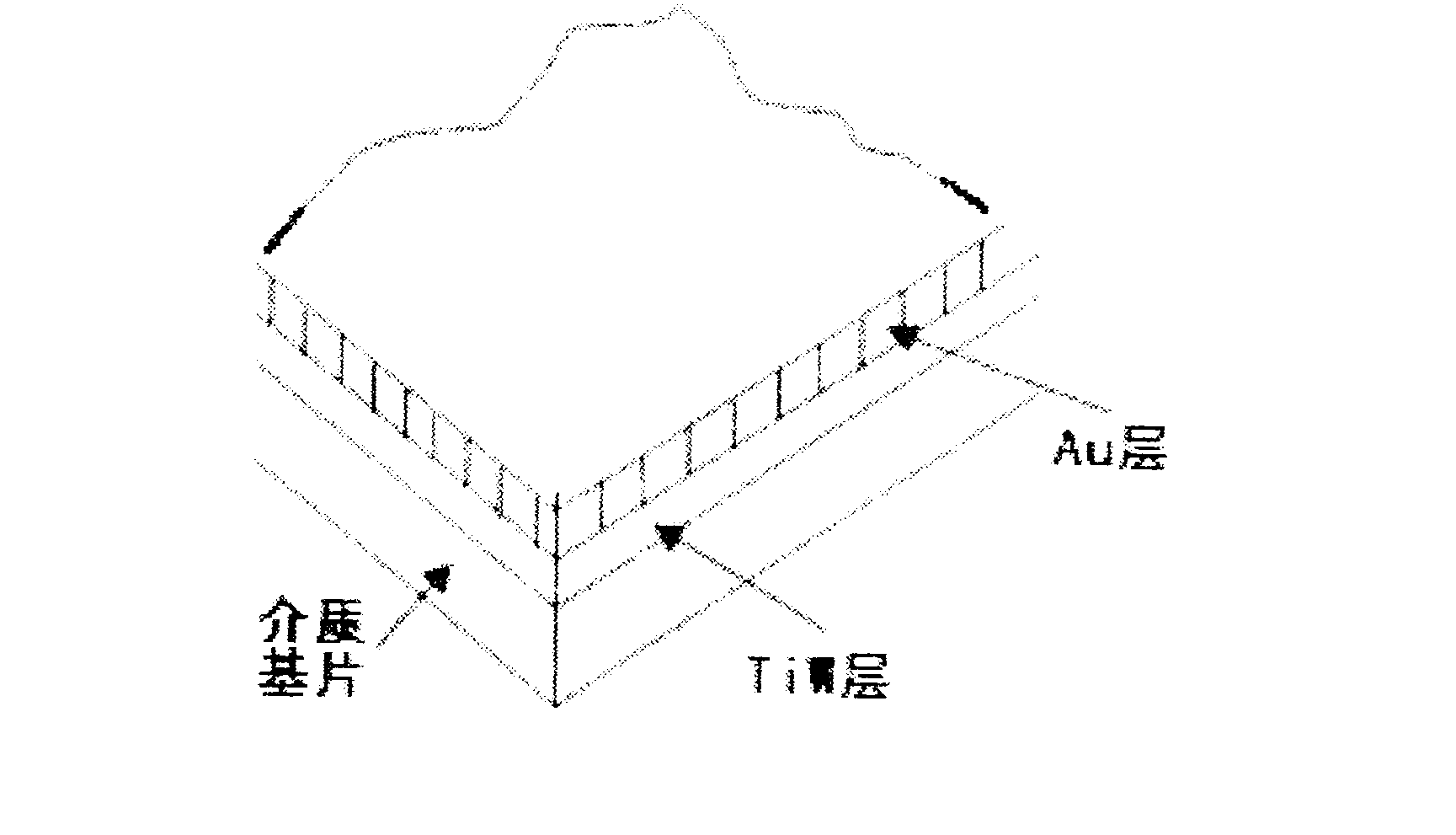

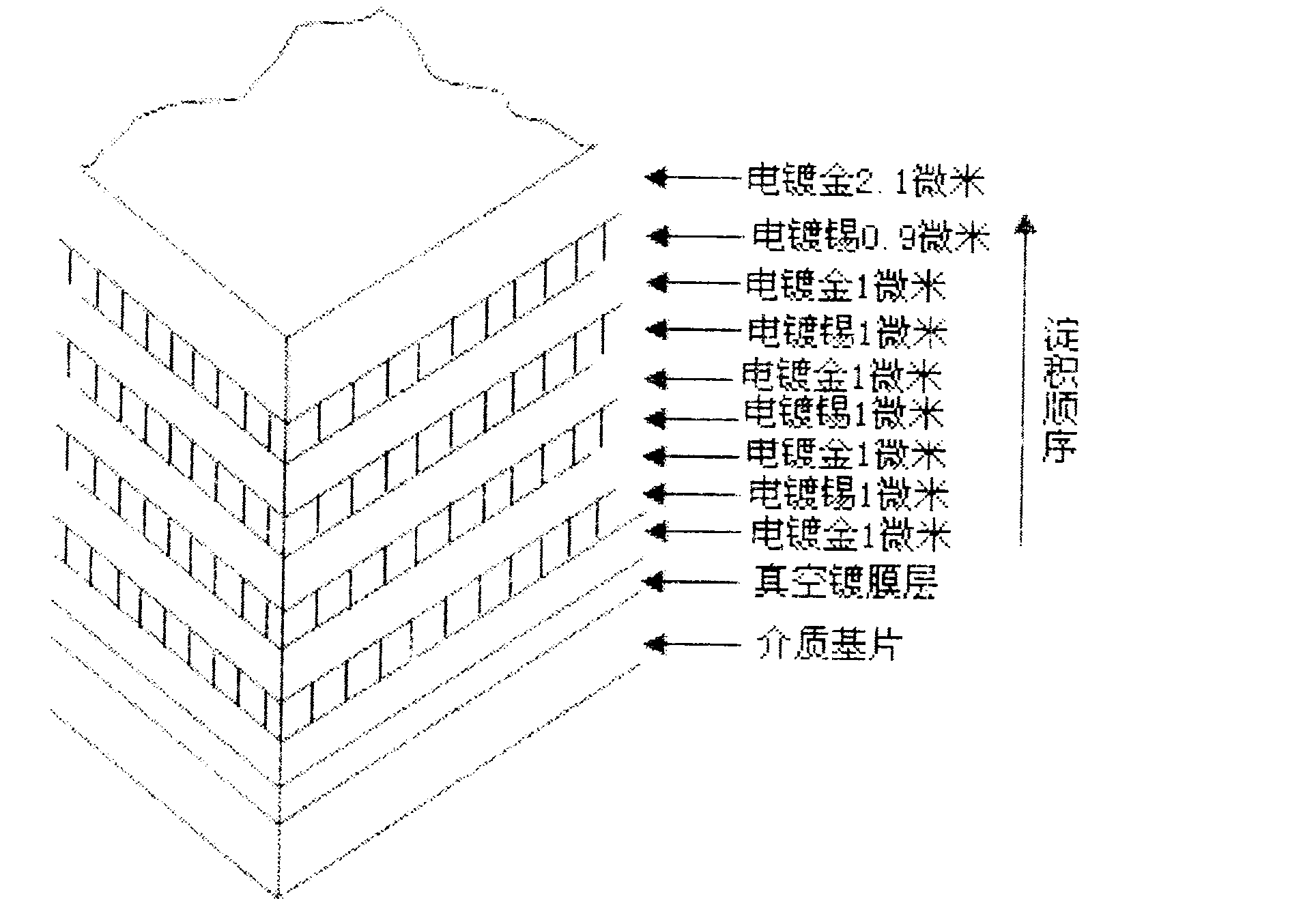

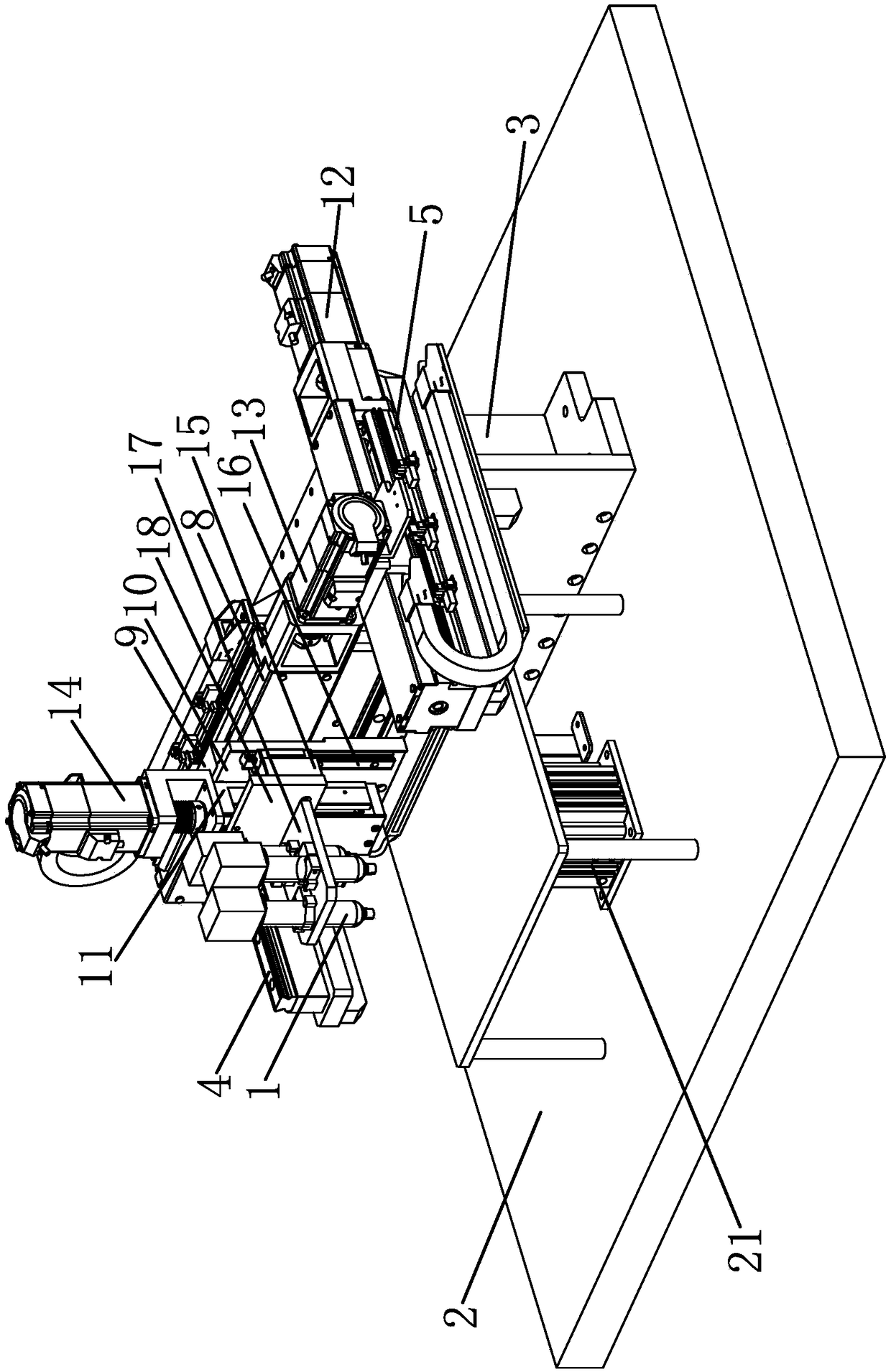

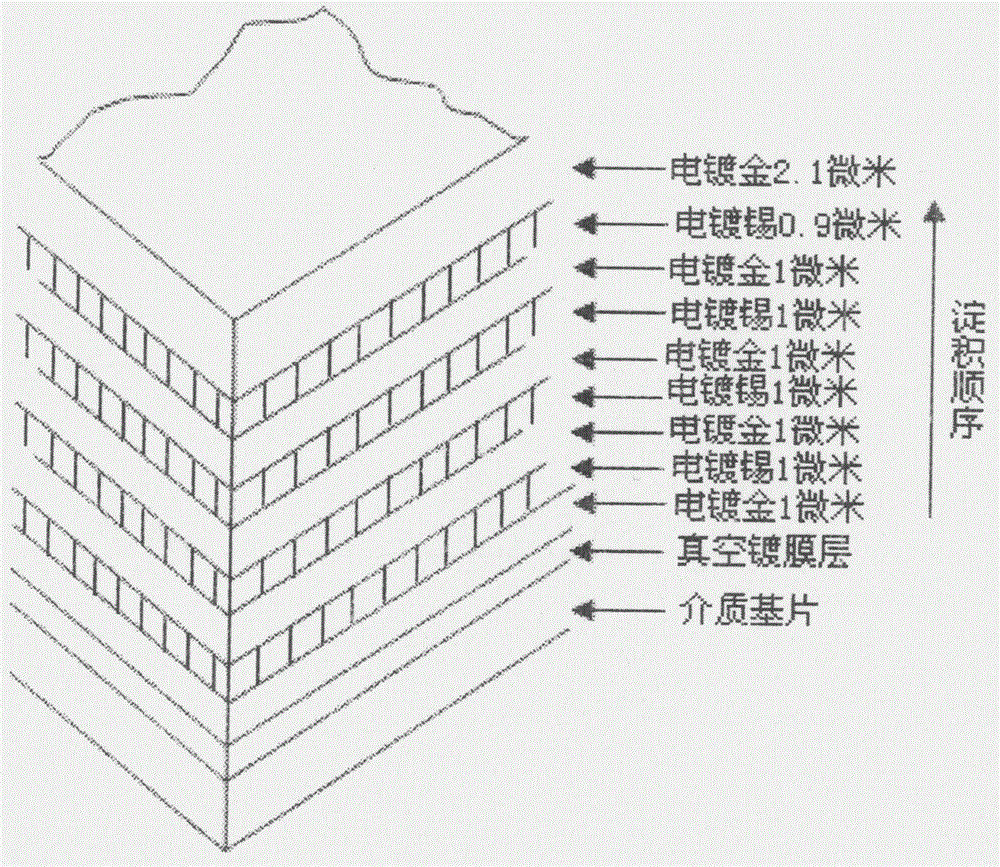

Brazed layer predeposition method

ActiveCN103264202AReduce processing workloadImprove thickness uniformitySoldering apparatusSemiconductor/solid-state device manufacturingHybrid integrated circuitSolder paste

The invention provides a brazed layer predeposition method, which comprises the following steps: A: vacuum sputtering coating a seed layer, and B: depositing each layer through a manner of sequentially alternating a gold layer and a tin layer. Through the scheme, the brazed layer predeposition method not only solves the problems existed in the prior art, and has the obvious advantages that aiming at a hybrid integrated circuit adopting braze, a process method by adopting soldering paste or soldering flux pieces in traditional soldering is improved, a layer of soldering flux layer with each component weight ratio being equivalent to components of the soldering flux pieces is deposited on a circuit soldering face (generally refers to a back face), the circuit can be directly placed on a soldering position when soldering is carried out, and soldering is realized through heating. Due to the technology, the processing workload for forming the soldering flux pieces can be reduced, and wastes caused by position offset among soldering positions, the soldering flux pieces, and the circuit to be soldered when soldering is carried out can be reduced.

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

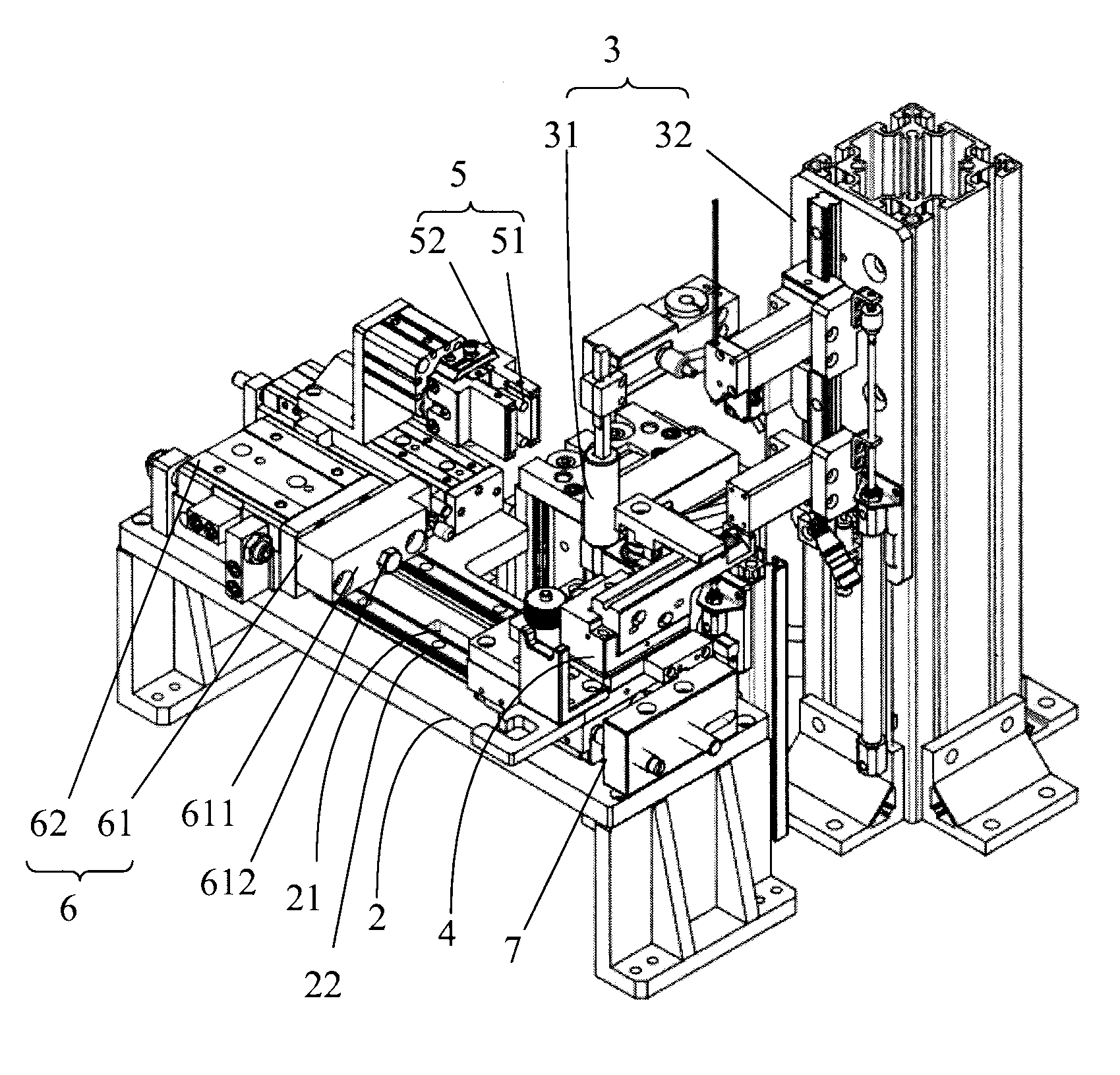

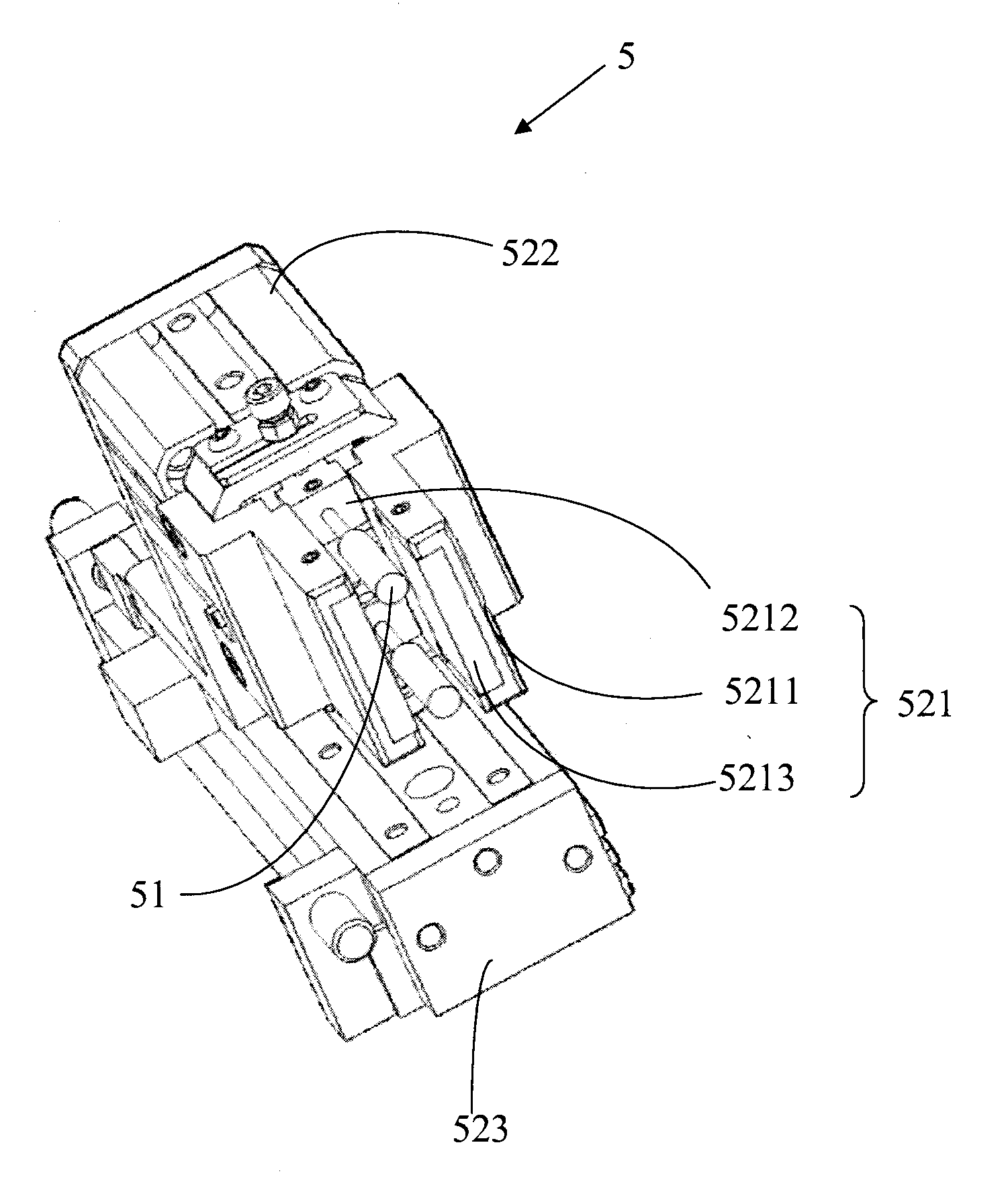

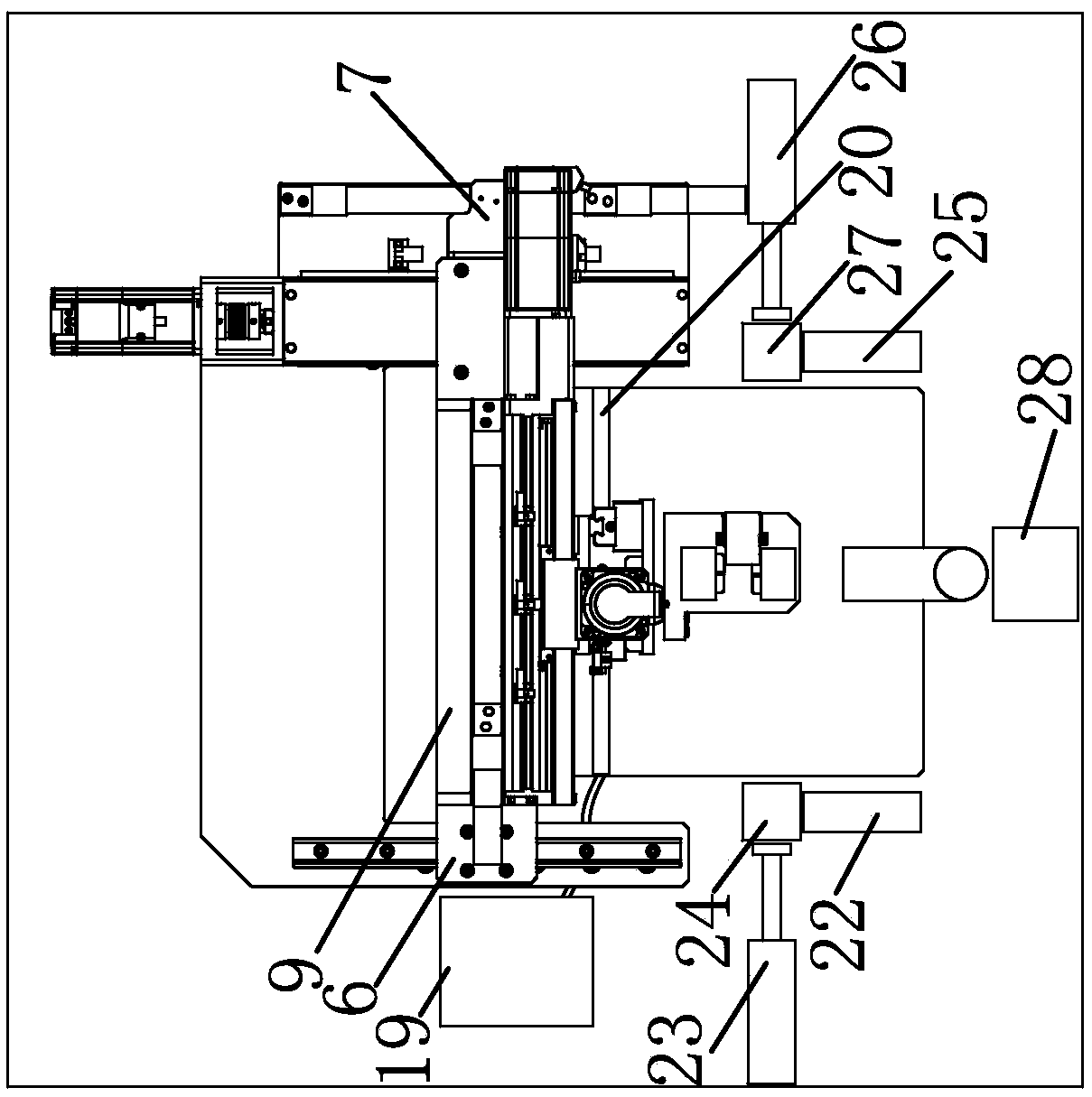

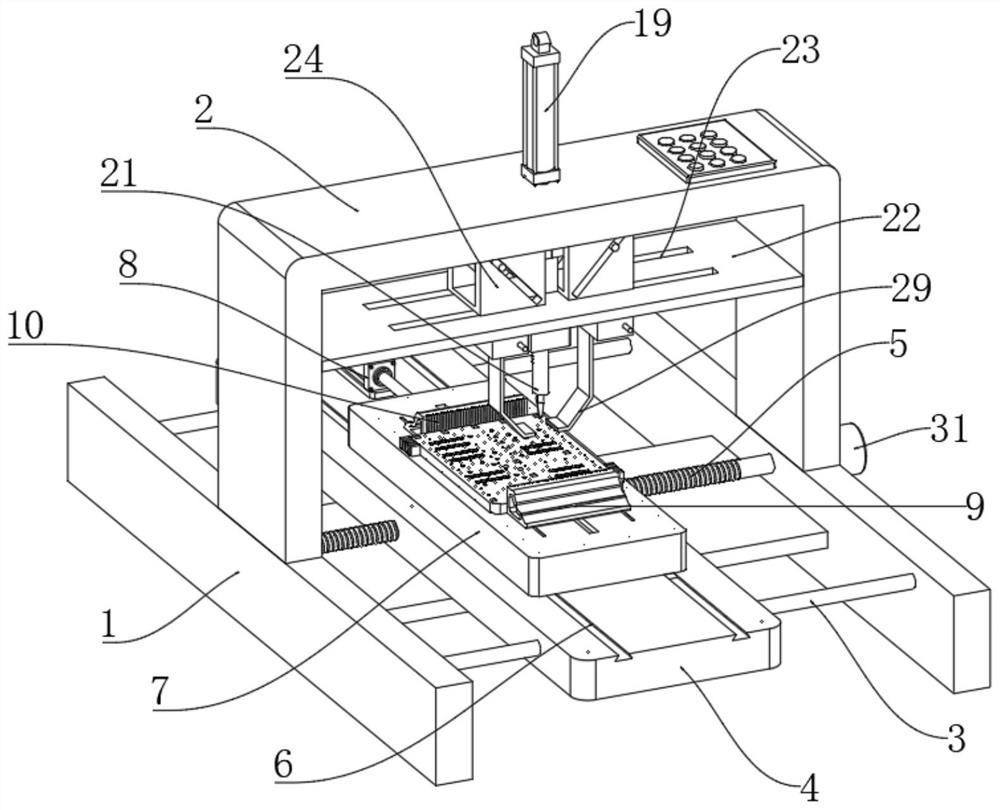

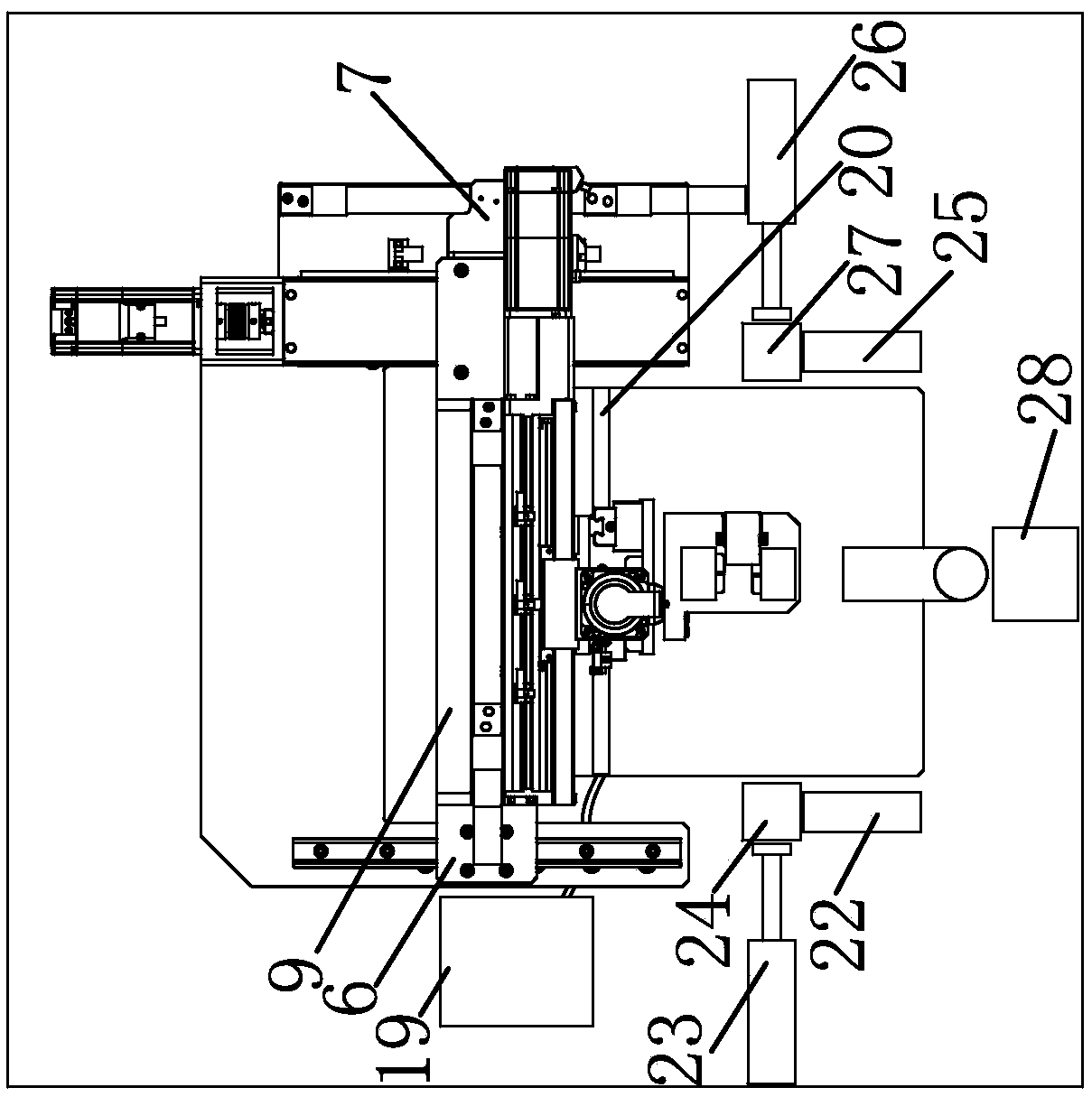

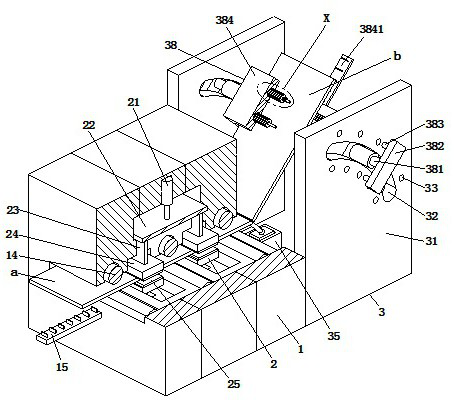

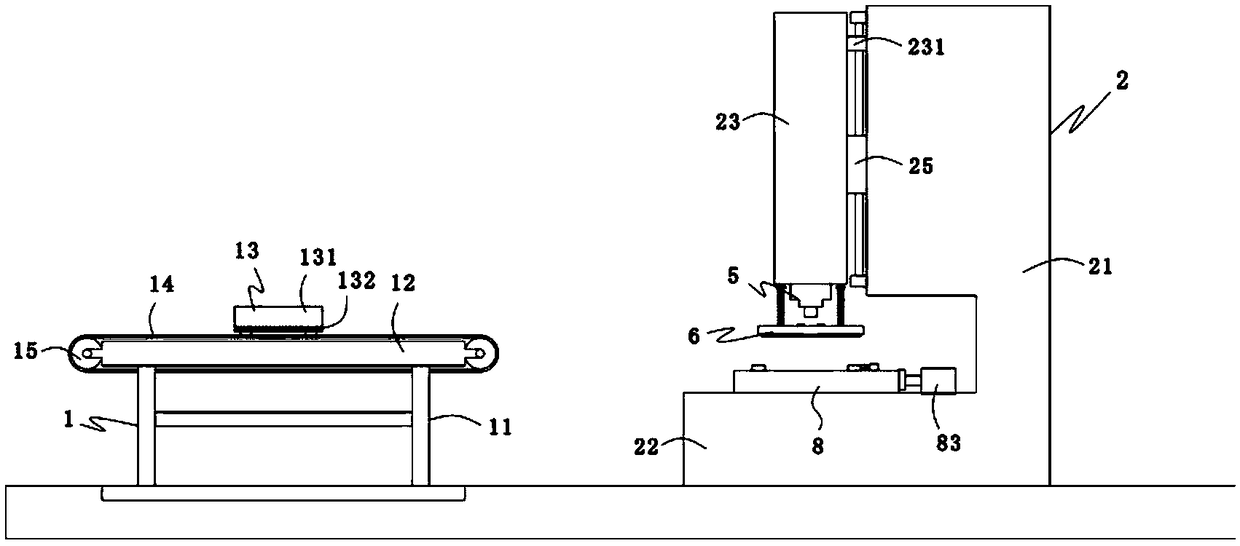

Automatic welding machine

PendingCN108655620AImprove welding efficiencyQuick unloadingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention provides an automatic welding machine, and belongs to the technical field of welding machines. The automatic welding machine solves the problem that the welding effect is poor in the prior art. The automatic welding machine comprises a working table, a welding table is arranged above the working table, a plurality of welding heads are arranged on one side of the welding table, a support is arranged on the working table, the support is provided with an X-axis displacement mechanism capable of driving the corresponding welding head to move back and forth along the X axis, a Y-axisdisplacement mechanism capable of driving the corresponding welding head to move back and forth along the Y axis and a Z axis displacement mechanism capable of driving the corresponding welding head to move back and forth along the Z axis, a first feeding mechanism capable of feeding first welding parts is arranged on one side of the welding table, a second feeding mechanism capable of feeding second welding parts is arranged on the other side of the welding table, a discharging mechanism used for discharging welding machine finished products is arranged on the front side of the welding table,and the working table is further provided with a cleaning mechanism used for removing welding sundries. The automatic welding machine has the advantage that the welding effect is improved.

Owner:浙江豪精机电有限公司

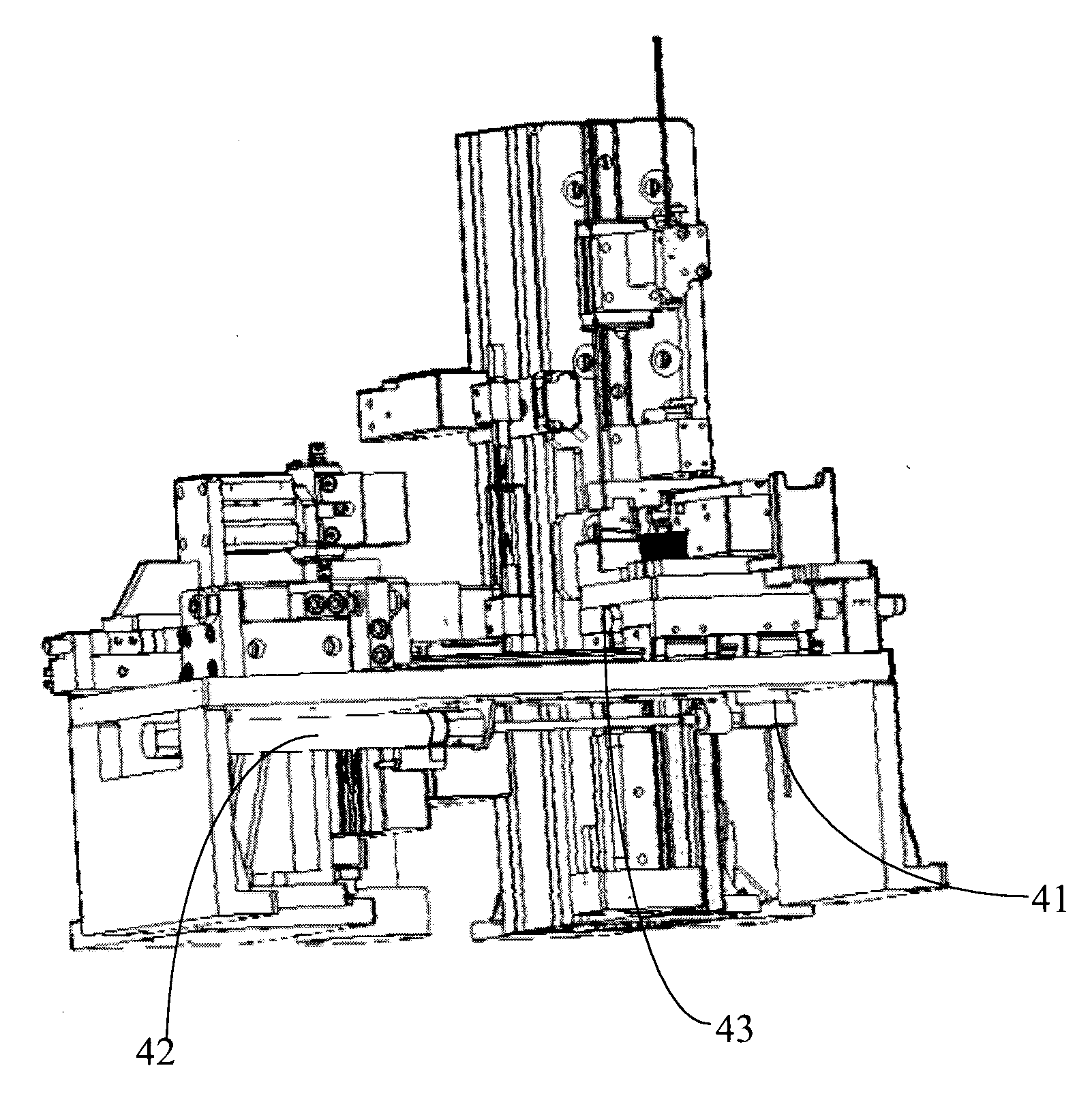

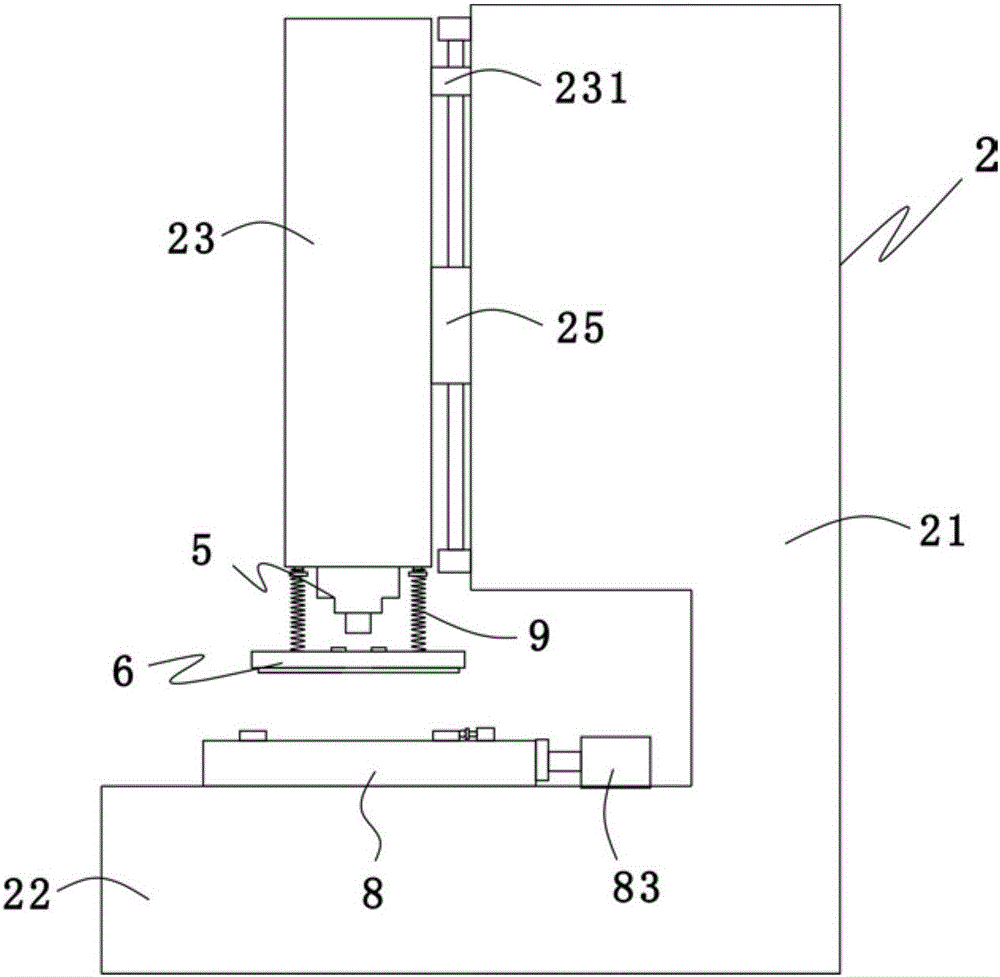

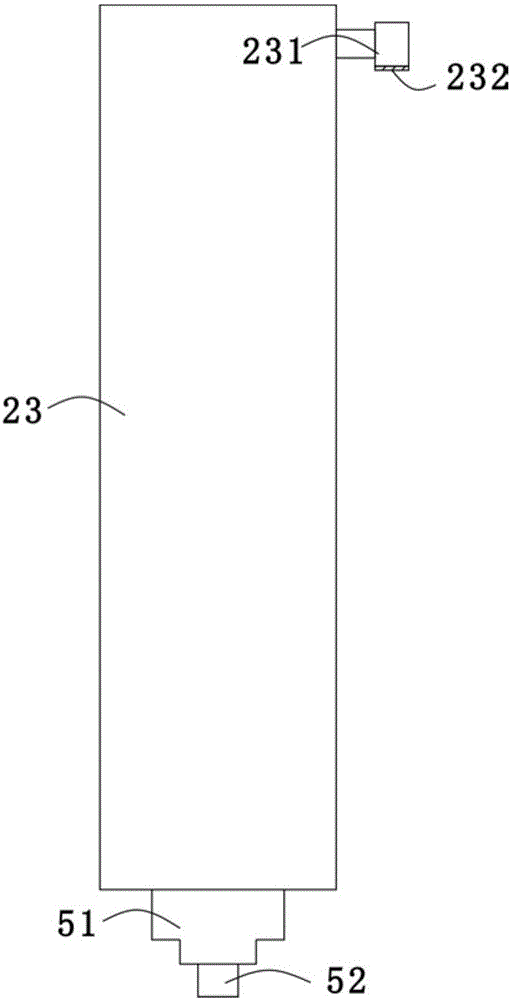

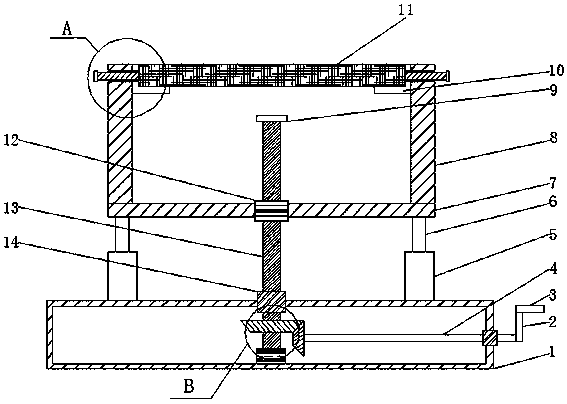

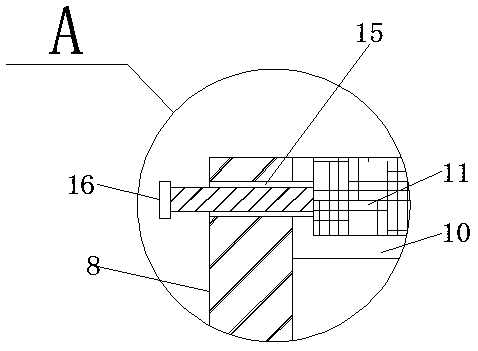

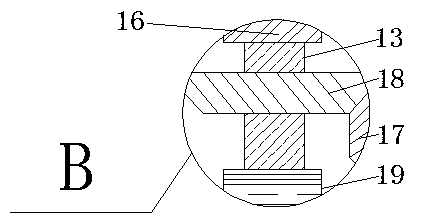

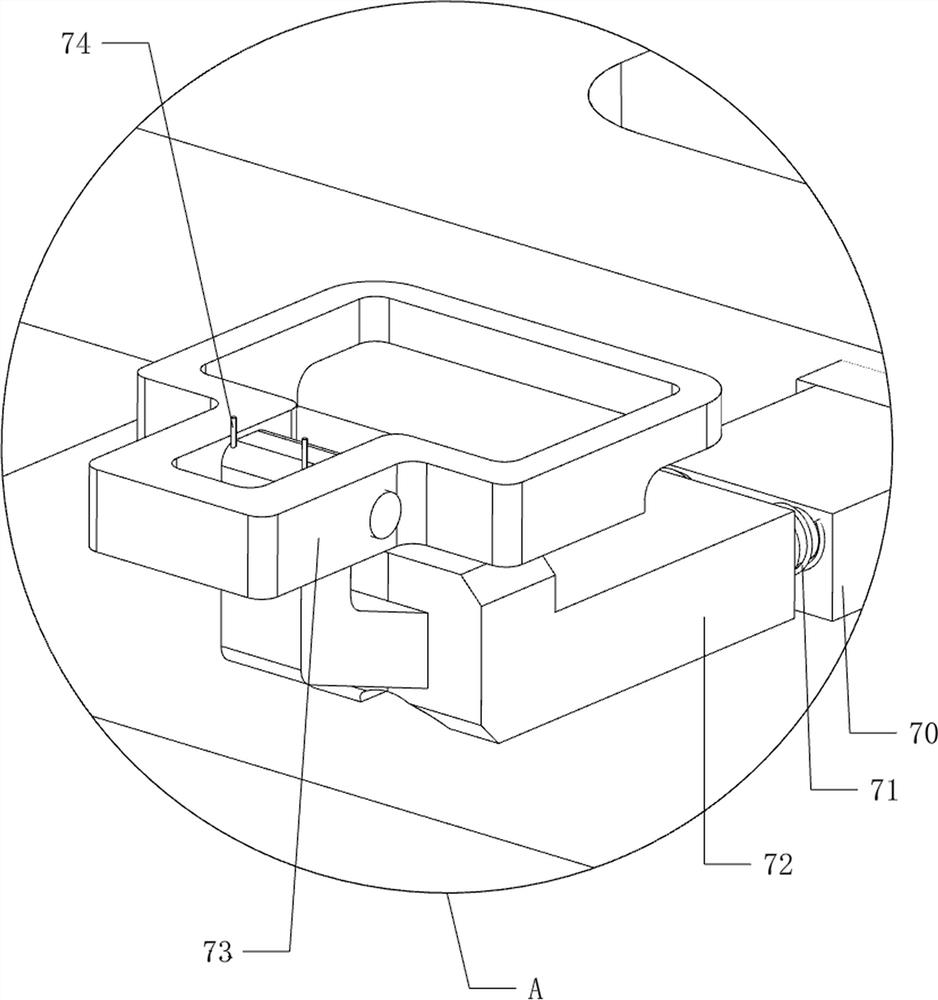

Novel pressure welding system

The invention discloses a novel pressure welding system. The novel pressure welding system comprises a cleaning unit for cleaning impurities on surfaces of to-be-machined workpieces and a pressure welding unit for performing pressure welding operation on the workpieces, wherein the pressure welding unit comprises a rack, a workbench arranged on the rack, a pressure welding power arm capable of acting along the rack up and down, a pressure welding assembly connected with the pressure welding power arm, a heating structure for heating the pressure welding assembly as well as a first drive part for driving the pressure welding power arm to act up and down; the pressure welding assembly comprises a pressure welding head and a pressure dispersion part connected to the pressure welding power arm through an elastic part, and in the initial state, the pressure dispersion part is located below a pressure welding head and above the workbench. The novel pressure welding system can effectively disperse pressure applied by the pressure welding head to the workpieces, prevent workpiece deformation or damage caused by over-high pressure on to-be-welded positions and reduce the scrap rate of the workpieces; the pressure welding position is accurate and the welding quality and efficiency are improved.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

Excavation bucket welding device for earthwork construction engineering machinery

ActiveCN109290706ANo need to hold manuallyWelding is environmentally friendly and convenientWelding/cutting auxillary devicesDirt cleaningArchitectural engineeringAirbag

The invention discloses an excavation bucket welding device for earthwork construction engineering machinery. The device comprises a base; four hydraulic oil cylinders are distributed on the left sideof the top of the base at equal intervals; the same placing tank is hinged to the tops of the four hydraulic oil cylinders; a mechanical arm is arranged on the right side of the top of the base; a dust sucking cover and an electric welding pen are connected to the top of the mechanical arm through fastening bolts in sequence; a mounting groove is formed in the bottom inner wall of the placing tank; a fixed electromagnet is arranged on the bottom inner wall of the mounting groove; the same positioning airbag is arranged around the bottom inner wall of the placing tank; and a hollow rectangularframe is arranged at the top of the placing tank. The device is suitable for welding excavation buckets with different sizes, achieves higher environmental protection and convenience during welding,has no need to manually hold plate raw materials, prevents influence on the filtering effect by accumulation of dust on one side of a filter net plate, and meanwhile, prevents influence on the weldingeffect by falling of the dust in the placing tank.

Owner:临沂市宇顺机械有限公司

Welding device with air purification function

InactiveCN111872553APlay a warm-up effectAvoid burnsLaser beam welding apparatusEngineeringErbium lasers

The invention relates to a welding device with an air purification function. The device comprises a workbench, a control box and a laser device, wherein the control box is arranged above the workbenchand fixedly connected with the workbench, the laser device is arranged at the bottom of the control box, an execution system is arranged in the control box, and a purification mechanism and an auxiliary mechanism are arranged at the bottom of the control box; the auxiliary mechanism comprises a fixed pipe, a rotating pipe, a rotating ring, a first bearing, a driving assembly and two auxiliary assemblies; each auxiliary assembly comprises a cleaning rod, a sliding block, a supporting rod, a spring and two fixed blocks; and the purification mechanism comprises a fixed bevel gear and two purification assemblies. According to the welding device with the air purification function, the function of removing impurities on a workpiece is achieved through the auxiliary mechanism, so that the welding effect is prevented from being affected by the impurities; and in addition, the air purification function is achieved through the purification mechanism.

Owner:GUANGZHOU LINDIAN TECH CO LTD

An elbow joint flange welding forming machine

ActiveCN113601074BEasy alignmentImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringPipe welding

Owner:徐州市瑞泰钢管有限公司

Ultrasonic hot drilling device with optical fiber laser lamp

ActiveCN109249735APrevent crushingPrevent affecting the welding effectInlaying equipmentLaser beam welding apparatusEngineeringUltrasonic generator

The invention provides an ultrasonic hot drilling device with an optical fiber laser lamp. The ultrasonic hot drilling device comprises an in intelligent system, a control box and a base. The intelligent system comprises a sensing device and a control device, the sensing device comprises a temperature sensor and a pressure sensor, the control device comprises the optical fiber laser lamp, a motor,an ultrasonic generator, a pneumatic telescopic rod and an electric valve, a motor box is welded on the control box, the pneumatic telescopic rod comprises an air cylinder and a telescopic rod, the air cylinder is welded on the inner side wall of the motor box via first motor bases, first mounting holes and second mounting holes are formed in the bottom of the control box, and the telescopic rodis welded on the inner side walls of the first mounting holes. The ultrasonic hot drilling device with the optical fiber laser lamp has the advantages that the ultrasonic hot drilling device is novelin design and has diversified functions, and the hot connection efficiency can be effectively improved.

Owner:永嘉思慧特工业设计有限公司

Positioning device for steel production welding

InactiveCN112404843AEasy to moveEasy to fixWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStructural engineering

The invention discloses a positioning device for steel production welding which comprises a device base and a steel placing plate. A positioning adjusting sliding groove is formed in the upper part ofthe device base; positioning supporting rods are arranged in the positioning adjusting sliding groove; a buffer spring is arranged on the left side of one positioning supporting rod; a pushing air cylinder is arranged on the right side of the positioning supporting rod; transverse rods are arranged above the positioning supporting rods; tightening bolts are arranged on the surfaces of the transverse rods; first pressing blocks are arranged below the tightening bolts; second pressing blocks are arranged below the first pressing blocks; pressing plate sliding grooves are formed in the surfacesof the positioning supporting rods; and the steel placing plate is arranged on the left side of the positioning adjusting sliding groove. The positioning device for steel production welding is provided with the first pressing blocks and the second pressing blocks, so that positioning and fixing of steel can be achieved; and the distances between the first pressing blocks and the second pressing blocks can be adjusted by the tightening bolts, so that positioning and fixing of steel with different thicknesses are achieved, and welding is facilitated.

Owner:湖南武陵机械制造有限公司

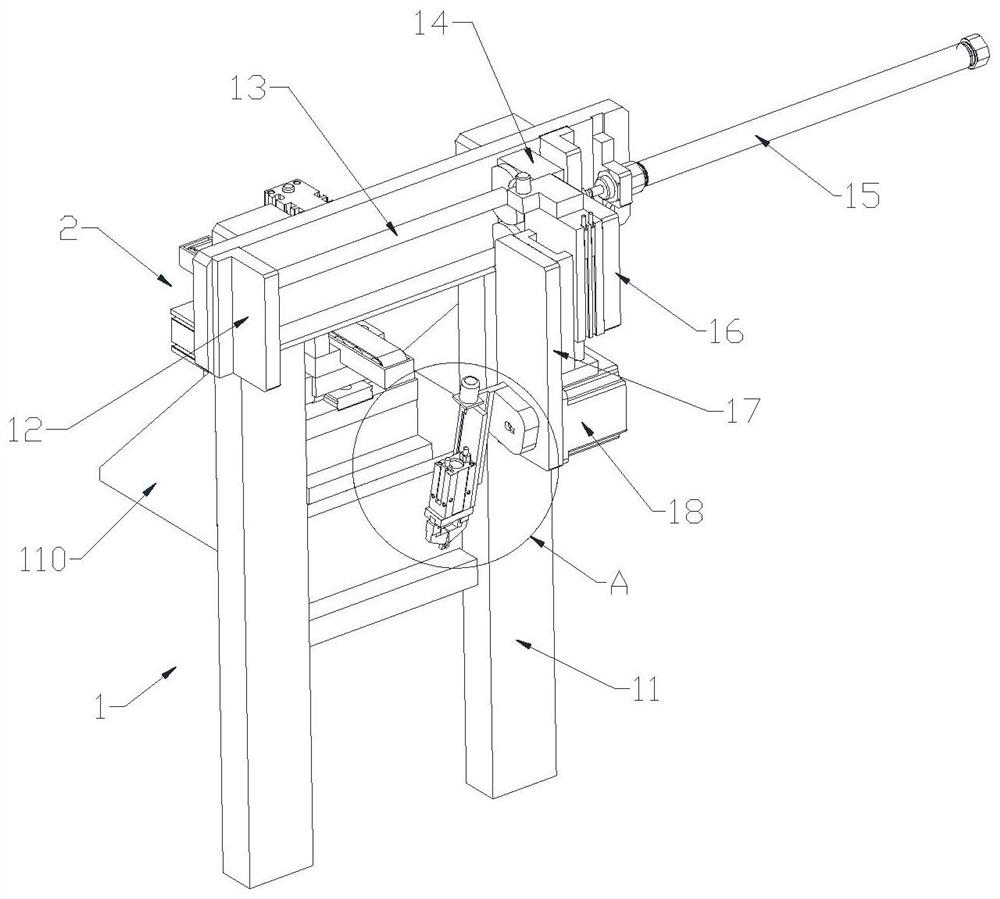

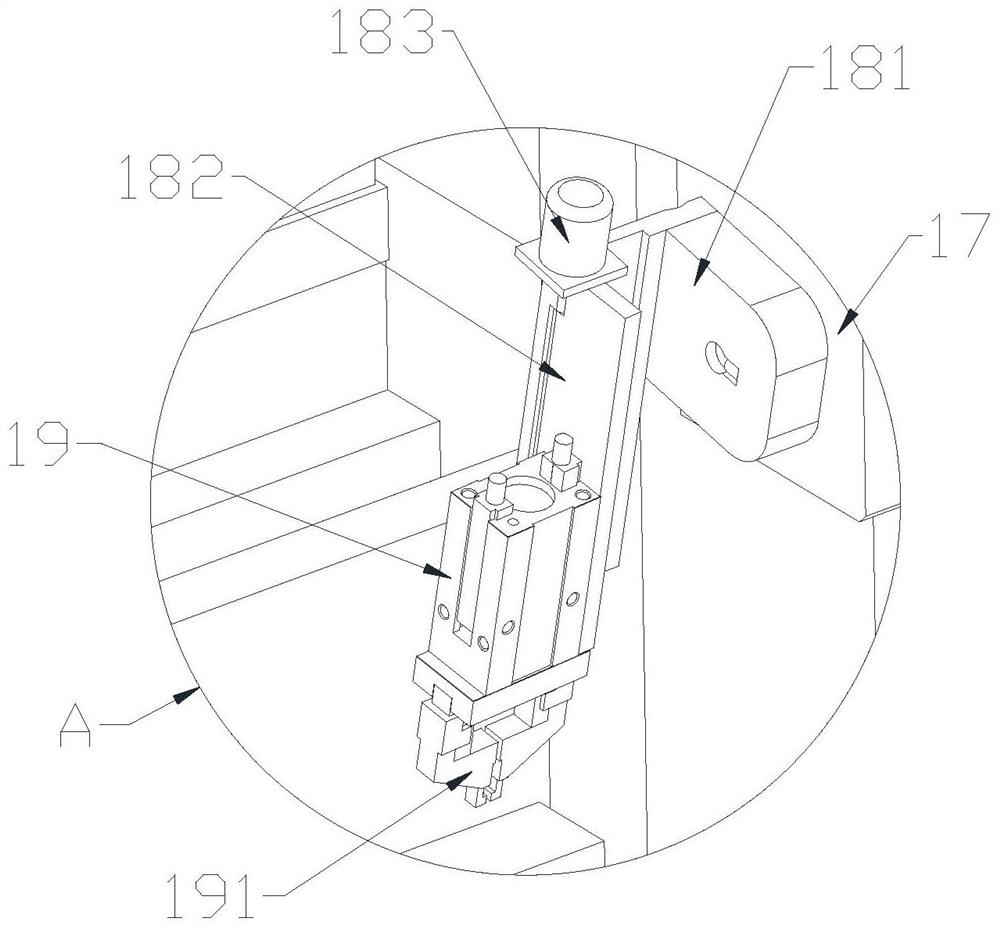

Photosensitive sensing assembly manufacturing device of automobile data recorder

ActiveCN114309868APrecise deliveryAvoid errorsSoldering auxillary devicesElectric machineryEngineering

The invention discloses an automobile data recorder photosensitive sensing assembly manufacturing device which comprises a device base, a gantry support is fixedly installed on the device base, a horizontal guide rod is fixedly installed on the device base, a main sliding seat is slidably installed on the horizontal guide rod, and the main sliding seat is in threaded connection with a first lead screw; the first lead screw is driven by a first motor, a main sliding groove is formed in the main sliding seat, a secondary sliding seat is slidably mounted in the main sliding groove, a limiting sliding groove is formed in the surface of the secondary sliding seat, and the secondary sliding seat is slidably connected with a first clamping block and a second clamping block through the limiting sliding groove; and the first clamping block and the second clamping block are mounted on a driving structure with a speed multiplication function through a connecting rod. Through the work of the main sliding seat and the secondary sliding seat, the photosensitive circuit assembly can be quickly conveyed to a specified part, and the photosensitive circuit assembly can be moved for multiple times in the welding process to accurately find a welding part, so that the welding gun does not need to horizontally move, and the welding error of the welding gun is prevented.

Owner:深圳咏华盛世技术有限公司

Welding device of CO2 ceramic lining

InactiveCN110216351AHeight adjustablePrevent affecting the welding effectArc welding apparatusMechanical engineering

The invention discloses a welding device of a CO2 ceramic lining. The welding device comprises a base, a mounting plate and the ceramic lining. A bearing seat is fixedly mounted at the middle positionat the bottom end in the base. A shaft sleeve is fixedly mounted at the middle position of the top of the base. A threaded rotating shaft is movably mounted on the base through the bearing seat. Oneend of the threaded rotating shaft penetrates through the base through the shaft sleeve. A second gear is mounted at the bottom of the threaded rotating shaft in a sleeved connection manner. The second gear is located in the base. The shaft sleeve is arranged at the middle position of one side of the base. A rotating rod is movably mounted on the base through the shaft sleeve. A first gear is fixedly mounted at one end of the rotating rod and is located on one side of the second gear, and the first gear is engaged with the second gear. Through a series of structures, the device has the advantages that the ceramic lining can be conveniently fixed, and the height of the ceramic lining can be adjusted conveniently.

Owner:鹤壁天宏钢结构有限公司

Ultrasonic automatic rotary disc type plastic welder

The invention discloses an ultrasonic automatic rotary disc type plastic welder. The ultrasonic automatic rotary disc type plastic welder comprises a supporting assembly, a welding assembly and a fixing assembly, wherein the supporting assembly comprises a fixed base, a stand column, a supporting base, a supporting table, a hydraulic pump, a hydraulic pipeline, a hydraulic cylinder and an electrical box; the fixed base is fixedly connected to the hydraulic pump and the electrical box separately; the electrical box is positioned above the fixed base; when plastic is fixedly arranged on the rotary disc, a handle can be pulled for separating first clamps from second clamps; the handle is loosened, and the rotary disc and a torsion bracket fix the plastic by the first clamps and the second clamps via a torsion spring, so that the clamps fix the plastic more firmly to prevent plastic from deviating during welding to affect the welding affect; and compared with a conventional plastic fixingmethod, a novel plastic welder further increases the yield of the welded product while improving working efficiency.

Owner:SUZHOU LIN XINYUAN AUTOMATION TECH CO LTD

Plastic pipe hot melting welding machine

InactiveCN109703041APrevent slipping outReduce the effect of weldingTubular articlesWater pipeEngineering

The invention belongs to the technical field of plastics, and particularly relates to a plastic pipe hot melting welding machine. The welding machine includes a mounting shell, a preset spring, a hotmelting block, driving arms, a limiting plate, a driving mechanism, a trigger mechanism and a driving swing rod, according to the plastic water pipe welding machine, firstly, the driving swing rod iscontrolled to swing downwards, thus two plastic pipes are heated through a hot melting machine, then the driving swing rod is controlled to swing upwards, thus the two driving arms firstly drive the plastic pipes to move away to the two sides, then the driving swing rod swings upwards to control the hot melting block to move upwards, after the hot melting block completely moves to the upper side,the driving swing rod is again driven to swing downwards, the two driving arms are controlled to drive the plastic pipes to move by driving the driving swing rod, and finally, the two plastic pipes are welded together through contact pressure adding. The phenomena that the welding effect is affected and the leakage openings are caused by welding due to the fact that pipe orifices cannot be aligneddue to manual pressure on the two plastic pipes are avoided; and meanwhile the phenomenon that welding effect is affected due to the fact that the plastic pipes heated originally is solidified due toheating for twice is prevented.

Owner:圣大管业科技股份有限公司

Cleaning mechanism for automatic welding machine

PendingCN108714751AImprove welding efficiencyGuarantee welding qualityWelding/cutting auxillary devicesAuxillary welding devicesWeldingEngineering

The invention provides a cleaning mechanism for an automatic welding machine, belongs to the technical field of welding machines, and solves the problem that a welding table cannot be cleaned in the prior art. In the cleaning mechanism for the automatic welding machine, the automatic welding machine comprises a working table, wherein the welding table is arranged above the working table; a plurality of welding heads is arranged at one side of the welding table; a bracket is arranged on the working table; the cleaning mechanism is arranged on the welding table and comprises a fan and a waste box; the waste box is fixed at one side of the working table; a dust collection box is arranged on the working table; the dust collection box is communicated with the waste box through an air duct; andthe fan is arranged in the air duct. The cleaning mechanism has the advantage of automatically cleaning the welding table.

Owner:浙江豪精机电有限公司

A kind of brazing layer pre-deposition method

ActiveCN103264202BReduce processing workloadReduce causeSoldering apparatusSemiconductor/solid-state device manufacturingSputteringWorkload

The invention provides a brazed layer predeposition method, which comprises the following steps: A: vacuum sputtering coating a seed layer, and B: depositing each layer through a manner of sequentially alternating a gold layer and a tin layer. Through the scheme, the brazed layer predeposition method not only solves the problems existed in the prior art, and has the obvious advantages that aiming at a hybrid integrated circuit adopting braze, a process method by adopting soldering paste or soldering flux pieces in traditional soldering is improved, a layer of soldering flux layer with each component weight ratio being equivalent to components of the soldering flux pieces is deposited on a circuit soldering face (generally refers to a back face), the circuit can be directly placed on a soldering position when soldering is carried out, and soldering is realized through heating. Due to the technology, the processing workload for forming the soldering flux pieces can be reduced, and wastes caused by position offset among soldering positions, the soldering flux pieces, and the circuit to be soldered when soldering is carried out can be reduced.

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

A thin steel plate welding equipment for tooling processing of petroleum accessories

ActiveCN114043120BImprove stabilityImprove applicabilityWelding/cutting auxillary devicesAuxillary welding devicesSheet steelWelding defect

The invention relates to the technical field of tooling processing of petroleum accessories, in particular to a thin steel plate welding equipment for tooling processing of petroleum accessories, which includes a base, a fixing unit and a welding unit, the fixing unit is installed inside the base, and the welding unit is arranged on the base Right end; the present invention can solve the problems existing in the welding between thin steel plates: two thin steel plates are usually butted manually, so that the angle between the steel plates cannot be effectively controlled, so that the two thin steel plates lack precision when butt jointed, and it is easy to cause two Large gaps and dislocations appear at the joints of the two thin steel plates, thereby affecting the welding effect; the present invention can respectively limit and fix the two thin steel plates, so that the stability of the thin steel plates during welding can be improved, thereby avoiding welding defects; The invention can adjust the angle between two thin steel plates, thereby enhancing the welding effect and improving the applicability of the equipment.

Owner:山东柏源技术有限公司

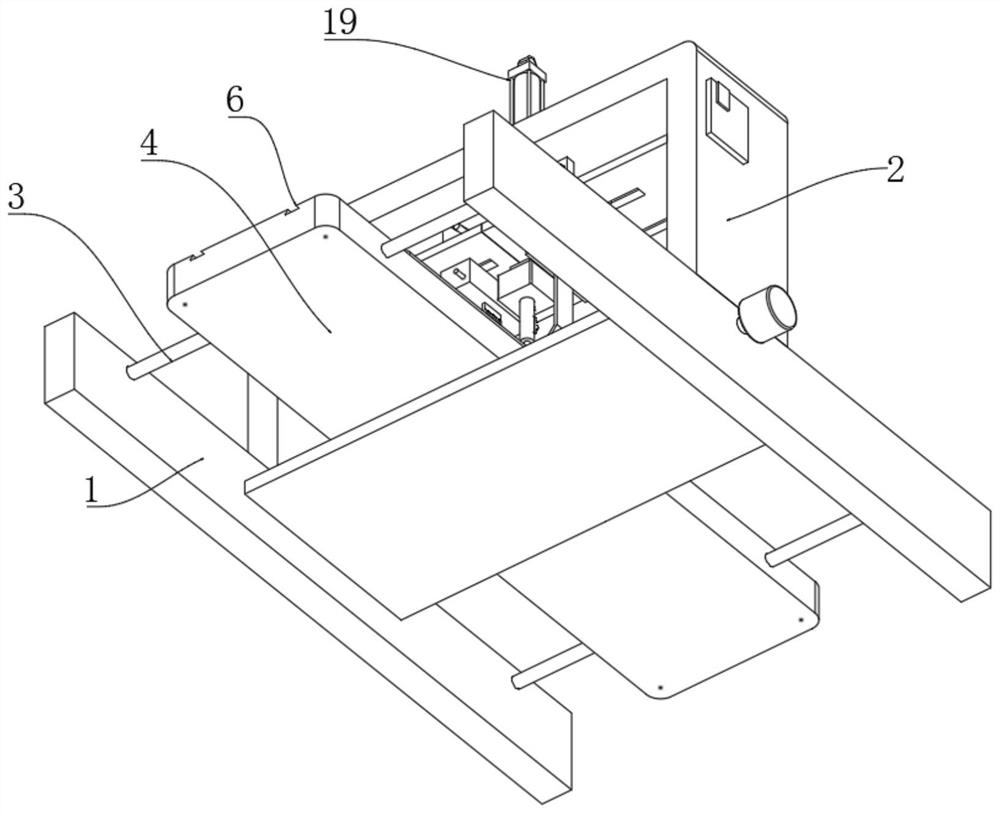

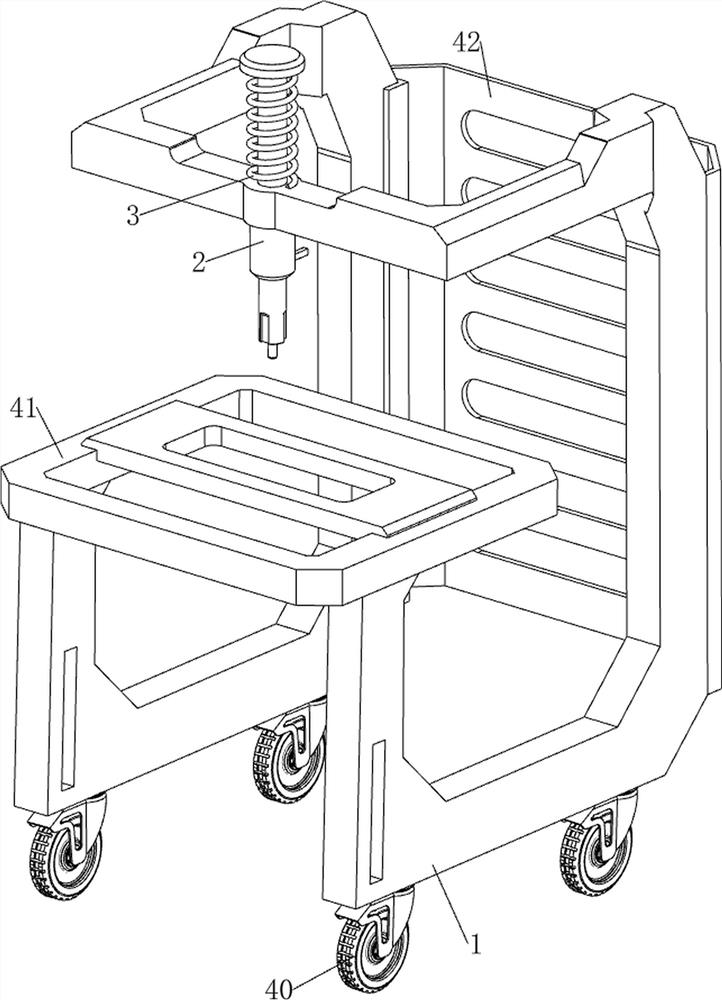

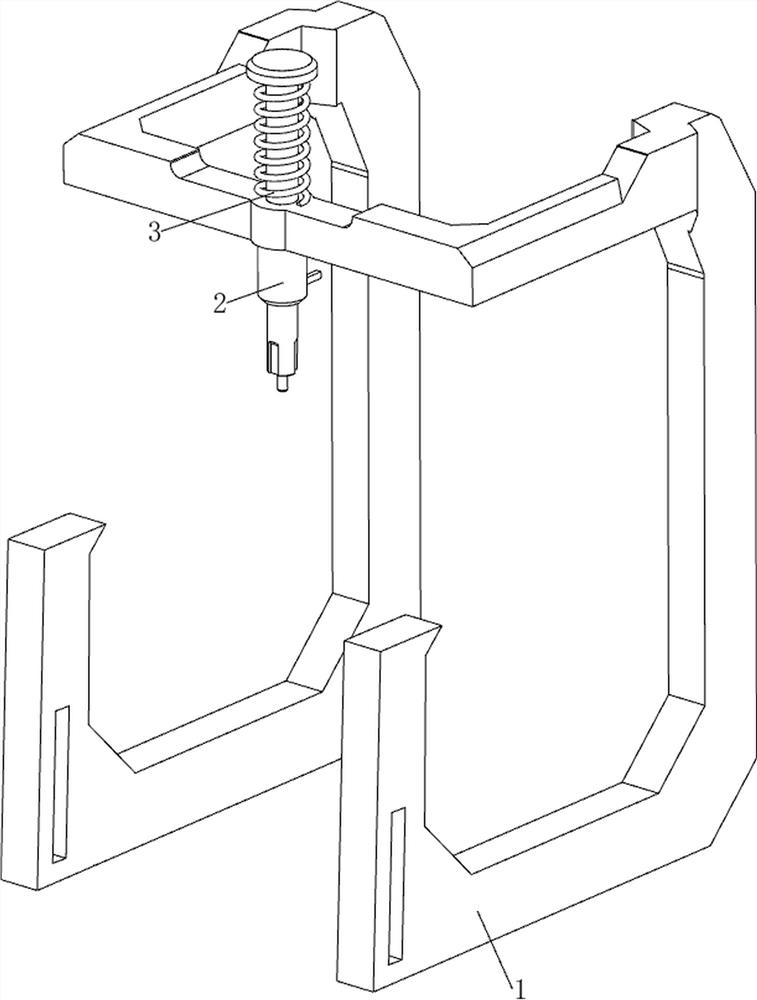

Movable workbench for electronic component welding

PendingCN113828980APrevent affecting the welding effectWelding/cutting auxillary devicesAuxillary welding devicesEngineeringElectronic component

The invention relates to a workbench, and particularly relates to a movable workbench for electronic component welding. The movable workbench for electronic component welding replaces a manual control welding gun with a machine, meanwhile, a contact of the welding gun is positioned during welding, safety accidents caused by shaking of the contact are prevented, and the welding efficiency is guaranteed. The movable workbench for electronic component welding comprises a mounting frame, the welding gun, a first spring, a moving mechanism and a pressing mechanism, wherein the welding gun is arranged on one side of the top of the mounting frame in a sliding mode, the first spring is connected between the welding gun and the top of the mounting frame, the moving mechanism is arranged on the outer side of the mounting frame, and the pressing mechanism is arranged on the lower portion of the mounting frame. The pressing mechanism and the moving mechanism are arranged, the welding gun is driven to move downwards to make contact with an electric plate, a welding head emits heat to weld the electric plate, and basic functions are achieved.

Owner:深圳市六盛世纪电子有限公司

A pressure welding system

The invention discloses a novel pressure welding system. The novel pressure welding system comprises a cleaning unit for cleaning impurities on surfaces of to-be-machined workpieces and a pressure welding unit for performing pressure welding operation on the workpieces, wherein the pressure welding unit comprises a rack, a workbench arranged on the rack, a pressure welding power arm capable of acting along the rack up and down, a pressure welding assembly connected with the pressure welding power arm, a heating structure for heating the pressure welding assembly as well as a first drive part for driving the pressure welding power arm to act up and down; the pressure welding assembly comprises a pressure welding head and a pressure dispersion part connected to the pressure welding power arm through an elastic part, and in the initial state, the pressure dispersion part is located below a pressure welding head and above the workbench. The novel pressure welding system can effectively disperse pressure applied by the pressure welding head to the workpieces, prevent workpiece deformation or damage caused by over-high pressure on to-be-welded positions and reduce the scrap rate of the workpieces; the pressure welding position is accurate and the welding quality and efficiency are improved.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

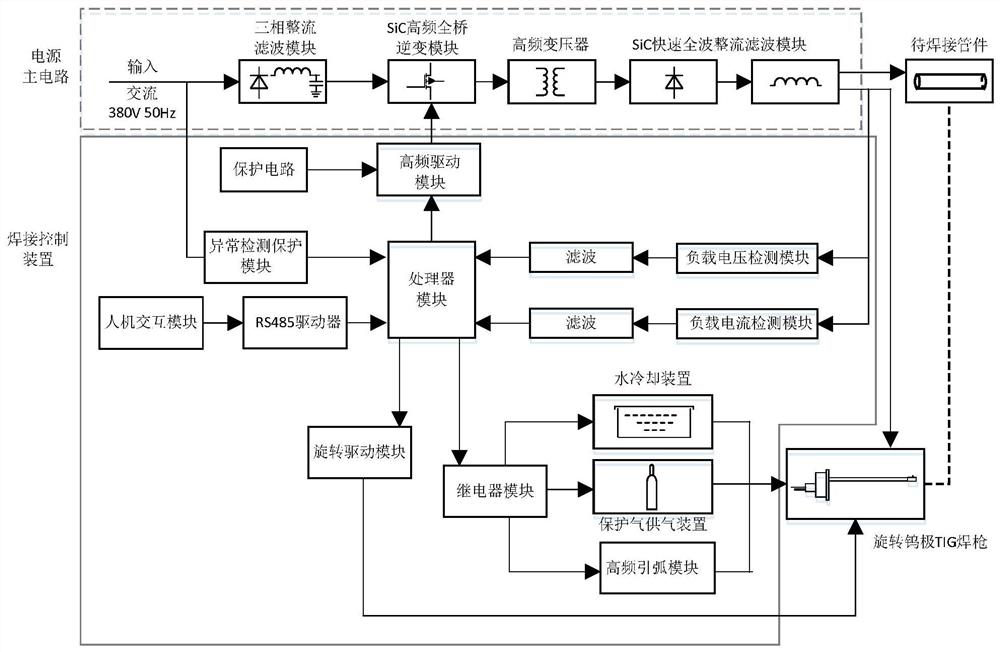

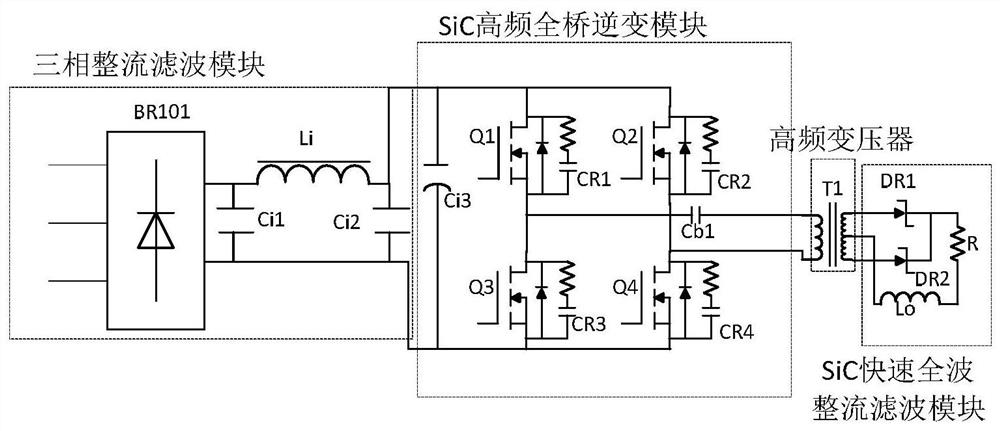

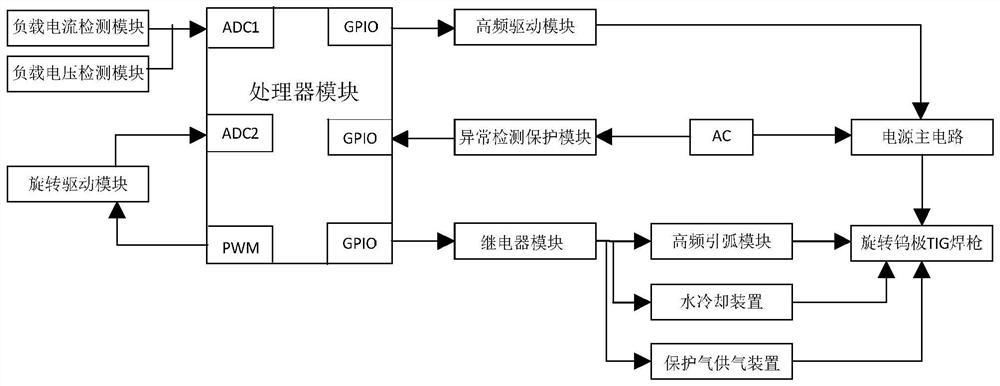

A rotary tungsten electrode tig welding system for inner wall welding of extremely small diameter pipe fittings

ActiveCN113814532BAdapt to welding needsSolve needsShielding gas supply/evacuation devicesElectrode supporting devicesWelding power supplyShielding gas

The invention provides a rotary tungsten electrode TIG welding system for welding the inner wall of an extremely small diameter pipe, which is characterized in that it comprises a rotary tungsten electrode TIG welding torch, a high-frequency inverter welding power source, a water cooling device and a protective gas supply device; The variable welding power source includes the main circuit of the power source and the welding control device; the rotating tungsten electrode TIG welding torch includes a conductive rod with a tungsten electrode and a rotary device; the conductive rod is connected with the main circuit of the power source; the main circuit of the power source and the rotary device are respectively connected with the welding control device; The welding control device is connected with the conductive rod through the high-frequency arc striking module; the shielding gas supply device and the water cooling device are respectively connected with the conductive rod. The system can realize the welding of the inner wall of extremely small-diameter pipe fittings, and can solve the problem of water cooling and air supply in narrow spaces. The structure is ingenious and flexible, and has good adaptability to wide working conditions.

Owner:SOUTH CHINA UNIV OF TECH

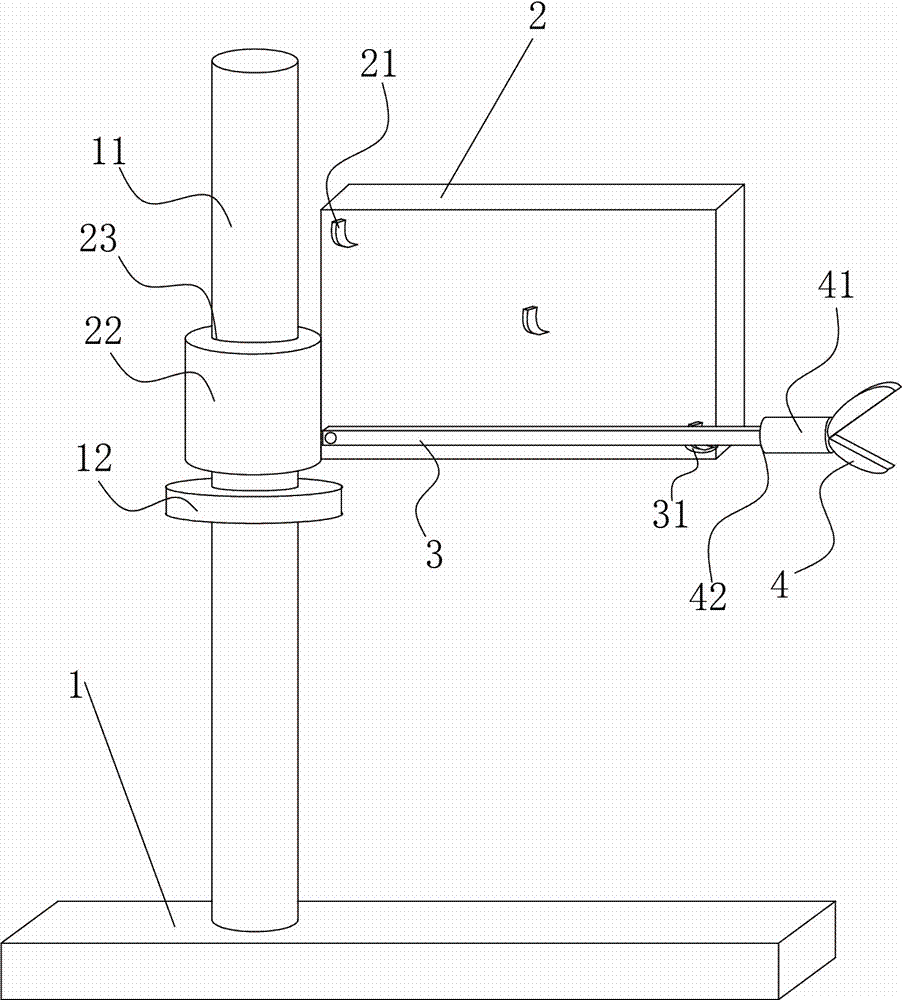

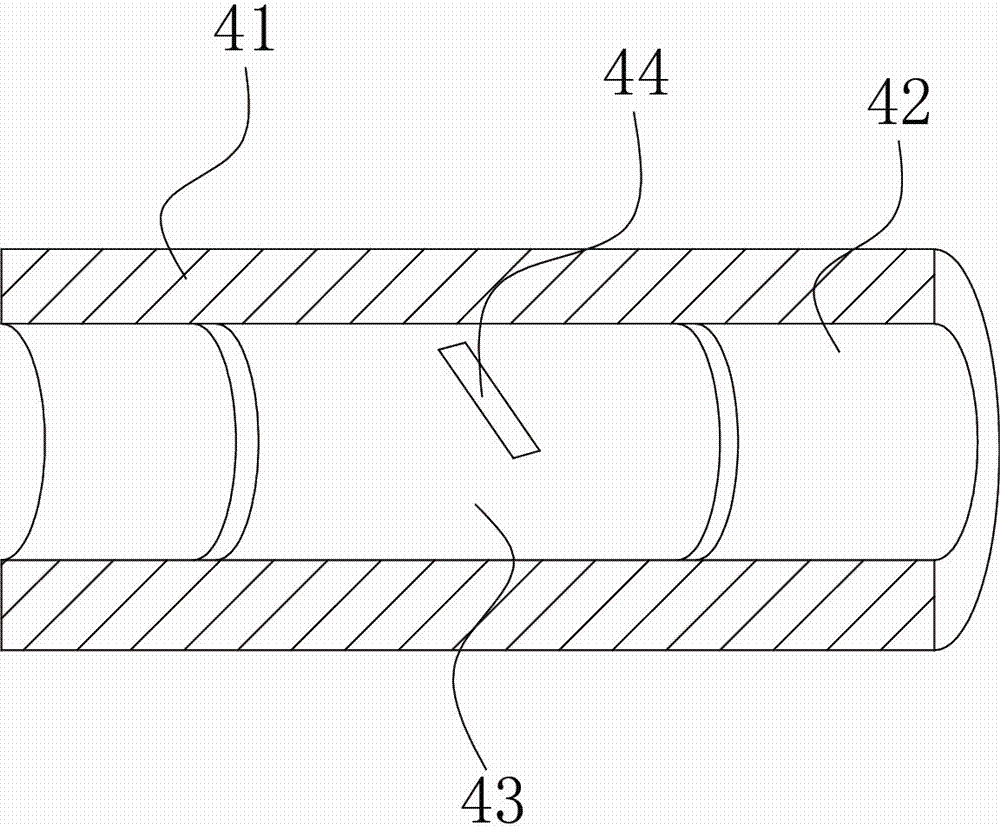

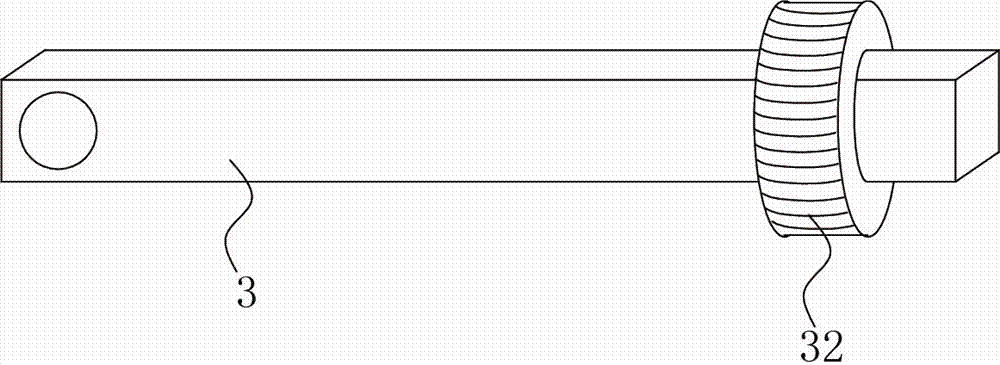

An adjustable bracket for welders to practice welding

ActiveCN103978327BAdjustable angleEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPhysical exercise

Owner:NINGBO MINGXIN CHEM MACHINERY

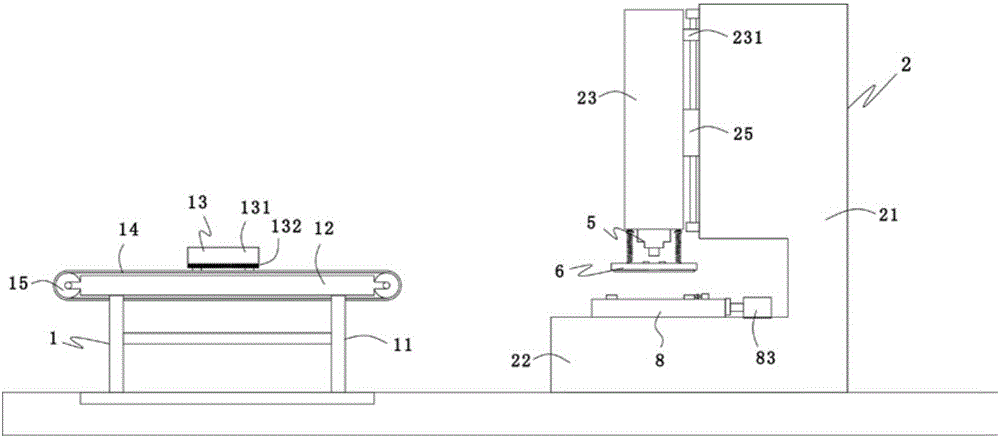

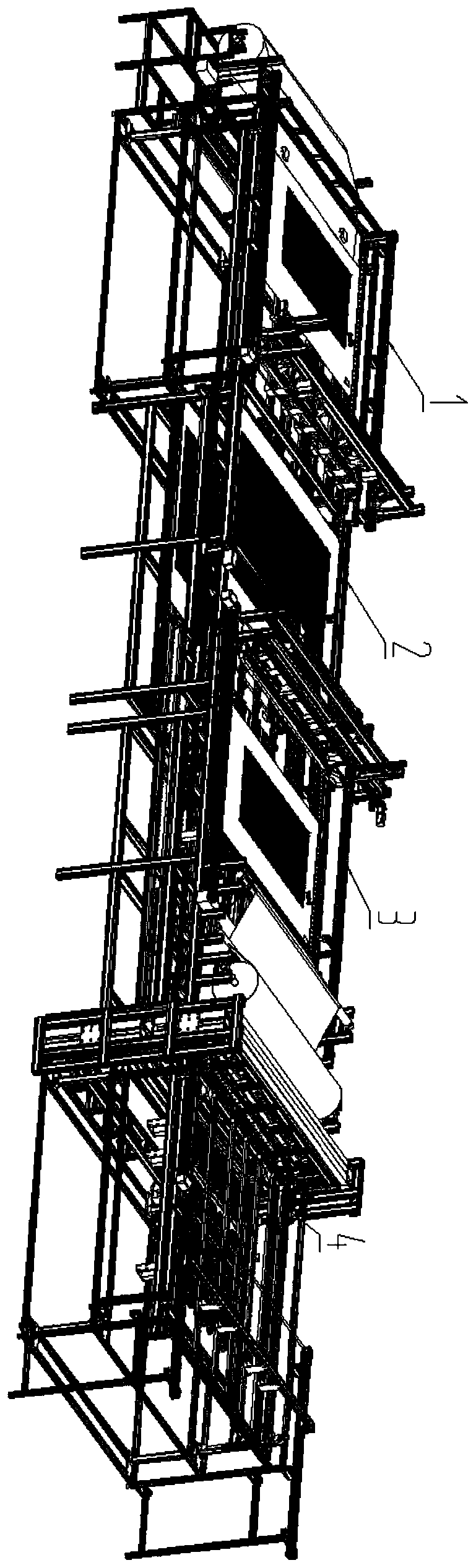

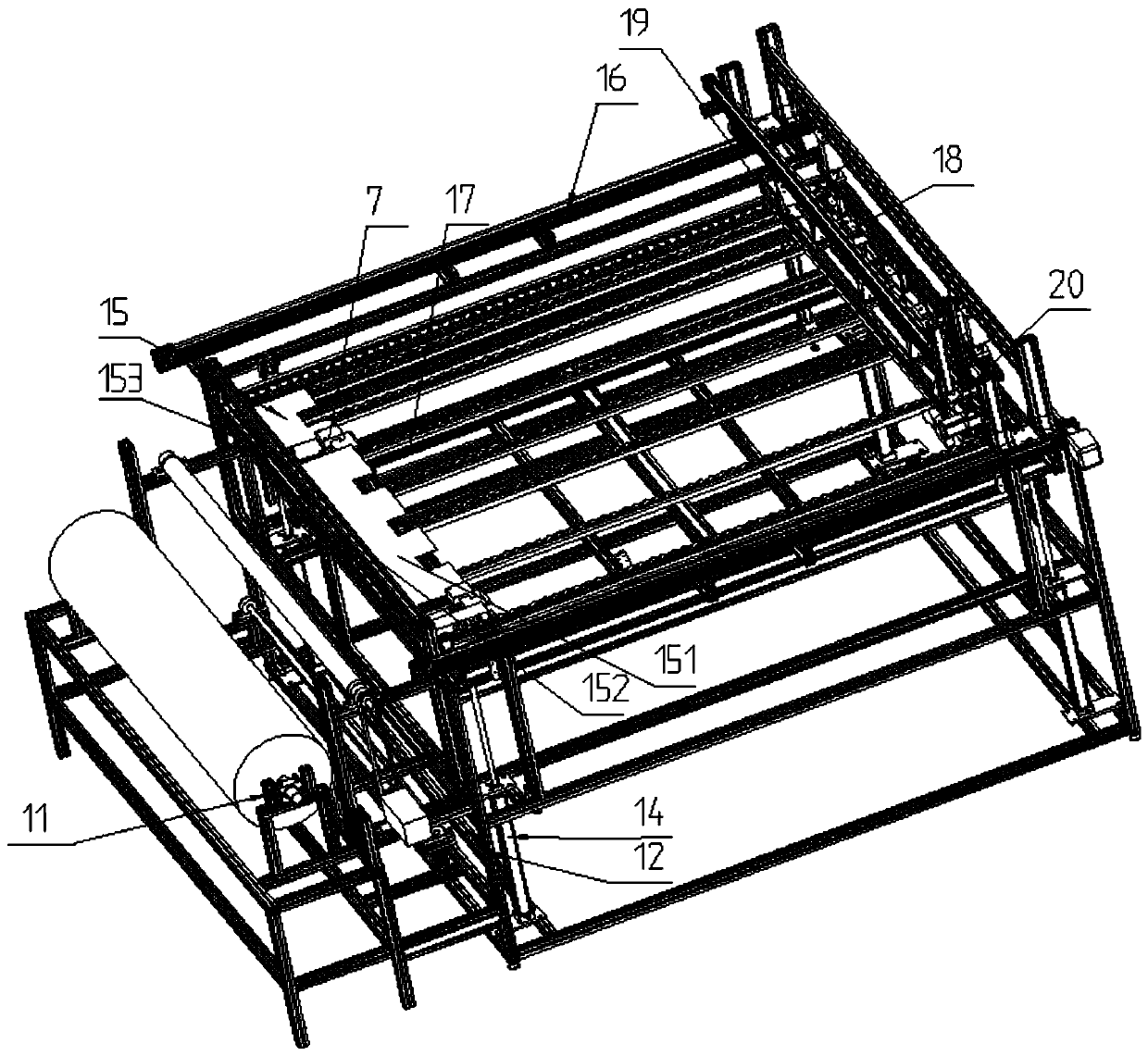

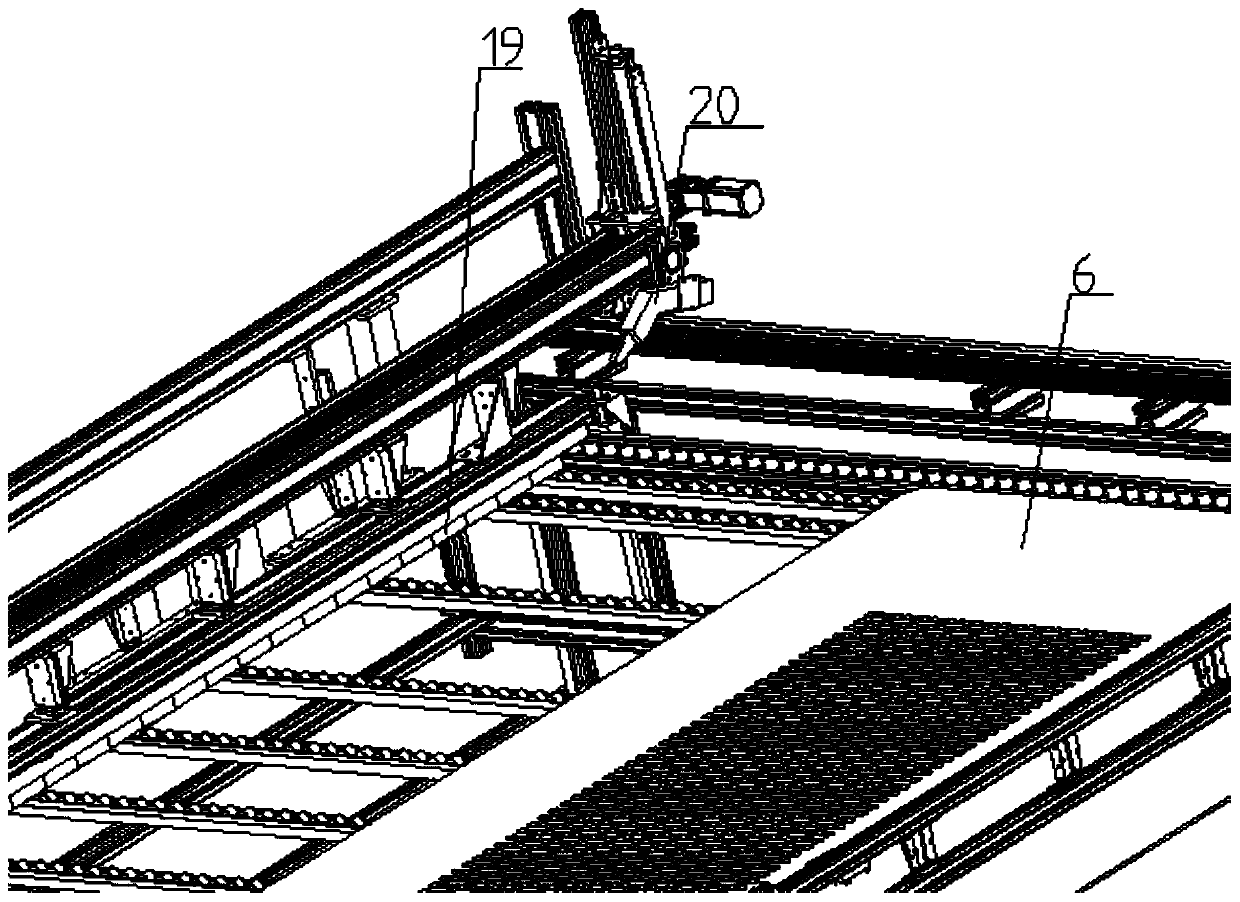

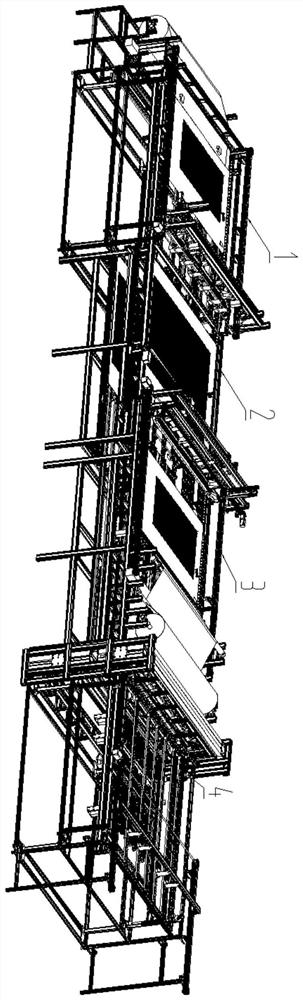

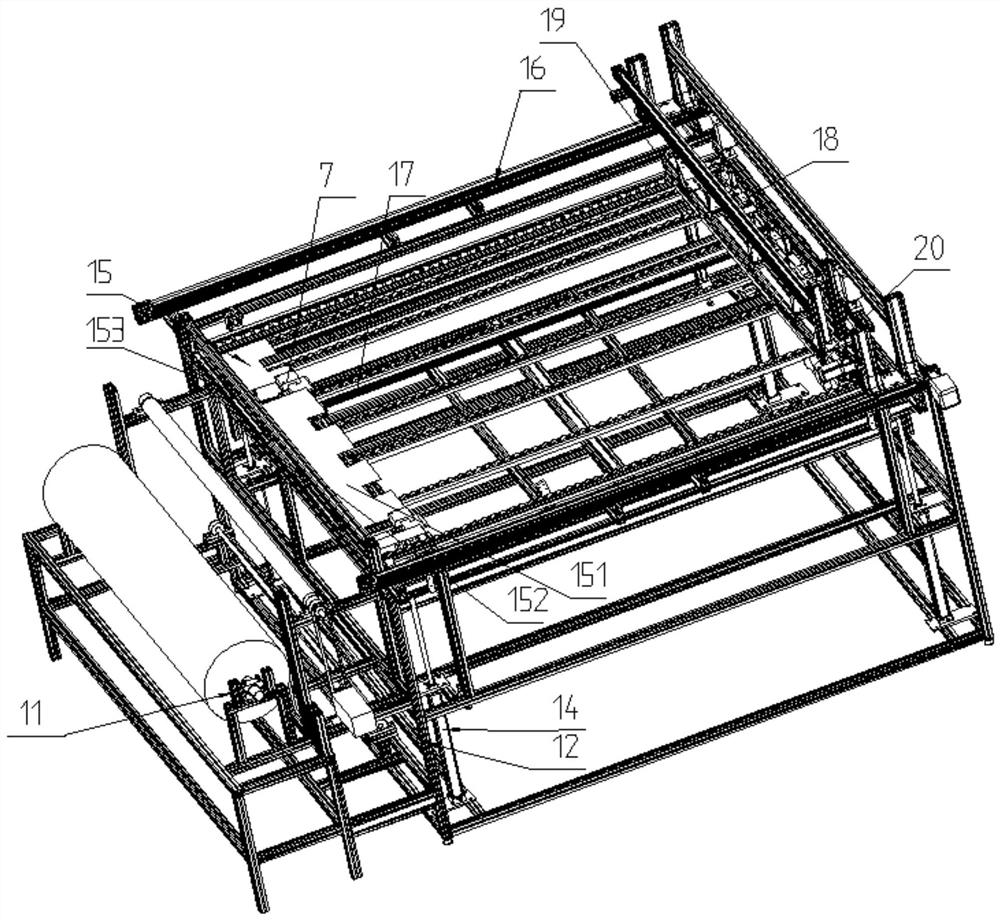

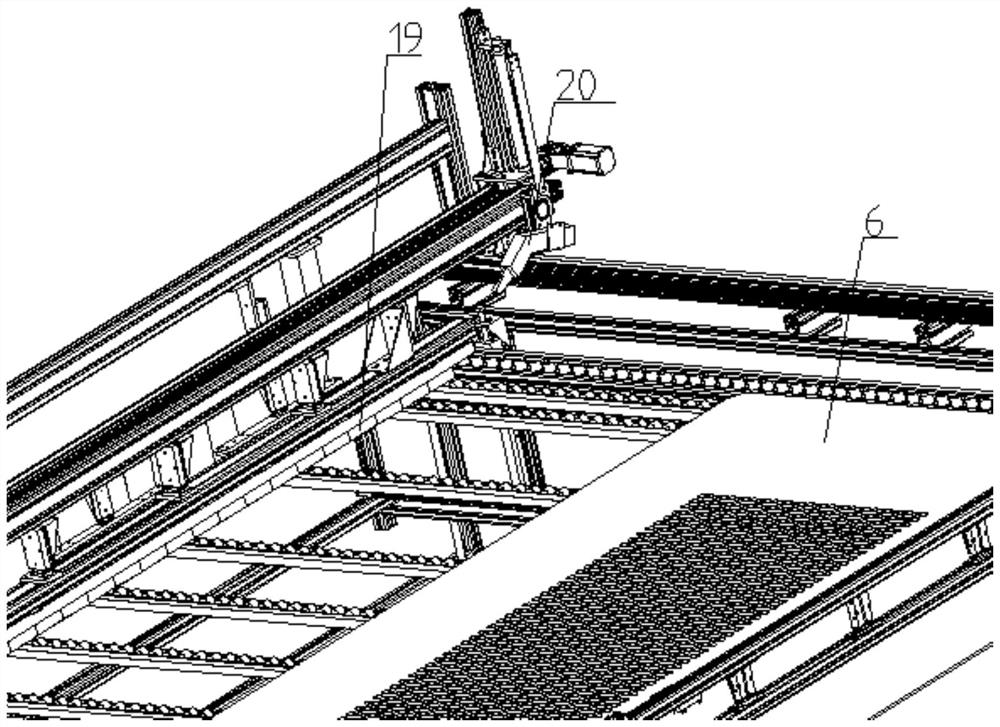

Electric blanket automatic production device capable of producing different types of electric blankets

ActiveCN110012566ARealize fully automatic weldingRealize automatic recyclingBlanketBed linenConductor CoilElectrical and Electronics engineering

The invention relates to an electric blanket automatic production device capable of producing different types of electric blankets. The device comprises an electric blanket first time laying device, an electric blanket automatic winding device, an electric blanket second time laying device, and an electric blanket automatic welding and cloth taking device. The electric blanket first time laying device is used for performing first time laying and cutting and sending a laid electric blanket template to a next station, the electric blanket automatic winding device is used for winding and sendingthe wound electric blanket template to a next station, the electric blanket second time laying device is used for performing second time laying and cutting and sending the laid electric blanket template to a next station, and the electric blanket automatic welding and cloth taking device is used for welding an electric blanket and taking a finished product of the electric blanket. The electric blanket automatic production device can produce different types of electric blankets, the position of the electric blanket can be aligned to achieve accurate processing, the device can operate continuously, the automatic recovery and recycling of the electric blanket template can be achieved, the efficiency is high, and the device is convenient to use.

Owner:WUHAN TEXTILE UNIV

Brush motor disc assembling device

ActiveCN114221508ALow structural costPrevent affecting the welding effectContact member cases/bases manufactureElectric machinesCircular discElectric machine

The invention discloses a brush motor disc assembling device which comprises a piece taking assembly, the piece taking assembly comprises a first support, a sliding block in sliding fit is arranged on one side of the first support, a first sliding table is fixedly connected to the sliding block, a first lifting plate is arranged at the sliding end of the first sliding table, and a first motor is arranged on one side of the first lifting plate; and a second support fixedly connected is arranged on a rotating shaft of the first motor, a second mounting plate rotationally connected is arranged in the second support, a pneumatic claw fixedly connected is arranged on the second mounting plate, a feeding assembly fixedly connected is arranged on the third support, and a welding assembly is arranged at one end of the part taking assembly. According to the assembling device, automatic feeding design is adopted, effective separation, feeding and feeding of the electric brush mounting frame are achieved during feeding of the vibration disc, clamping structure rotating design is adopted during mounting of the electric brush mounting frame and the electric brush disc, the electric brush mounting frame is pressed during welding, then welding is conducted, the electric brush mounting frame is prevented from deviating during welding, and the welding quality is improved. The welding effect is influenced.

Owner:安徽中腾汽车零部件有限公司

An excavating bucket welding device for earthwork construction engineering machinery

ActiveCN109290706BNo need to hold manuallyWelding is environmentally friendly and convenientWelding/cutting auxillary devicesDirt cleaningRobotic armHydraulic ram

The invention discloses an excavating bucket welding device for earth-rock construction engineering machinery, which comprises a base, four hydraulic oil cylinders distributed equidistantly on the left side of the top of the base, and the tops of the four hydraulic oil cylinders are hinged with the same placement groove , the right side of the top of the base is provided with a mechanical arm, and the top of the mechanical arm is sequentially connected with a vacuum cover and an electric welding pen through fastening bolts, the bottom inner wall of the placement groove is provided with an installation groove, and the bottom inner wall of the installation groove A fixed electromagnet is provided, the same positioning airbag is provided around the inner wall of the bottom of the placement groove, and a hollow rectangular frame is arranged on the top of the placement groove. The invention is applicable to the welding of excavating buckets of different sizes, which makes the welding more environmentally friendly and convenient, without the need to manually hold the sheet material, prevents dust from accumulating on one side of the filter screen plate and affects the filtering effect, and prevents the dust from falling into the placement tank to affect the welding effect .

Owner:临沂市宇顺机械有限公司

Resistance welding machine for continuous welding seam heat treatment

InactiveCN110064829AGuaranteed welding strengthAvoid Structural InsufficiencyResistance welding apparatusElectrical resistance and conductanceFixed frame

The invention belongs to the field of welding, and particularly relates to a resistance welding machine for continuous welding seam heat treatment. The resistance welding machine comprises a base, a mounting bracket, a preheating mechanism, a heat treatment mechanism, a heat preservation mechanism, fixing mechanisms and a spacing adjusting mechanism; a welding plate is arranged on the upper surface of the base; the fixing mechanisms are arranged on the upper surfaces of the left and right ends of the welding plate; the upper ends of the fixing mechanisms are fixedly connected with two ends ofthe lower surface of the mounting bracket through first hydraulic rods; the lower surface of the middle part of the mounting bracket is fixedly connected with a welding block through a second hydraulic rod; a welding head is fixedly connected with the lower surface of the middle part of the welding block; the upper end of the preheating mechanism is fixedly connected with the lower surface of theright end of the welding block; and the preheating mechanism comprises a connecting column, a mounting seat, a laser lamp, a conductive block, a sliding metal block and a fixing frame. The resistancewelding machine is mainly used for solving the problems that in the prior art, a steel structure is damaged due to too large temperature difference when steel is welded, and the temperature of a welding area is high during welding, so that parts are damaged easily and welding heat is wasted.

Owner:何前进

An electric blanket automatic production device capable of producing different types of electric blankets

ActiveCN110012566BRealize fully automatic weldingAchieve recyclingBlanketBed linenProcess engineeringIndustrial engineering

The invention relates to an automatic production device for electric blankets capable of producing different types of electric blankets, comprising a first spreading device for electric blankets, an automatic winding device for electric blankets, a second spreading device for electric blankets and an electric blanket Automatic welding and cloth fetching device; the first spreading device for electric blankets is used for spreading and cutting the cloth for the first time and sending the laid electric blanket template to the next station; the automatic winding device for electric blankets is used for Carry out winding and send the electric blanket template with the electric heating wire to the next station; the electric blanket second spreading device is used for the second spreading, cutting and sending the laid electric blanket template The next station: electric blanket automatic welding and cloth taking device is used to weld the electric blanket and get the finished electric blanket. The invention can automatically produce different types of electric blankets, can align the positions of the electric blankets to realize precise processing, can work continuously, can realize automatic recovery and recycling of electric blanket templates, has high efficiency, and is convenient to use.

Owner:WUHAN TEXTILE UNIV

An ultrasonic drilling device with fiber laser lamp

ActiveCN109249735BPrevent crushingPrevent affecting the welding effectInlaying equipmentLaser beam welding apparatusElectric machineryLaser light

The invention provides an ultrasonic hot drilling device with an optical fiber laser lamp. The ultrasonic hot drilling device comprises an in intelligent system, a control box and a base. The intelligent system comprises a sensing device and a control device, the sensing device comprises a temperature sensor and a pressure sensor, the control device comprises the optical fiber laser lamp, a motor,an ultrasonic generator, a pneumatic telescopic rod and an electric valve, a motor box is welded on the control box, the pneumatic telescopic rod comprises an air cylinder and a telescopic rod, the air cylinder is welded on the inner side wall of the motor box via first motor bases, first mounting holes and second mounting holes are formed in the bottom of the control box, and the telescopic rodis welded on the inner side walls of the first mounting holes. The ultrasonic hot drilling device with the optical fiber laser lamp has the advantages that the ultrasonic hot drilling device is novelin design and has diversified functions, and the hot connection efficiency can be effectively improved.

Owner:永嘉思慧特工业设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com