An elbow joint flange welding forming machine

A flange welding and elbow connection technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of easy welding deviation, hidden safety hazards for workers, and the requirement to adjust the angle of elbows and flanges. , to achieve the effect of improving welding efficiency, avoiding potential safety hazards and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

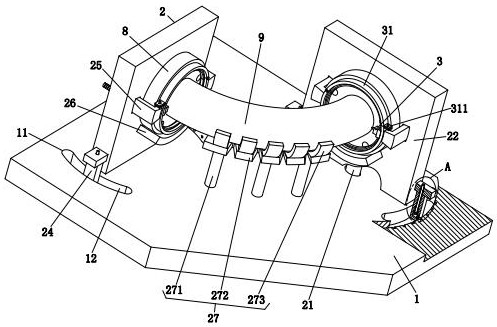

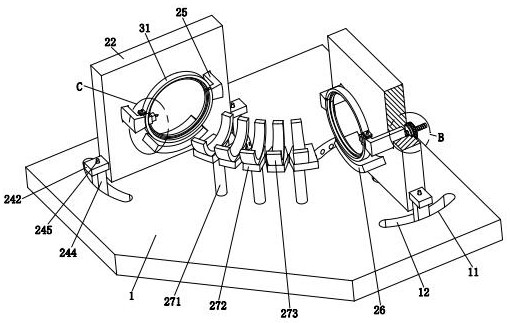

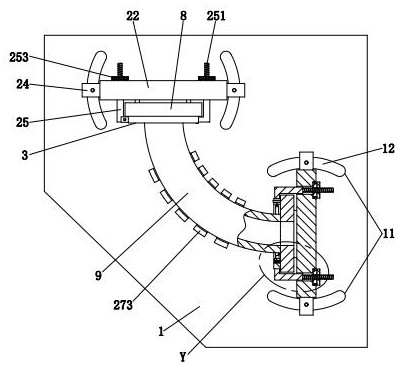

[0034] refer to figure 1 , figure 2 , image 3 , a flange welding and forming machine for elbow connection, comprising a bottom plate 1, a clamping unit 2 and a welding unit 3, two sliding groups 11 are arranged symmetrically on the upper end of the bottom plate 1, and the two sliding groups 11 are vertically arranged, And each sliding group 11 includes two oppositely arranged arc-shaped chutes 12, and the centers of circles of the two arc-shaped chutes 12 on each sliding group 11 coincide; 2 is provided with a welding unit 3 .

[0035] refer to figure 1 , figure 2 , Figure 6 , Figure 7 , the clamping unit 2 includes a support column 21, a rotating plate 22, a sliding groove 23, a locking assembly 24, an L-shaped block 25, a baffle plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com