Plastic pipe hot melting welding machine

A hot-melt welding and plastic pipe technology, applied in the field of plastics, can solve the problems of plastic pipe solidification, inability to heat at the same time, welding failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

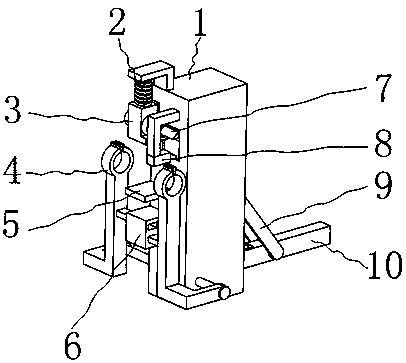

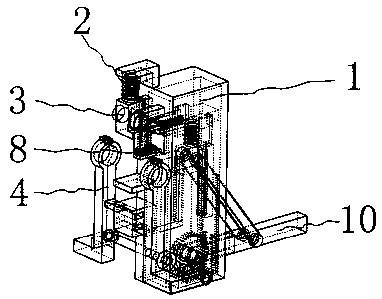

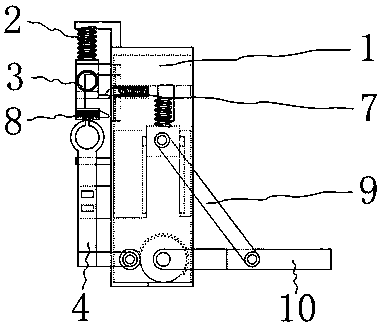

[0044] Such as figure 1 , 2 As shown, it includes installation shell 1, return spring 2, hot melt block 3, drive arm 4, limit plate 5, guide block 6, drive mechanism 7, trigger mechanism 8, drive swing rod 10, threaded rod 18, guide rod 12, guide groove 15, T-shaped slide block 31, drive plate 49, drive spring 19, slide block 20, wherein as Figure 7 As shown, there is a threaded hole 28 on the installation shell 1, such as Figure 6 As shown, the threaded rod 18 is installed on the fixed shell through the threaded hole 28, and the two ends of the threaded rod 18 pass through the mounting shell 1 and are located on both sides of the mounting shell 1; Figure 5 As shown, one end of the driving arm 4 has a detachable fixing ring 11 for fixing the plastic pipe, and the other end of the driving arm 4 is installed on the two ends of the threaded rod 18 through screw fit; one side of the driving arm 4 is equipped with a guide rod 12, Such as Figure 4 As shown, there are two thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com