A rotary tungsten electrode tig welding system for inner wall welding of extremely small diameter pipe fittings

A welding system and tungsten electrode technology, applied in the direction of electrode fittings, welding equipment, welding accessories, etc., can solve the problems of extremely small-diameter pipe welding, large overall structure, and increased structural volume, and achieve small welding heat input and welding The effect of small current and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

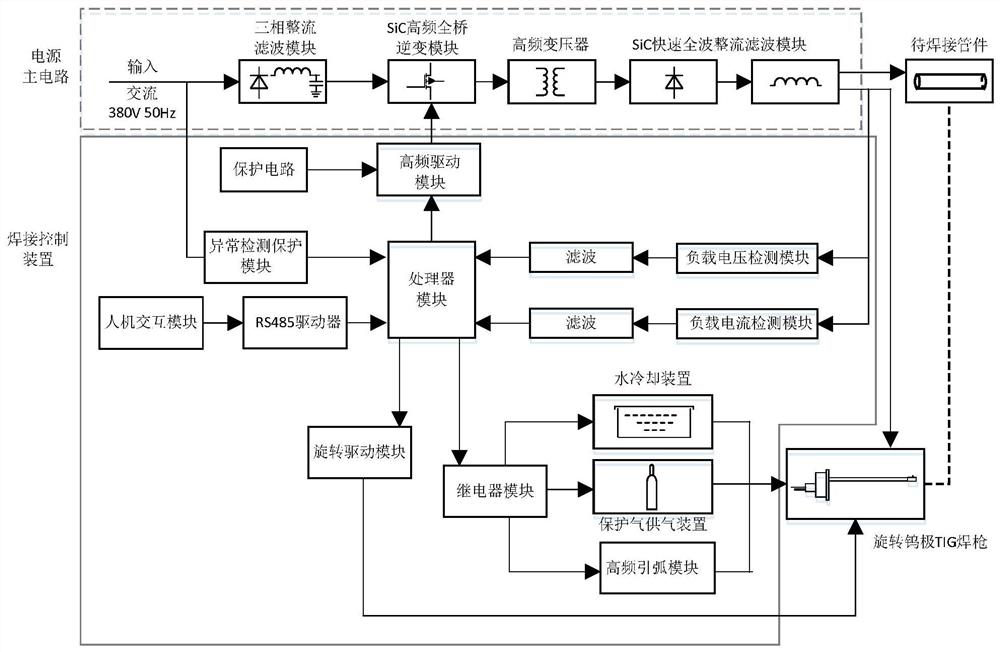

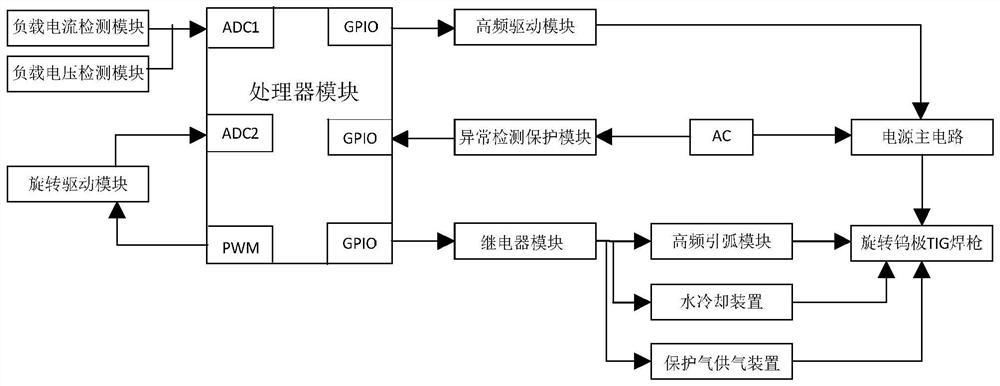

[0045] like Figure 1 to Figure 8 As shown in the present embodiment, a rotary tungsten electrode TIG welding system for welding the inner wall of an extremely small diameter pipe includes a rotary tungsten electrode TIG welding torch, a high-frequency inverter welding power source, a water cooling device and a protective gas supply device; The variable welding power source includes the main circuit of the power source and the welding control device.

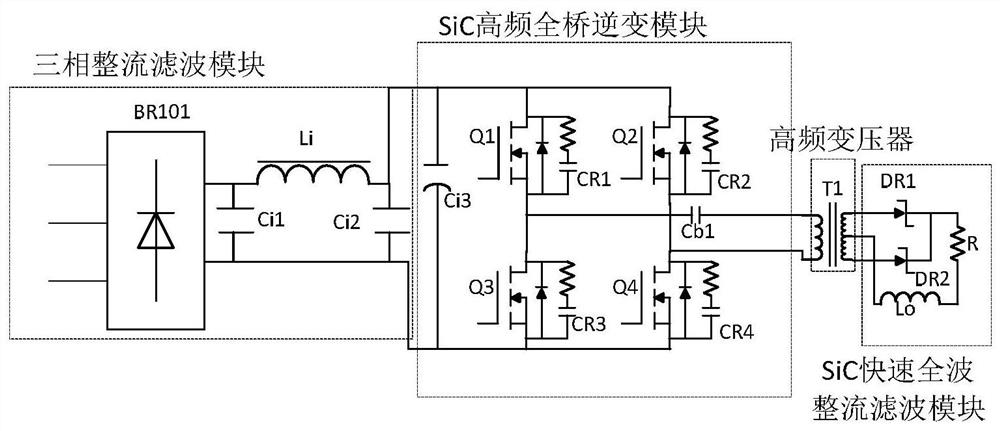

[0046] The main circuit of the power supply includes a three-phase rectifier and filter module, a SiC high-frequency full-bridge inverter module, a high-frequency transformer and a SiC fast full-wave rectifier and filter module, which are connected in sequence. The SiC high-frequency full-bridge inverter module adopts a SiC full-bridge inverter topology with an inverter frequency of up to 200kHz, which is mature and stable. The SiC MOSFET is used as the power switch; the alternating current input from the industrial three-phase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com