An excavating bucket welding device for earthwork construction engineering machinery

A technology of construction machinery and welding equipment, which is applied in welding equipment, auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of easily affecting the welding effect, polluting the environment, inconvenient operation, etc., and achieves the effect of environmental protection and convenience of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments.

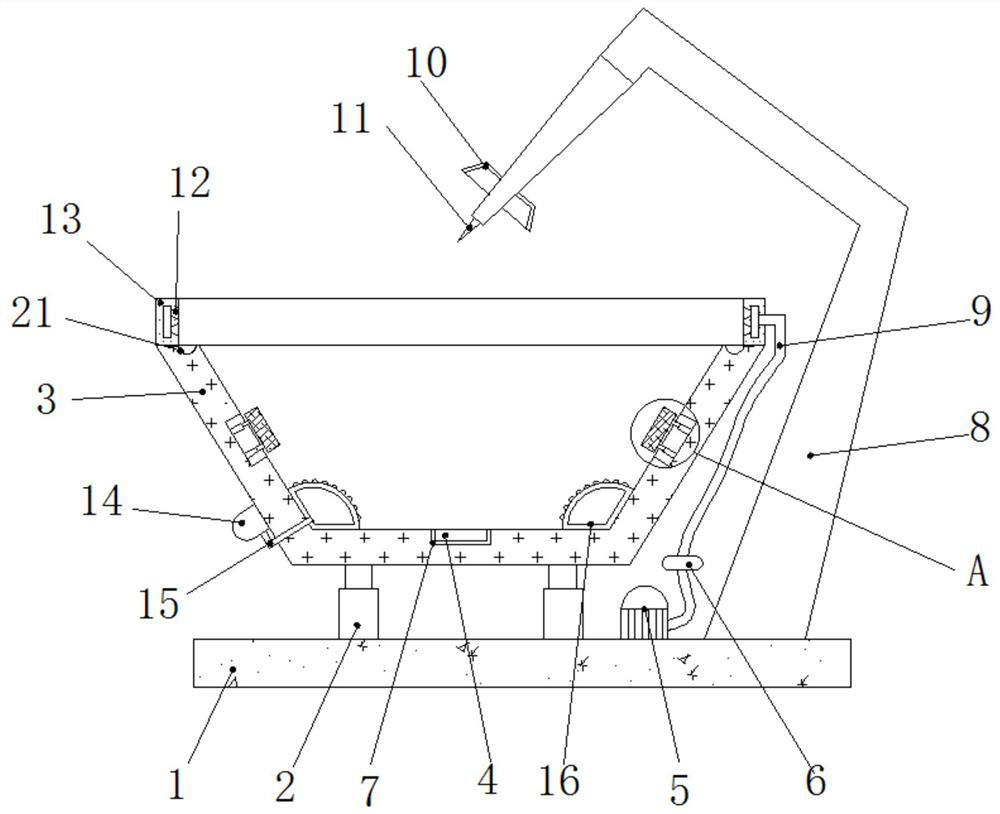

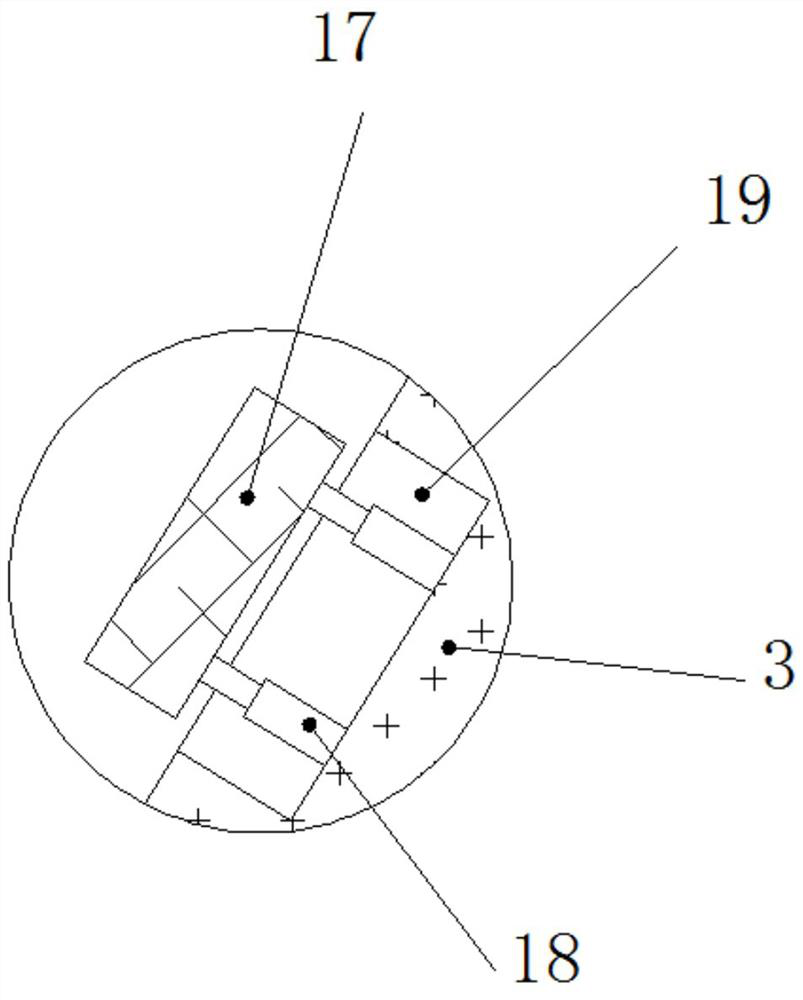

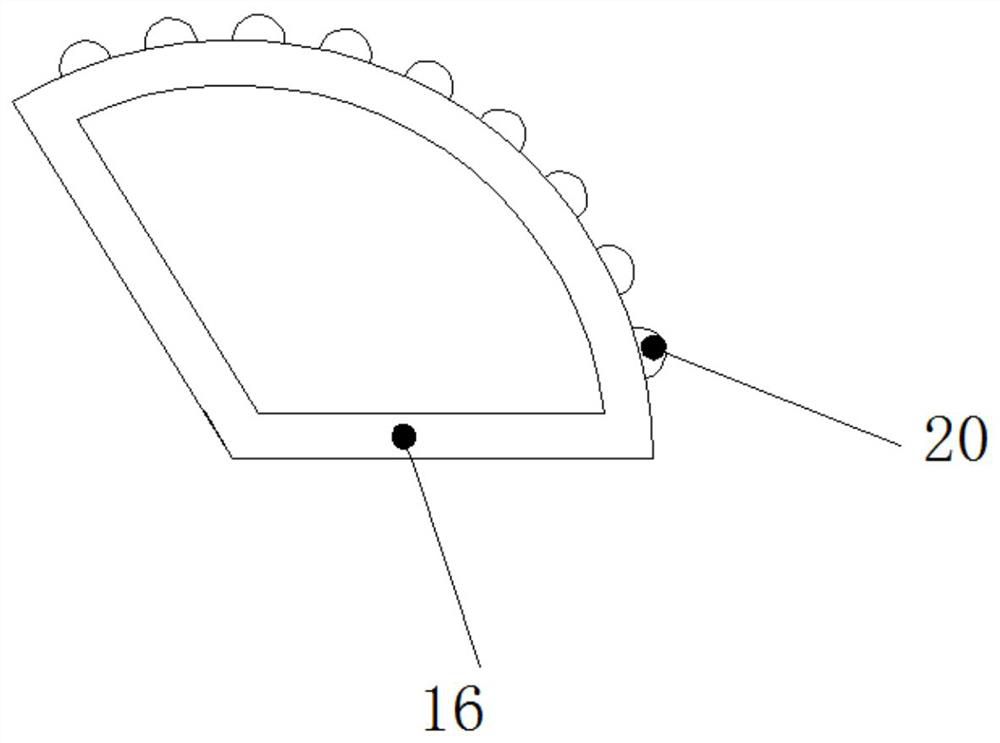

[0021]ReferFigure 1-3A excavation bucket welding device for earthwork construction construction construction, including a base 1, and the left side of the top of the base 1 is connected to a hydraulic cylinder 2 having four equal distance distributions by fastening bolts, and the top hinges of the four hydraulic cylinders 2 have the same One placement slot 3, the right side of the top of the base 1 is connected to the mechanical arm 8 by the fastening bolt, and the top of the robot arm 8 is sequentially connected by fastening bolts, and the bottom inner wall of the bottom portion of the groove 3 is opened. There is a mounting groove 7, and the bottom inner wall of the mounting groove 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com