Patents

Literature

79results about How to "Avoid affecting the welding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

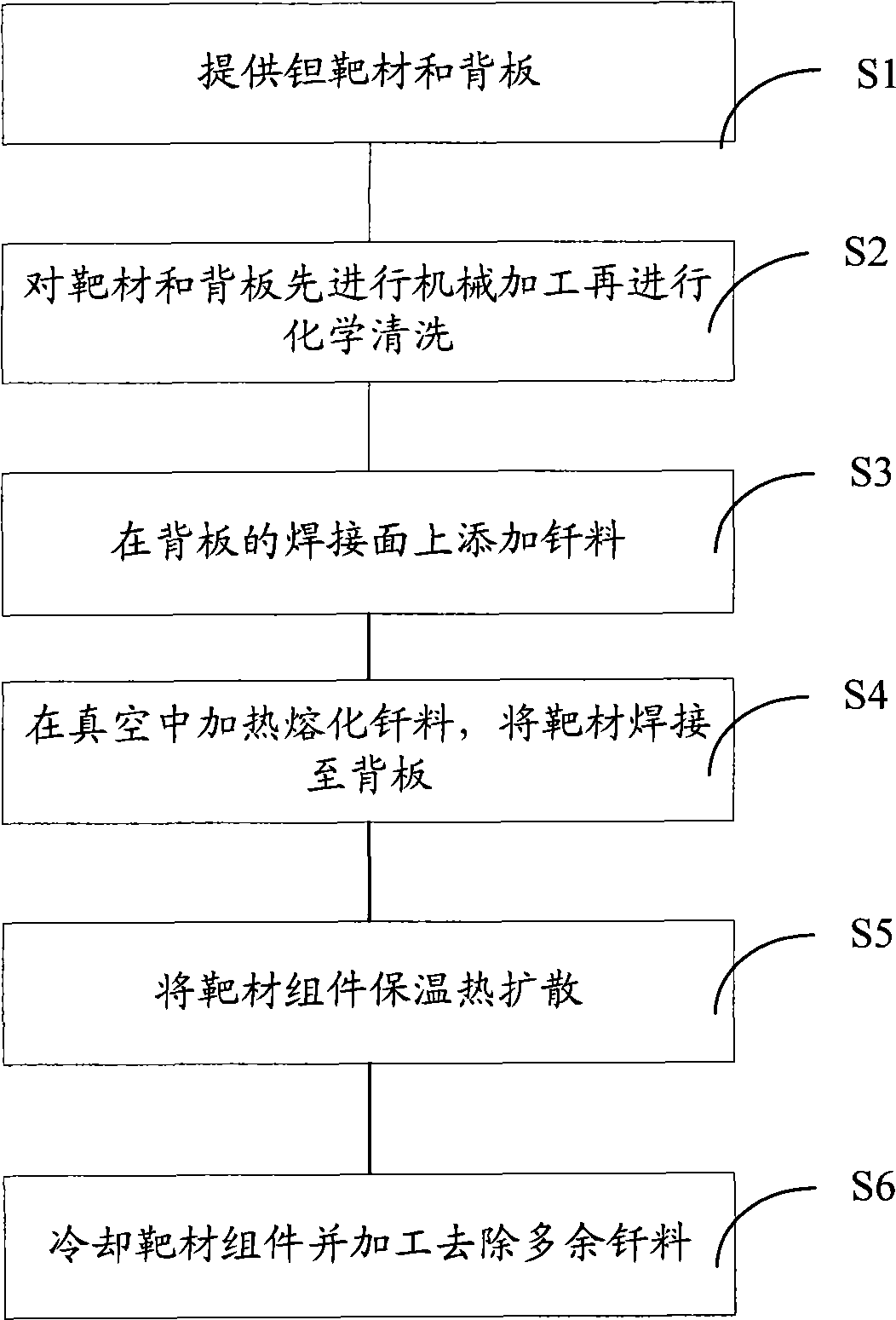

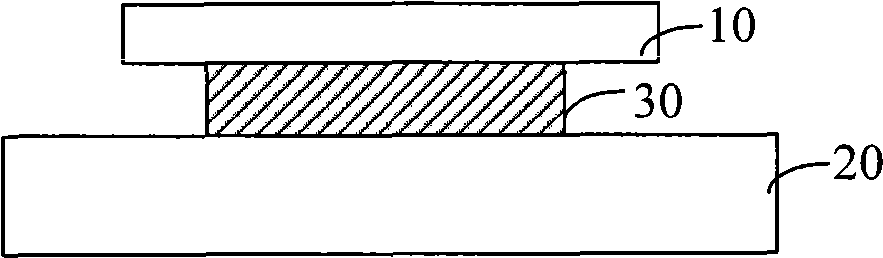

Method for welding target material and back board

InactiveCN101543924APrevent disengagementPrevent oxidationVacuum evaporation coatingSputtering coatingThermal insulationCentral layer

A method for welding a target material and a back board includes a step of providing a tantalum target material and a back board; a step of adding solder on a welding surface of the back board; a step of forming a metal central layer on a welding surface containing the tantalum target material in vacuum; a step of implementing thermal insulation and heat diffusion treatment; and a step of cooling the target material component, and removing the redundant solder through a mechanical treatment. By means of implementing a large area welding in a vacuum circumstance, the method of the invention is capable of preventing a metallic welding surface from being oxidized, is favorable to infiltrate the solder and the metal, the bonding strength between the tantalum target material and the back board is improved, thereby the abjunction of the tantalum target material is avoided from the back board during a sputtering process, and a sputter coating may be implemented normally.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

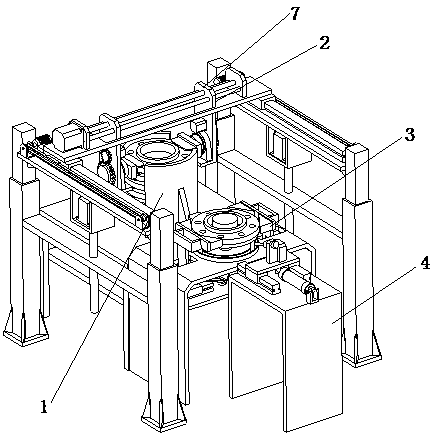

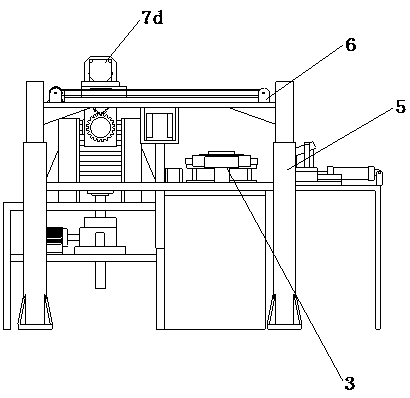

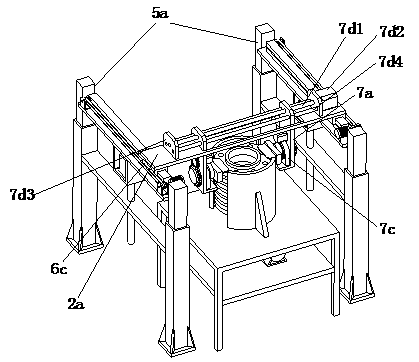

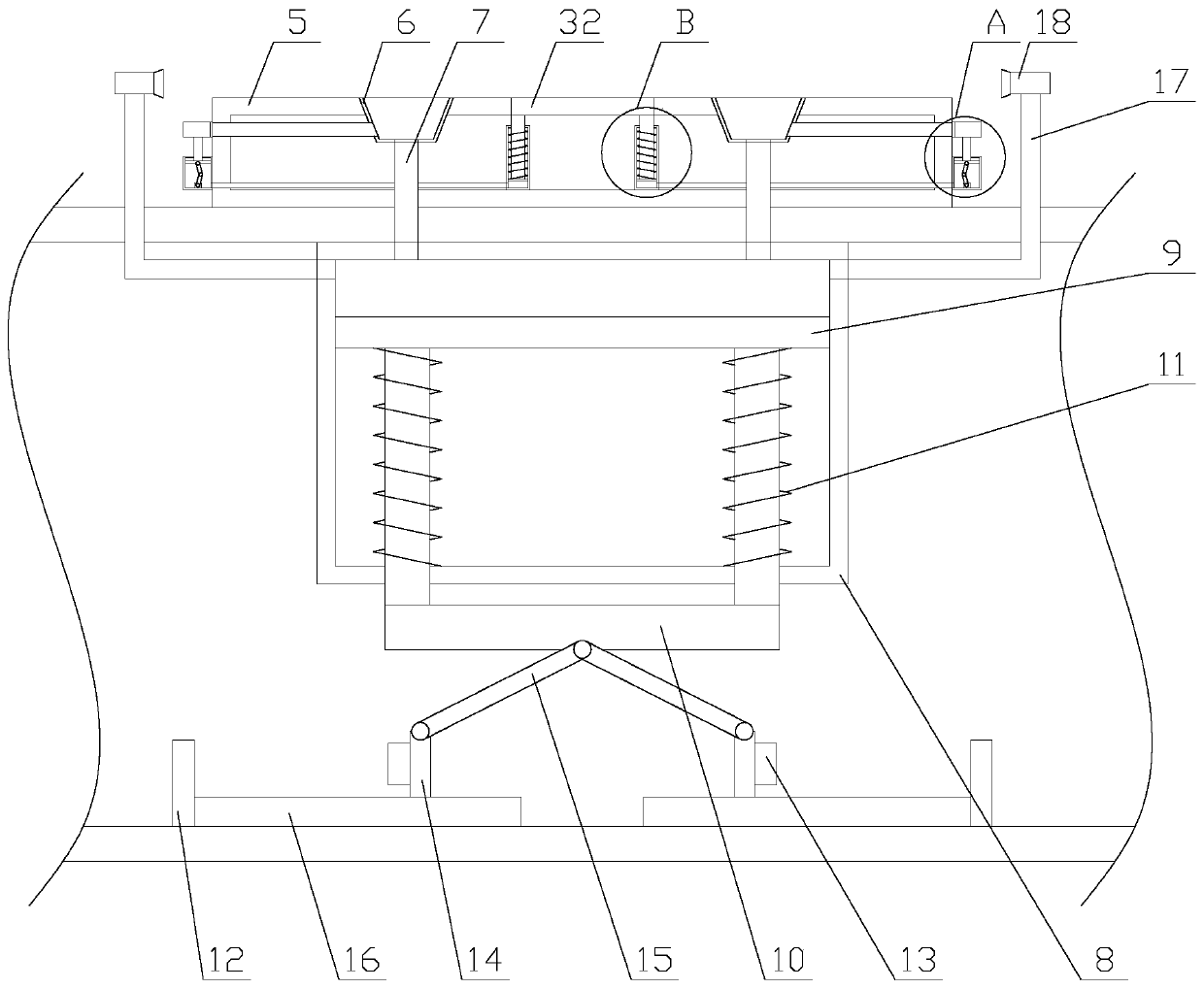

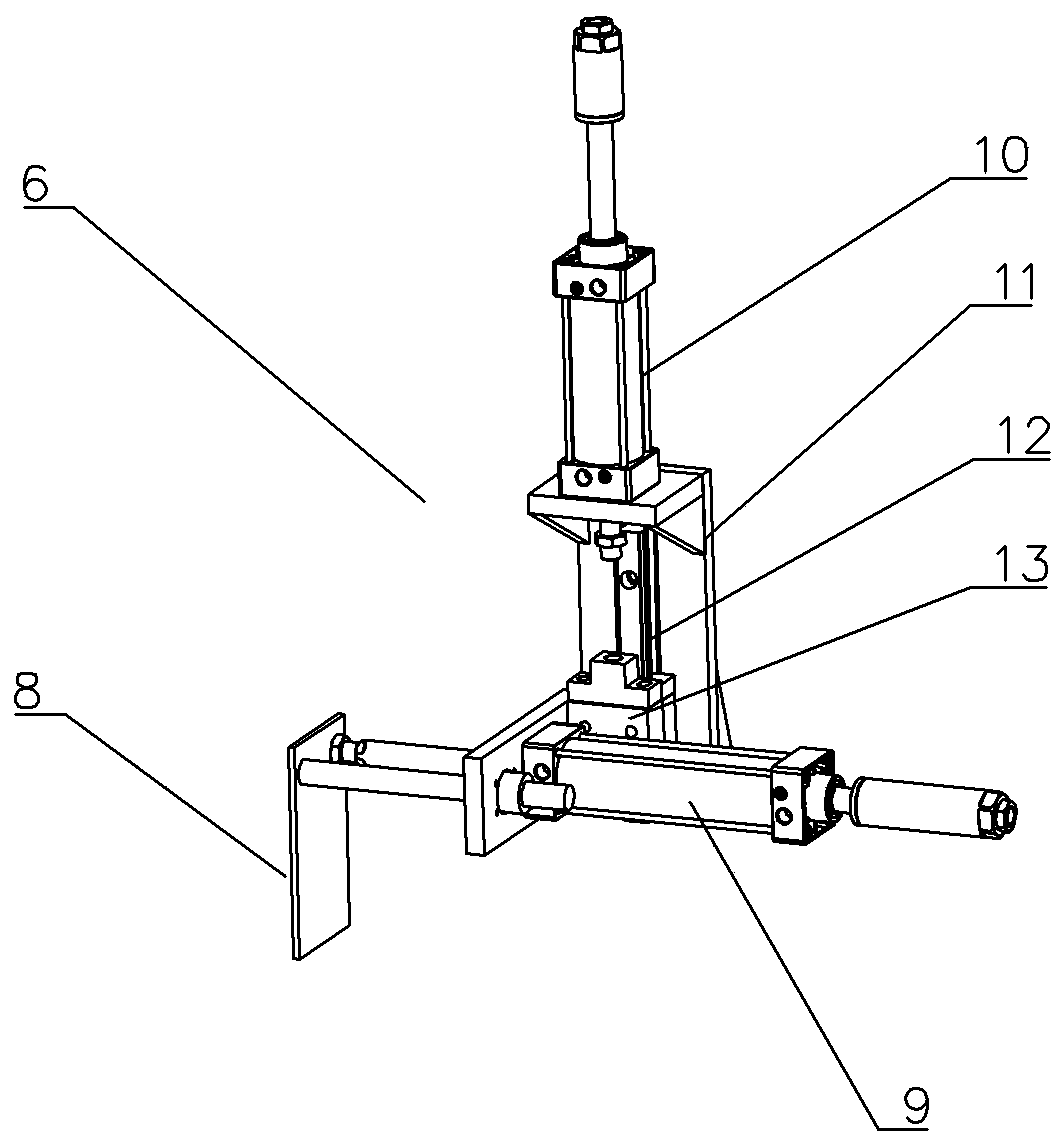

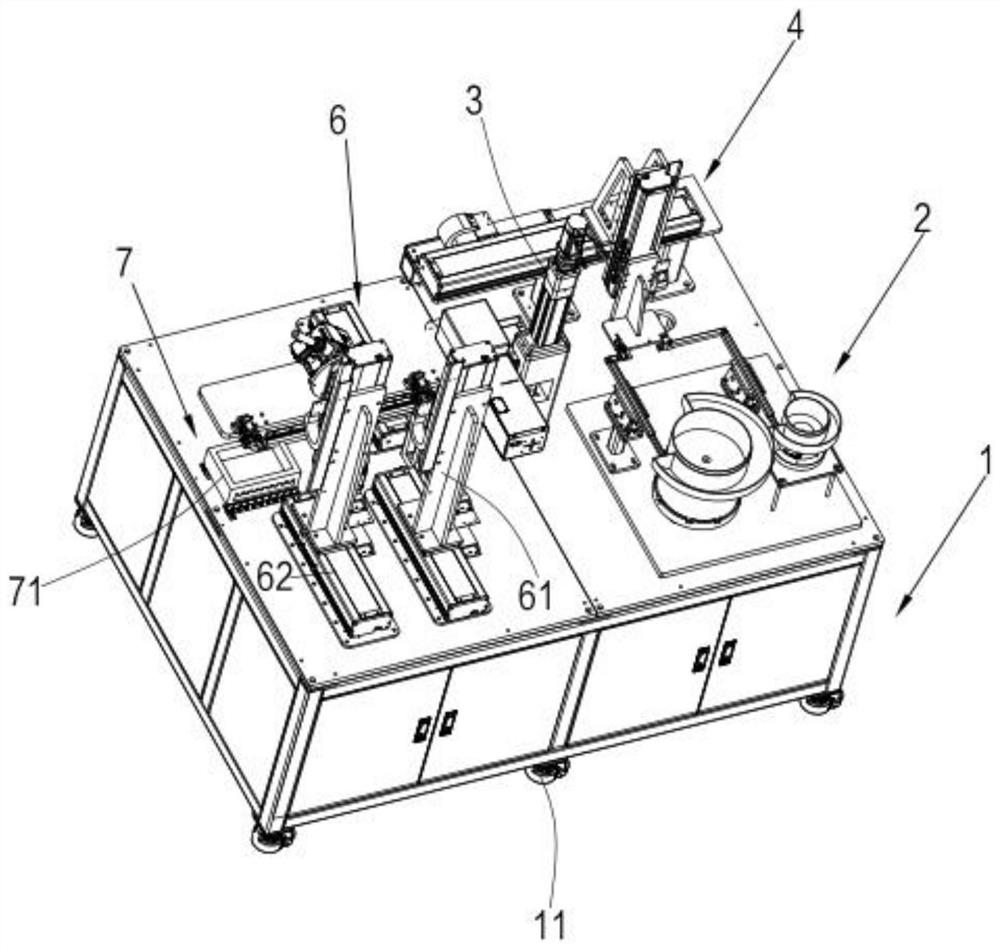

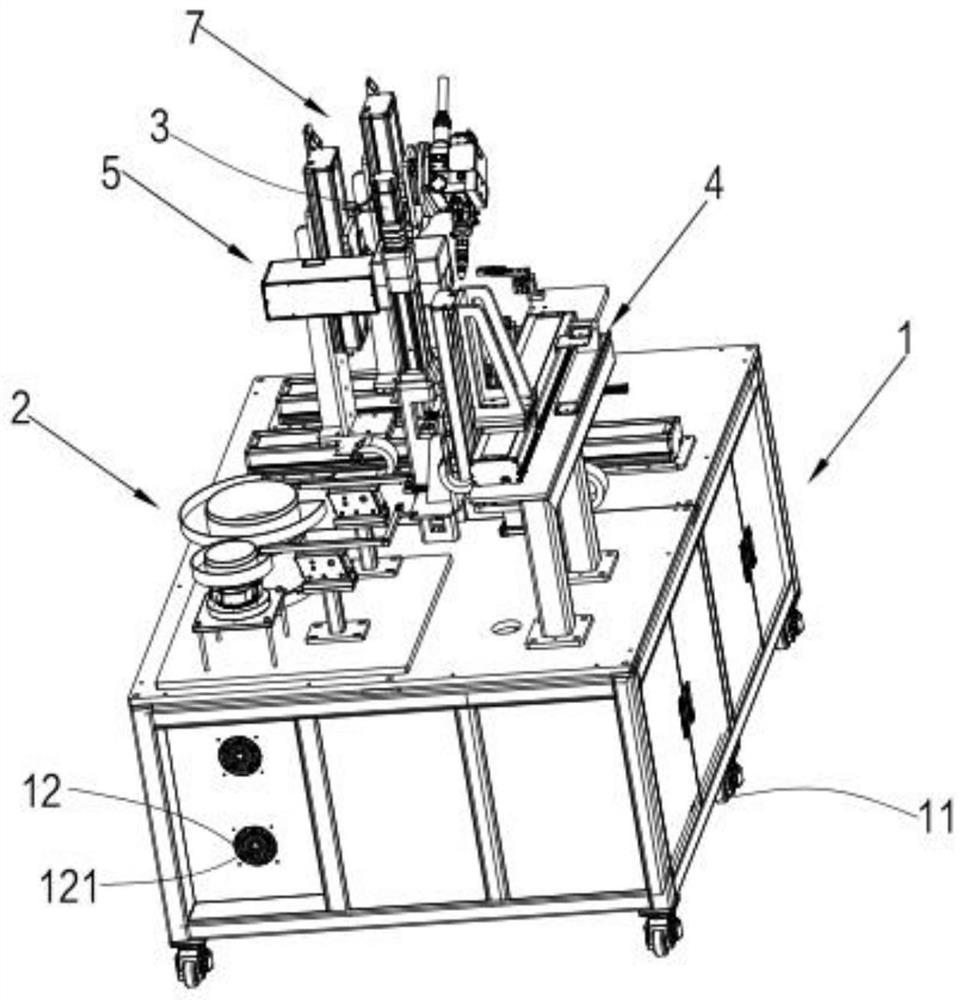

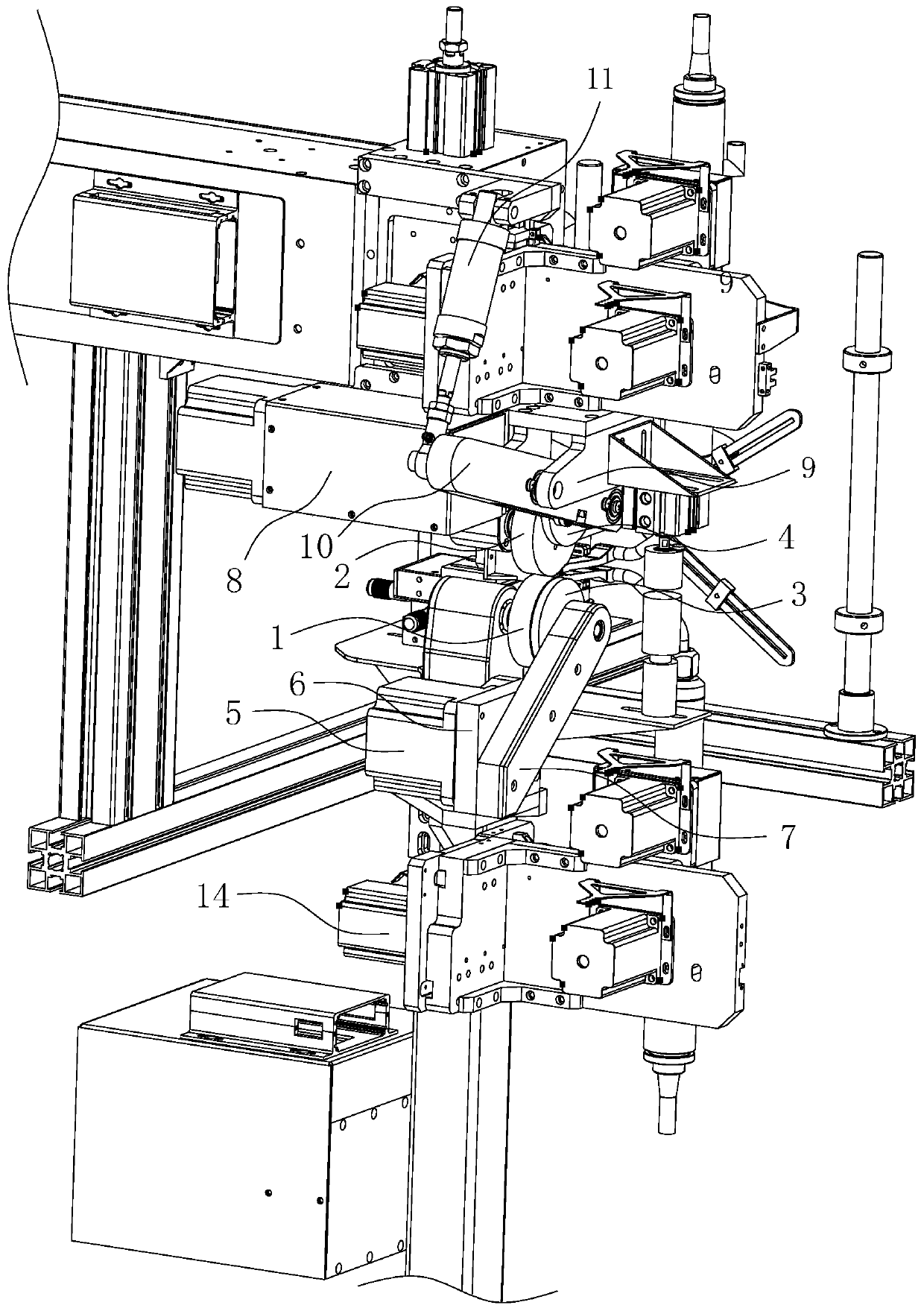

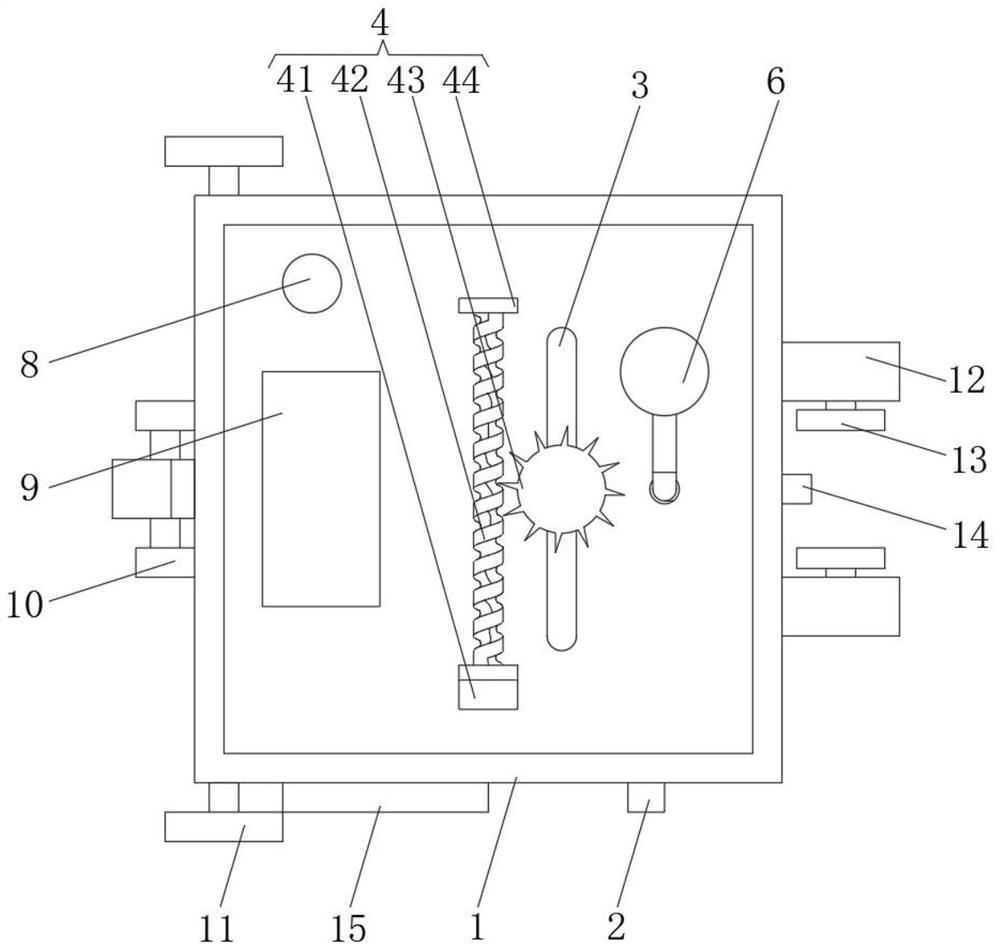

Automatic flange welding robot

ActiveCN109175824AHigh degree of automationReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringTransfer mechanism

The invention discloses an automatic flange welding robot, and belongs to the technical field of welding equipment. The automatic flange welding robot comprises a storage mechanism, a transferring mechanism, a limiting mechanism and a welding mechanism, wherein the transferring mechanism comprises a mounting plate, a lifting assembly, a feeding component and a clamping assembly; the clamping assembly comprises a driving component and two clamping components, and the two clamping components are identical in structure and each comprise a supporting vertical plate and a rotating piece; and each supporting vertical plate is of an L-shaped structure. According to the robot, a flange can be overturned by 180 degrees through the rotating pieces to complete the turnover operation of the flange, aworker does not need to manually carry out the turnover operation, and the automatic feeding operation of the flange can be achieved through the storage mechanism and the transferring mechanism. Besides, the flange can be automatically rotated through a rotating assembly, a notch in the flange can be aligned to a welding machine, and the welding operation can be carried out conveniently on the notch of the flange through the welding machine.

Owner:山东祥通橡塑科技有限公司

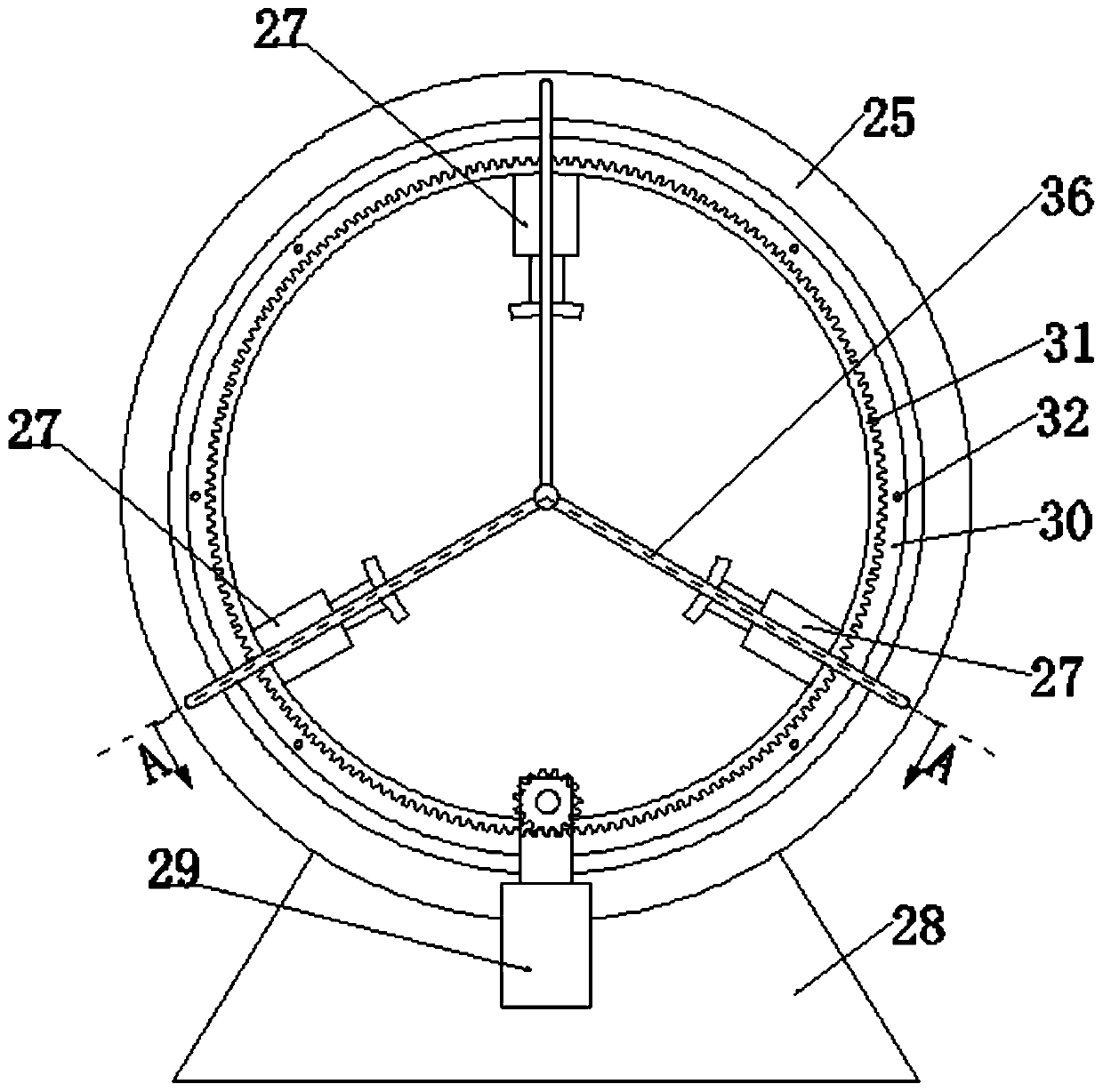

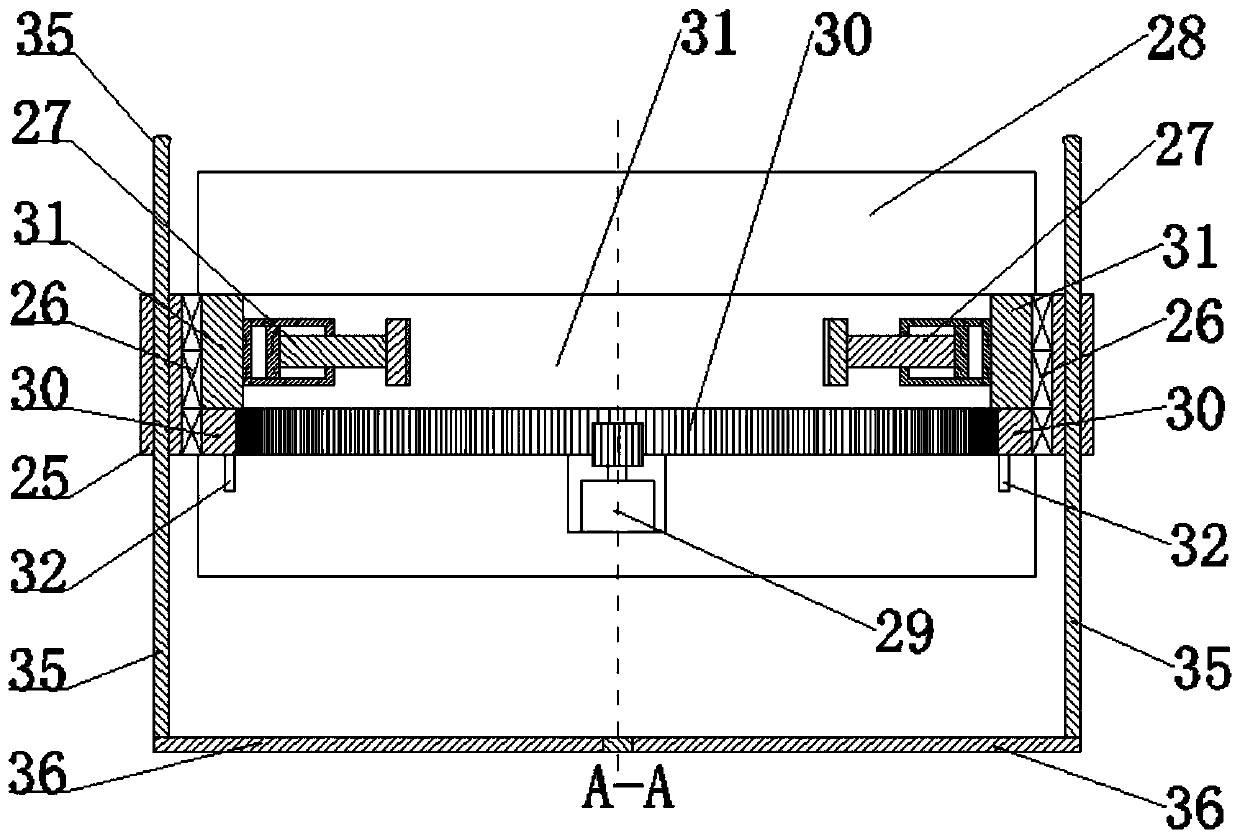

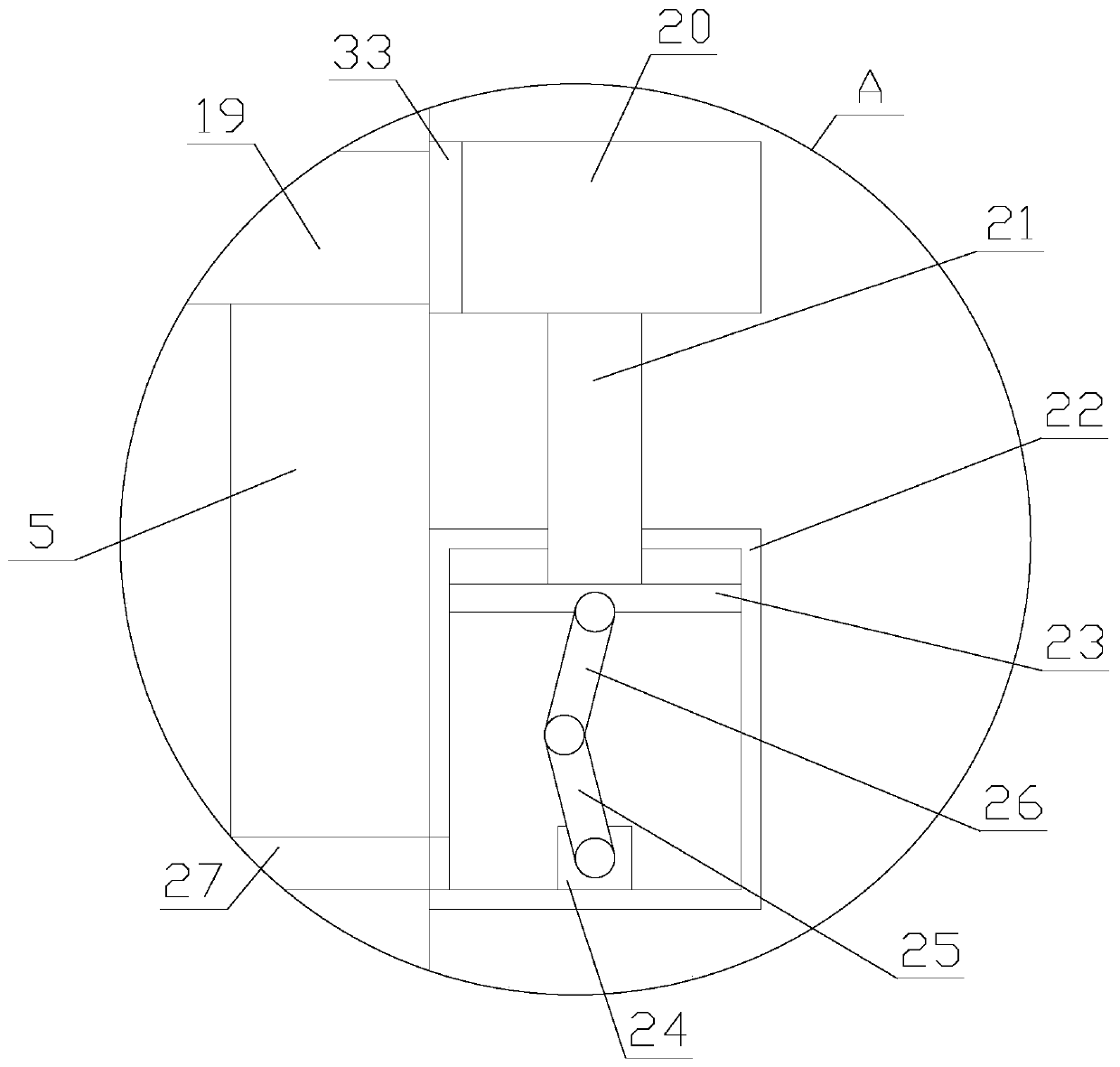

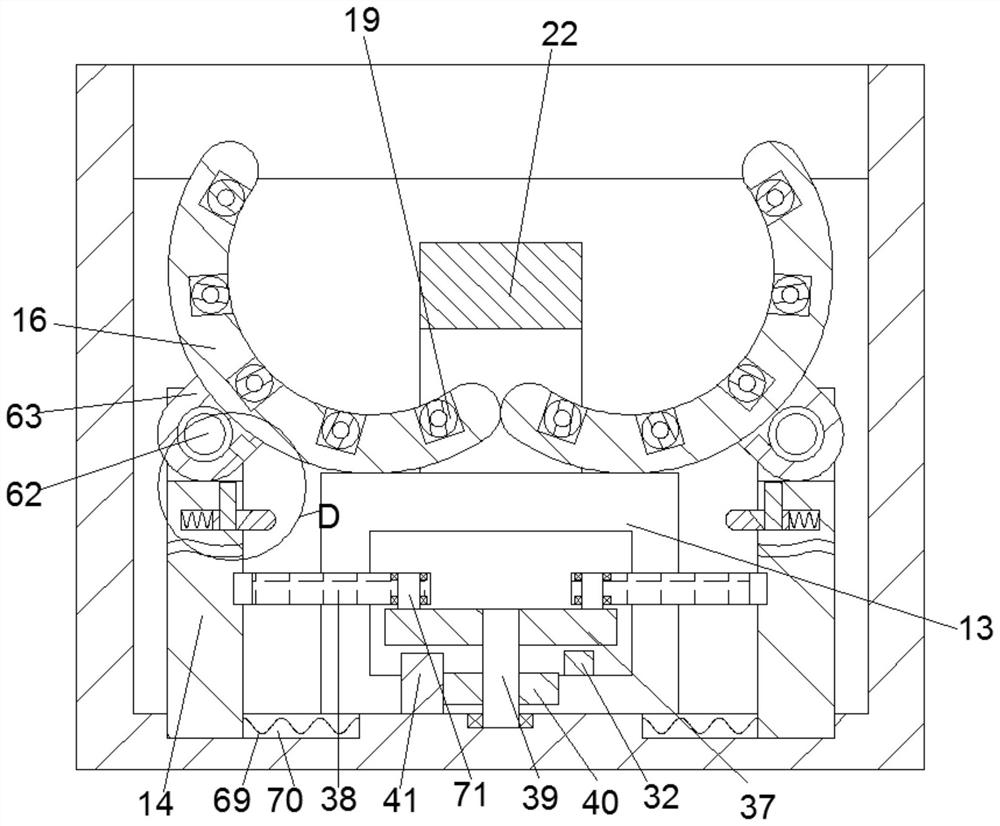

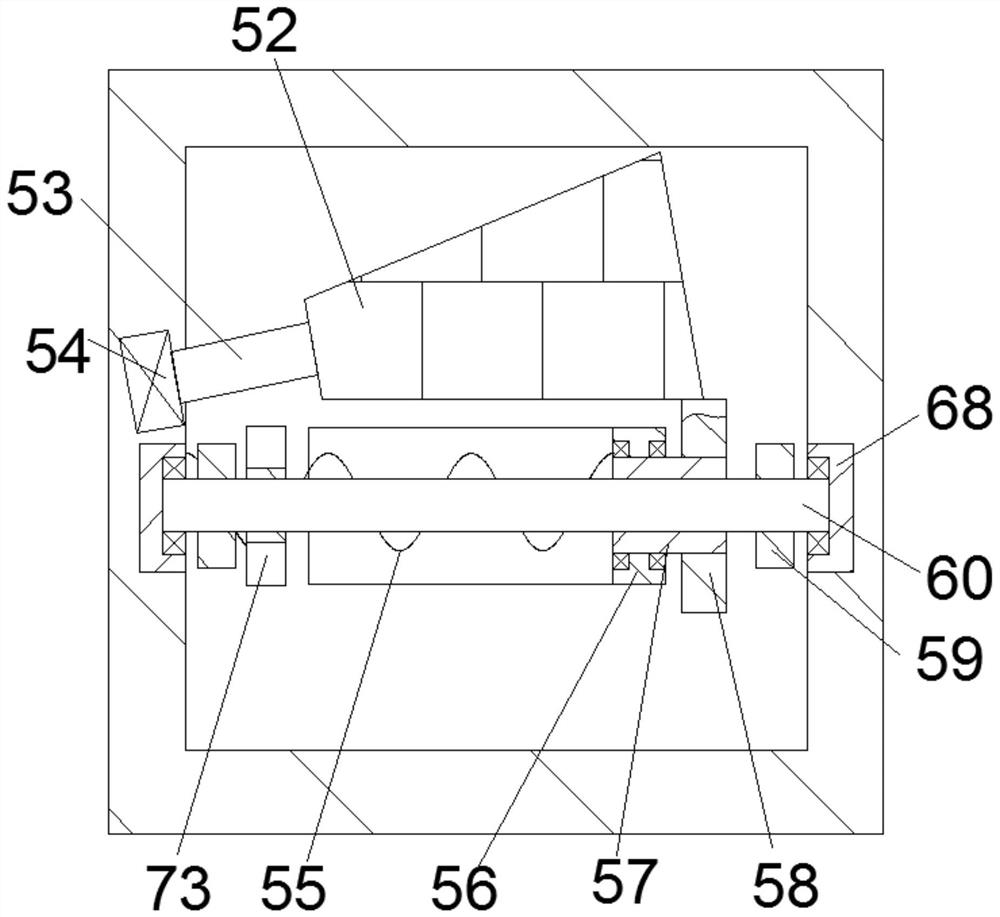

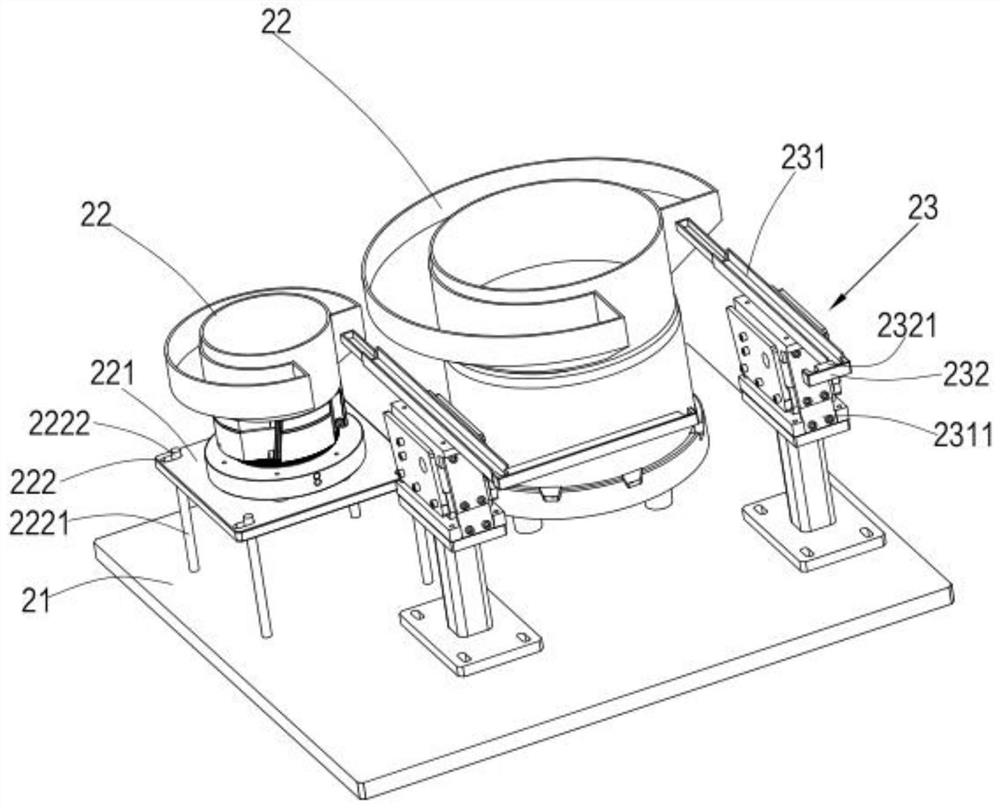

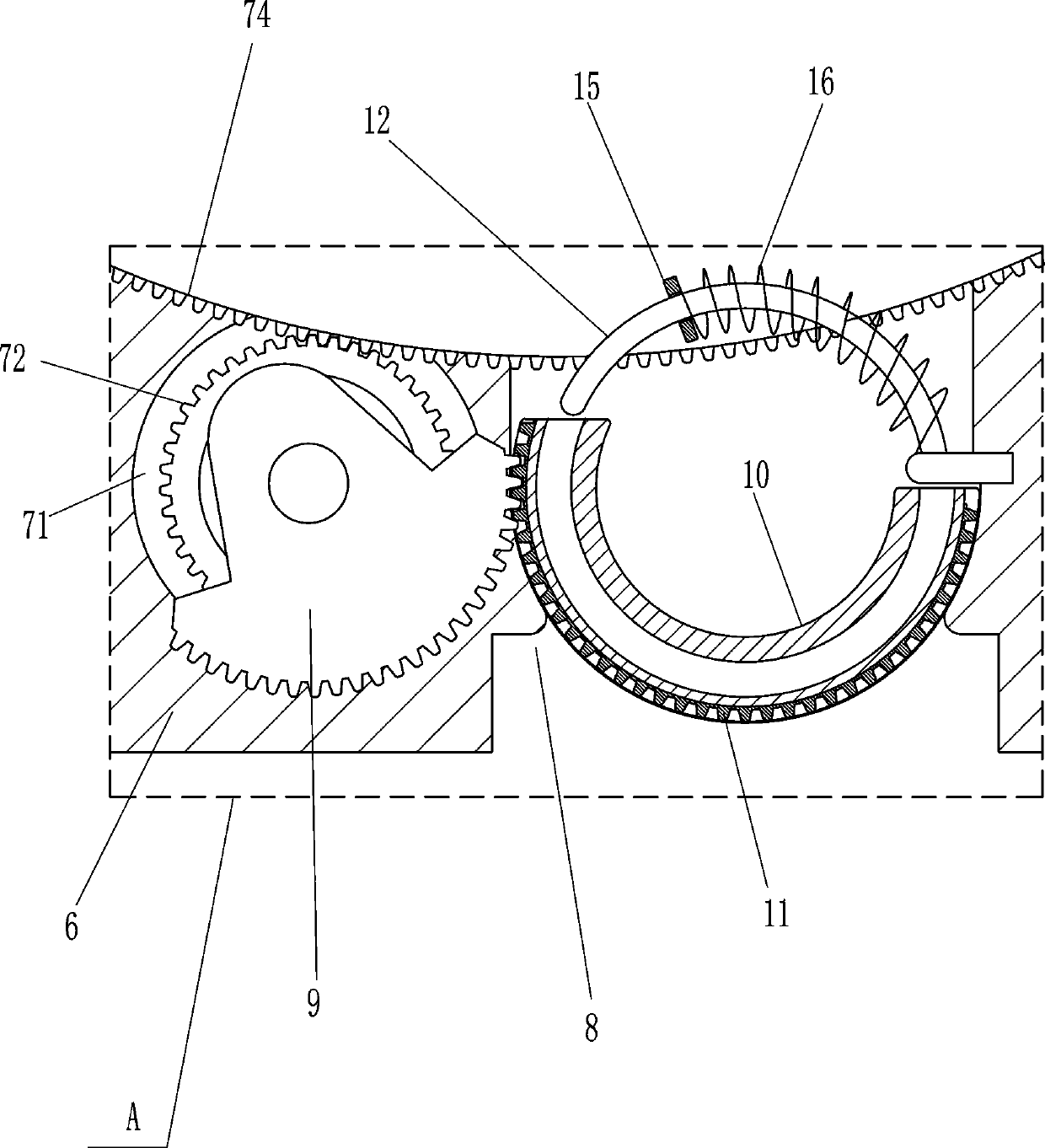

Synchronous clamping eccentricity detection device for circular workpiece

PendingCN110579164AGuaranteed stabilityImprove welding qualityMechanical measuring arrangementsNon-electric welding apparatusEngineeringWelding

The invention discloses a synchronous clamping eccentricity detection device for a circular workpiece. The synchronous clamping eccentricity detection device comprises a detection device body and a clamping-rotating mechanism, the detection device body is arranged on the clamping-rotating mechanism, the clamping-rotating mechanism comprises a cylindrical annular mounting base, a clamping area is formed in an inner cavity of the annular mounting base, and the detection device body is arranged around the center line of the annular mounting base; and the detection device body comprises a slidingpart and a detection part, the sliding part is movably inserted into the cylinder wall of the annular installation base in a penetrating mode, the detection part is fixedly installed on the sliding part, and an alignment mark is arranged on the detection part. According to the synchronous clamping eccentricity detection device for the circular workpiece, after that the cylindrical workpiece to bewelded is fixed, whether the cylindrical workpiece is offset can be determined, a clamping cylinder is adjusted in time, the rotating stability of the cylindrical workpiece during welding is ensured,and the welding quality is improved.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

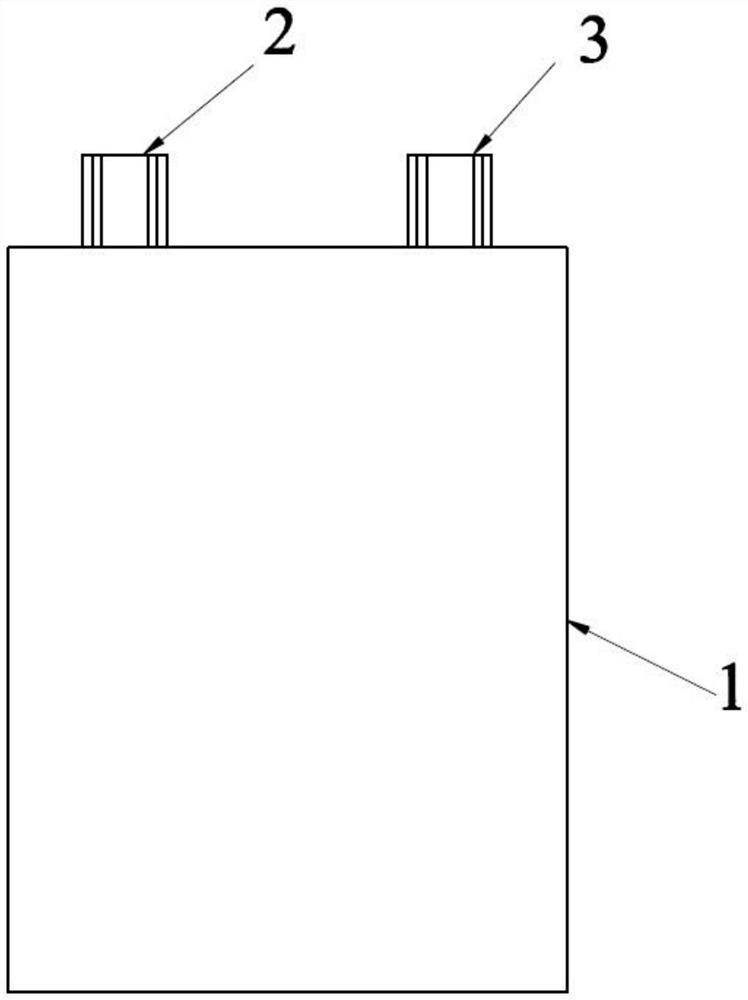

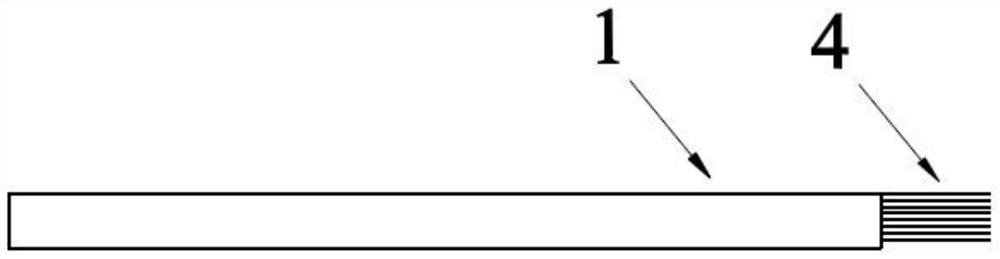

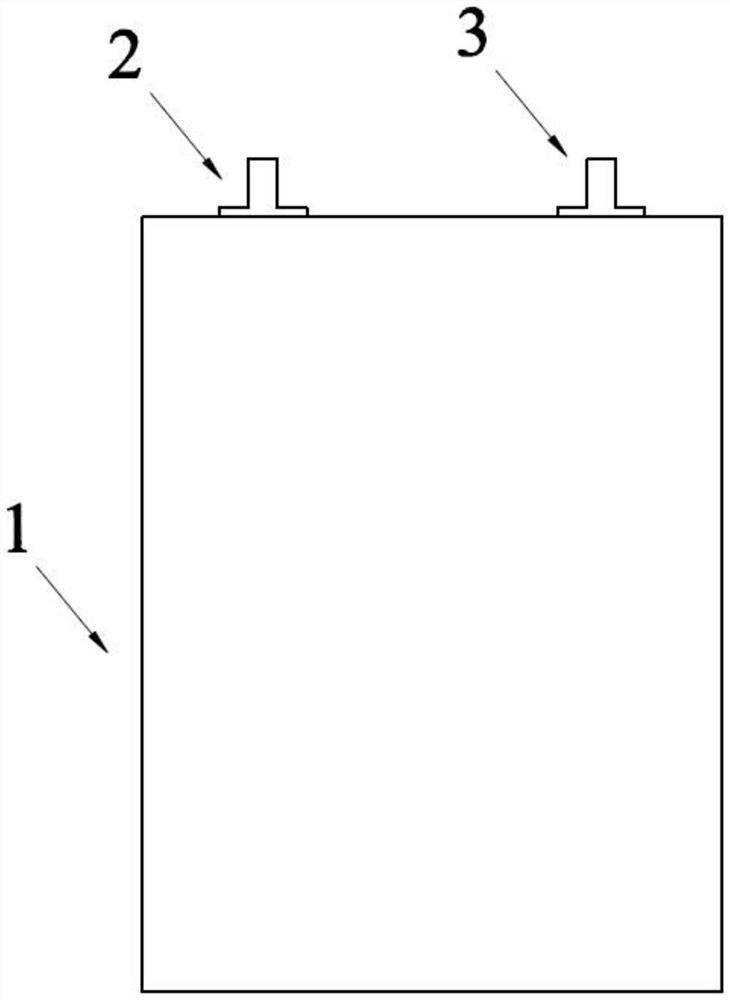

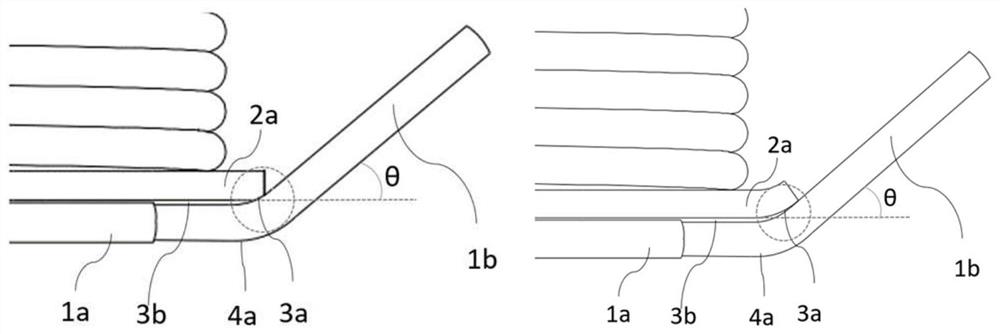

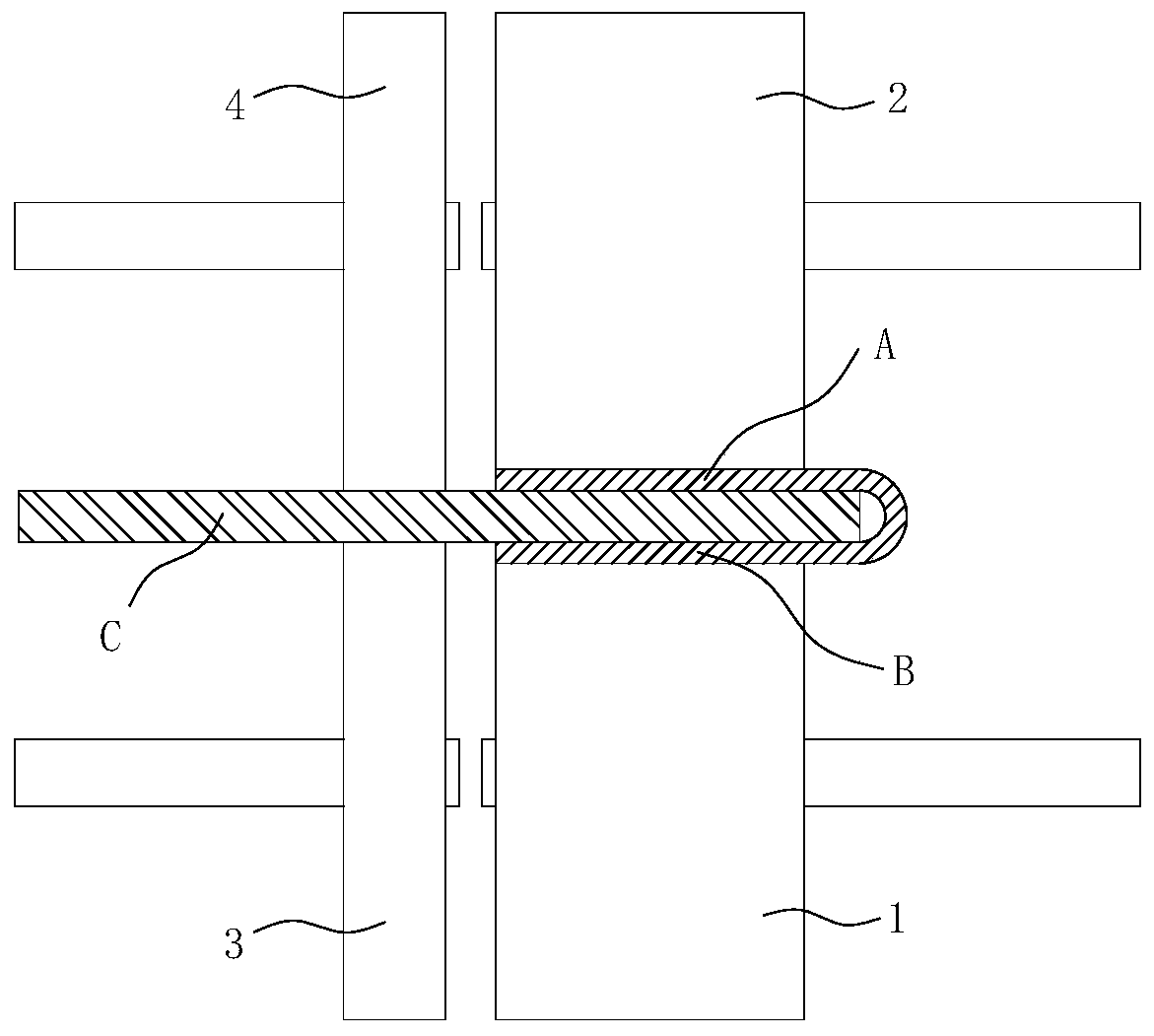

Tab bending method for multi-tab battery cell

ActiveCN113571845AImprove consistencyEasy to pass throughFinal product manufactureSecondary cellsElectrical polarityEngineering

The invention belongs to the technical field of batteries, and particularly relates to a tab bending method of a multi-tab battery cell. The method comprises the following steps of 1, respectively cutting tabs on two pole pieces, and sequentially winding the two pole pieces and a diaphragm to prepare a naked battery cell with a multi-tab structure; 2, overlapping a plurality of tabs with the same polarity and then cutting, hot-pressing and bending into a foil tab group with a preset shape, meanwhile, bending a metal strap tab with a through hole by a preset angle, wherein tab glue is pasted to the surface of the metal strap tab; 3, enabling the foil tab group to pass through the through hole, wrapping the root of the metal strap tab, and then fixedly connecting the foil tab group with the metal strap tab; and 4, pasting protective adhesive paper on the foil tab group and the metal strap tab. By optimizing the multi-tab process, the stability of the multi-tab structure is improved, and the position consistency of the bent tabs can be improved.

Owner:HUIZHOU LIWINON NEW ENERGY TECH CO LTD

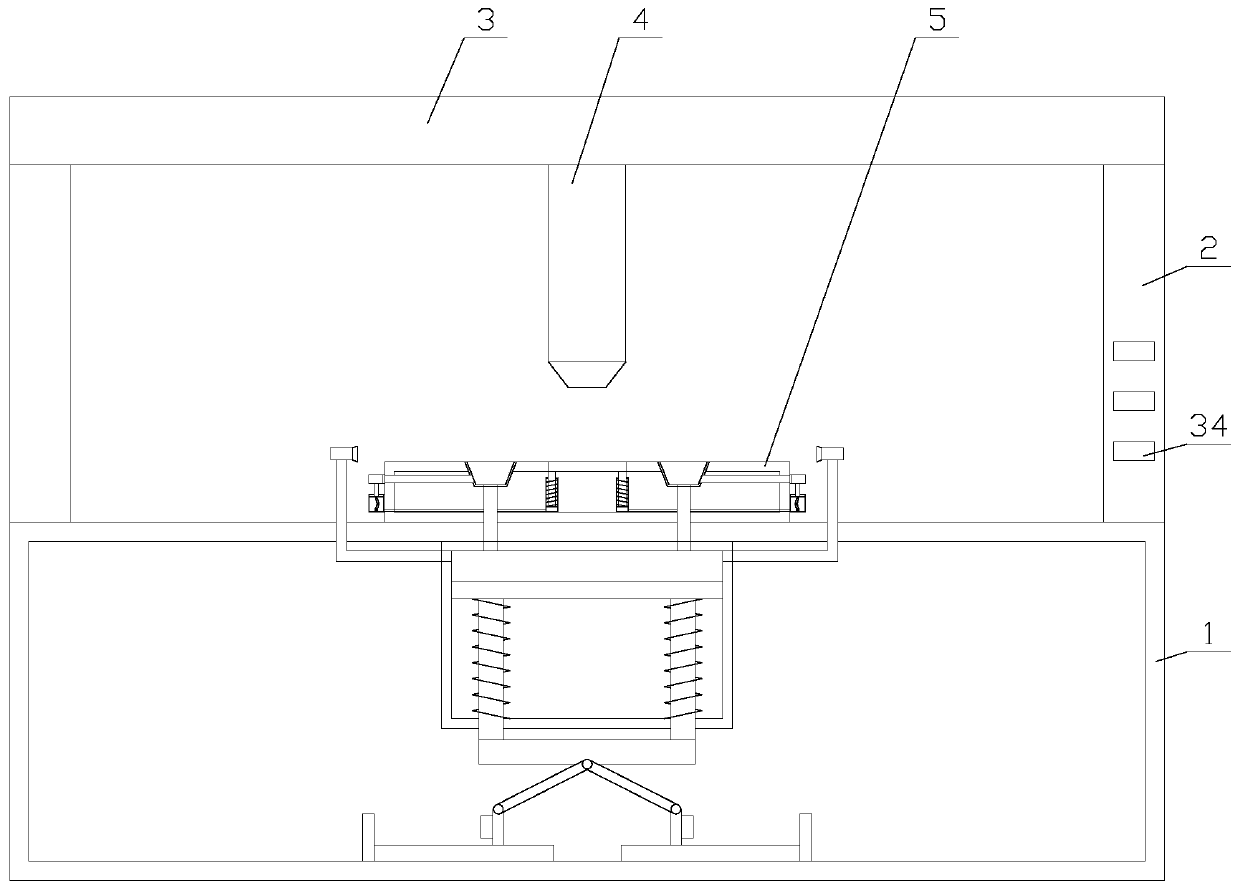

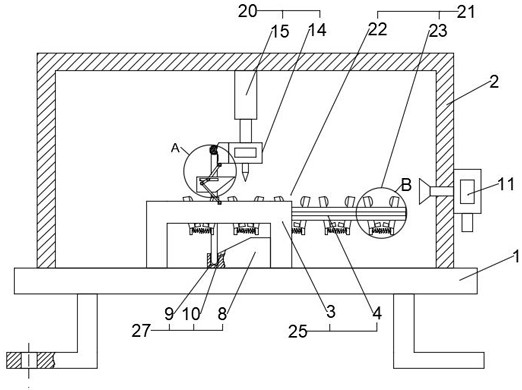

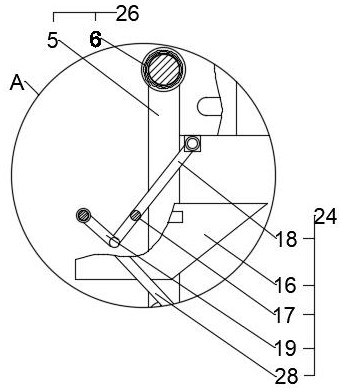

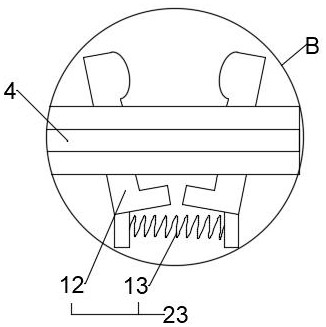

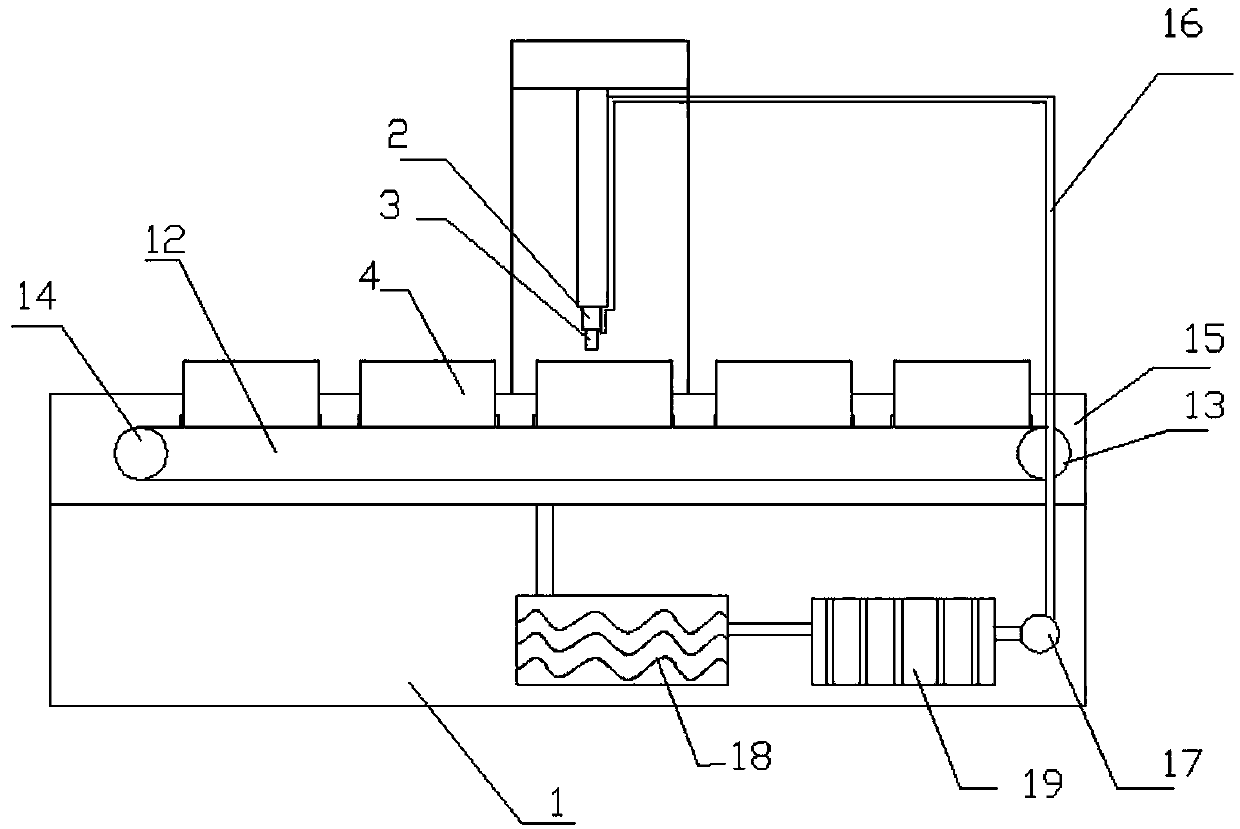

High-convenience laser welding equipment with fixing function

InactiveCN111203635ARealize dust removal functionAvoid affecting the welding effectWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPipe

The invention relates to high-convenience laser welding equipment with a fixing function. The equipment comprises a base, a workbench, a supporting plate, a welding head and two supporting rods and further comprises a stabilizing mechanism and a material taking mechanism; the stabilizing mechanism comprises an air cylinder, a piston, a supporting frame, a driving assembly, two first springs, two fixing assemblies, two dust removing assemblies and two ventilating assemblies, wherein the fixing assemblies comprise suction cups and first connecting pipes; and the material taking mechanism comprises a moving plate and two lifting assemblies, wherein the lifting assemblies comprise lifting boxes, lifting rods, lifting plates and second springs. According to the high-convenience laser welding equipment with the fixing function, through the stabilizing mechanism, the function of fixing work pieces is achieved, and the situation that the welding effect is affected by the deviation of the positions of the work pieces during welding is avoided; and through the material taking mechanism, the work pieces are jacked up, and the work pieces are separated from the workbench, so that the convenience of material taking is improved, and the practicability is high.

Owner:深圳市琦美创科技有限公司

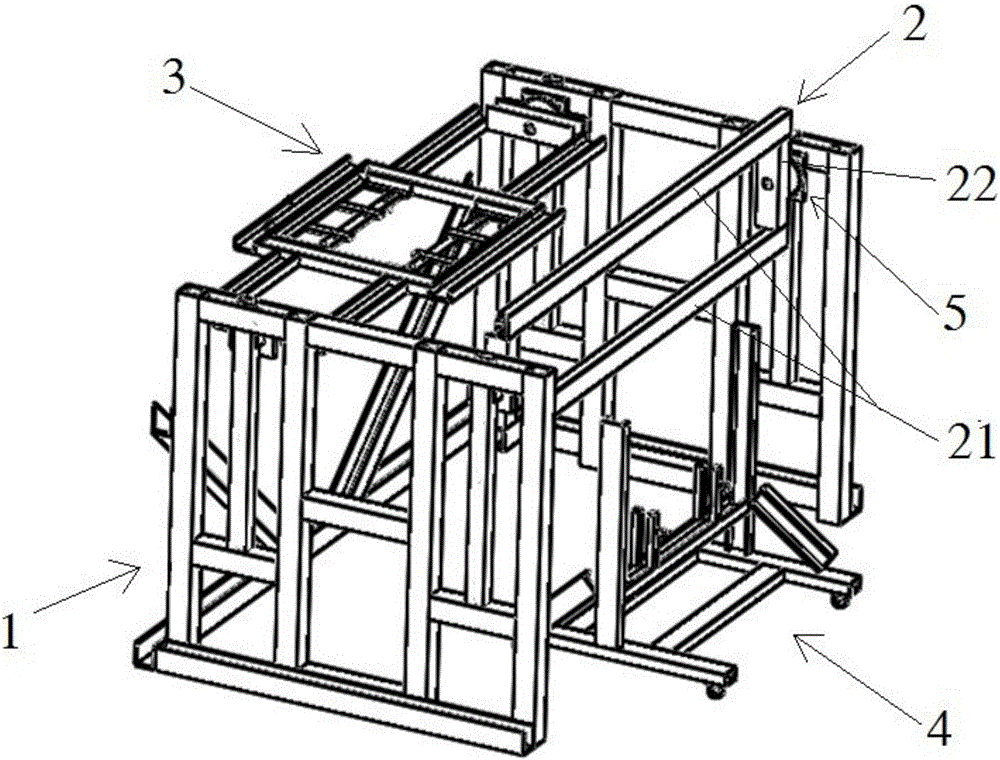

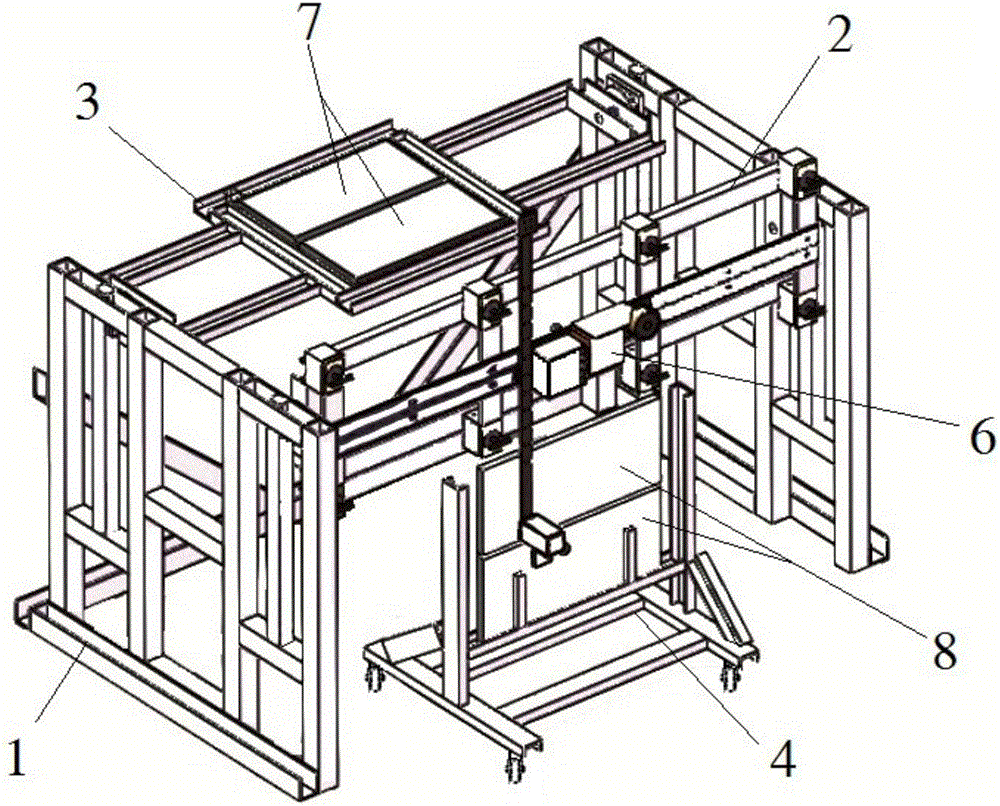

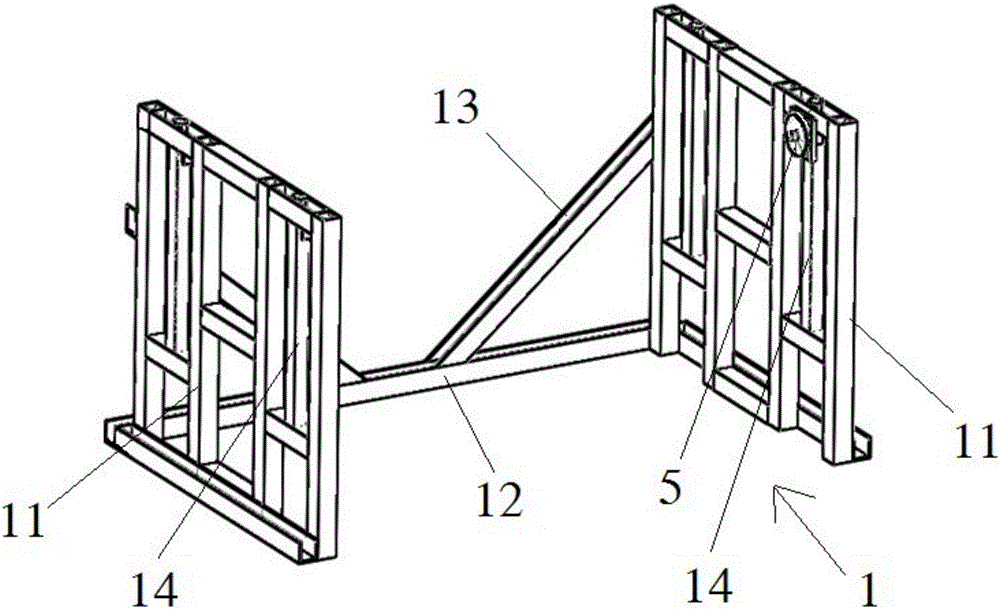

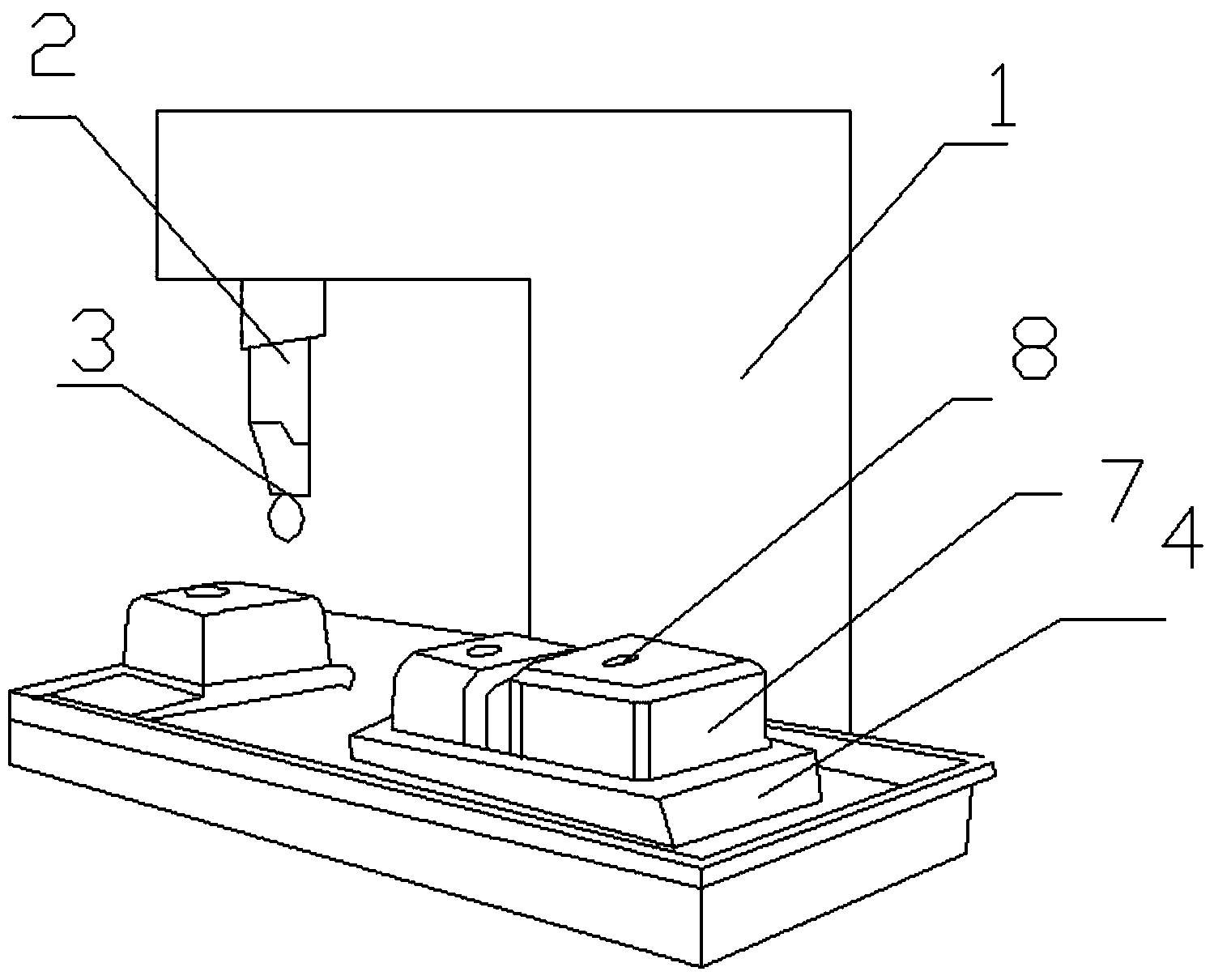

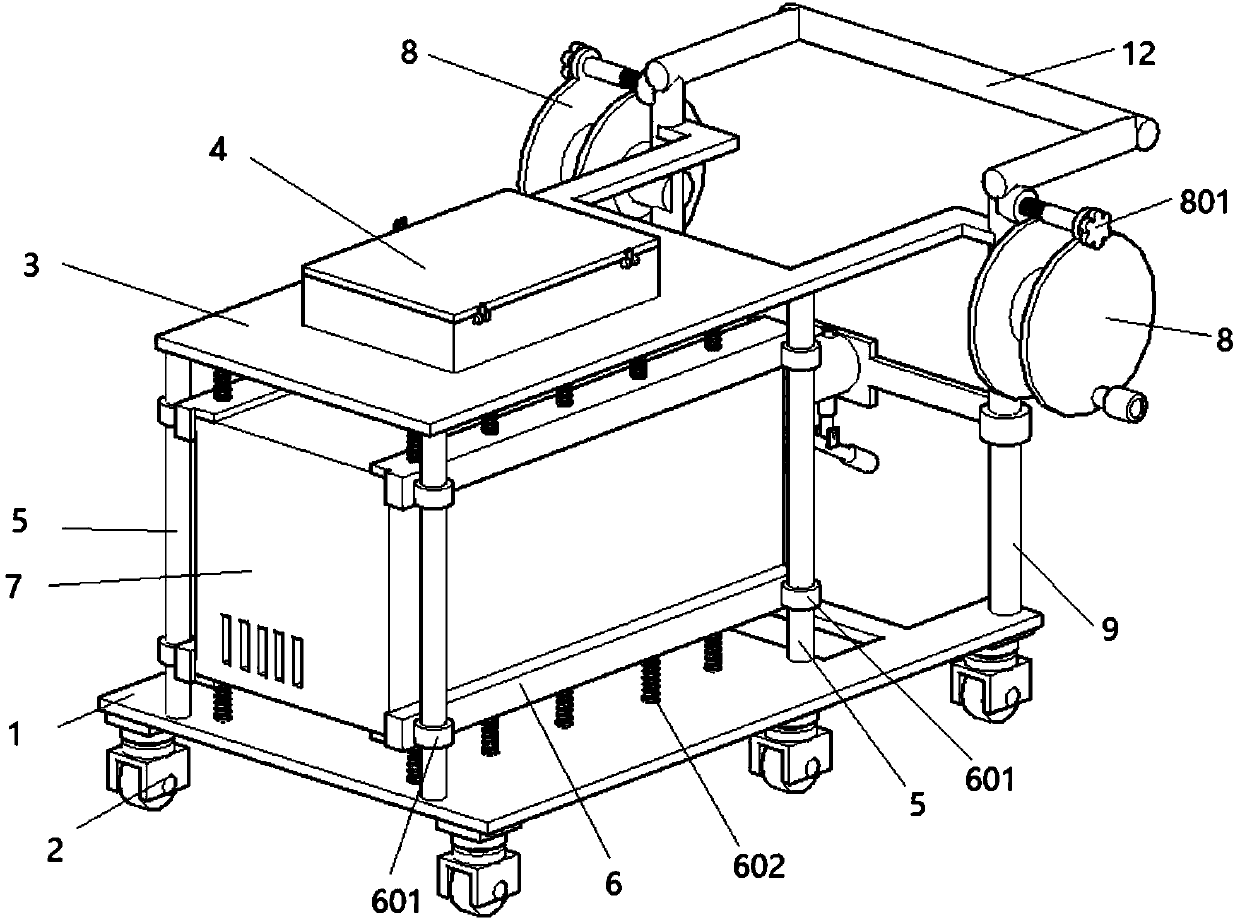

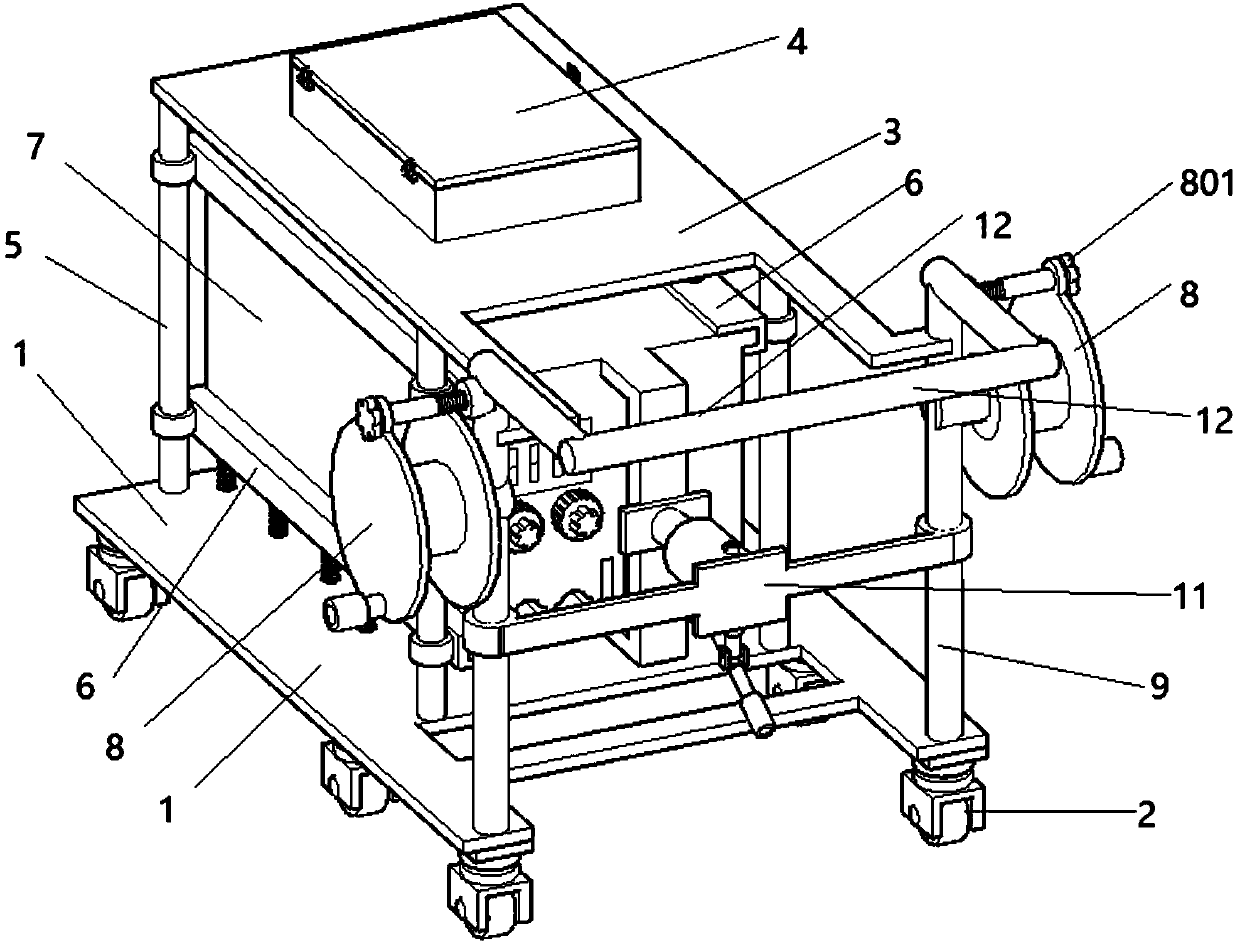

Tool for automatic welding training

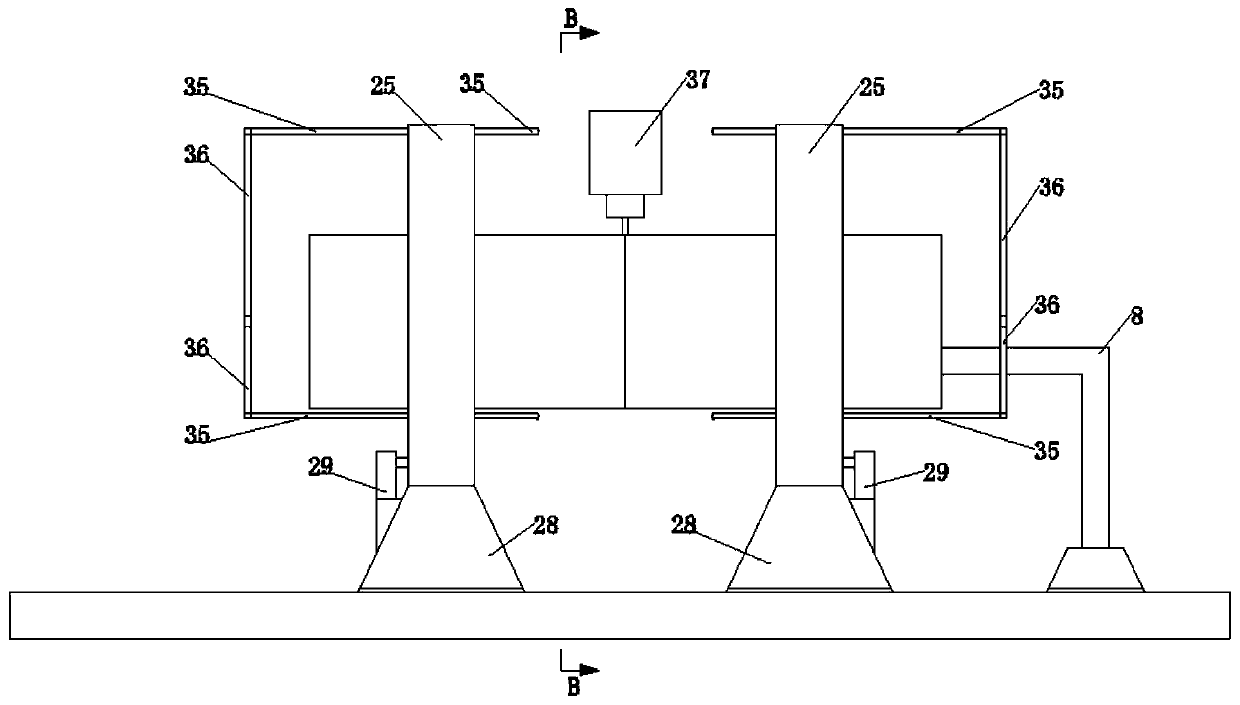

ActiveCN106670716AAvoid affecting the welding effectIncrease the types of welding trainingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention relates to the field of automatic welding training, in particular to a tool for automatic welding training. The tool for automatic welding training aims at achieving the effects that efficiency and safety of automatic welding operation training are improved. The tool comprises a peripheral support frame, an automatic welding equipment mounting platform and a horizontal test piece storage rack. The two ends of the automatic welding equipment mounting platform are connected with the peripheral support frame through rotary locating and connecting pieces, and the automatic welding equipment mounting platform can rotate around the rotary locating and connecting pieces in the peripheral support frame. The horizontal test piece storage rack and the automatic welding equipment mounting platform located at a flat-welding position or an overhead-welding position are located in the same horizontal plane. A rotary locating disc in each rotary locating and connecting piece is fixedly mounted on the peripheral support frame and provided with a central hole and locating holes. The locating end of each locating shaft is arranged in the central hole of the corresponding rotary locating disc in a penetrating manner. The connection end of each locating shaft is fixedly connected with the automatic welding equipment mounting platform, and the locating end of each locating shaft is provided with a locating pin groove. When the tool for automatic welding training is used for conducting automatic welding training, training is conducted safely, and efficiency is high.

Owner:CHINA NUCLEAR IND 23 CONSTR

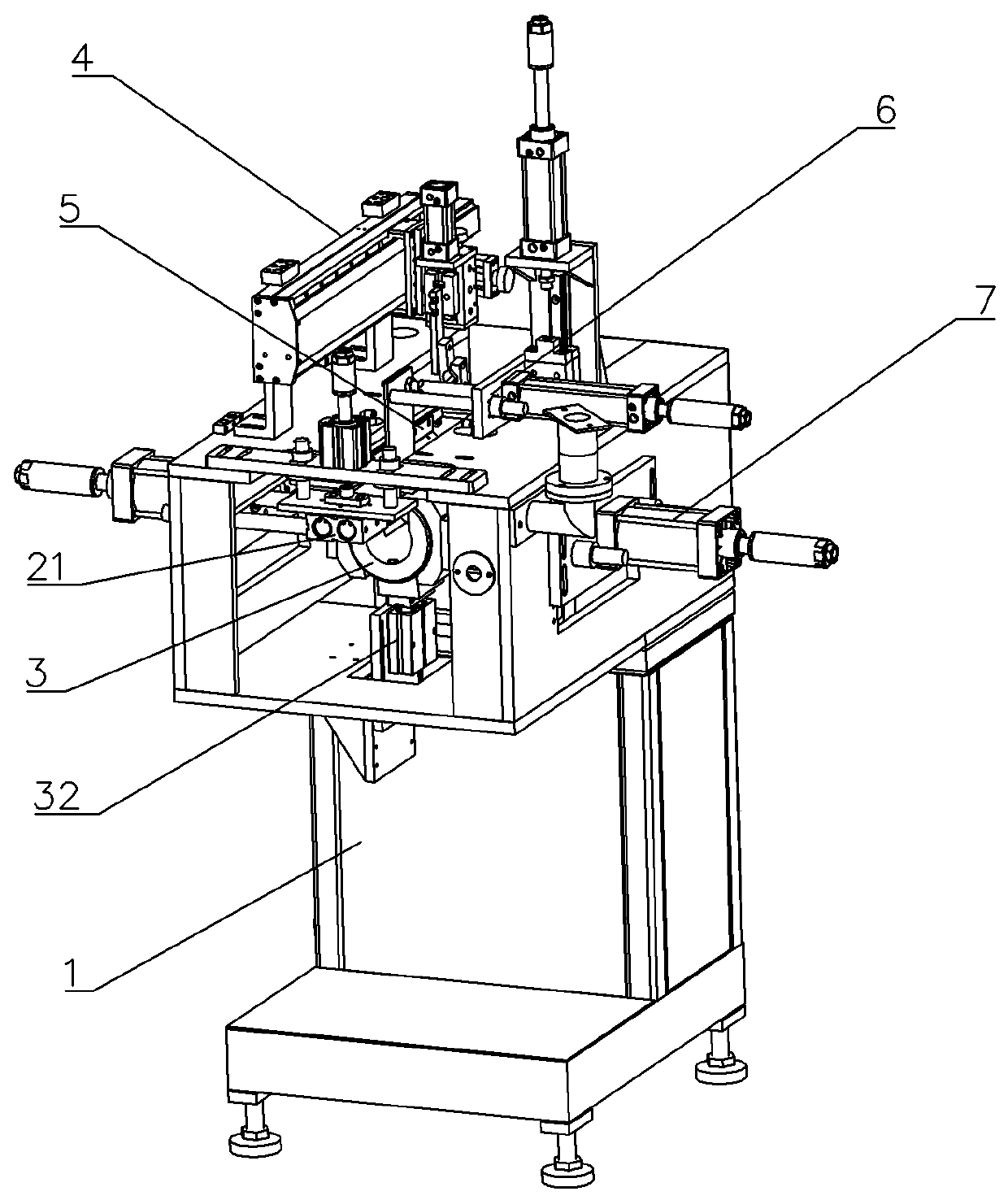

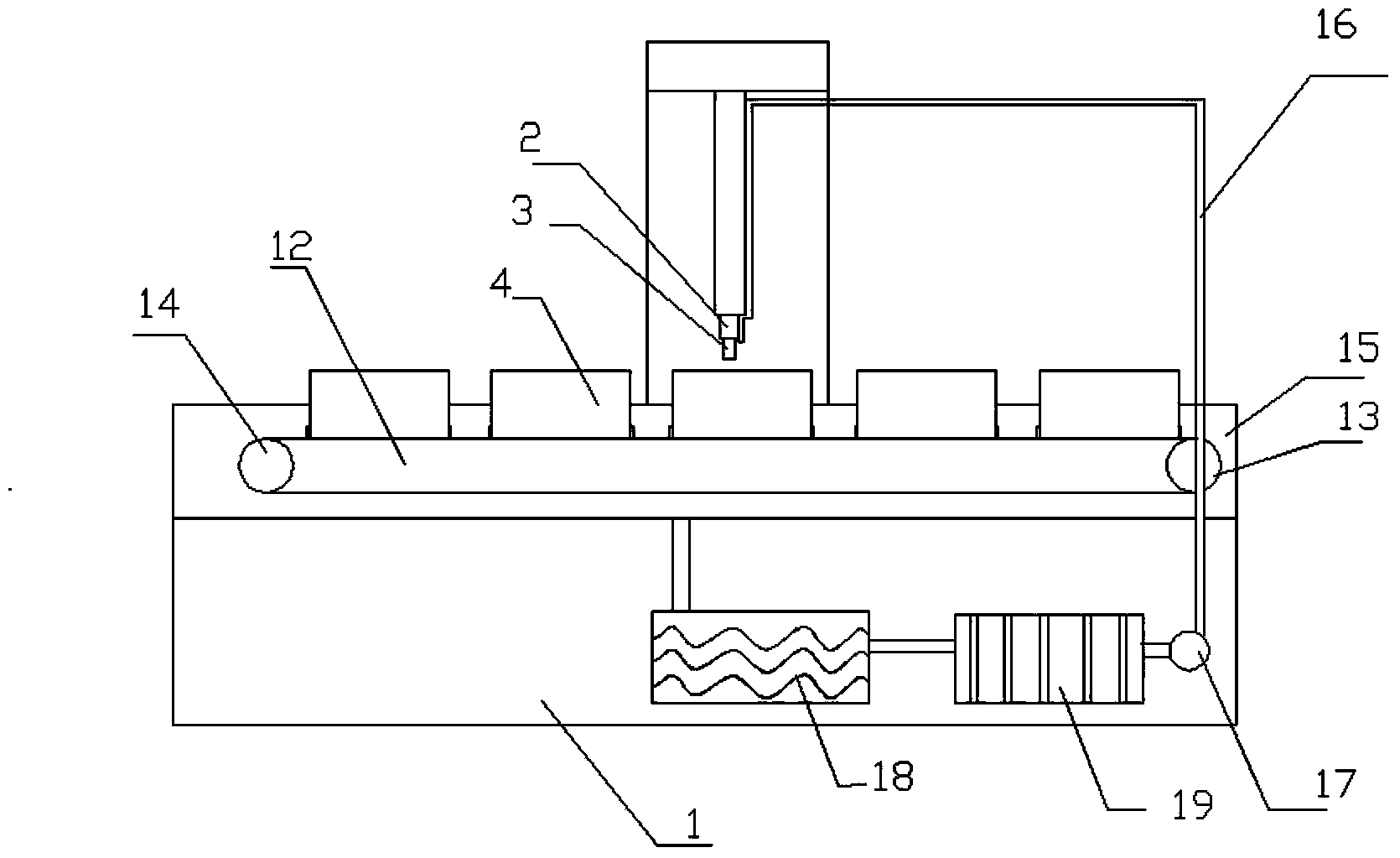

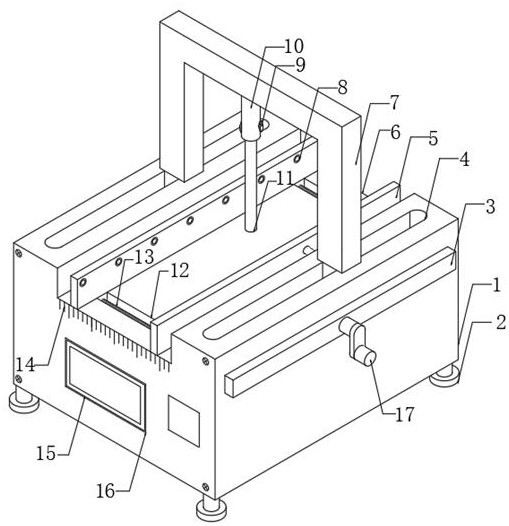

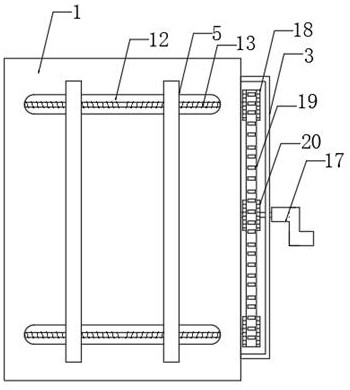

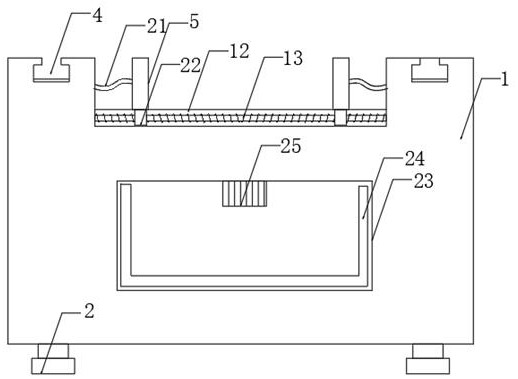

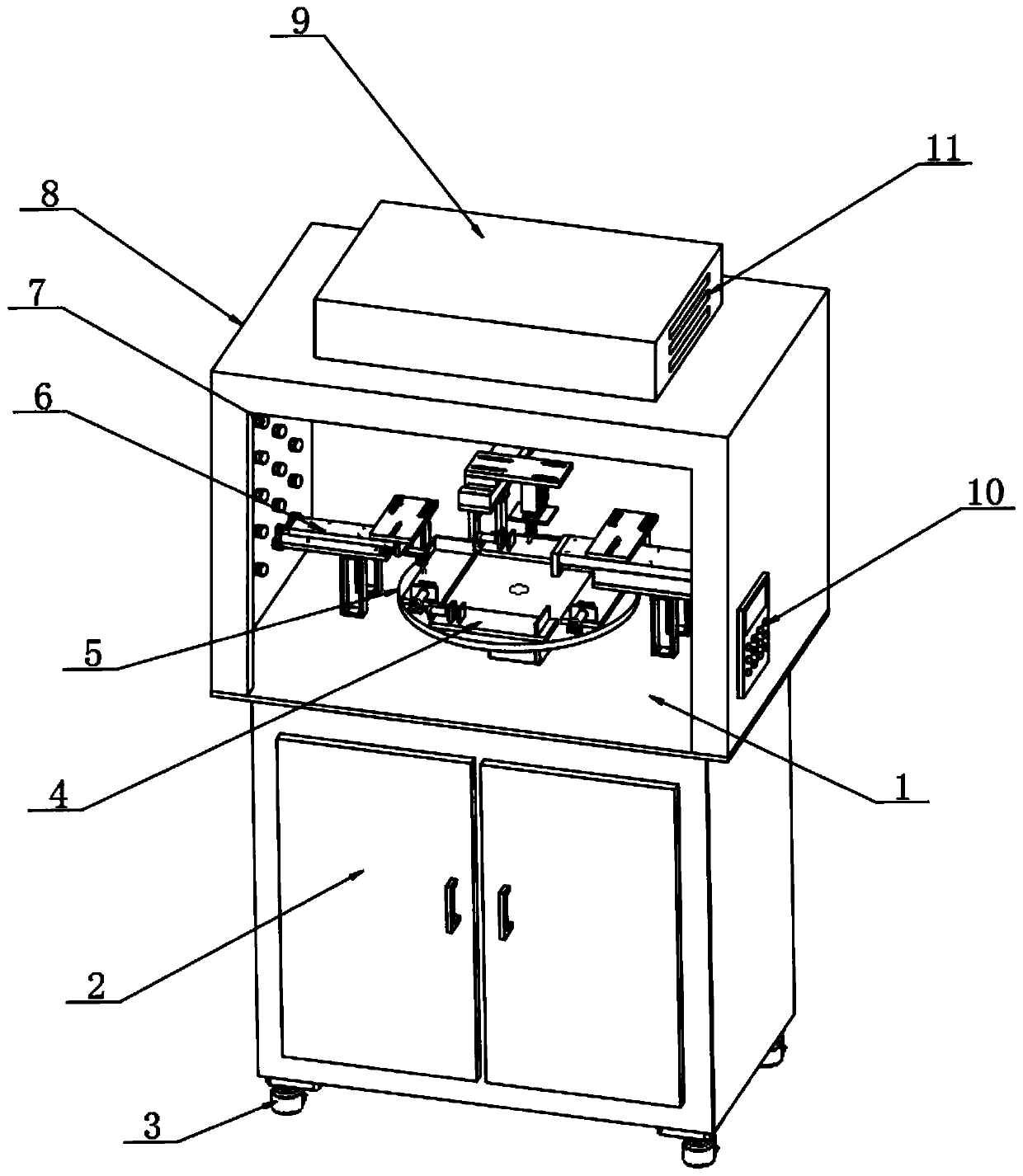

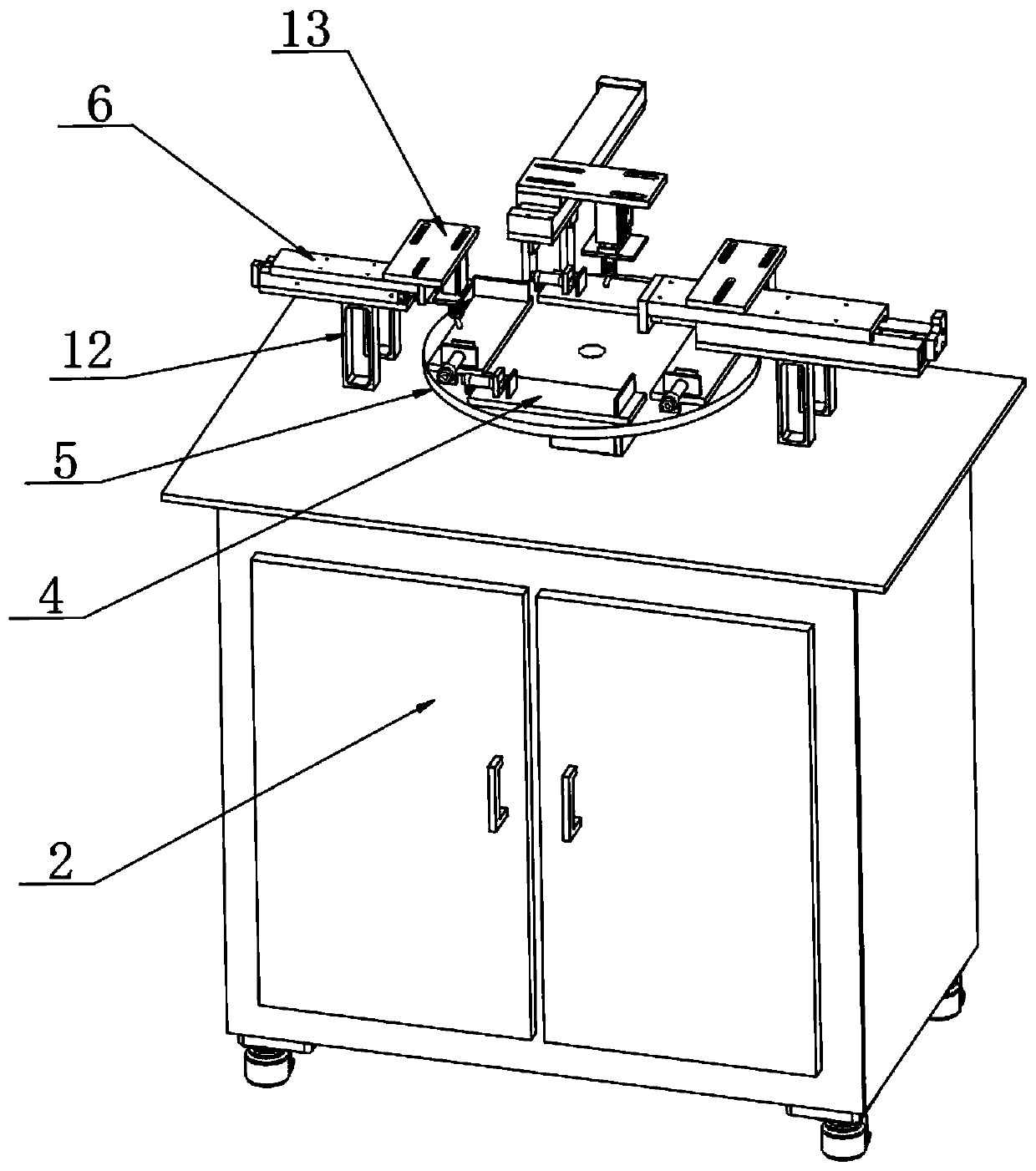

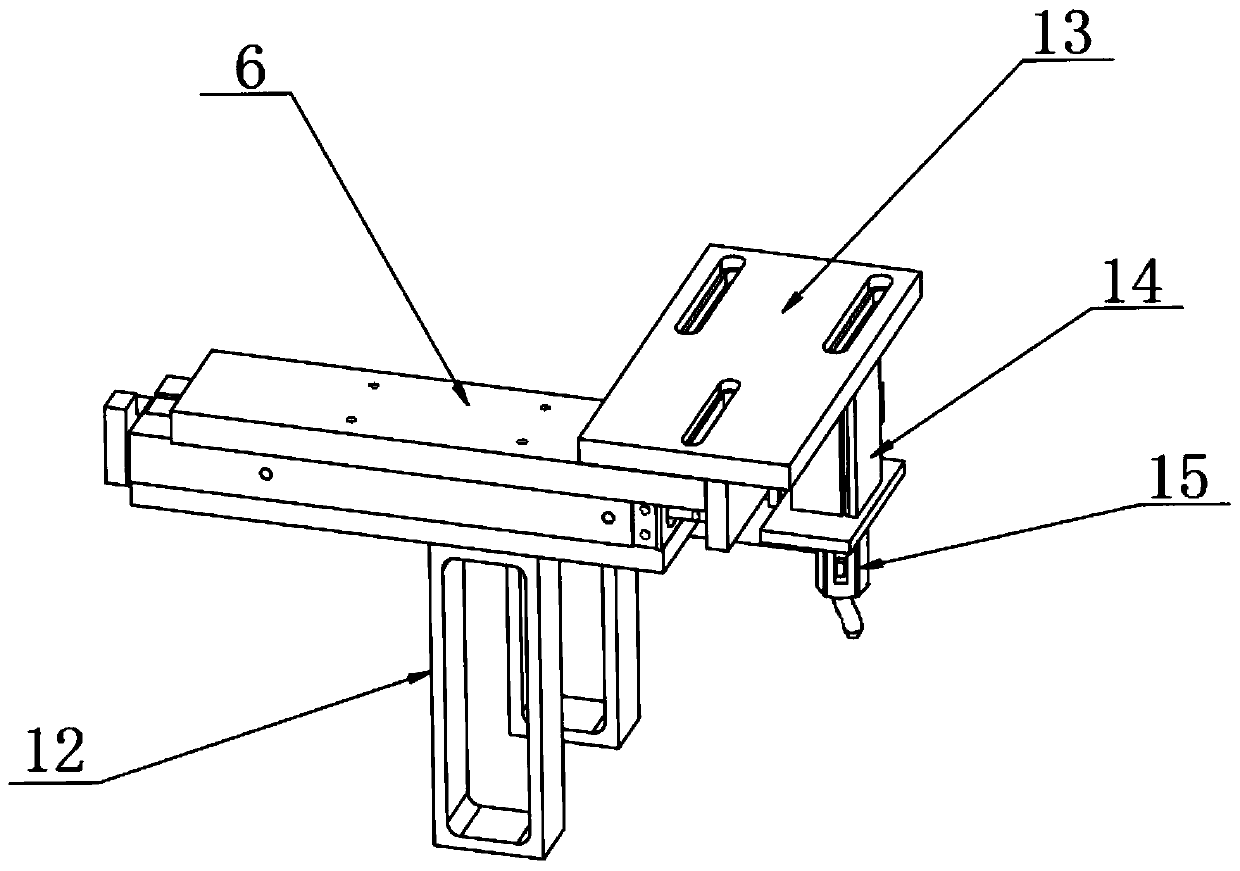

Full-automatic straight seam welding equipment

InactiveCN110293356AGuaranteed positionNo displacement deviation will occurWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSeam welding

The invention discloses full-automatic straight seam welding equipment. The full-automatic straight seam welding equipment comprises a rack, wherein a main shaft where workpieces are placed is arranged in the middle of the rack; a welding mechanism, a positioning assembly and a clamping assembly are arranged on the periphery of the main shaft, and the welding mechanism is arranged over the main shaft; the positioning assembly is at least composed of clamping mechanisms arranged on the left side and the right side above the main shaft and a positioning plate mechanism movably arranged between the clamping mechanisms on the left side and the right side; and the clamping assembly is at least composed of side edge positioning mechanisms arranged on the left side and the right side of the mainshaft. According to the full-automatic straight seam welding equipment, the positioning plate mechanism is arranged to locate the welding welding placing position of the workpieces in advance, so thatthe welding position of the workpieces is conveniently and effectively ensured; and meanwhile, the clamping mechanisms and the side edge positioning mechanisms ensure that no displacement deviation occurs when the workpieces are welded, so that the influence of the deviation on the welding effect in the welding process is avoided, the welding quality of the workpieces is effectively guaranteed, and the production efficiency is improved.

Owner:HONY MACHINERY CO LTD

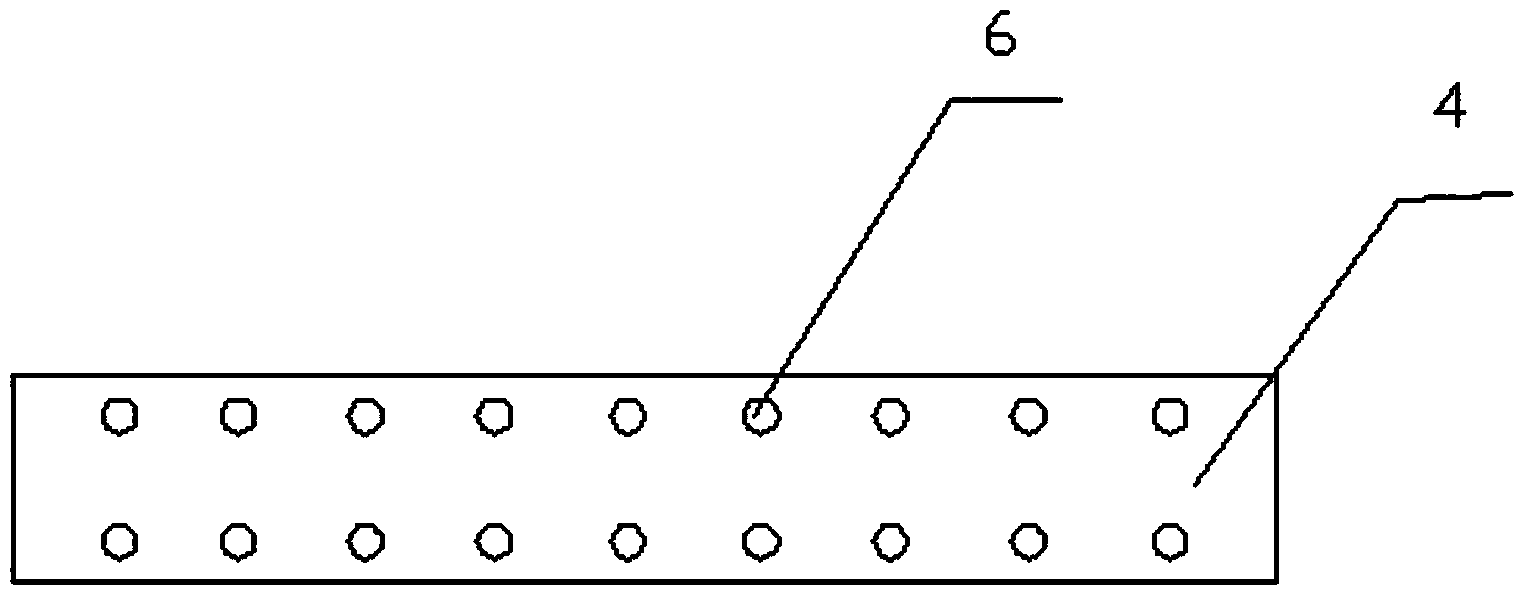

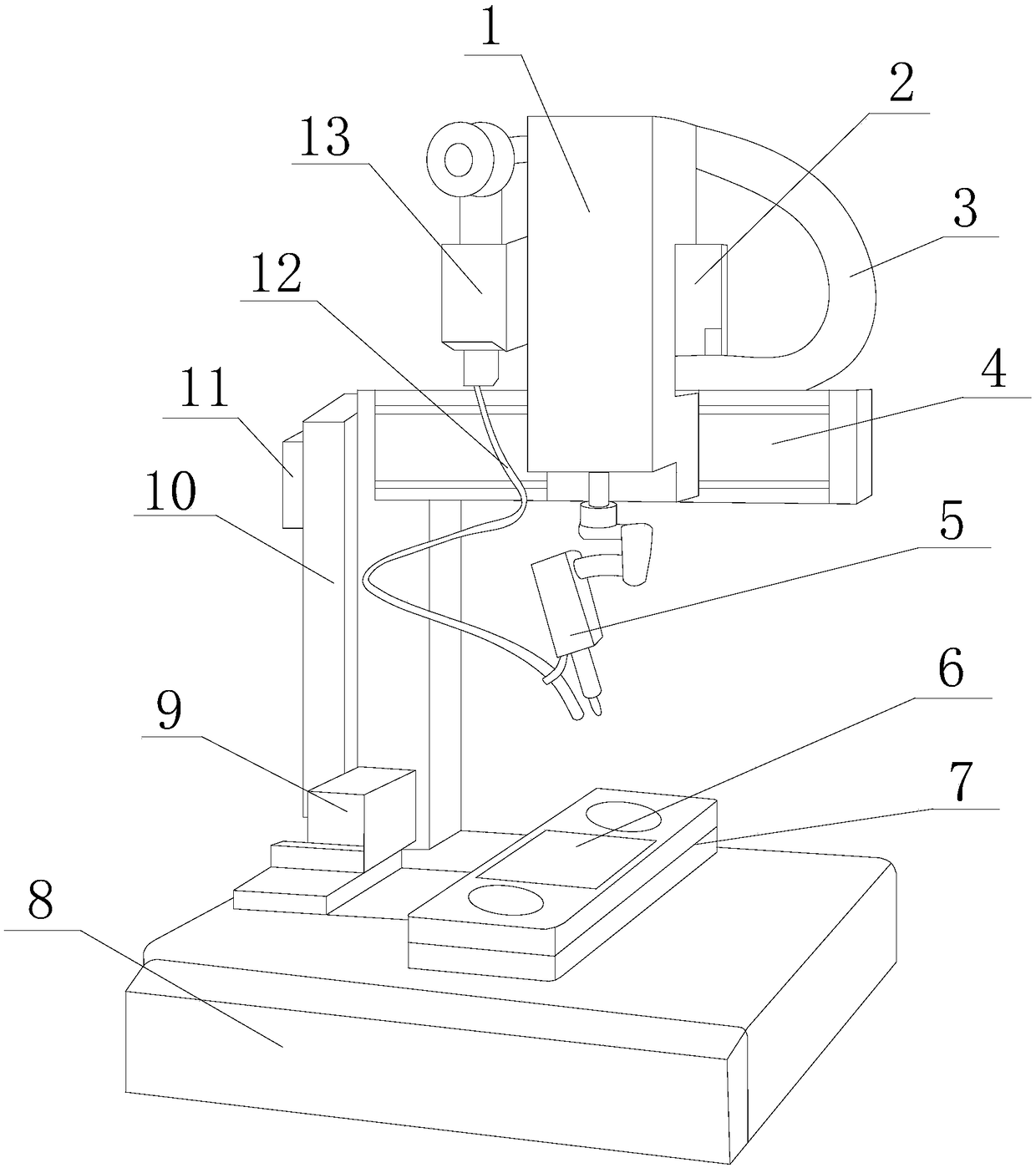

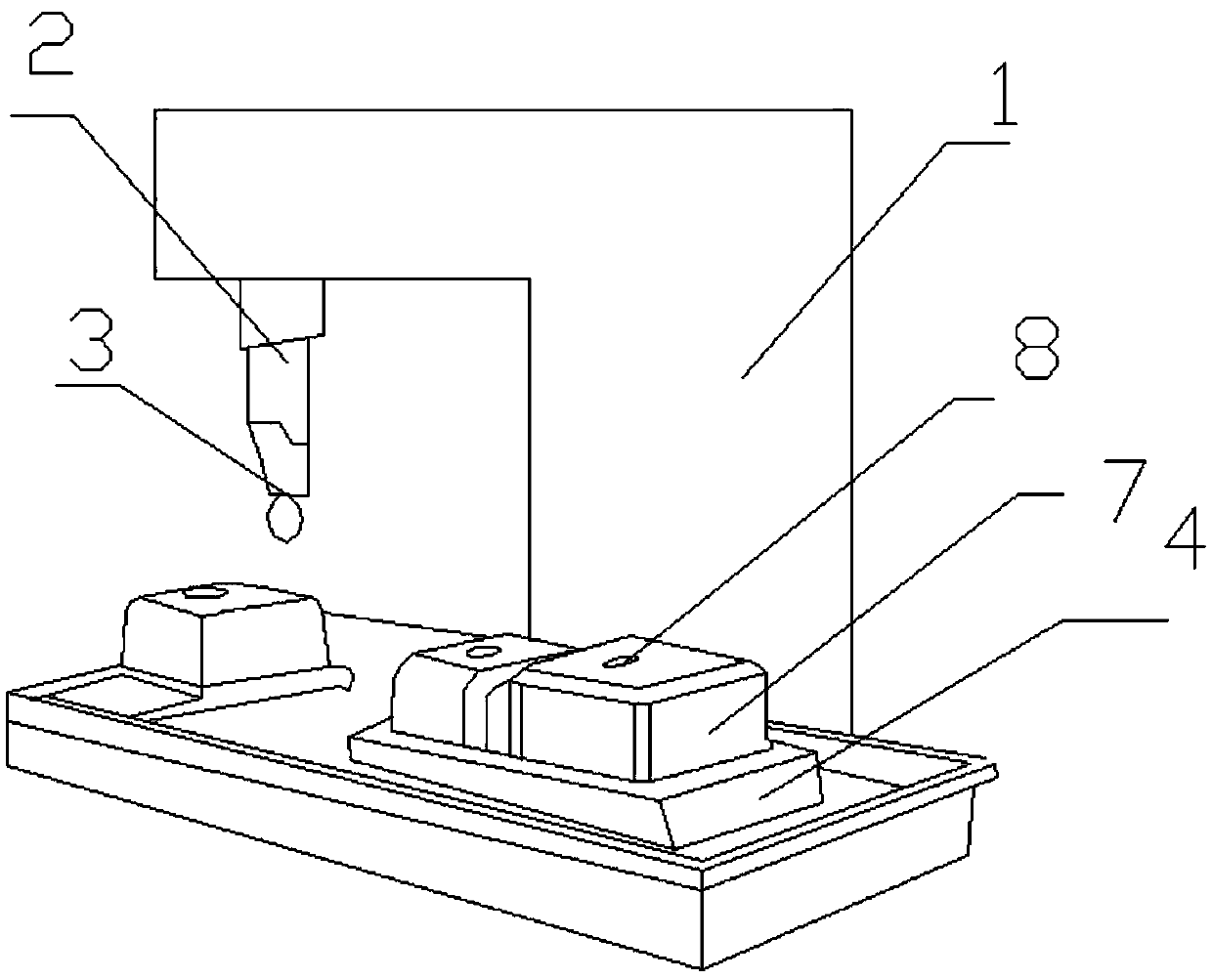

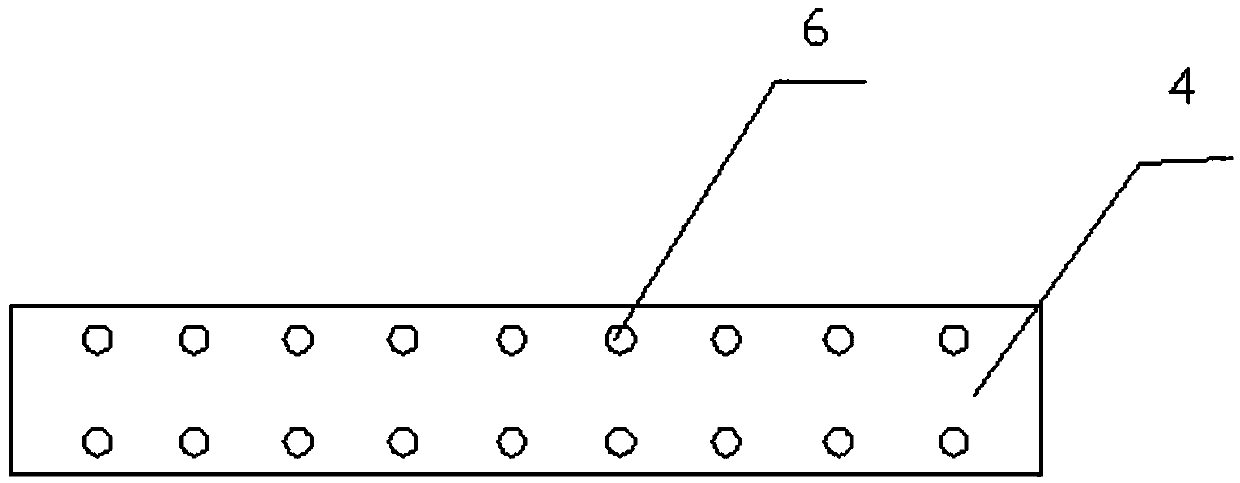

Special electric welding machine for welding stainless steel water tank

InactiveCN104227217AExtended service lifeAvoid displacementWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWater tanks

The invention discloses a special electric welding machine for welding a stainless steel water tank. The special electric welding machine comprises a rack, a welding head connecting rack and a welding head, wherein the welding head is connected to the rack by virtue of the welding head connecting rack; the special electric welding machine further comprises a workbench and at least two locating pieces; the workbench is fixedly arranged on the rack and positioned below the welding head; the workbench is provided with multiple locating holes; the locating pieces are arranged in the locating holes. As actual conditions during stainless steel water tank welding are fully considered, the special electric welding machine is accurate in locating and free from welding deviation.

Owner:湖州佳士不锈钢制品有限公司

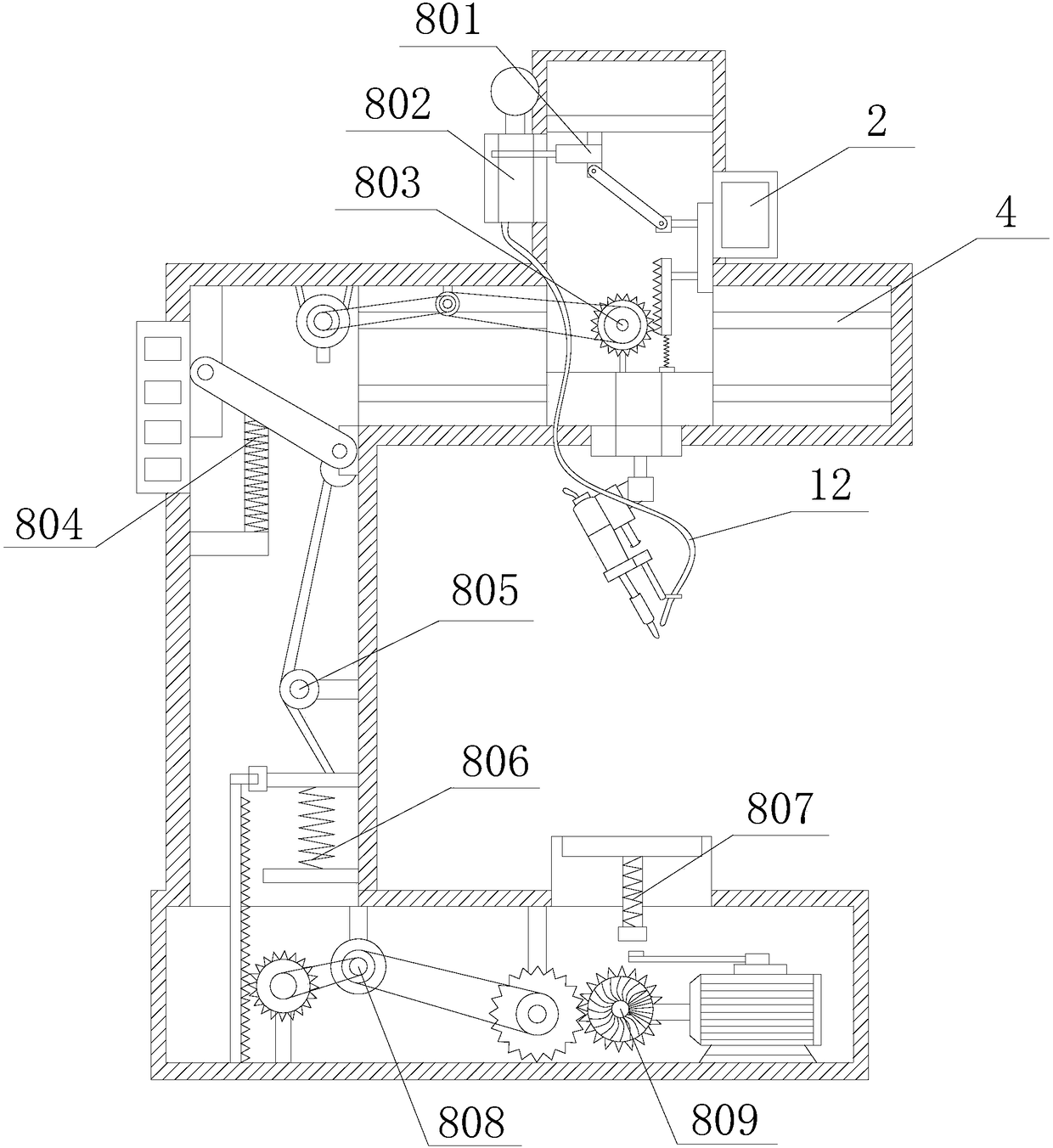

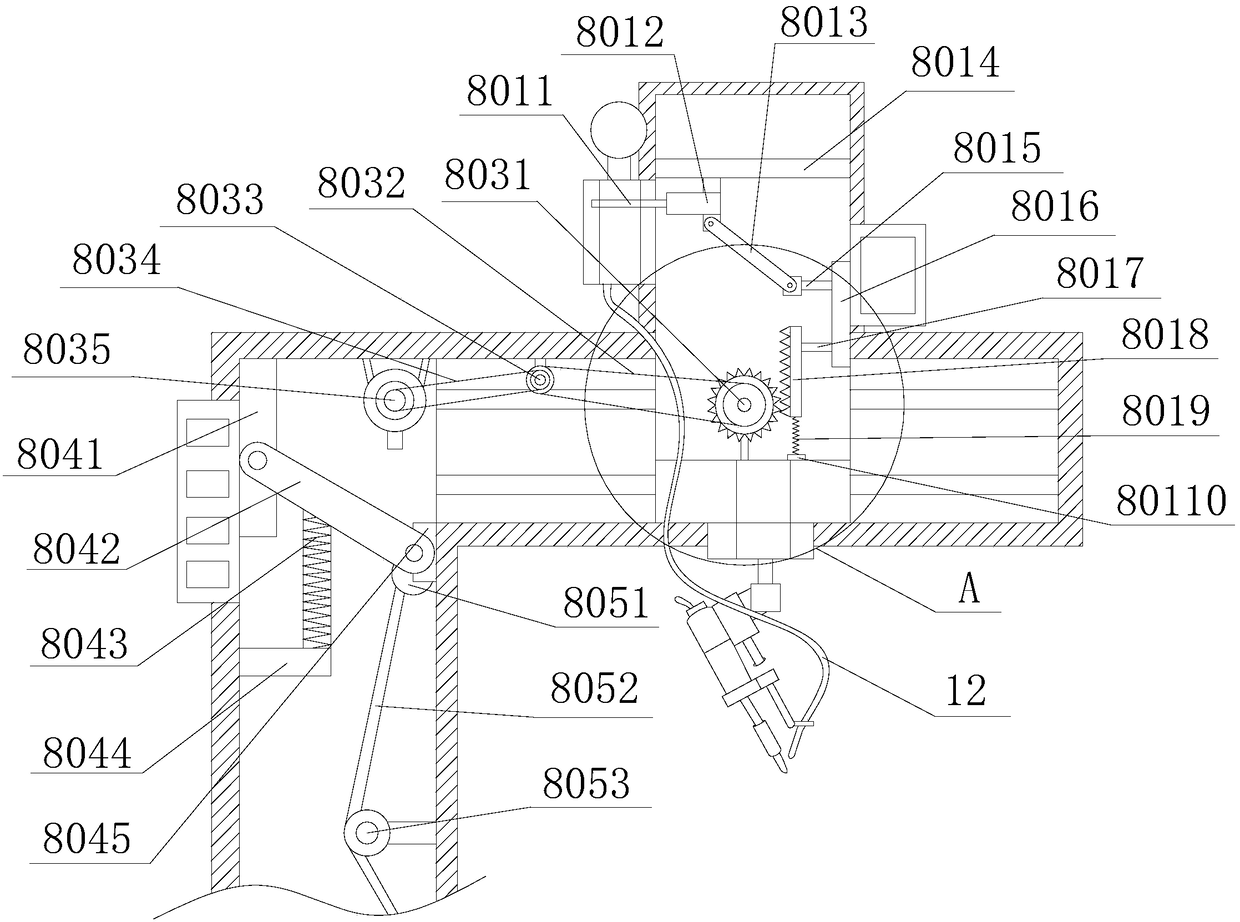

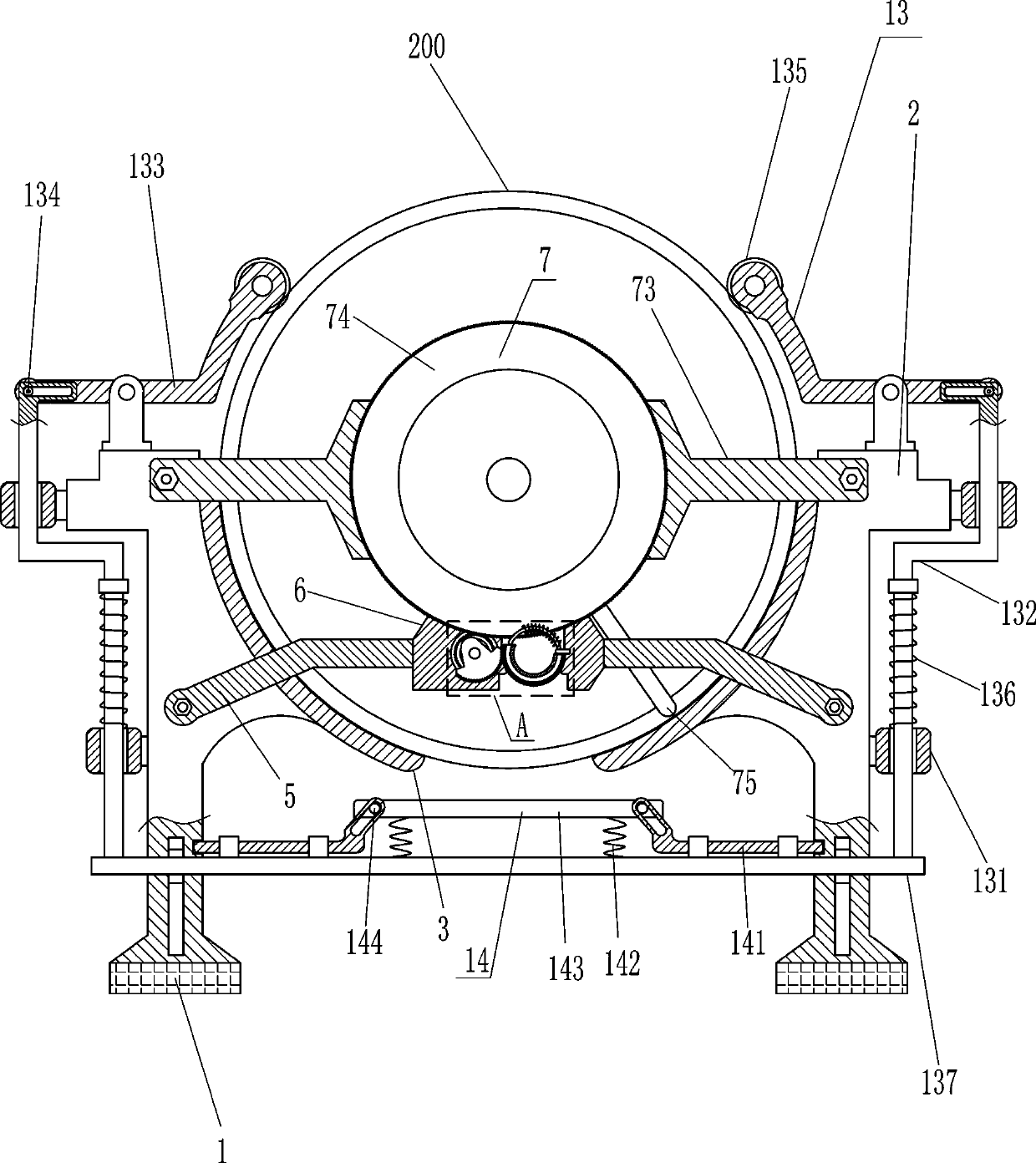

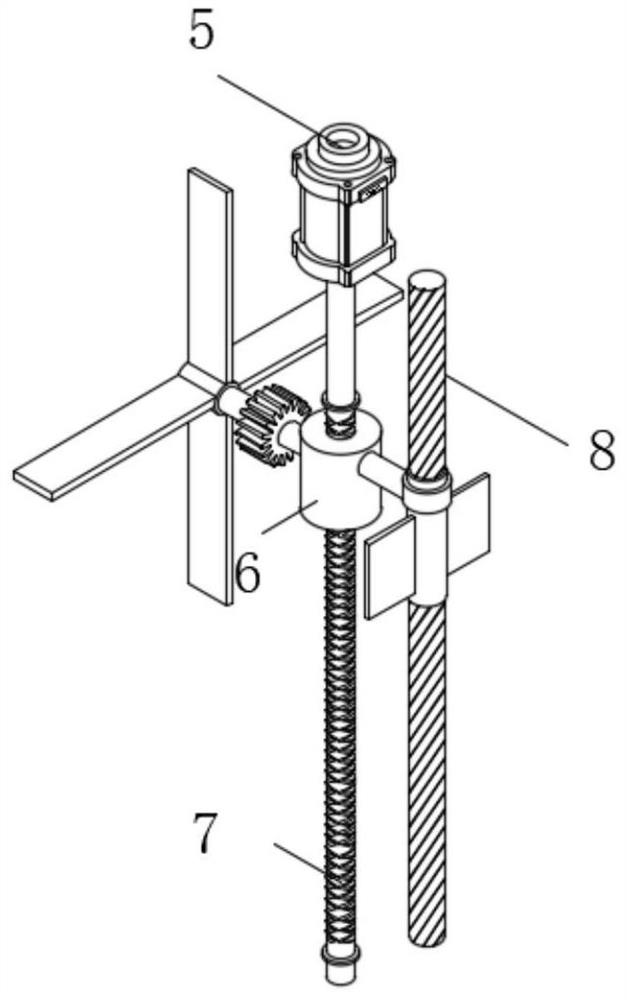

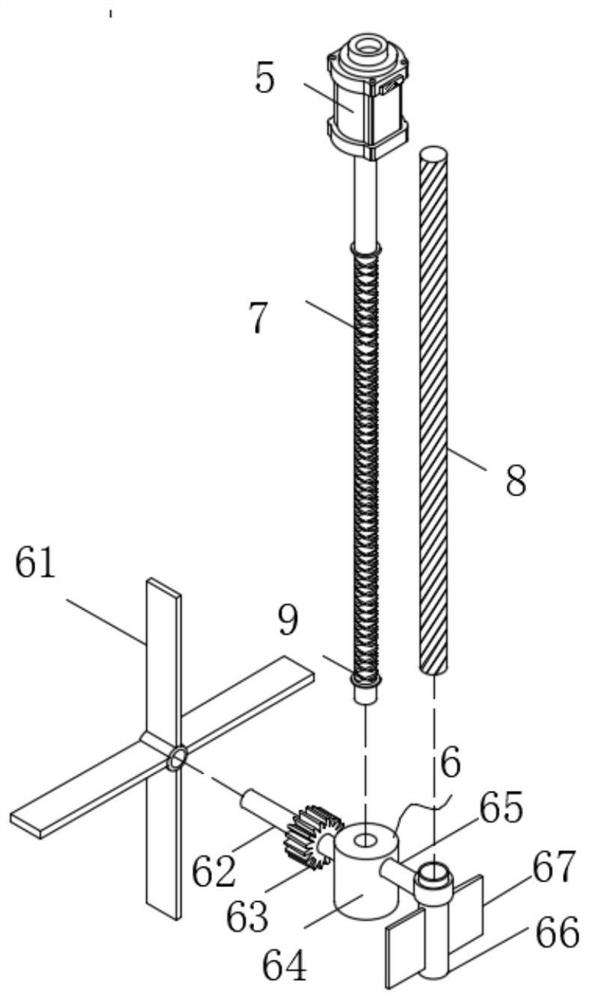

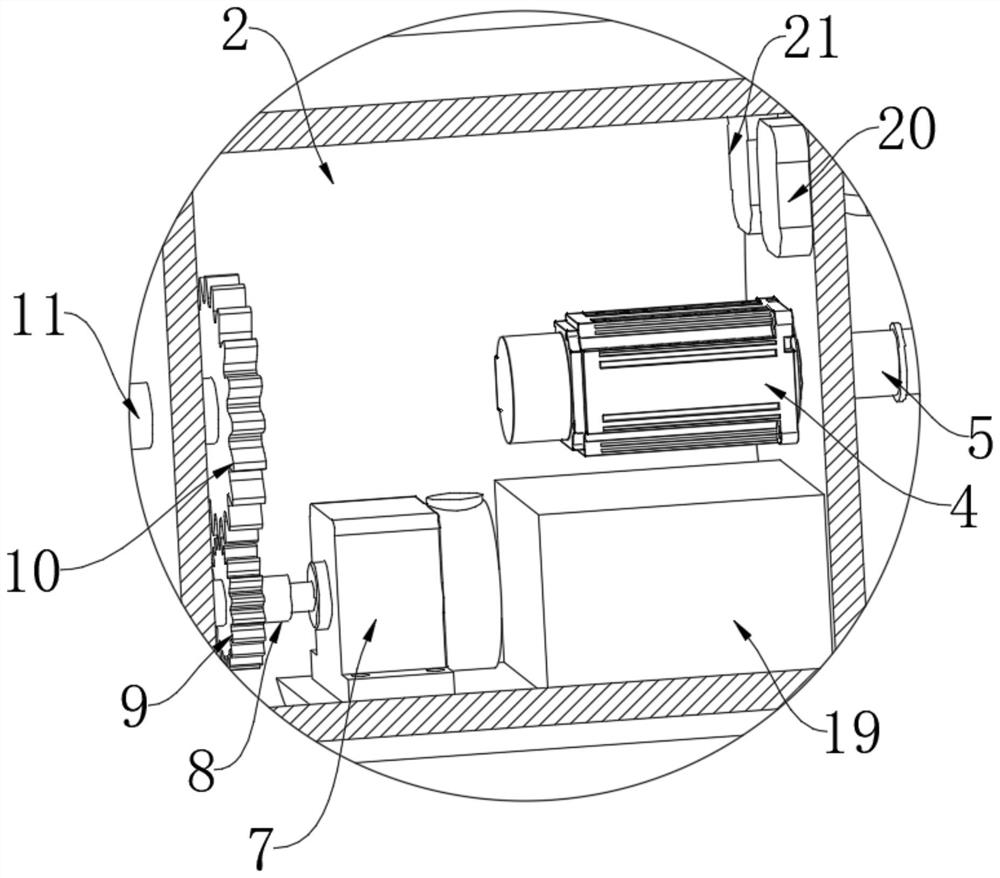

Arc welding track table for robot workstation teaching and demonstration recording mechanism thereof

InactiveCN111613099AEasy to fixAvoid affecting the welding effectEducational modelsCleaning using gasesCrankGear wheel

The invention discloses an arc welding track table for robot workstation teaching and a demonstration recording mechanism of the arc welding track table. The arc welding track table comprises a tracktable, a welding groove is formed in the middle of the track table; sliding grooves are formed in the two sides of the groove bottom of the welding groove, two sliding blocks are slidably connected into each sliding groove, forward and reverse lead screws are rotatably connected to the groove walls of the two sides of each sliding groove through embedded bearings, the two ends of each forward andreverse lead screw are in threaded connection with the middles of the corresponding sliding blocks, and limiting plates are fixedly installed at the top ends of the two sliding blocks on the same side. According to the invention, a Z-shaped crank drives a driving gear to rotate; the driving gear is in transmission connection with two driven gears through chains; therefore, the driving gear rotatesto drive the two driven gears to rotate synchronously, the driven gears rotate to drive the two forward and reverse lead screws to rotate synchronously, the two limiting plates are driven to be separated and closed through the synchronous rotation of the forward and reverse lead screws, a welded object in the welding process can be firmly fixed conveniently, and the welding effect is prevented from being affected.

Owner:广东卓瑞科技教育股份有限公司

Reductant composition and preparation method thereof, and welding method

InactiveCN103212921AReduce scumSpeed up the flowWelding/cutting media/materialsSoldering mediaTherapeutic effectReducing agent

The invention provides a reductant composition which comprises a nonionic surfactant, an antioxidant and ammonium metaphosphate. Meanwhile, the invention further discloses a preparation method of the reductant composition and a welding method. The reductant composition provided by the invention used in wave-soldering is excellent in scum treatment effect, and convenient and safe to use.

Owner:SHENZHEN KUNQI XINHUA

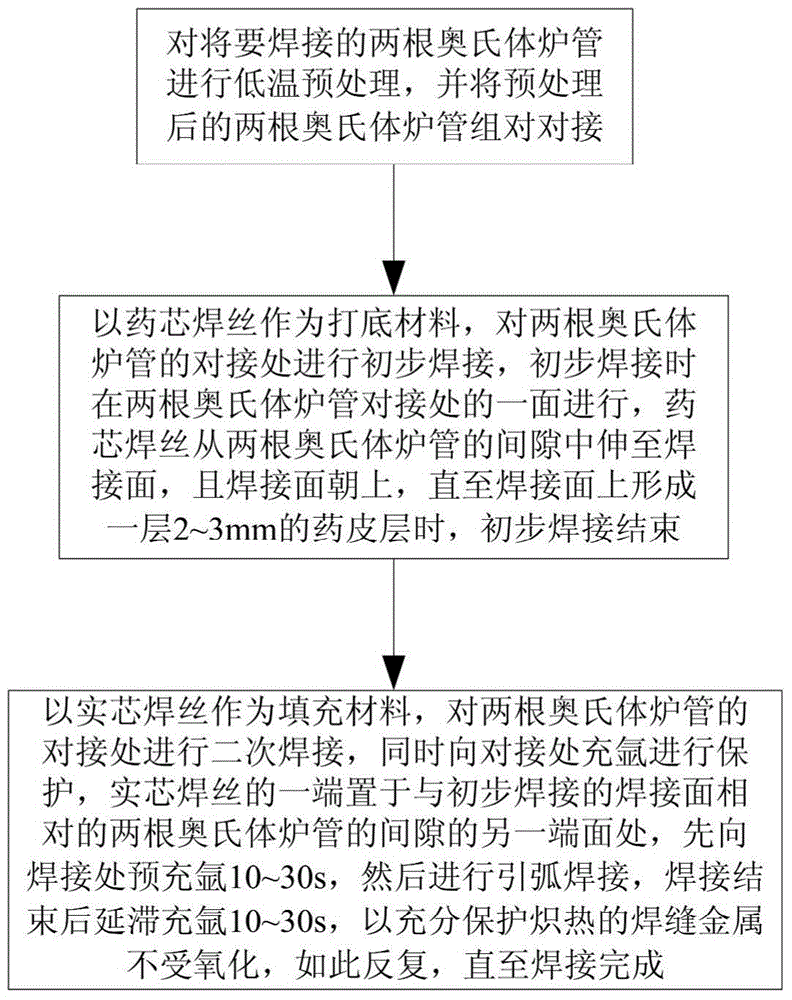

Austenite furnace tube welding method

ActiveCN104439631AReduce dissolved carbonAvoid corrosionMetal working apparatusTubular articlesFilling materialsEngineering

The invention relates to the field of furnace tube welding, in particular to an austenite furnace tube welding method. The method comprises the steps that two preprocessed austenite furnace tubes are assembled and connected in an abutting mode; a flux-cored wire is used as backing welding materials, preliminary welding is carried out on one face of the position where the two austenite furnace tubes are connected in the abutting mode, the flux-cored wire extends from a gap between the two austenite furnace tubes to the welding face, the welding face faces upwards, and preliminary welding is ended when a coating layer is formed on the welding face; a flux-cored wire is used as filling materials, secondary welding is carried out on the position where the two austenite furnace tubes are connected in the abutting mode, meanwhile, the abutting connection position is filled with argon for protection, one end of the flux-cored wire is placed on the other end face, opposite to the welding face where the preliminary welding is carried out, of the gap between the two austenite furnace tubes, the flux-cored wire is molten constantly until welding is completed. According to the austenite furnace tube welding method, inconvenience brought when furnace tube bottoming welding tubes are filled with argon for protection is omitted, argon is saved, working efficiency is improved, meanwhile, crystal corrosion is avoided, residual stress in the welding process is reduced, and hot cracks are prevented from being generated.

Owner:CHINA NAT CHEM ENG NO 16 CONSTR +1

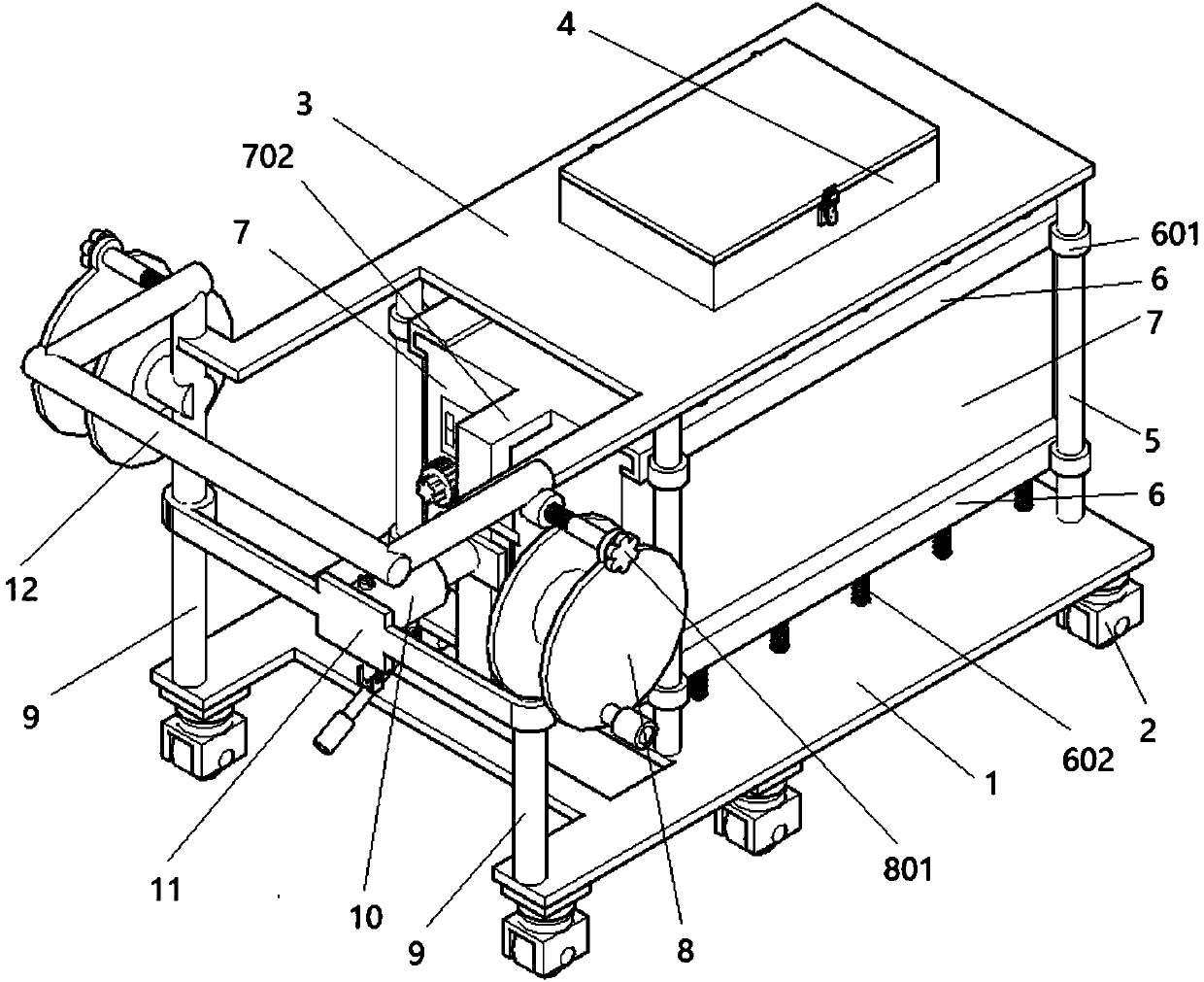

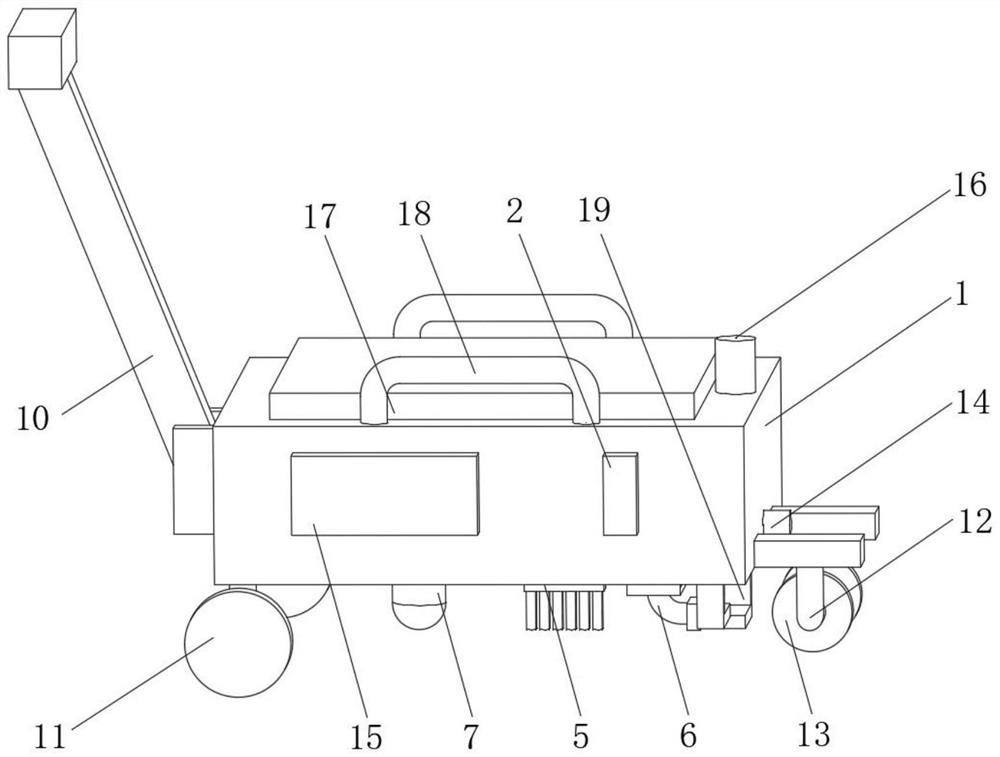

Portable automatic spot welding robot

ActiveCN108372340ARealize deliveryAvoid wastingSolder feeding devicesSoldering auxillary devicesElectrical controlEngineering

The invention discloses a portable automatic spot welding robot. The portable automatic spot welding robot structurally comprises a welding head workbench, an electric control cabinet, a driving cable, a moving rail, soldering iron, a placing groove, a mounting base plate, a workbench, a tin recovery box, a supporting column, a touch screen, a tin guide pipe and a tin feeding box. The portable automatic spot welding robot has the advantages that in order to realize more accurate spot welding operation, a lifting driving mechanism is arranged on the workbench, equipment required to be welded isplaced on the position, the equipment cannot be started under the condition that the equipment is placed in a misplaced mode, the phenomenon that the welding effect is affected due to the fact that the equipment is deviated in the welding process can be avoided, a pin mechanism is arranged so that accurate tin feeding can be realized, the situation that tin materials are wasted due to the fact that the tin materials are accumulated and block a channel in the conveying process can be avoided, and therefore efficient and accurate welding can be realized, and meanwhile, the environmental protection and conservation effects can be achieved.

Owner:福建惠安新然石材有限公司

Electric welding machine provided with adjustable hydraulic fastening mechanism

InactiveCN107552929AEasy to useAvoid affecting the welding effectWelding accessoriesHydraulic cylinderEngineering

The invention provides an electric welding machine equipped with an adjustable hydraulic fastening mechanism, which includes a second support rod, a hydraulic cylinder, a pressure rod, a telescopic baffle, a pressure relief knob, an oil cylinder supporting slide plate and a push rod, which are arranged close to the top plate Five shock-absorbing springs are arranged equidistantly on the top end faces of the two left-right symmetrical slide rails, and the above-mentioned two slide rails are connected and fixed together with the top plate through the five shock-absorbing springs at their tops; the electric welding machine Two rectangular slide plates protrude up and down symmetrically on the side walls of the left and right sides of the main body, and the welding machine body slides through the above slide plates and is placed inside the chute of the four slide rails. The setting of the welding rod holding box in the present invention, the welding rod holding box can store welding rods of different materials in categories, so that the welding rods can be integrated and stored together with the electric welding machine, which is convenient for taking and using the welding rods, and at the same time, the heat generated during electric welding can heat the welding rods Store the welding rod inside the box to avoid excessive humidity of the welding rod from affecting the welding effect.

Owner:朱志坚

Smokeless welding devices for machine manufacturing

InactiveCN111390436AEasy to adjustThe adjustment mechanism is easy to use with the welding gunWelding/cutting auxillary devicesDirt cleaningMachine buildingFlue gas

The invention discloses a smokeless welding device for machine manufacturing, and relates to the technical field of machine manufacturing. The smokeless welding device comprises a workbench, and further comprises an adjusting mechanism, a clamping mechanism, a flue gas purifying mechanism and a welding table located in the middle of the upper end of the workbench, and four placing plates are arranged on the upper surface of the welding table in a rectangular shape. According to the welding device, three welding guns are used in cooperation with a rotary welding table, multiple welding positions on a machined object can be conveniently welded at a time, continuous welding of the machined object can be achieved, meanwhile, the clamping mechanism is designed in cooperation with the placing plates, the machined object can be conveniently clamped and fixed, and influence on welding effect due to movement or shaking of the machined object in welding process is avoided; and in addition, a protective shell is used in cooperation with the flue gas purifying mechanism, flue gas generated in the welding process is conveniently sucked into a purification cavity to be purified and then discharged, and the device is low in cost, high in welding effect and suitable for welding machining of large-batch objects.

Owner:JIANGSU OCEAN UNIV

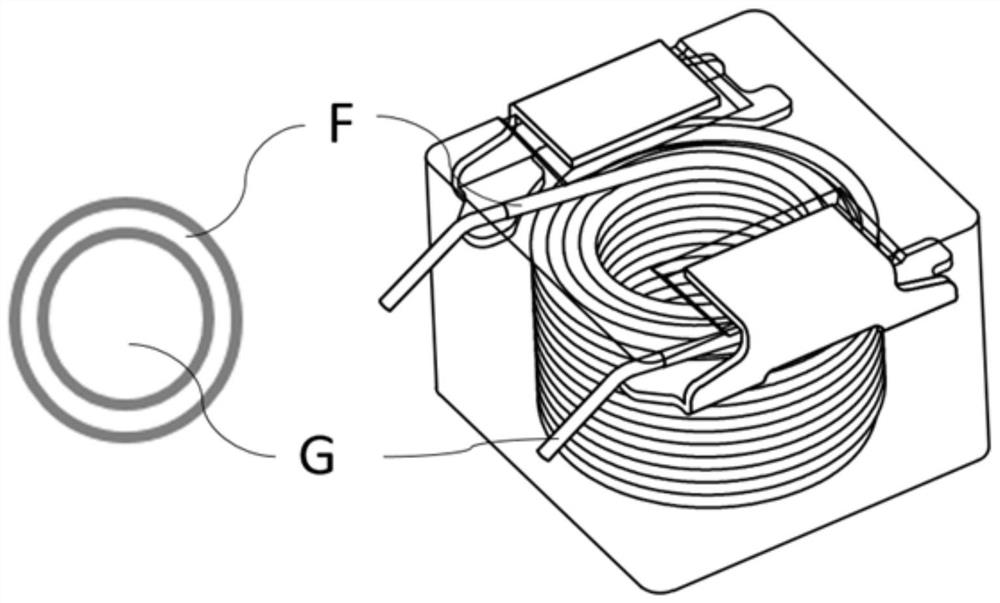

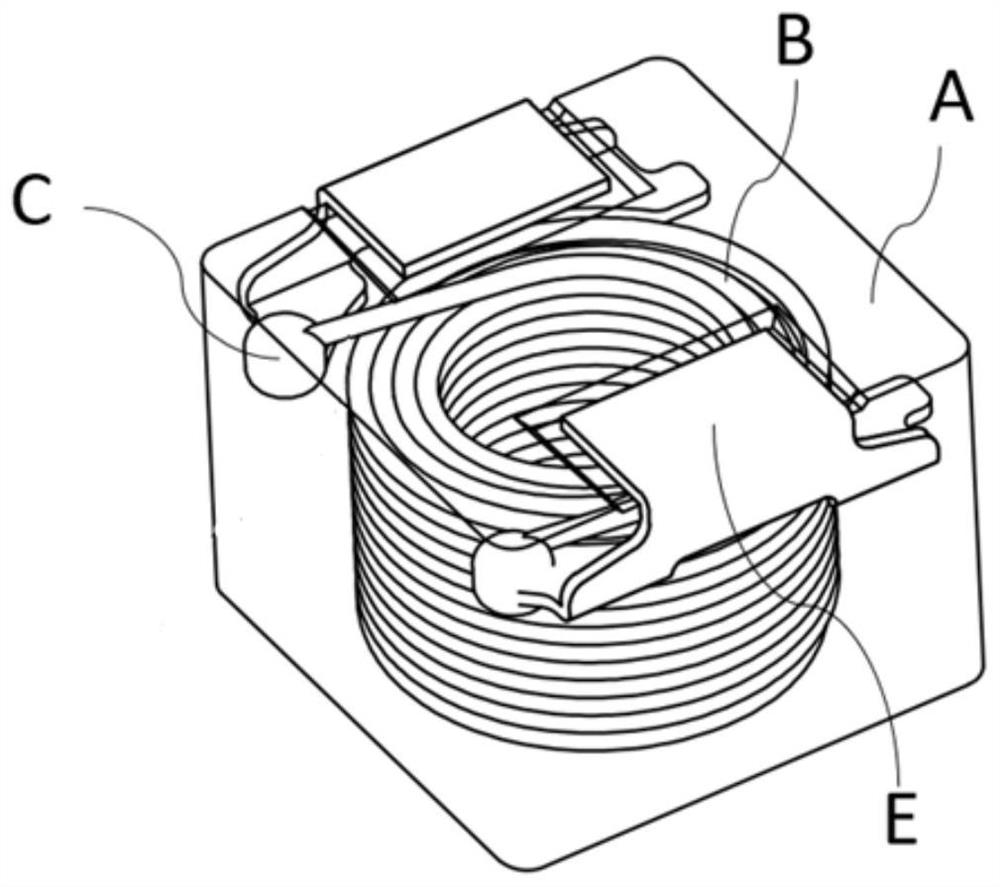

Coil component

PendingCN114242408ASolve the problem of virtual solderingEliminates the risk of an open circuit in an integral inductorTransformers/inductances coils/windings/connectionsPhysicsInductor

A coil component according to the present invention comprises: a coil formed by winding an enameled copper wire; the lead-out wire is formed by an extended free end; the magnet contains a soft magnetic alloy material and resin, and wraps the coil, the welding spots and the outgoing line; a metal sheet is mounted on the surface of the magnet; protruding parts are arranged at the two ends of one end of the metal sheet, and the leading-out wires are located near the ends of the protruding parts and bent towards the protruding parts. Or the outgoing line and the protruding part are synchronously bent towards the direction of the protruding part near the end part of the protruding part; the leading-out wire is in contact with the end position of the protruding part to form a joint point, and the joint point forms a welding point after laser welding; according to the integrated inductor, no paint film is left at the welding position of the outgoing line, the outgoing line is bent according to requirements, the outgoing line is completely attached to the metal sheet in the welding process, pseudo soldering is avoided, and therefore the risk of open circuit of the integrated inductor is eliminated.

Owner:淮安顺络文盛电子有限公司

Excavation bucket welding device for earthwork construction engineering machinery

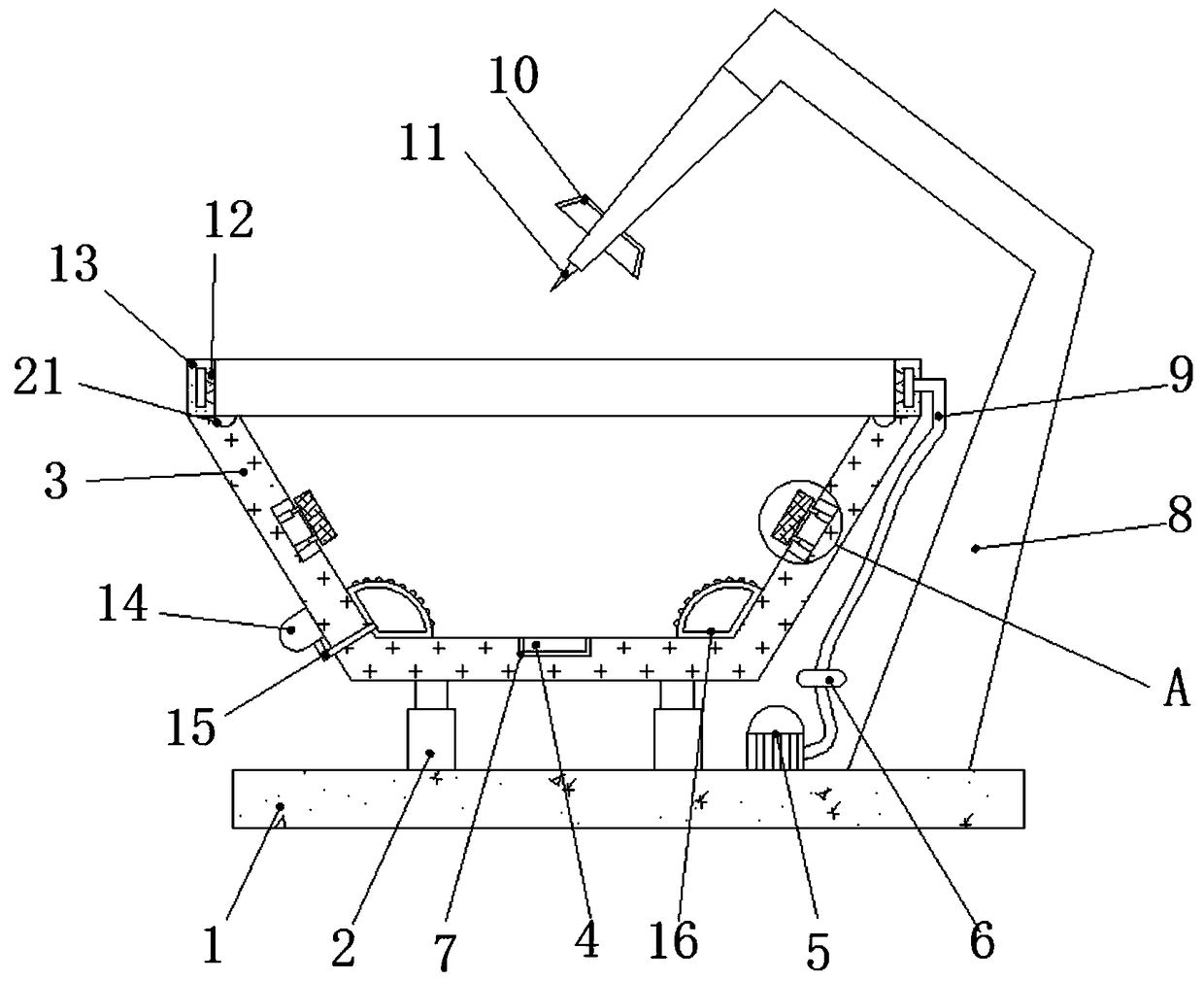

ActiveCN109290706ANo need to hold manuallyWelding is environmentally friendly and convenientWelding/cutting auxillary devicesDirt cleaningArchitectural engineeringAirbag

The invention discloses an excavation bucket welding device for earthwork construction engineering machinery. The device comprises a base; four hydraulic oil cylinders are distributed on the left sideof the top of the base at equal intervals; the same placing tank is hinged to the tops of the four hydraulic oil cylinders; a mechanical arm is arranged on the right side of the top of the base; a dust sucking cover and an electric welding pen are connected to the top of the mechanical arm through fastening bolts in sequence; a mounting groove is formed in the bottom inner wall of the placing tank; a fixed electromagnet is arranged on the bottom inner wall of the mounting groove; the same positioning airbag is arranged around the bottom inner wall of the placing tank; and a hollow rectangularframe is arranged at the top of the placing tank. The device is suitable for welding excavation buckets with different sizes, achieves higher environmental protection and convenience during welding,has no need to manually hold plate raw materials, prevents influence on the filtering effect by accumulation of dust on one side of a filter net plate, and meanwhile, prevents influence on the weldingeffect by falling of the dust in the placing tank.

Owner:临沂市宇顺机械有限公司

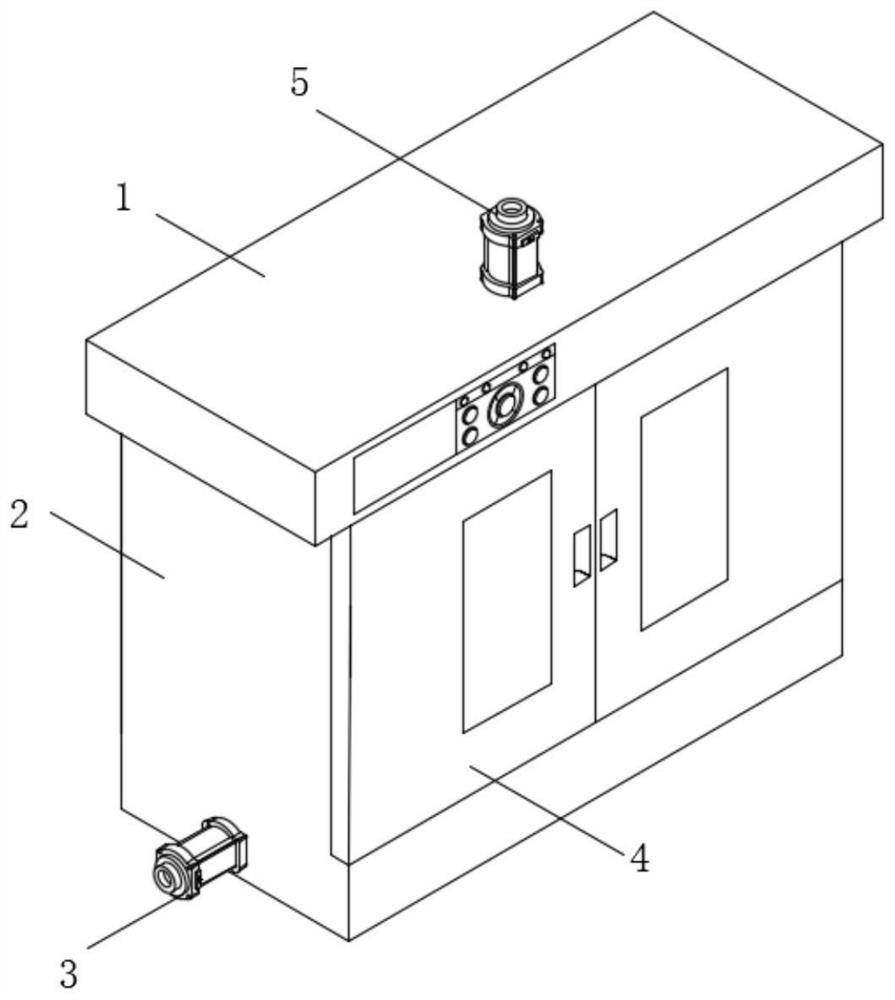

Welding device capable of being adjusted according to thickness of pipeline

InactiveCN113369788AAvoid shakingAvoid affecting the welding effectWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMechanics

The invention discloses a welding device capable of being adjusted according to the thickness of a pipeline. The welding device comprises a mounting box, a mounting cavity is formed in the mounting box, a stabilizing mechanism is arranged in the mounting cavity, the stabilizing mechanism comprises a placing box fixedly mounted on the bottom end wall of the mounting cavity, a placing cavity with an upward opening is formed in the placing box, two L-shaped placing blocks which can stretch out and draw back up and down are symmetrically and fixedly mounted on the left side and the right side of the bottom end wall of the mounting cavity relative to the placing box, placing springs are fixedly connected between the lower end faces of the upper sides of the placing blocks and the bottom end wall of the mounting cavity, the welding speed is adjusted according to the actual thickness of a to-be-welded pipeline, the welding effect is guaranteed when the pipeline is welded, the situation that the pipeline is not welded through or is not welded in place is avoided, and the welding effect is better by conducting comprehensive welding on the welding position in the welding process.

Owner:北海市交源智能科技有限公司

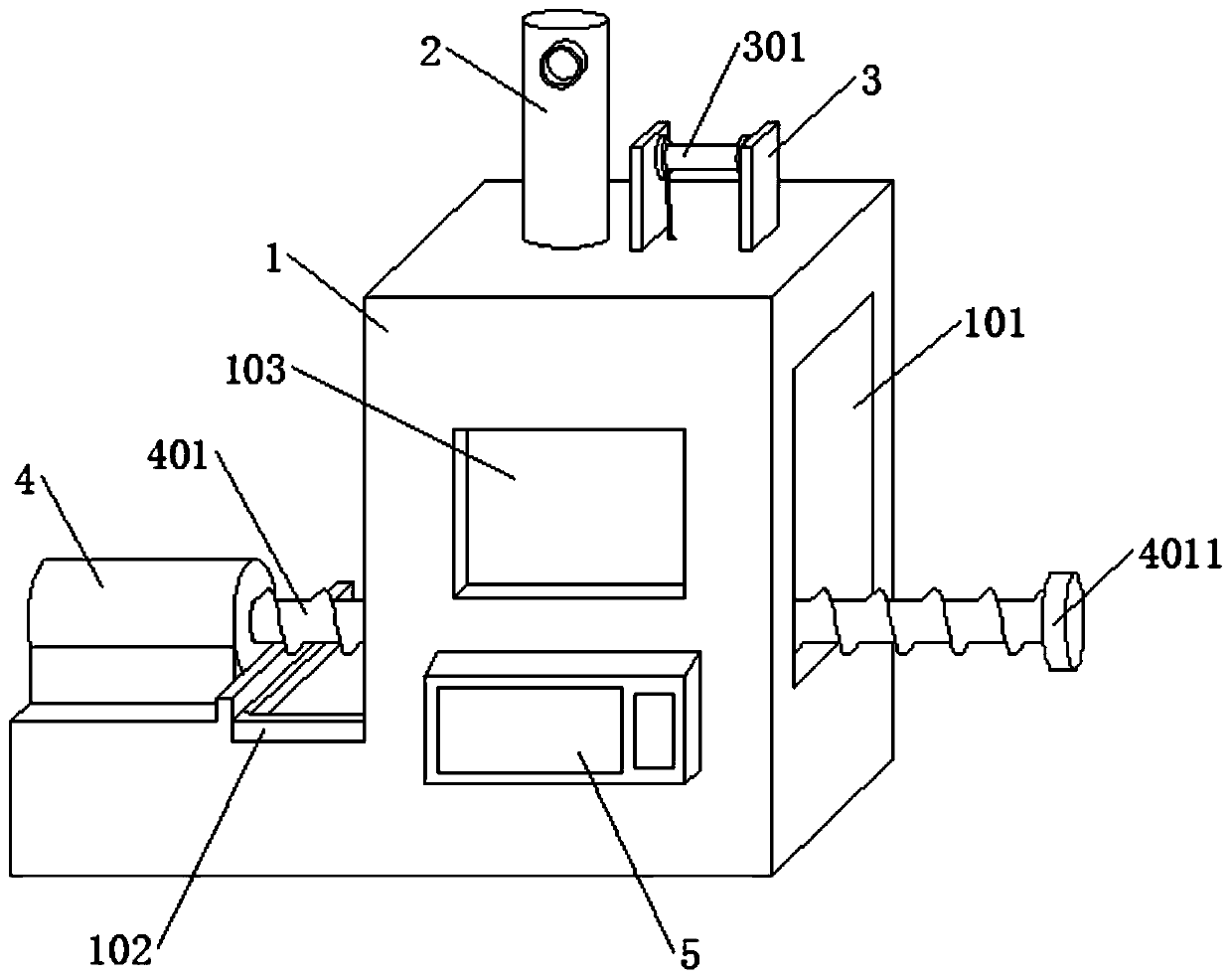

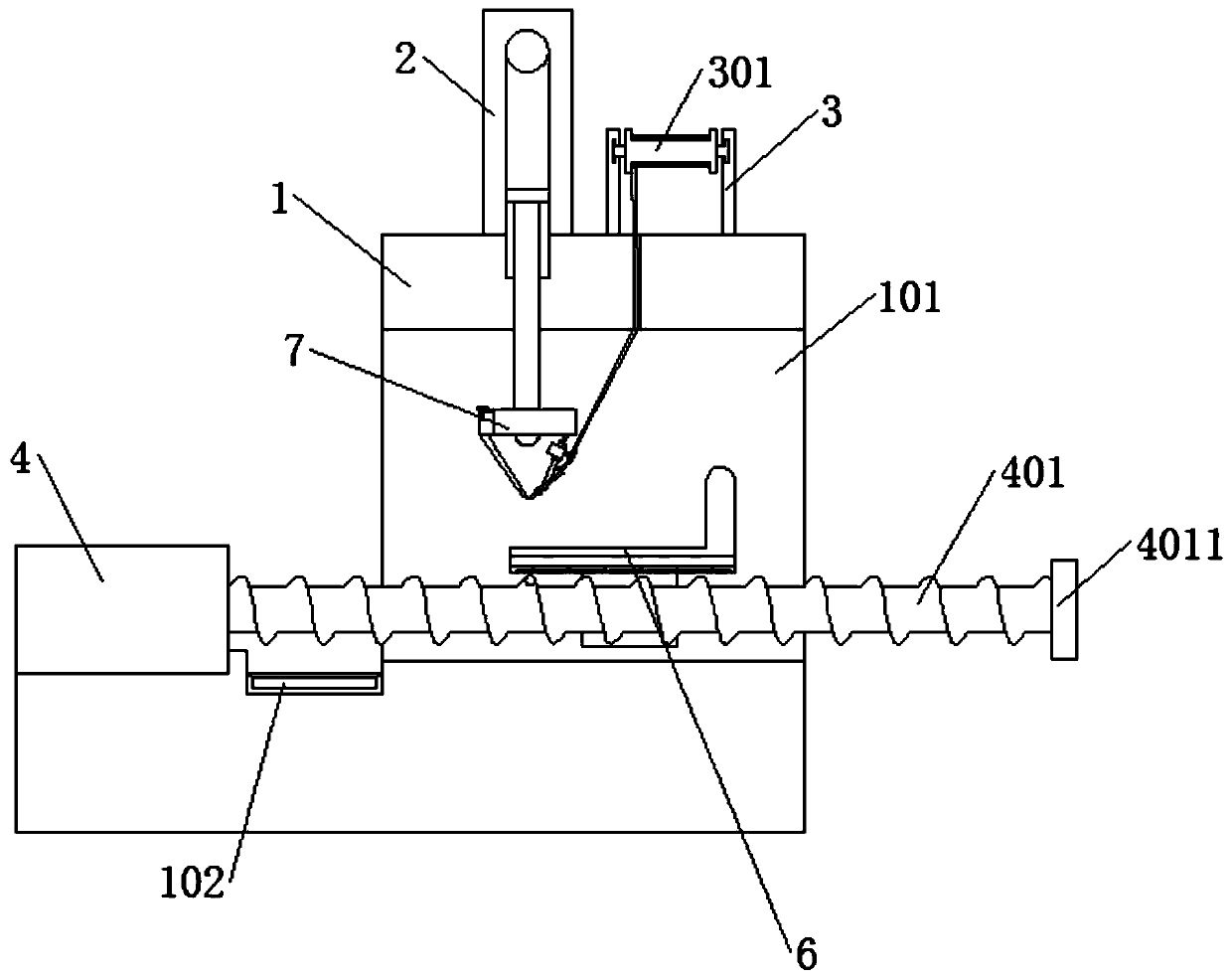

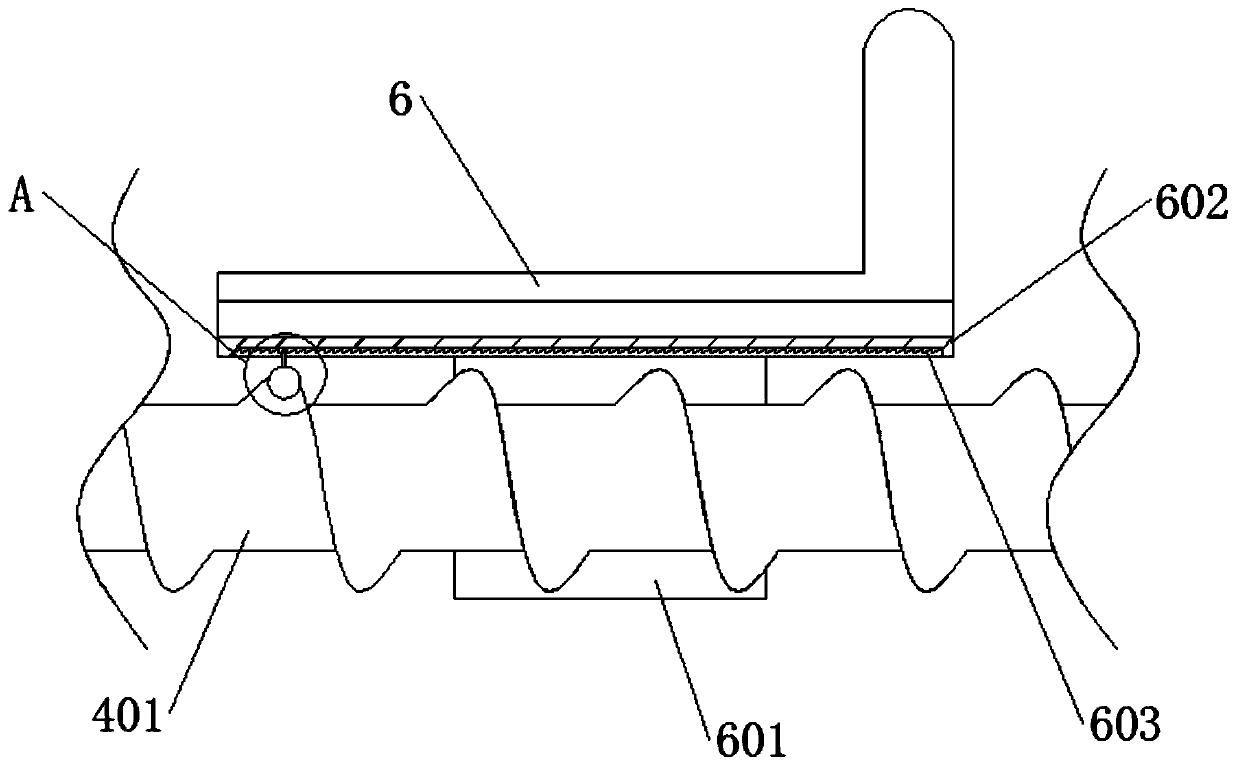

Sensor laser welding device

PendingCN112570892AAvoid affecting the welding effectRealize automated productionWelding/cutting auxillary devicesAuxillary welding devicesCapillary TubingEngineering

The invention relates to the technical field of sensor welding, in particular to a sensor laser welding device, and aims to solve the problems of incomplete automation and inconvenient welding in theprior art. The sensor laser welding device is characterized by comprising a rack, a feeding assembly, a pre-clamping assembly, moving assemblies, a positioning assembly, a welding assembly and a receiving assembly; the rack is used for supporting the sensor laser welding device; one of the two moving assemblies is located between the feeding assembly and the pre-clamping assembly; and the other moving assembly is located on one side of the pre-clamping assembly, the positioning assembly, ,the welding assembly and the material collecting assembly. Through the arrangement of the two moving assemblies, all stations are tightly combined, and automatic production is effectively achieved; and through the arrangement of the pre-clamping assembly, a capillary tube and a blind cover are pre-clampedin a three-point mode before welding, and the blind cover is prevented from moving in the capillary tube in a welding process.

Owner:无锡市时盛激光科技有限公司

Automatic welding equipment

InactiveCN110756935AAvoid inertiaConvenient welding workHeating appliancesMetal working apparatusSteel platesElectric machinery

The invention provides automatic welding equipment. The equipment comprises a shell, an electric air cylinder, a supporting frame, a winding roller, a motor, a programmable logic controller, an electromagnetic steel plate and a bearing disc, wherein the electric air cylinder is arranged on the left side of the top of the shell, the supporting frame is arranged on the right side of the top of the shell, the winding roller is arranged in the middle of the supporting frame, the motor is arranged at the top of the left side of the shell, the programmable logic controller is arranged at the bottomof the front end of the shell, the electromagnetic steel plate is arranged on the inner side of the shell, and the bearing disc is arranged at the bottom of the electric air cylinder. The whole automatic welding equipment is stable in structure, high in welding precision, convenient to use and operate, stable during installation and smooth in movement, and can effectively avoid the situation thata welding bearing platform moves greatly.

Owner:王晨曦

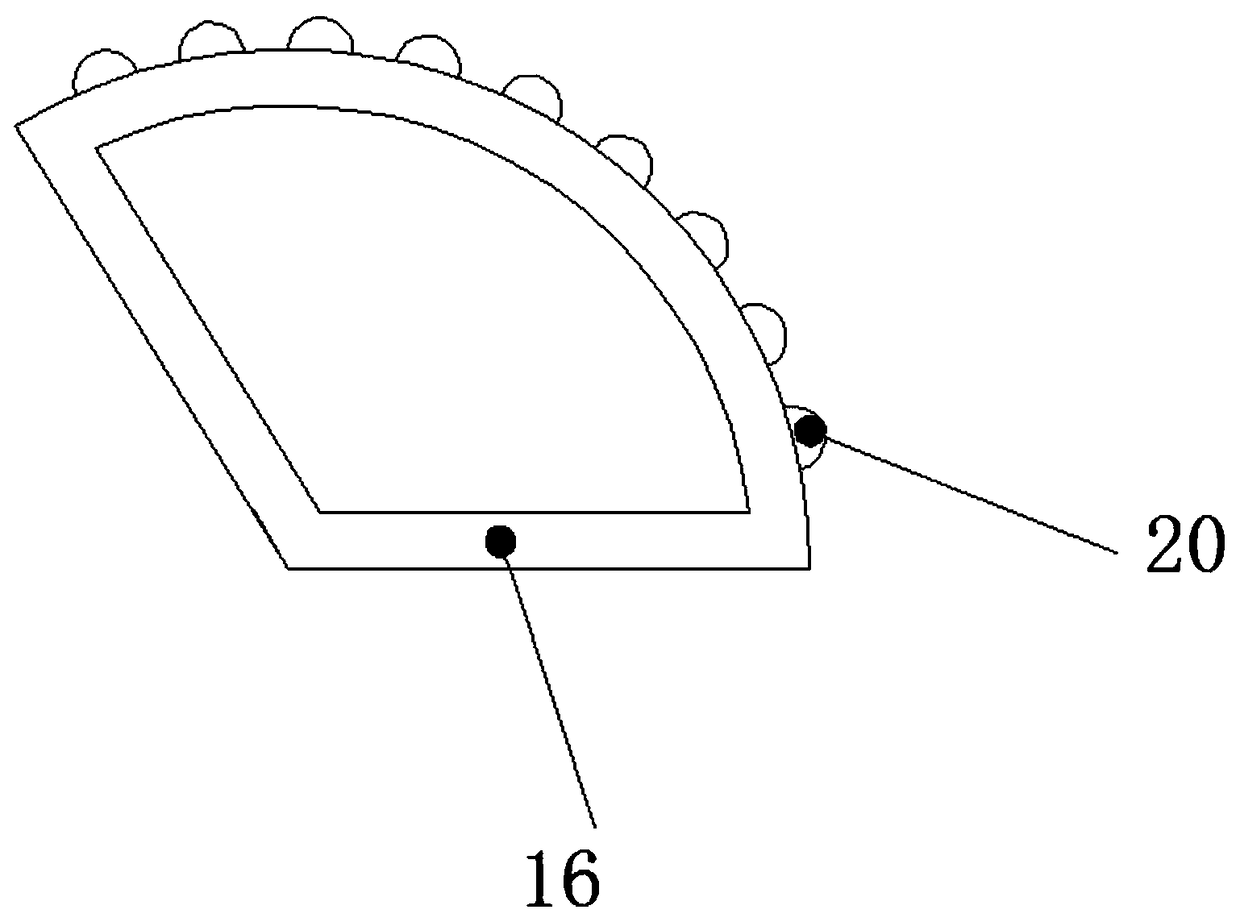

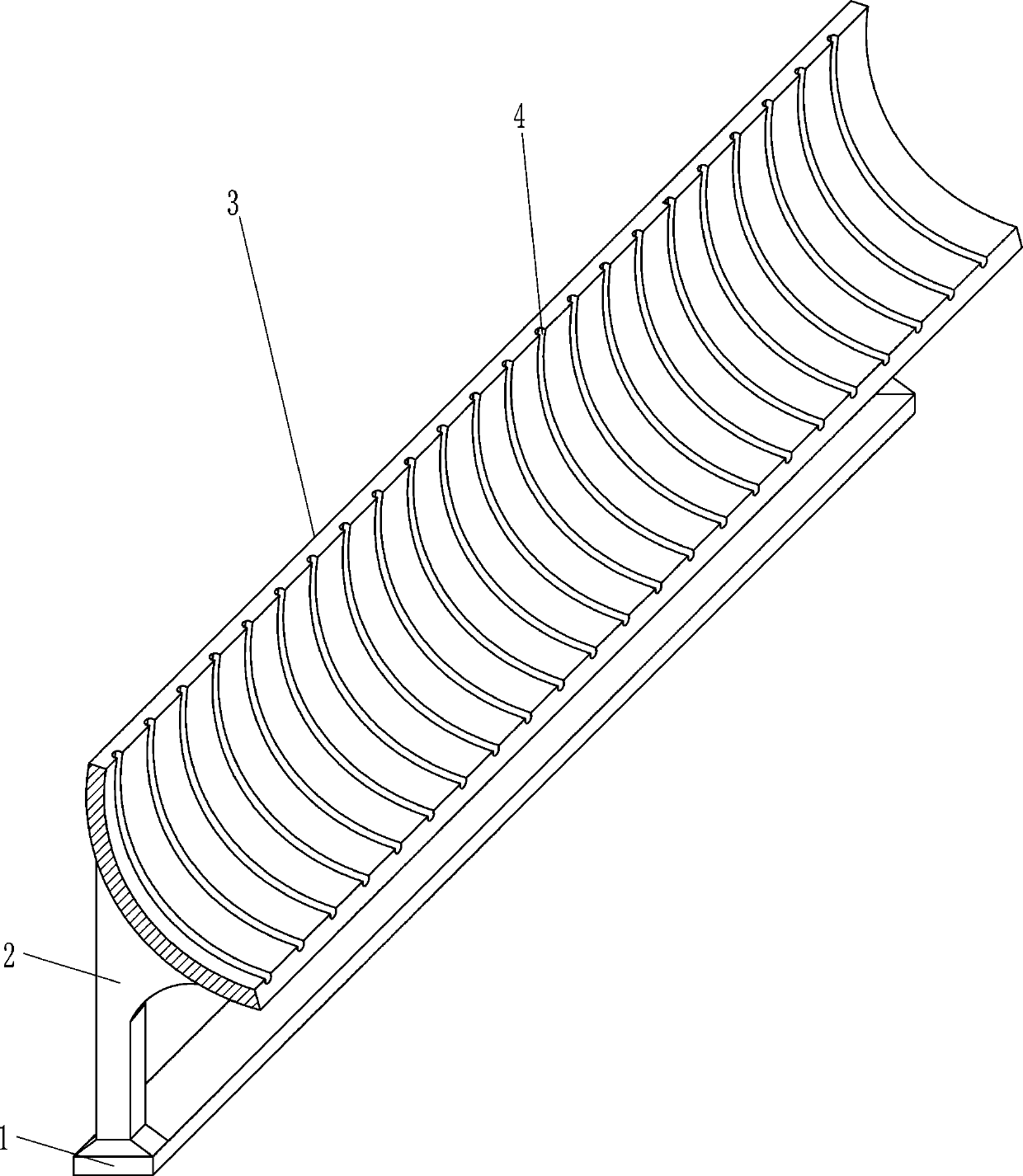

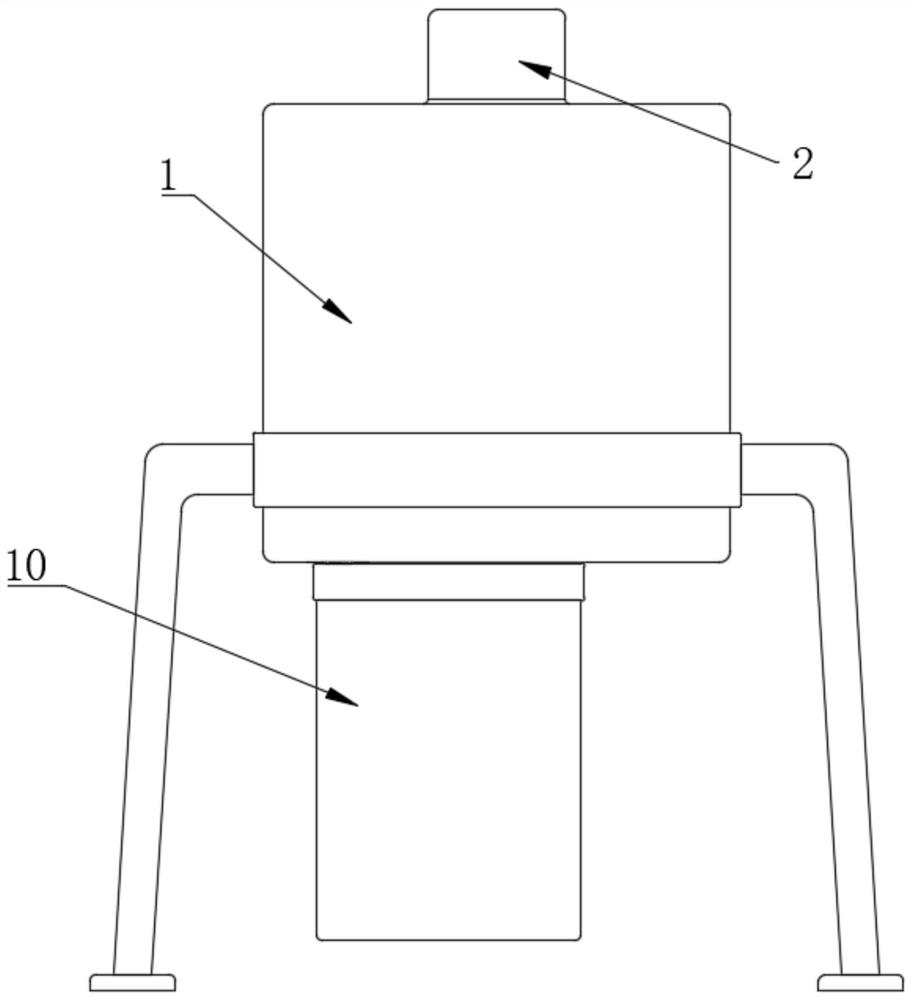

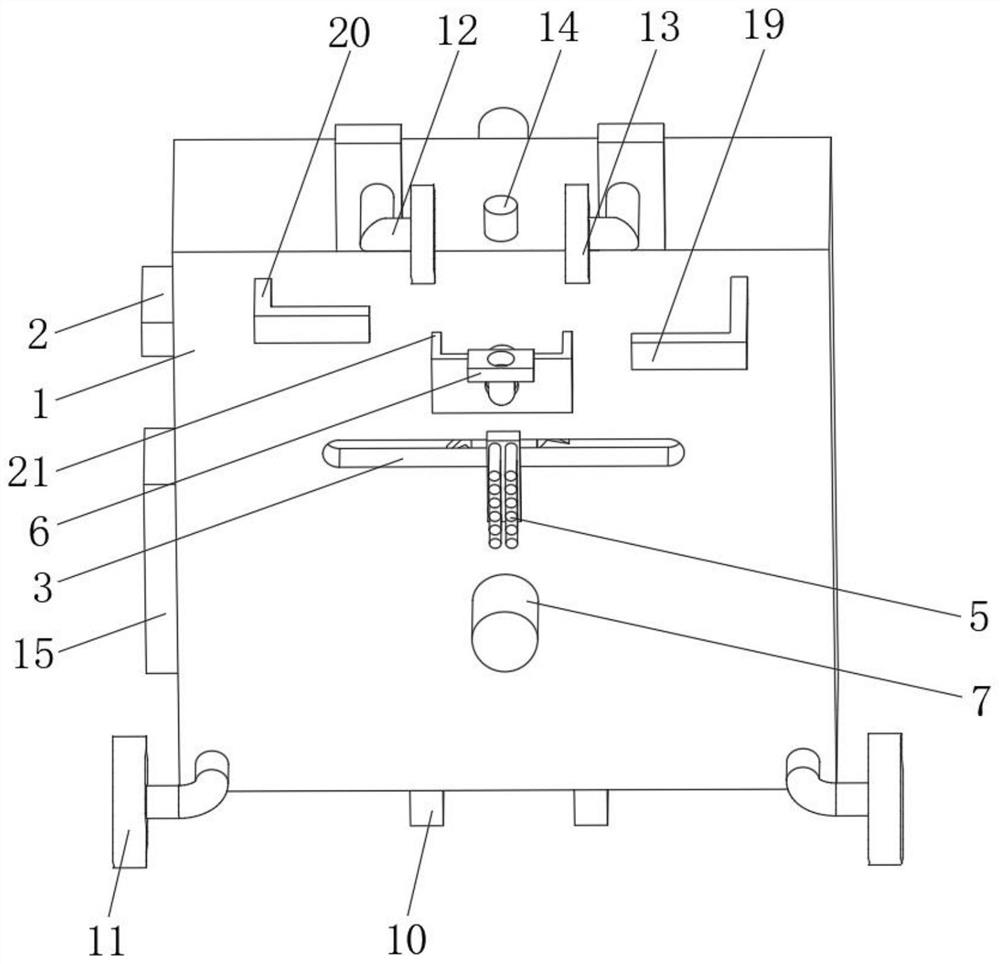

Auxiliary welding equipment for cylindrical foundation column steel bars

ActiveCN110977282AAvoid affecting the welding effectWelding/cutting auxillary devicesAuxillary welding devicesRebarWelding

The invention relates to auxiliary welding equipment, and particularly relates to an auxiliary welding equipment for cylindrical foundation column steel bars. The technical problem of the auxiliary welding equipment is how to design the auxiliary welding equipment for the cylindrical foundation column steel bars capable of fixing the circular steel bars and the long-strip-shaped steel bars duringwelding and ensuring the work efficiency. The auxiliary welding equipment for the cylindrical foundation column steel bars comprises a base, supports, arc-shaped plates, connecting frames and the like; the supports are connected to the front and rear sides of the tops of the two bases, the arc-shaped plates are arranged in the supports on the two sides, the two arc-shaped plates form a semi-circlewhich is not connected, arc-shaped grooves are uniformly formed in the arc-shaped plates at intervals, and the connecting frames are arranged on front walls and rear walls of the supports on two sides, and the connecting frames are located on the lower portions of the arc-shaped plates. According to the auxiliary welding equipment, firstly, steel bar rings are placed in the arc-shaped grooves onthe arc-shaped plates, then the long-strip-shaped steel bars are placed in the steel bar rings, and the steel bar rings are limited through the cooperation of a fixing assembly and a clamping assembly, therefore, and the problem that the steel bar rings are moved out of the arc-shaped grooves during welding can be avoided.

Owner:NANJING YUQUN COMM TECH CO LTD

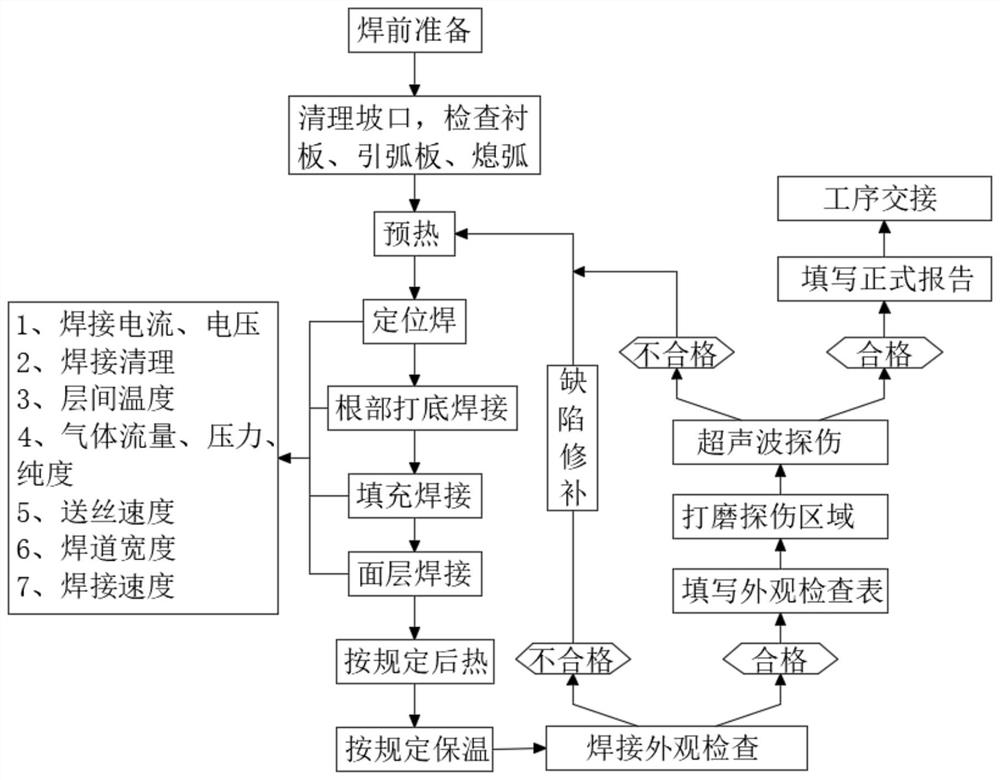

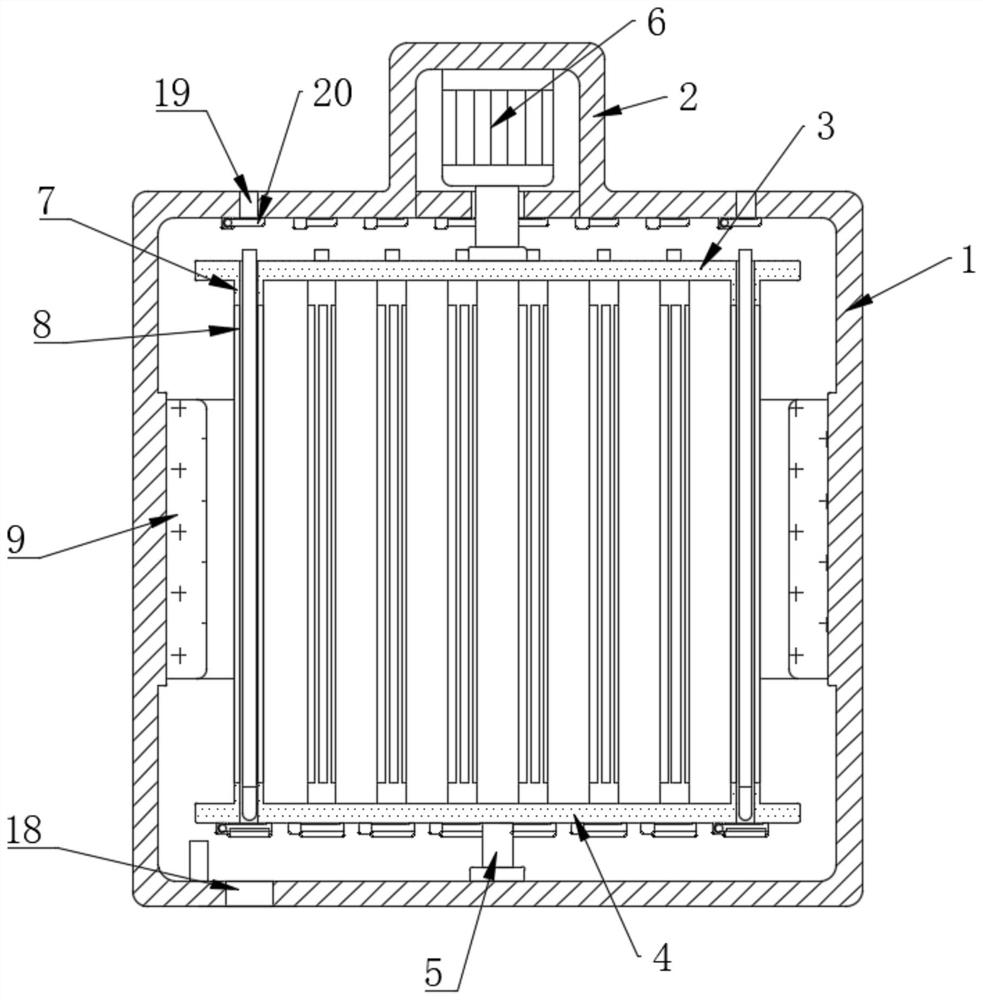

On-site welding process for steel structure

ActiveCN113070547AAvoid uneven dryingImprove drying effectWelding accessoriesEngineeringHeat conservation

The invention discloses an on-site welding process for a steel structure, and belongs to the technical field of steel structure welding. A welding rod drying box matched with the process for use is arranged and can dry welding rods required during welding. After the welding rods are dried, a heat preservation cylinder is used for carrying out heat preservation and moisture insulation on the dried welding rods, and the situation that after the welding rods are taken, water enters the welding rods, and the welding effect is affected is avoided. Compared with the prior art, the multiple welding rods are arranged in independent supporting rods to be dried, the situation that drying is uneven due to the fact that the welding rods are stacked together is avoided. When the dried welding rods are taken out, the heat preservation cylinder is inserted into the inner side of a discharging groove, the dried welding rods can automatically fall to the inner side of the heat preservation cylinder, and the situation that when the welding rods are taken out, a frame body is opened, and heat in the frame body is lost is avoided. External humid air entering the frame body and the heat preservation cylinder is reduced as much as possible, and the drying effect of the welding rods and the using effect of the heat preservation cylinder are further improved.

Owner:广西天正钢结构有限公司

High-safety welding device for intelligent door and window machining and welding technology

PendingCN114871556AAvoid local hyperthermiaReduce harmWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryEngineering

The invention discloses a high-safety welding device for intelligent door and window machining and a welding technology, and belongs to the technical field of welding, the high-safety welding device comprises a top shell and a welding machine shell, the top shell is fixedly mounted at the top of the welding machine shell, a top motor is fixedly mounted at the top of the top shell, and a side motor is fixedly mounted on the outer side wall of the welding machine shell; a telescopic electron beam welding head is movably installed on the inner wall of the welding machine shell, a machine door is slidably installed in the welding machine shell, a reciprocating lead screw is fixedly installed at one end of an output shaft of a top motor, and a limiting piece is fixedly installed outside the reciprocating lead screw. According to the movable heat dissipation device, the movable heat dissipation assembly is arranged in the movable heat dissipation device, real-time movable heat dissipation treatment in the welding process can be achieved so as to avoid the situation of local high heat of a welding area, strong light generated by welding can be reflected and absorbed in real time, and therefore the harm of the welding strong light to human eyes can be reduced to a large extent; and the use effect and the safety protection performance of equipment are improved.

Owner:涡阳县幸福门业有限公司

Vacuum laser welding device

ActiveCN113385817AImprove welding efficiencyAvoid pollutionLaser beam welding apparatusLinear motionEngineering

The invention is applicable to the field of welding devices, and provides a vacuum laser welding device. The vacuum laser welding device comprises a workbench and a shell, and further comprises a welding mechanism, a moving mechanism, a fixing mechanism and a material receiving mechanism, wherein the welding mechanism can vertically move to weld a workpiece; the moving mechanism comprises a driving mechanism which is in transmission connection with the welding mechanism, and the driving mechanism drives the workpiece to synchronously perform horizontal linear motion through the vertical motion of the welding mechanism; the fixing mechanism is connected with the driving mechanism, and the fixing mechanism is used for fixing and supporting the workpiece; and the material receiving mechanism is in transmission connection with the welding mechanism, and the material receiving mechanism is driven by the welding mechanism to collect the dropped welding flux in a horizontal motion mode. According to the vacuum laser welding device, the welding efficiency of the workpiece can be effectively improved, and meanwhile, the situation that the workpiece is installed before each welding, so that air enters a vacuum environment, and then the welding effect is influenced is avoided.

Owner:国宏激光科技(江苏)有限公司

Bench frame welding auxiliary device

InactiveCN109702414AEasy to weldAvoid affecting the welding effectWelding/cutting auxillary devicesAuxillary welding devicesEngineeringHand shaking

The invention relates to an auxiliary device, in particular to a bench frame welding auxiliary device. According to the bench frame welding auxiliary device, U-shaped frames can be fixed, welding is facilitated to people without affecting the welding effect, and people do not need to continuously move. The bench frame welding auxiliary device comprises a bracket, a rotating shaft, a first fixing plate and the like, wherein the rotating shaft is rotatably arranged at the middle of the upper part of the bracket, and the first fixing plate is fixedly connected at the front end of the rotating shaft. The U-shaped frames can be fixed through the actions of swinging clamping blocks and the first fixing plate, so that people can weld the U-shaped frames without manually pressing the U-shaped frames, and the welding effect is prevented from being influenced by hand shaking; welding positions of the U-shaped frames can be rotated to the upper part by rotating second fixing plates, so that people can weld conveniently; and people can more conveniently rotate the U-shaped frames through the action of a swinging handle, and the working efficiency is improved.

Owner:JIANGXI COLLEGE OF APPLIED TECH

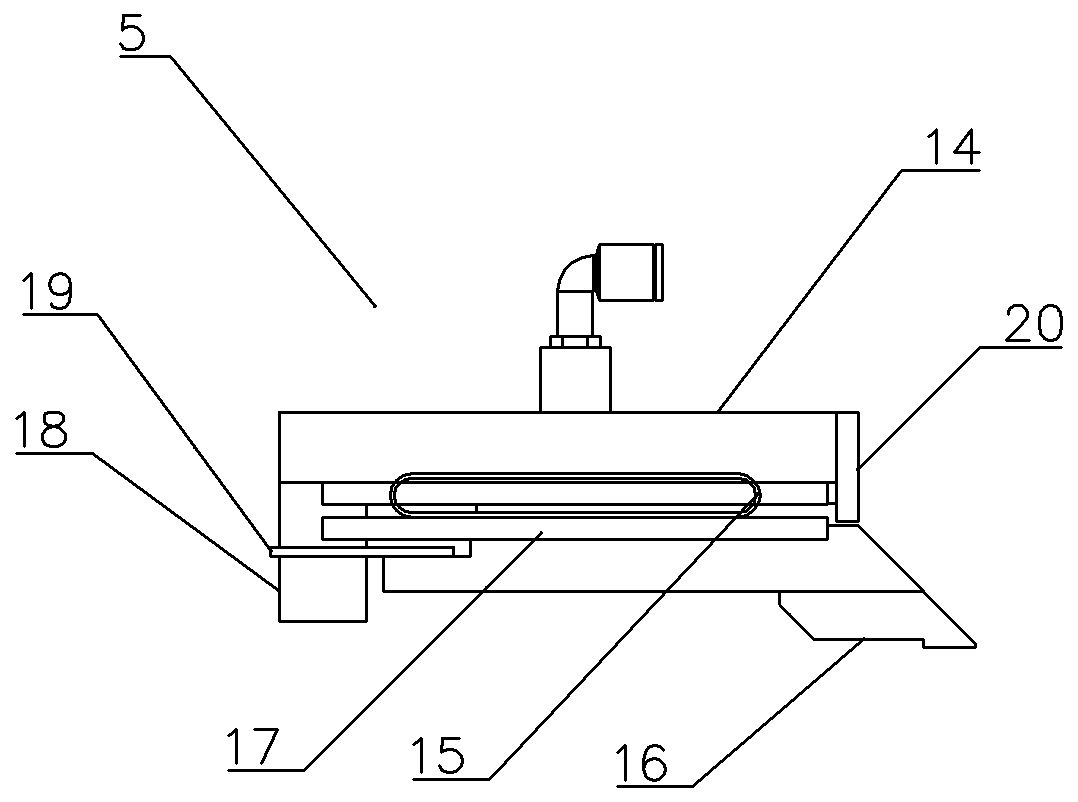

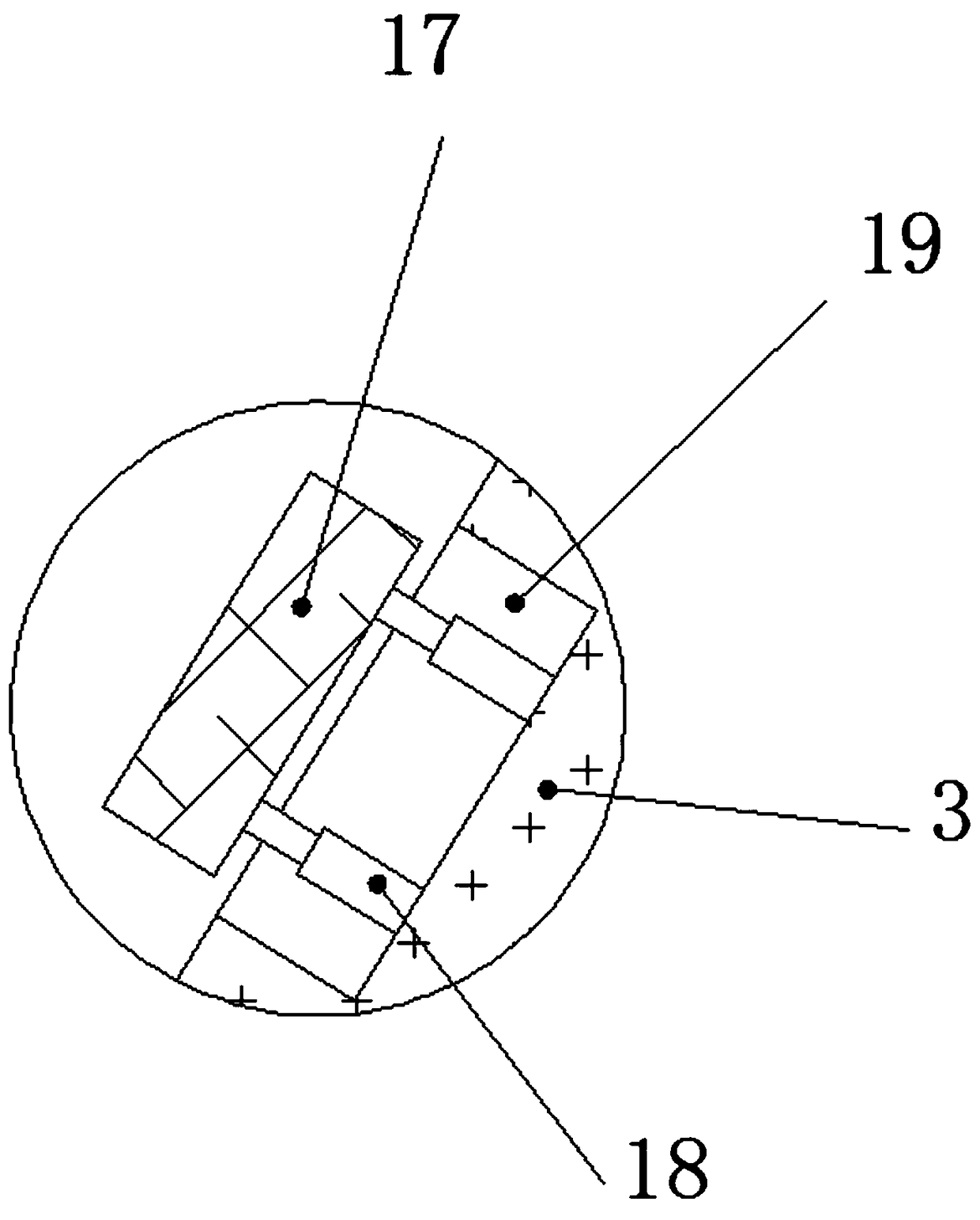

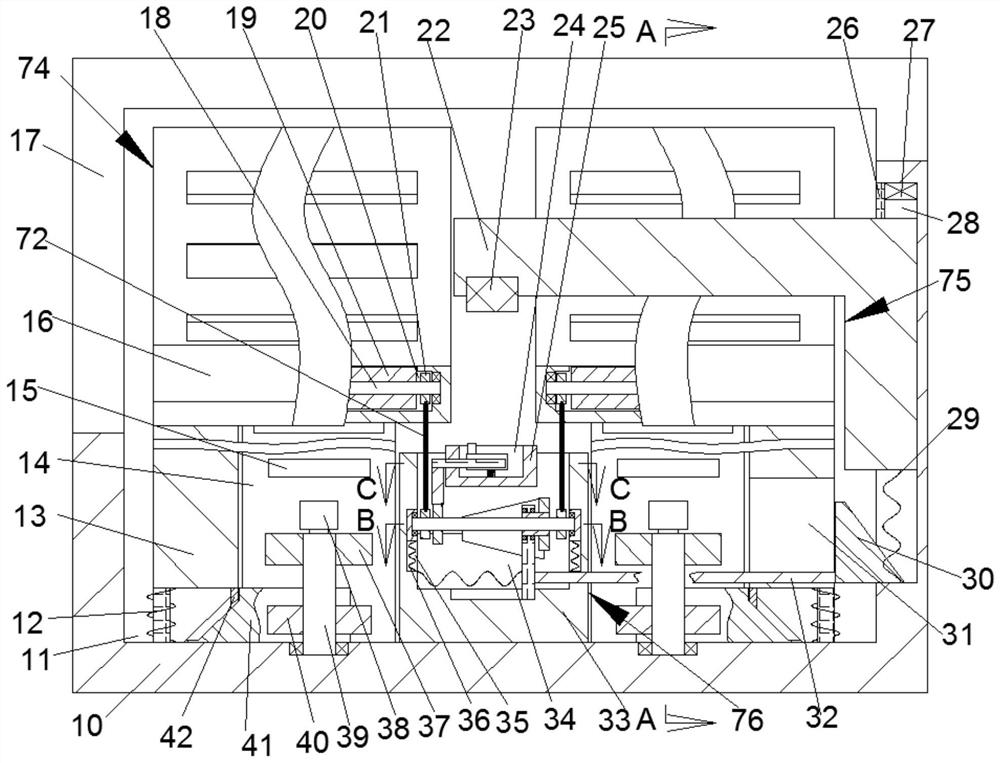

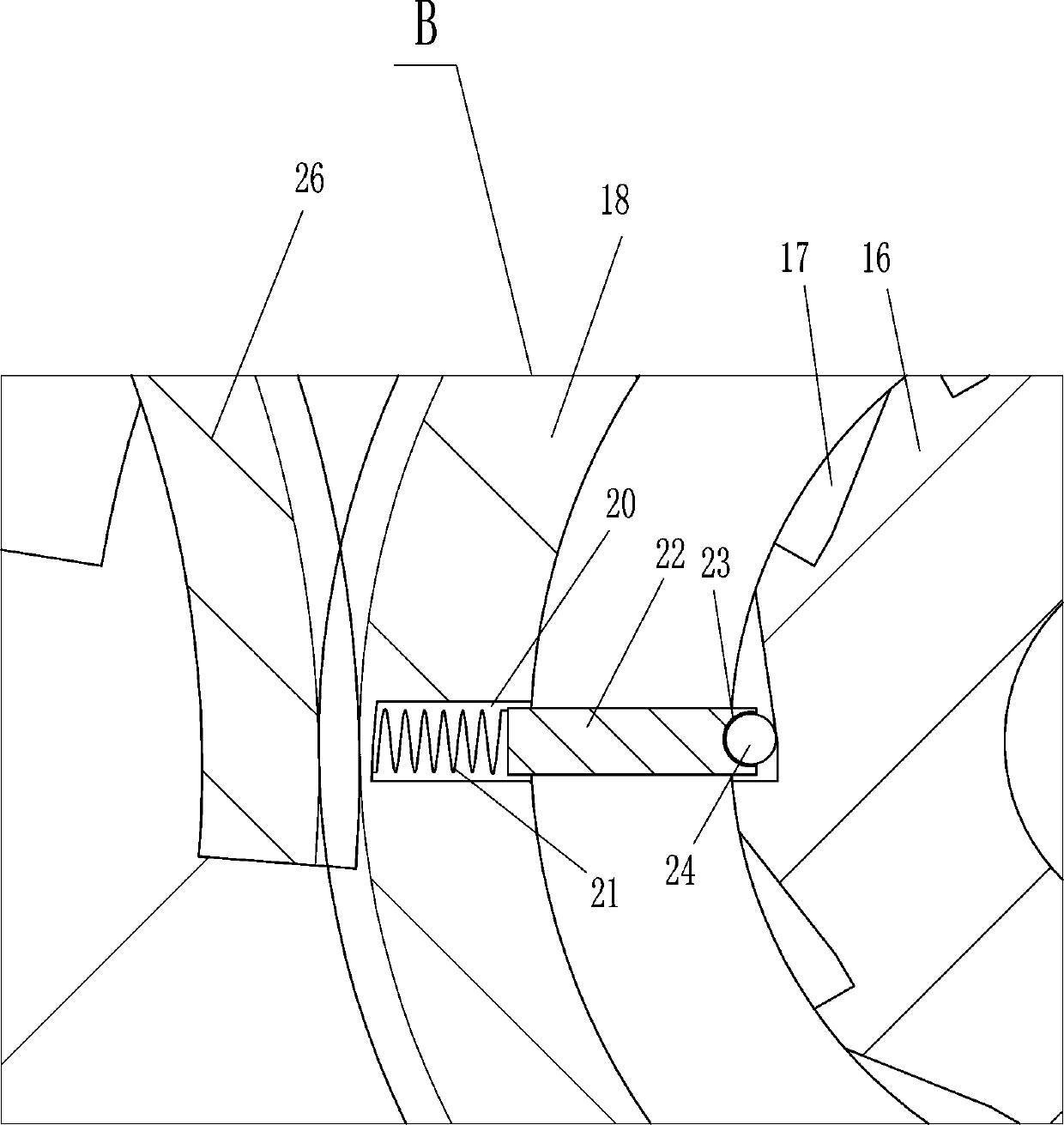

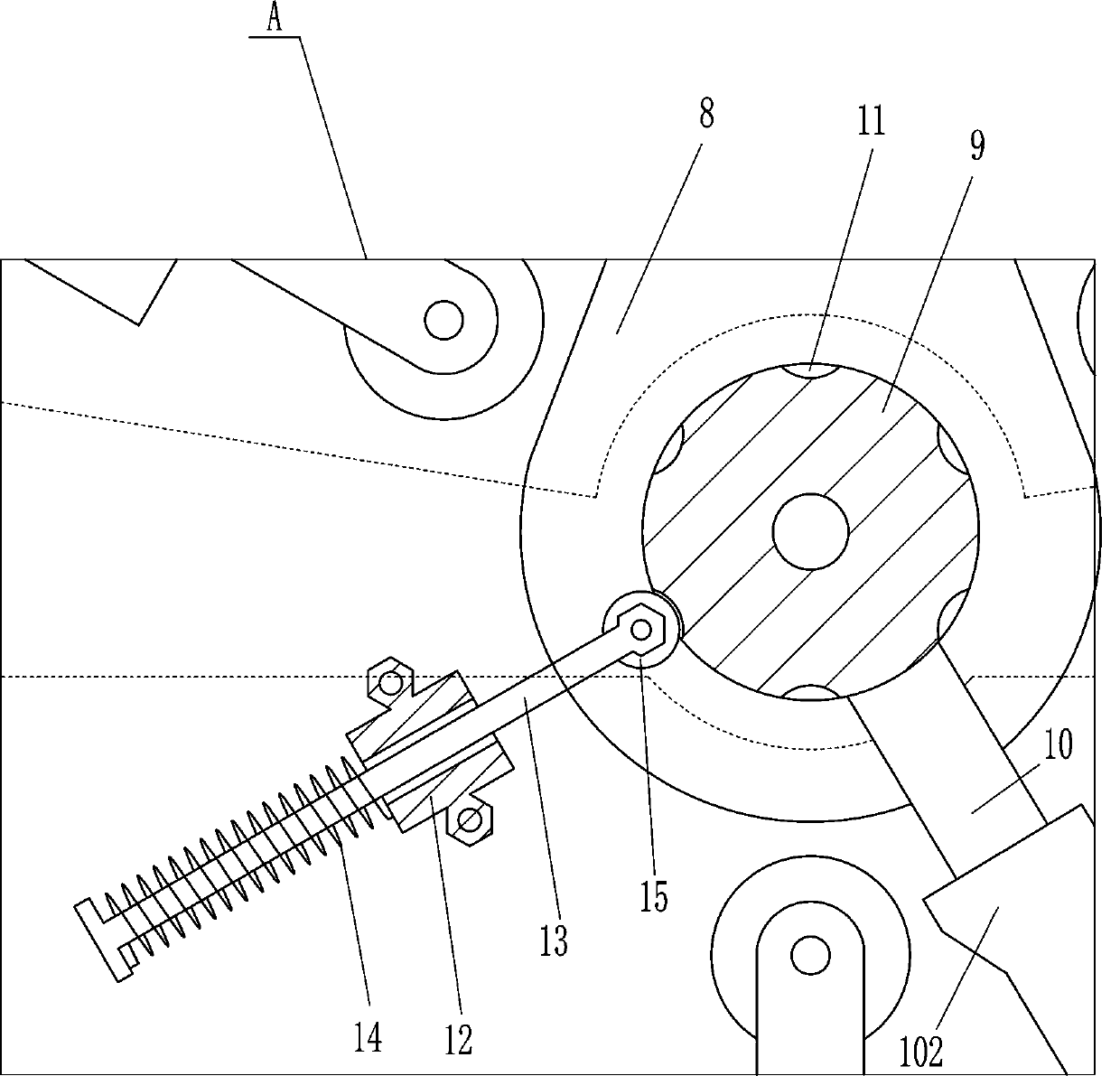

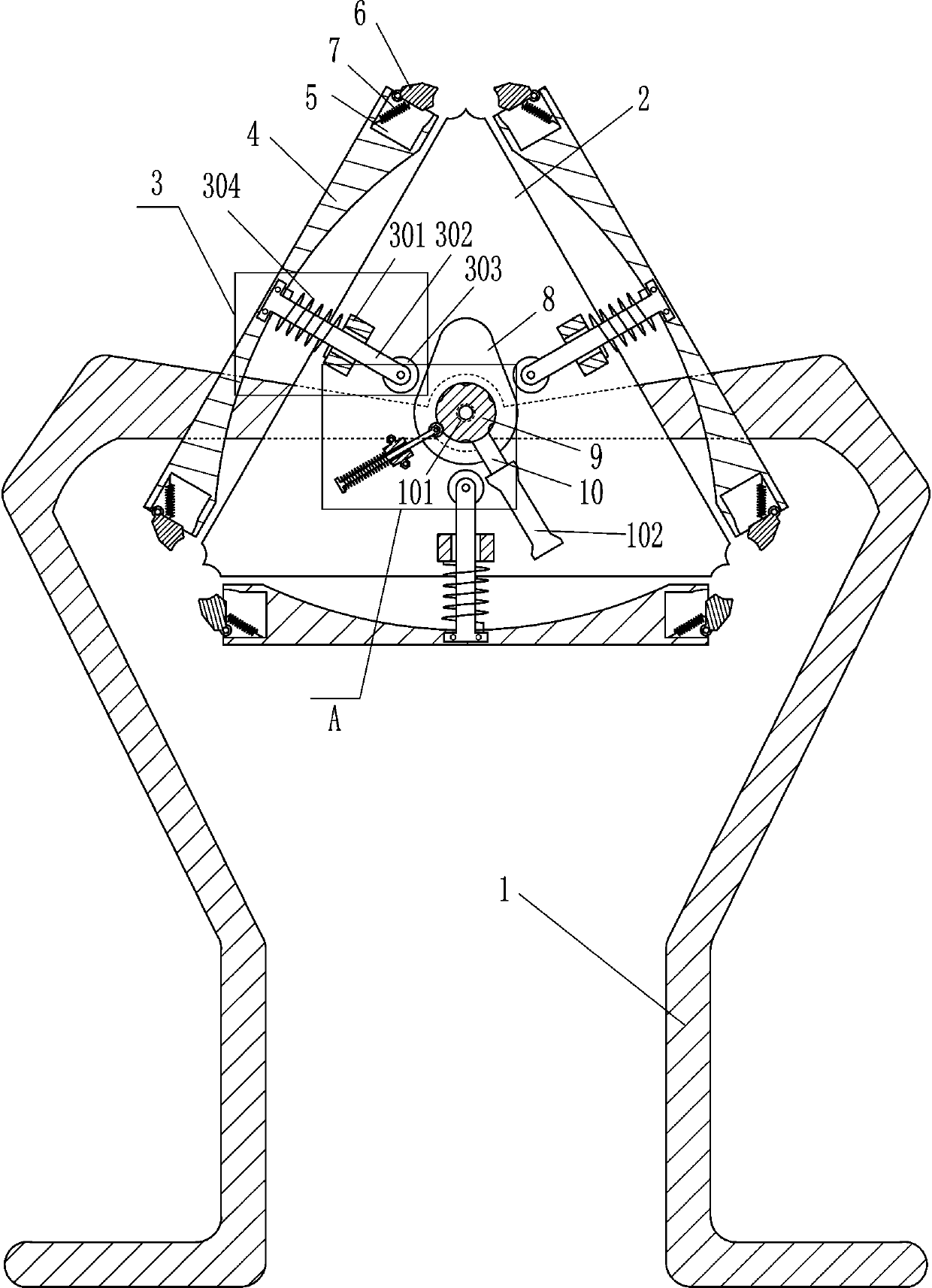

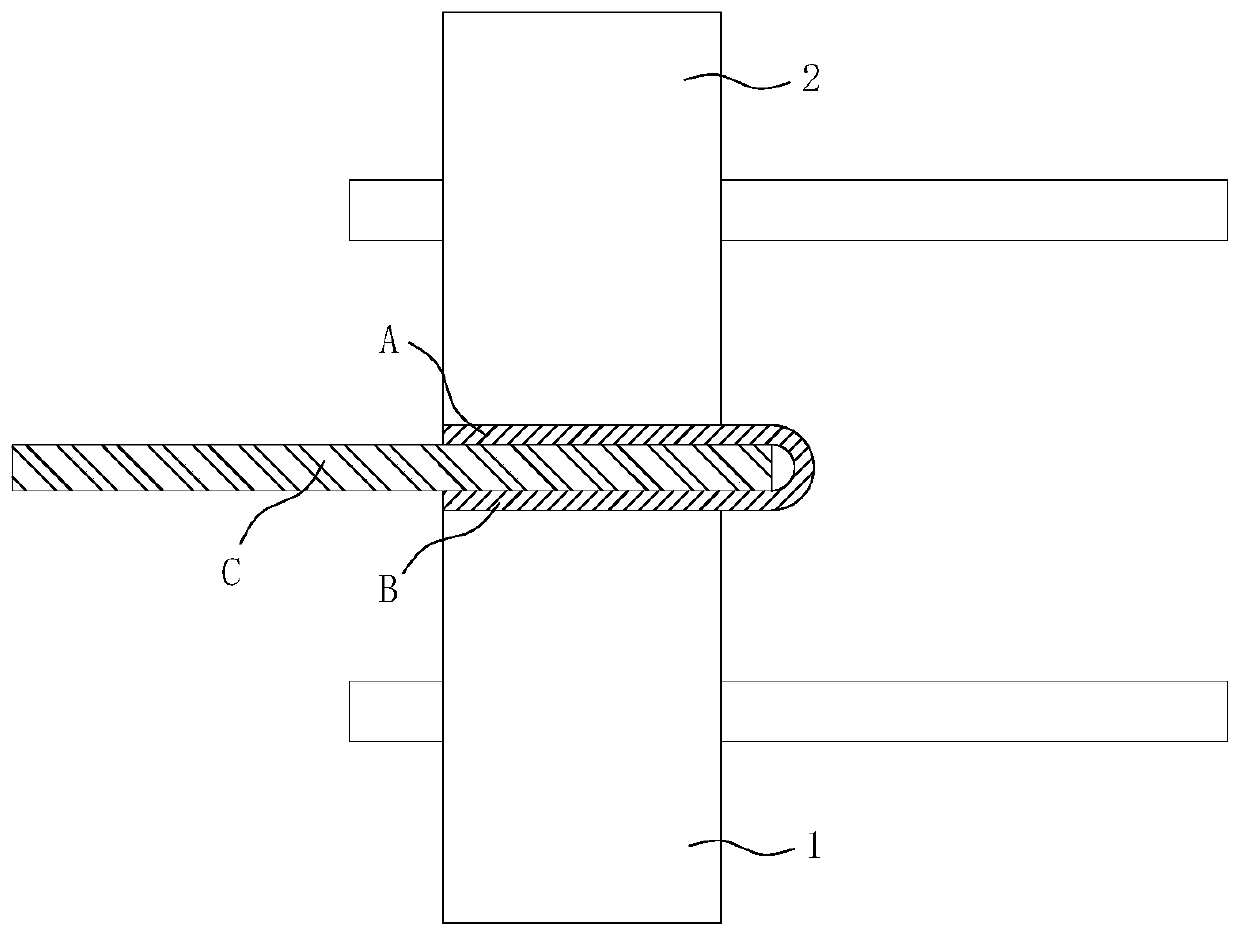

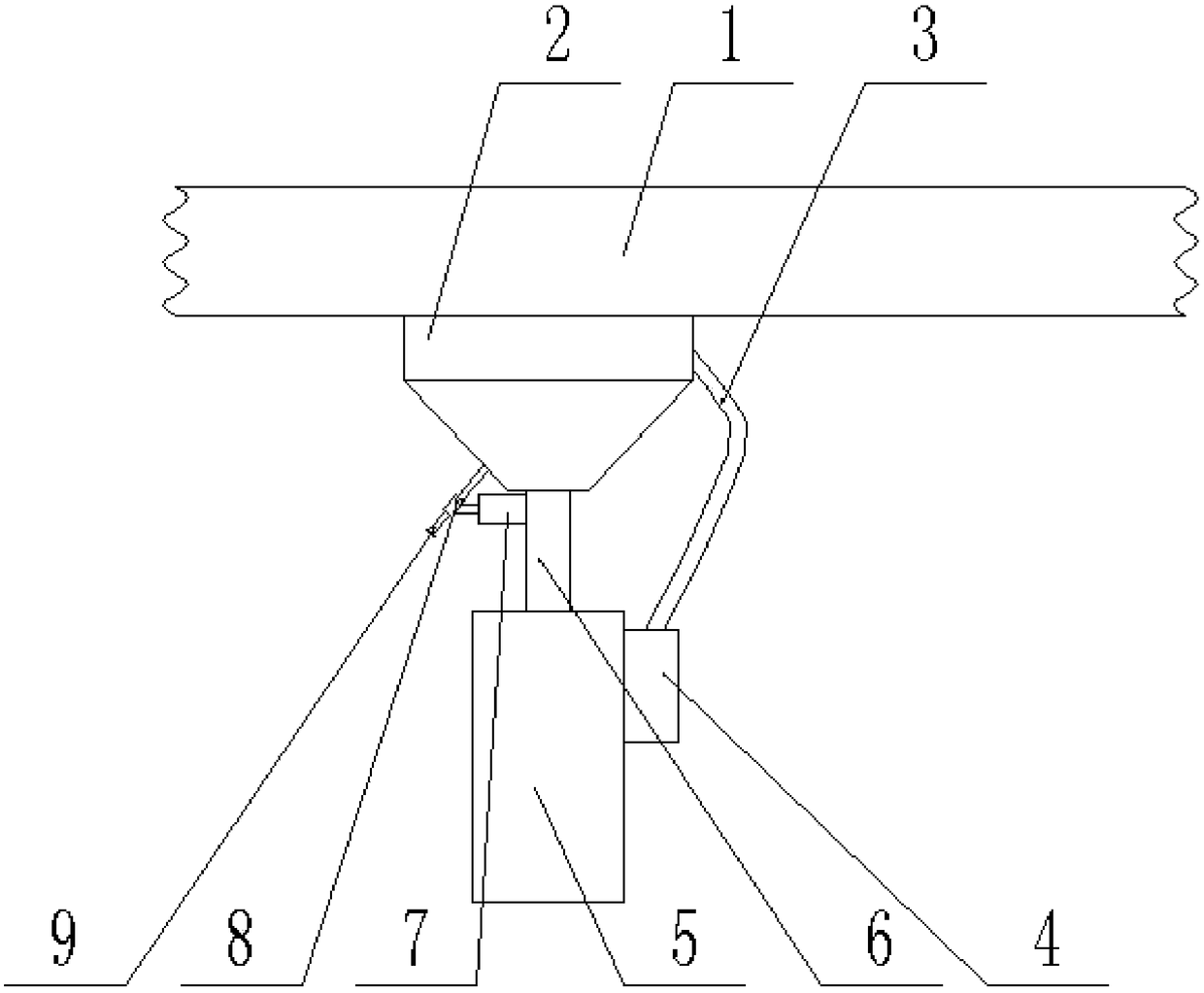

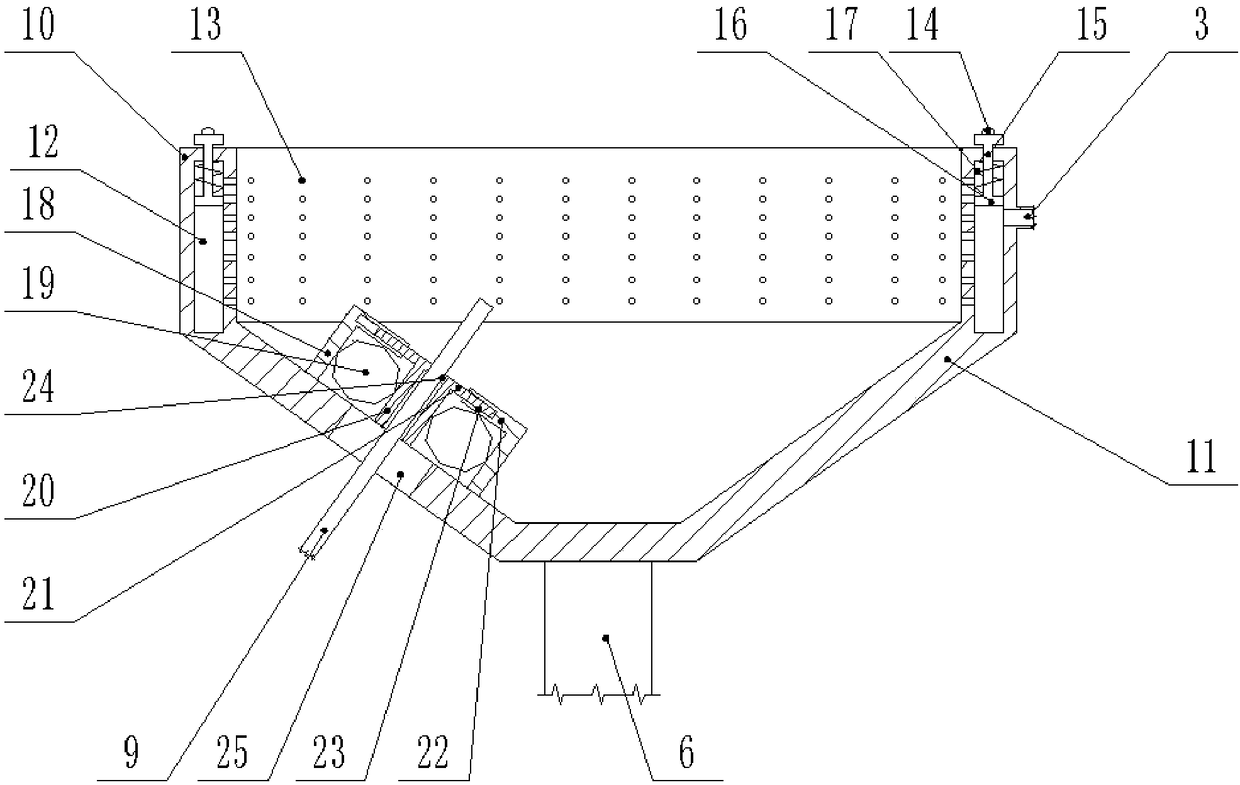

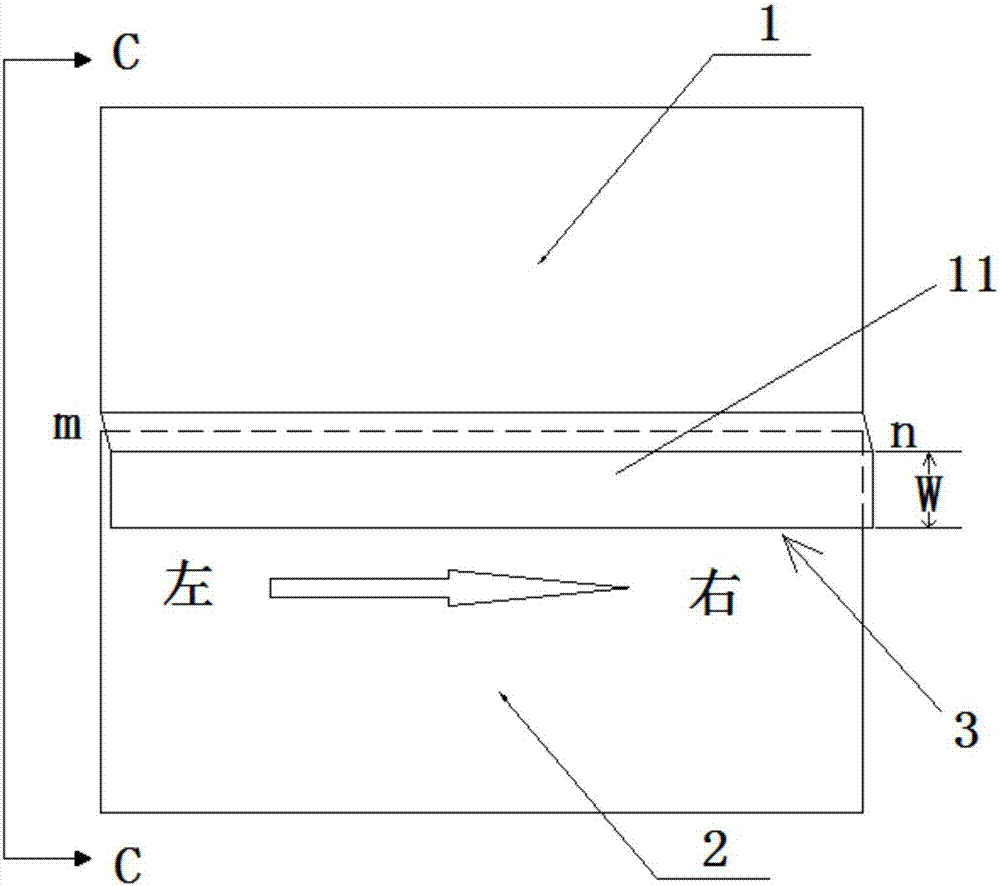

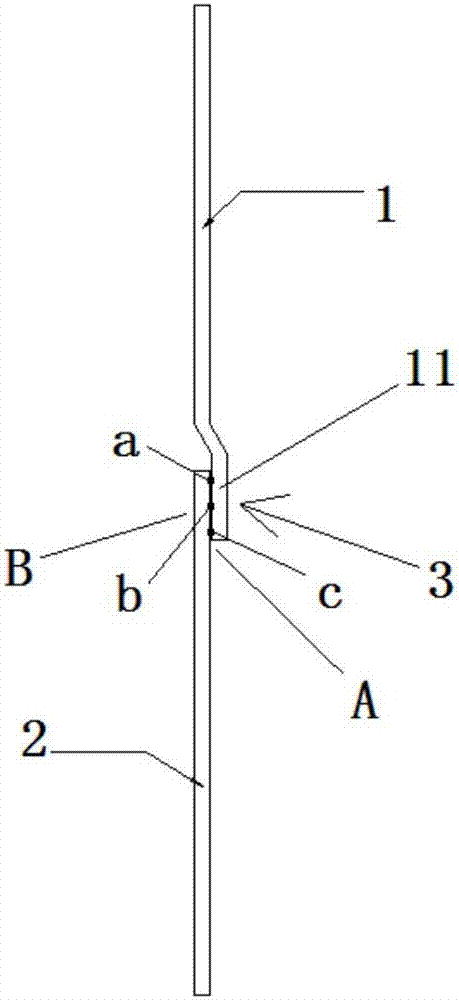

Double-wheel-set different-axis pressurizing mechanism for hot air welding machine and working method and using method of mechanism

The invention belongs to the technical field of hot melting welding, and particularly relates to a double-wheel-set different-axis pressurizing mechanism for a hot air welding machine and a working method and a using method of the mechanism. The mechanism comprises upper and lower belt wheel rotating synchronously and feeding and discharging wheels rotating synchronously; the synchronous rotatingspeed of the upper and lower belt wheels is V1, and the synchronous rotating speed of the feeding and discharging wheels is V2; and V2<=V1. According to the working method, the feeding wheel, the discharging wheel, the upper belt wheel and the lower belt wheel form a double-wheel-set structure and then rotate synchronously or differentially, and pressure conveying of a wiredrawing cloth, an upperedge covering belt and a lower edge covering belt is achieved. According to the using method, the upper edge covering belt, the lower edge covering belt and wiredrawing cloth penetrate into an inlet of the pressurizing mechanism, the upper belt wheel, the lower belt wheel, the feeding wheel and the discharging wheel rotate, and pressurizing conveying of the wiredrawing cloth, the upper edge covering belt and the lower edge covering belt is achieved. V2 is smaller than or equal to V1, the upper edge covering belt, the lower edge covering belt and the wiredrawing cloth are synchronously pressurized and conveyed, and materials are easy to turn round corners. The wiredrawing cloth is not prone to slipping due to resistance, the inner side section of the wiredrawing cloth is prevented from moving out of the upper and lower edge covering belts, welding is not prone to folding, and the welding quality is improved.

Owner:CHANGZHOU RUFA MACHINERY CO LTD

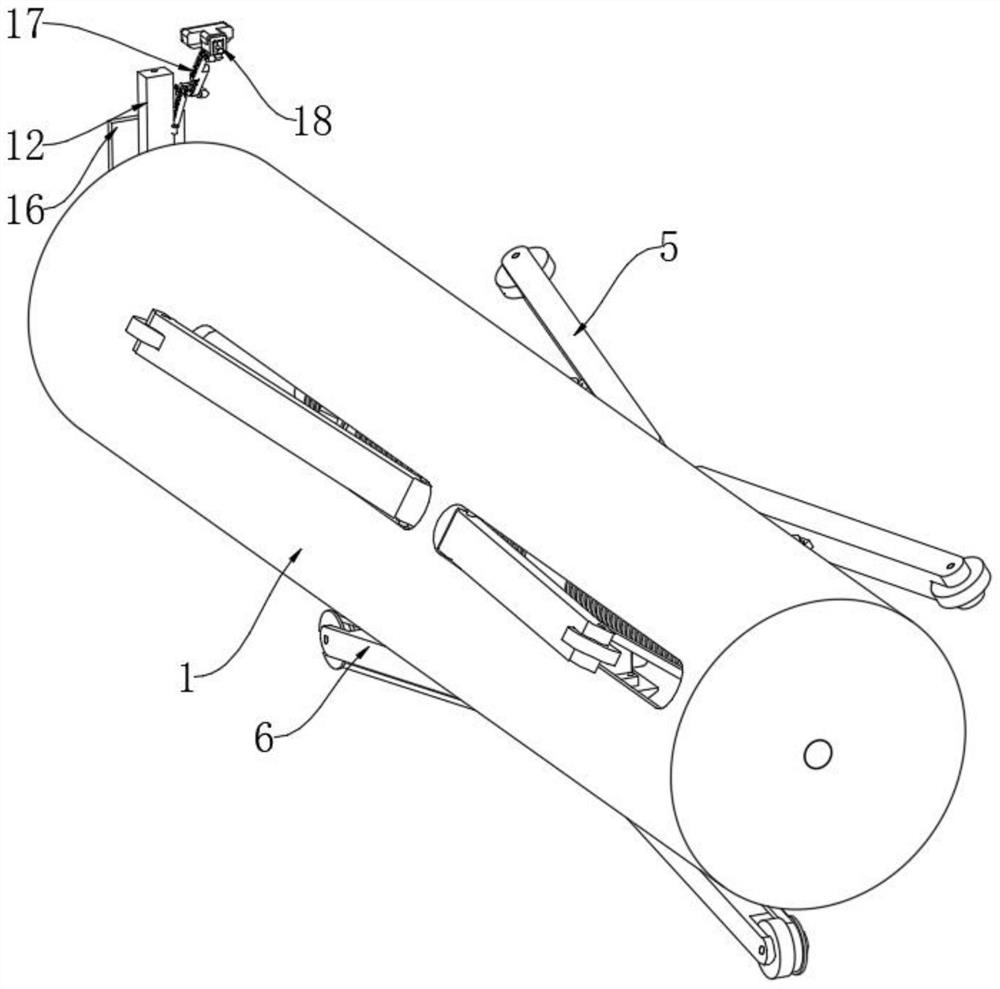

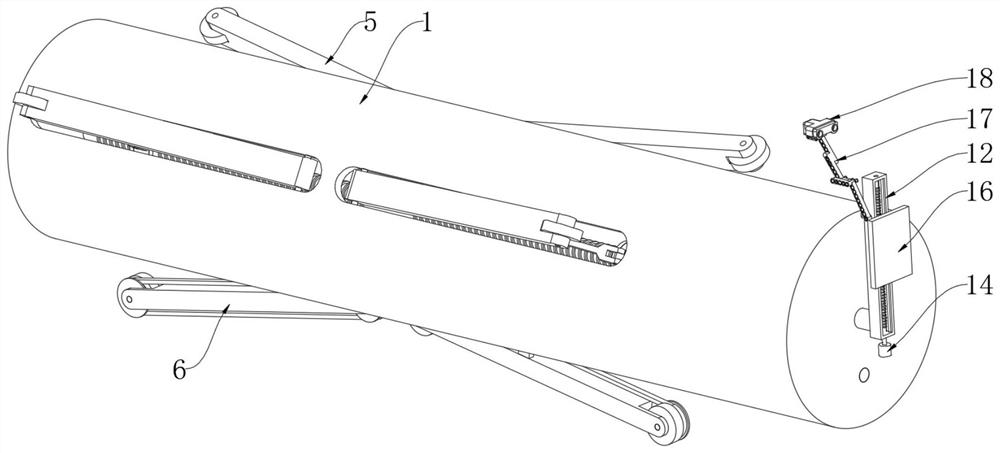

Automatic welding equipment

PendingCN113146115AReduce the conditions of useQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingElectric machinery

The invention discloses automatic welding equipment, and relates to the technical field of welding equipment. The automatic welding equipment comprises a barrel, and a driving cavity and a moving cavity are sequentially formed in the barrel from one end to the other end. Through mutual cooperation of a supporting driving motor, a threaded lead screw, a transmission sliding block, a transmission supporting ring and a supporting roller, the equipment can enter pipe fittings with different pipe diameters for inner girth welding, the influence of the depth of the pipe fittings is avoided, the use condition of the equipment is reduced, and the situation that the equipment cannot be used due to the large depth of the pipe fittings is avoided, so that the equipment is more practical and convenient to popularize; and through mutual cooperation of a displacement driving motor, a first double-groove belt pulley, a second double-groove belt pulley, a second lifting arm, a grooved roller and a second triangular belt, the equipment can be moved to a to-be-welded position, the situation that the welding effect is affected due to the fact that the equipment is unstable during welding is avoided, the quality of welding seams is improved, and the service life of the pipe fittings is prolonged.

Owner:NANJING INST OF TECH

An electric welding machine specially used for welding stainless steel sinks

InactiveCN104227217BExtended service lifeAvoid displacementWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses a special electric welding machine for welding a stainless steel water tank. The special electric welding machine comprises a rack, a welding head connecting rack and a welding head, wherein the welding head is connected to the rack by virtue of the welding head connecting rack; the special electric welding machine further comprises a workbench and at least two locating pieces; the workbench is fixedly arranged on the rack and positioned below the welding head; the workbench is provided with multiple locating holes; the locating pieces are arranged in the locating holes. As actual conditions during stainless steel water tank welding are fully considered, the special electric welding machine is accurate in locating and free from welding deviation.

Owner:湖州佳士不锈钢制品有限公司

Efficient geomembrane welding equipment

InactiveCN112356444AImprove welding efficiencyAvoid affecting the welding effectCleaning using toolsCleaning using gasesGeomembraneEngineering

The invention discloses efficient geomembrane welding equipment which comprises a working box and an adjusting unit. An inverter and a storage battery are sequentially arranged at the left end of thelower surface of an inner cavity of the working box, an air injection unit is arranged at the right end of the lower surface of the inner cavity of the working box, an adjusting groove is formed in the middle of the lower surface of the inner cavity of the working box, and a welding piece is arranged at the left end of the lower surface of the working box. According to the efficient geomembrane welding equipment, the welding position in front of two geomembranes is cleaned through high-pressure air in the air injection unit, and therefore the situation that the welding effect is affected by dust and impurities left at the welding position is avoided, the geomembranes cleaned by the air injection unit can be cleaned through a cleaning unit, and therefore the welding effect between the geomembranes can be achieved; and the cleaning unit can circularly move through the adjusting unit, then the cleaning range of the cleaning unit can be widened, and therefore the cleaning effect to the welding position of the geomembranes is improved.

Owner:朱爱成

Tool for automotive components manufacturing

ActiveCN108262582AEnsure safetyWon't burnWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMetal

The invention belongs to the technical field of accessory equipment for metal welding, and discloses a tool for automotive components manufacturing. The tool comprises a barrier cover with an openingin one end, and a hydraulic cylinder for controlling the barrier cover to lift up and down. An outer wall of the barrier cover is fixedly connected with an output shaft of the hydraulic cylinder; a through hole for inserting and swinging a welding rod is formed in the barrier cover; an exhaust mechanism surrounding the through hole and driven by the welding rod is arranged an on inner wall of thebarrier cover; a liquid storage cavity for storing a welding an anti-splash liquid is arranged in a wall of the barrier cover; spray holes communicating with the liquid storage cavity are formed in aninner wall of the barrier cover; an extruding part is slidably connected to an inner wall of the liquid storage cavity; one end of the extruding part is located in the liquid storage cavity; the other end of the extruding part stretches out of the liquid storage cavity; and a rolling part is arranged at one end, stretching out of the liquid storage cavity, of the extruding part. The invention aims to solve the problem that in the prior art, when an automobile door plate is welded, a welding flux falls under a gravity action.

Owner:重庆中壹迪工业设计有限公司

Stainless steel plate welding method for radiation environment

InactiveCN106891082AAvoid affecting the welding effectArc welding apparatusWelding/soldering/cutting articlesFillet weldNuclear power

The invention relates to the field of in-service maintenance of nuclear power plants, specifically relates to a welding method for repairing equipment and components in high-radiation areas of a nuclear power plant, and aims at ensuring the personal safety of repairing workers as well as reducing the repairing cost of the nuclear power plant. The stainless steel plate welding method for the radiation environment is applicable to stainless steel plates being 2-5mm in thickness. The method comprises the following steps: pairing and abutting two stainless steel plates, and forming abutting joints being 100+ / -10mm in width; fixing the abutting joints by spot welding; mounting an automatic welding machine for TIG automatic welding in the extending direction of the abutting joints; examining welded fillet welds after the automatic welding machine finishes the welding; and repairing welding gaps in the fillet welds in a manual welding manner. The method is applicable to welding and repairing of the equipment and components in the high-radiation areas of the nuclear power plant, and the injury of radiation on the bodies of the repairing workers can be reduced; the method is fast to weld, small in time consumption, and low in labor cost.

Owner:CHINA NUCLEAR IND 23 CONSTR +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com