Portable automatic spot welding robot

A technology of automation point and robot, applied in welding equipment, tin feeding device, auxiliary device, etc., can solve the problems of blockage of transportation channels, waste of materials, waste of equipment and materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

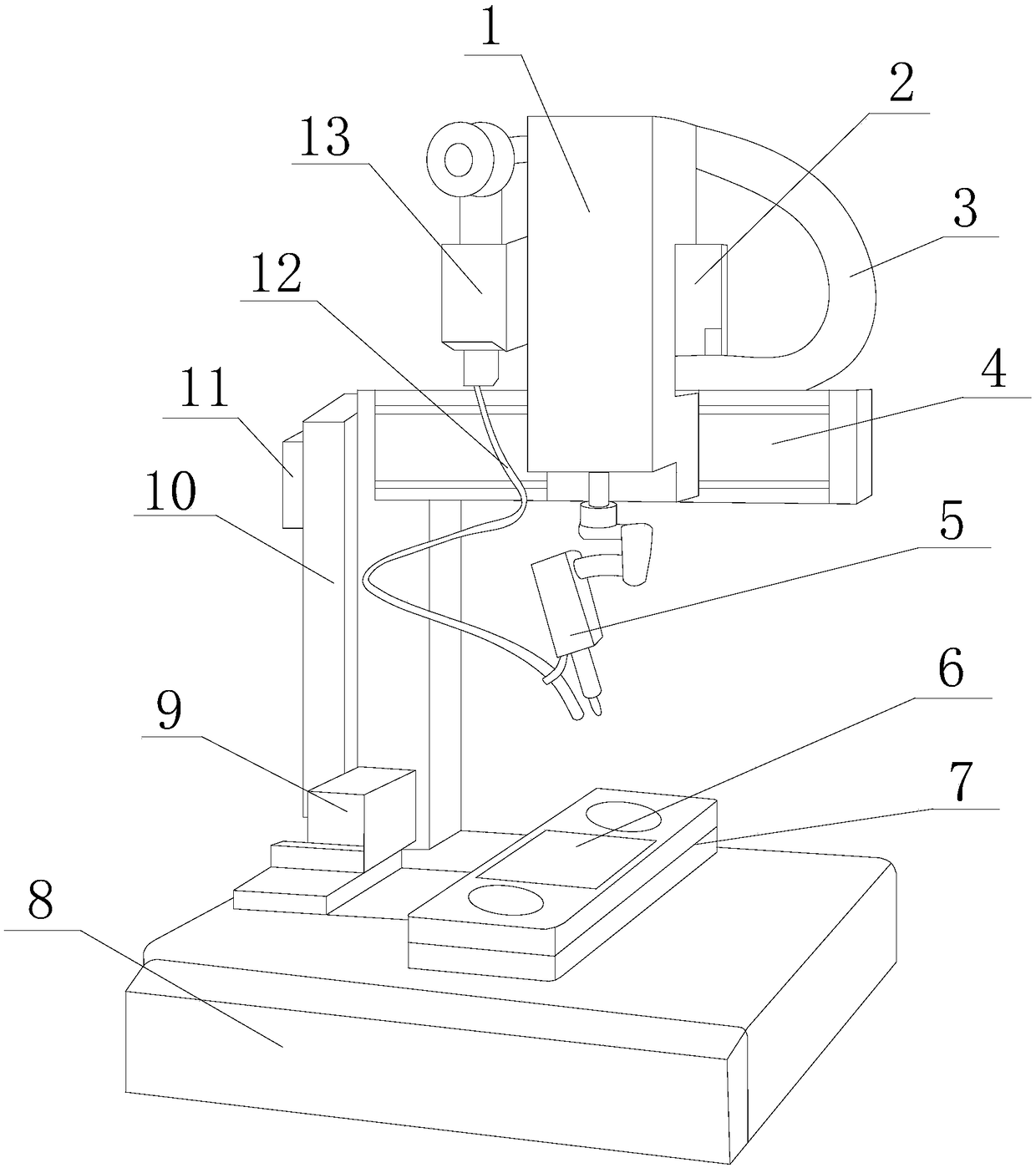

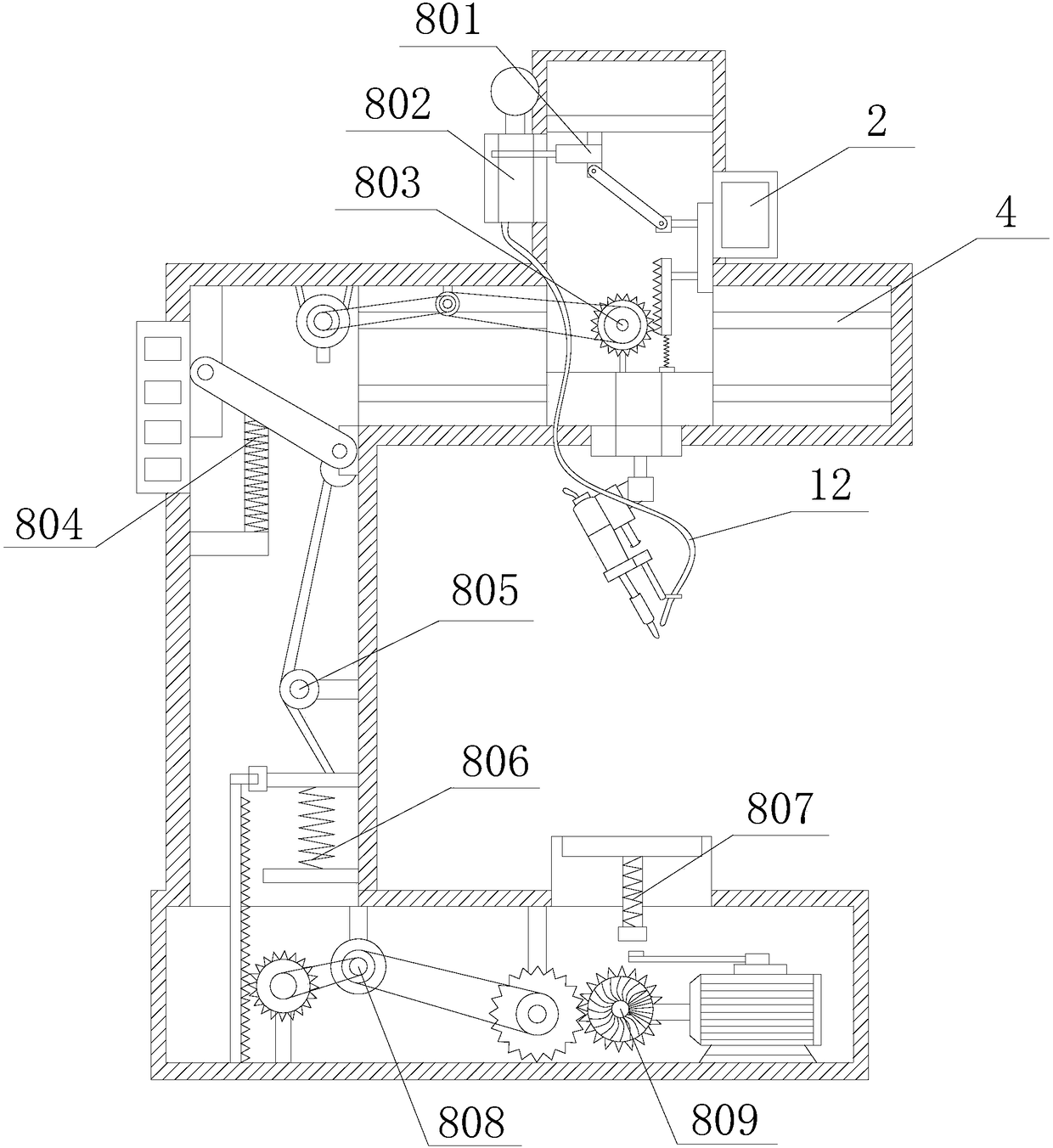

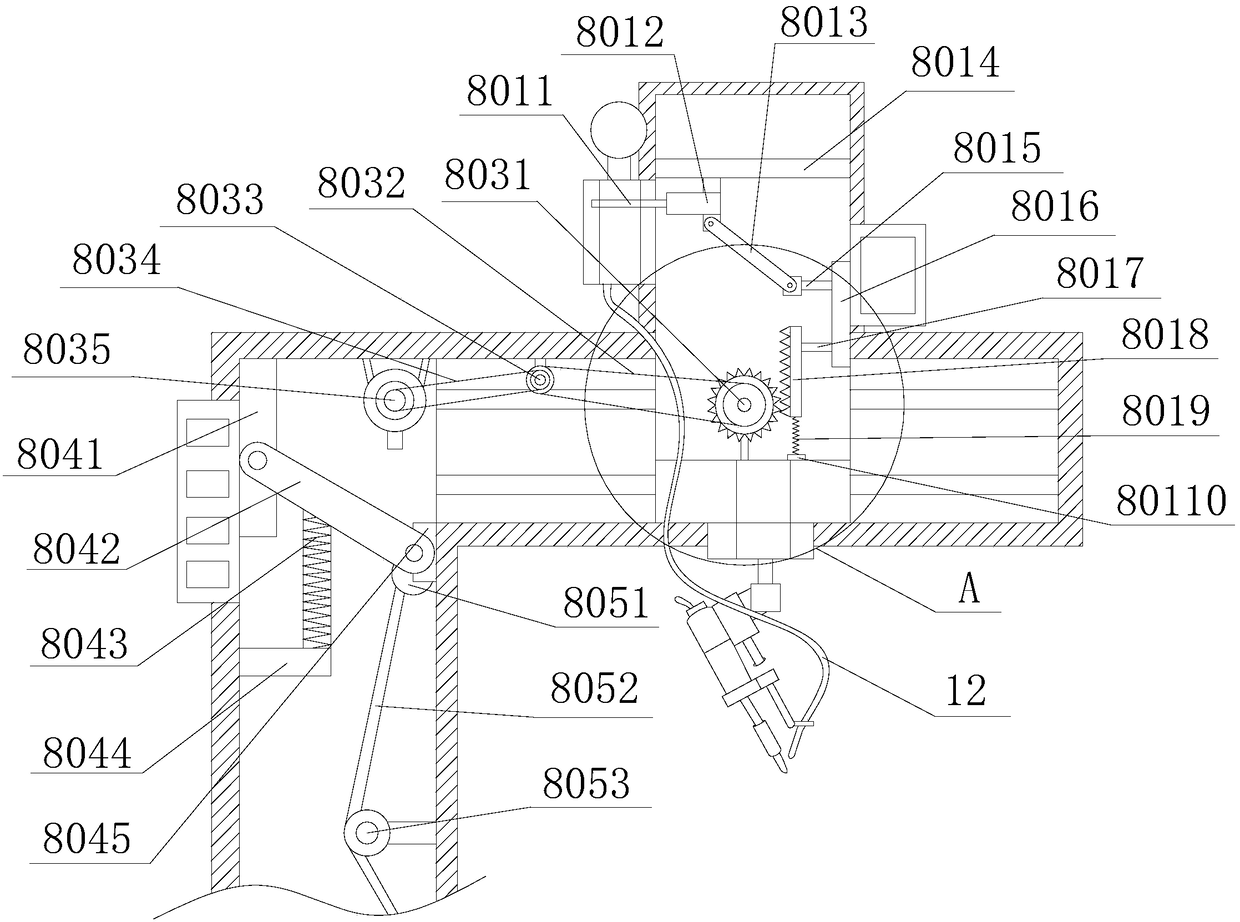

[0027] see Figure 1-Figure 6 , the present invention provides a portable automatic spot welding robot, the structure of which includes a welding head workbench 1, an electrical control box 2, a drive cable 3, a moving track 4, a soldering iron 5, a placement groove 6, an installation base plate 7, a workbench 8, a recycling Tin box 9, support column 10, touch screen 11, tin guide pipe 12, tin delivery box 13, the upper end surface of described workbench 8 is fixed with installation base plate 7 and recovery tin box 9, and described installation base plate 7 is cuboid structure and center The position is provided with a placement groove 6 and adopts clearance fit. The recycled tin box 9 is close to the left end of the support column 10 and is parallel to the installation base plate 7. A touch screen 11 is installed on the support column 10, and the signal inside the touch screen 11 terminal is electrically connected to the signal terminal of the electrical control box 2, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com