Stainless steel plate welding method for radiation environment

A stainless steel plate and welding method technology, applied in welding equipment, welding/welding/cutting items, arc welding equipment, etc., can solve problems such as long welding maintenance time, economic loss of nuclear power plants, and physical injuries of maintenance personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

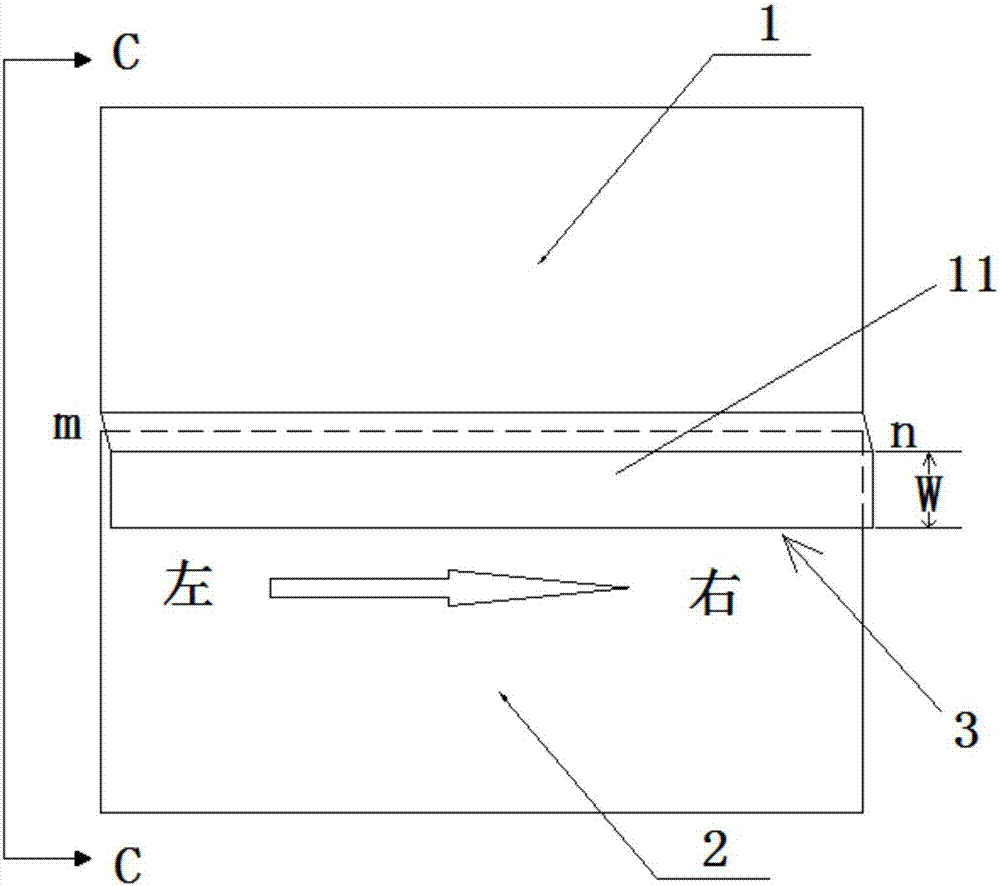

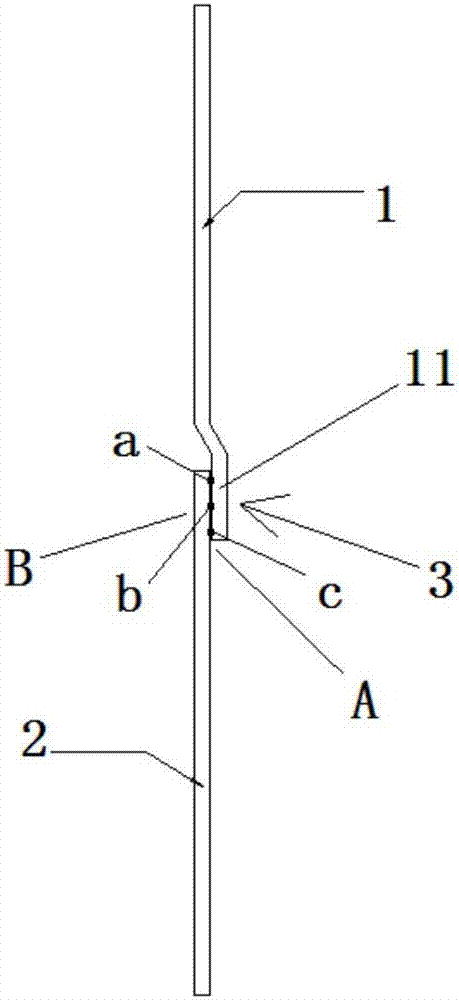

[0017] Below, combine figure 1 and 2 The method for welding a stainless steel plate with a thickness range of 2-5mm in the radiation environment of the present invention is described in detail, and the method includes the following steps:

[0018] Step S1, such as figure 1 and 2 As shown, the bending operation is performed on the side of the first stainless steel plate 1 facing the second stainless steel plate 2 , so that the side of the first stainless steel plate 1 facing the second stainless steel plate 2 is bent into a pair of laps 11 . The first stainless steel plate 1 and the second stainless steel plate 2 are paired and overlapped to form a lap joint 3, that is, the paired laps 11 of the first stainless steel plate 1 are pressed against the second stainless steel plate 2 on the welding front A to form a lap joint joint 3, and the first stainless steel plate 1 and the second stainless steel plate 2 are flush on the welding back B, and the width range w of the lap join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com