Tool for automotive components manufacturing

A technology for auto parts and tooling, applied in the direction of manufacturing tools, auxiliary devices, metal processing equipment, etc., can solve problems such as solder falling, and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is further described in detail through specific implementation methods:

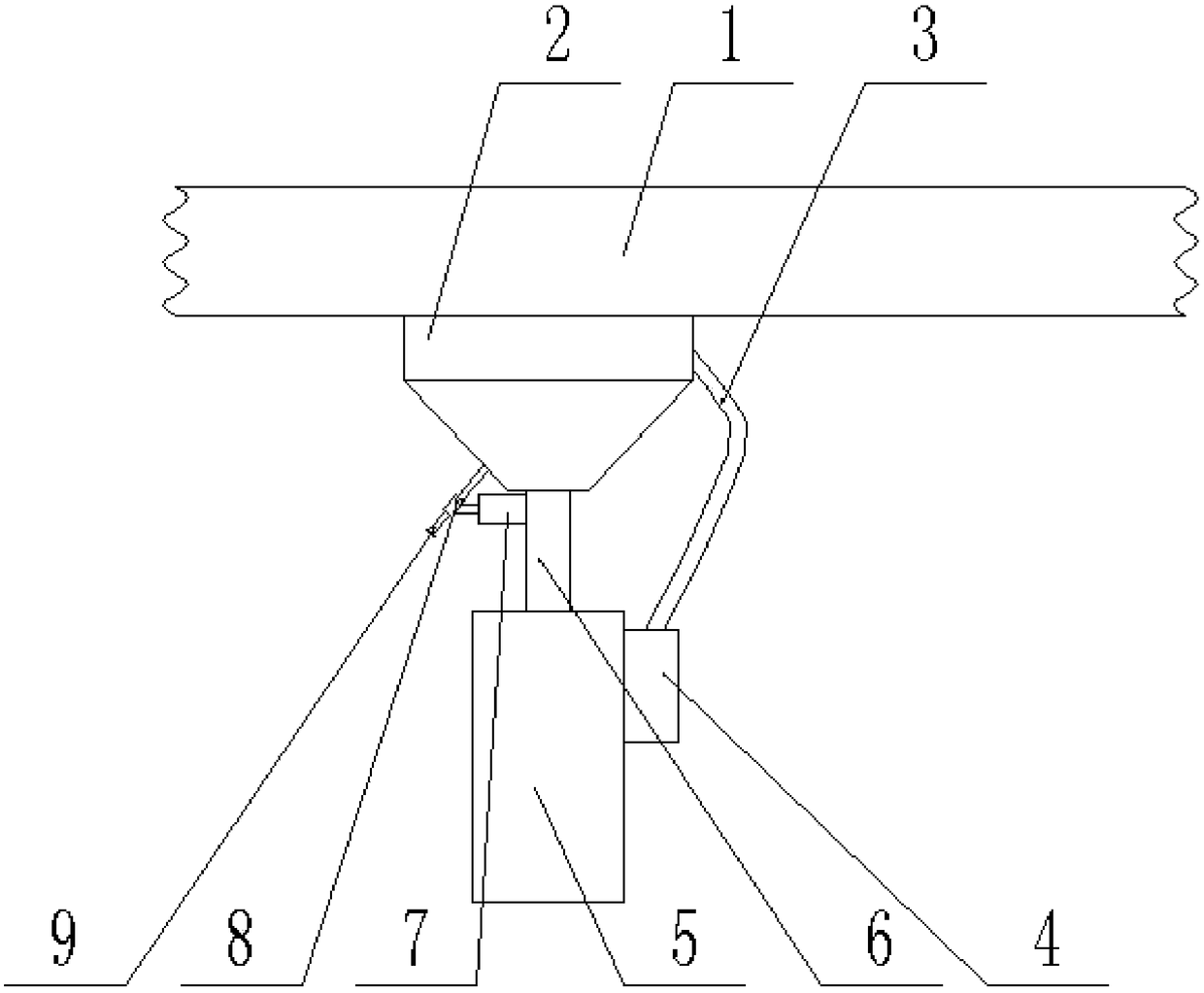

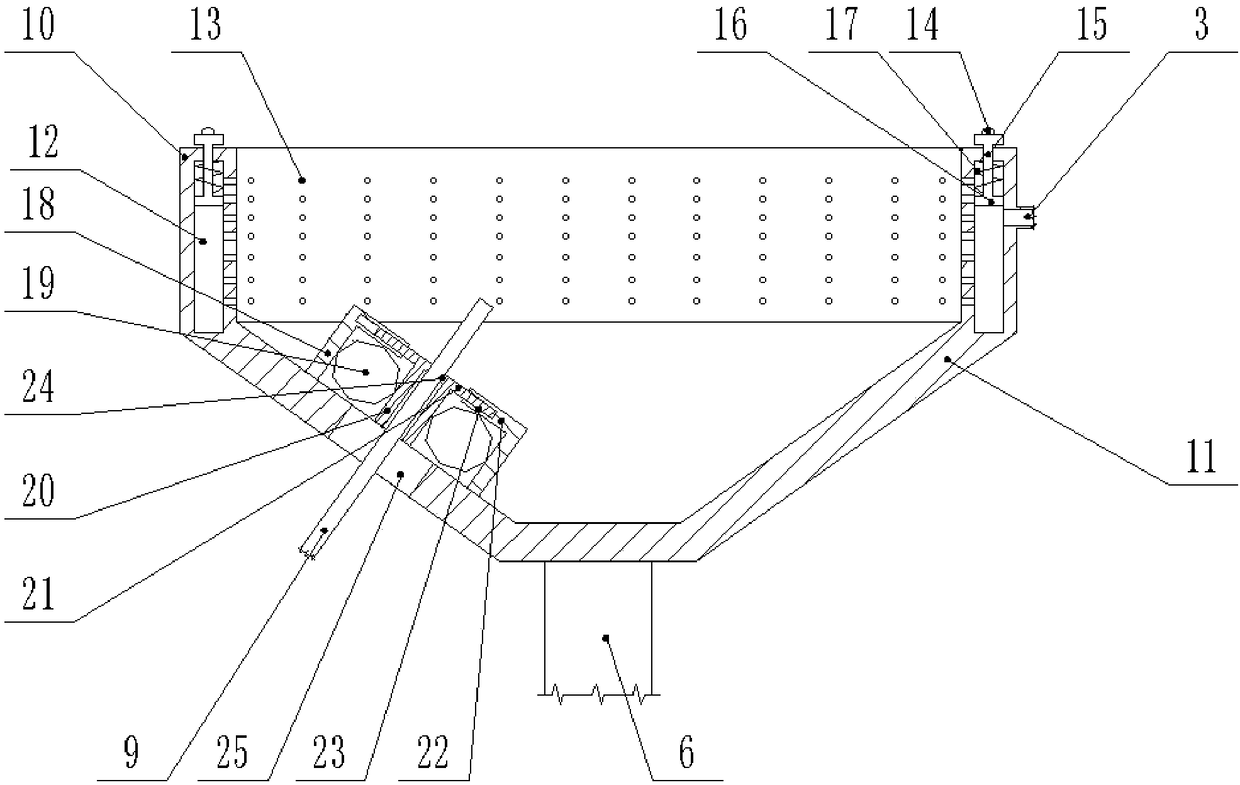

[0020] The reference signs in the accompanying drawings of the specification include: automobile door panel 1, barrier cover 2, infusion tube 3, liquid storage tank 4, hydraulic cylinder 5, output shaft 6, driving hydraulic cylinder 7, positioning sleeve 8, welding rod 9, ring segment 10. Round table section 11, liquid storage chamber 12, spray hole 13, ball 14, pressure rod 15, extrusion ring 16, tension spring 17, support plate 18, air bag 19, partition 20, sliding plate 21, baffle 22, Slide groove 23, drive hole 24, through hole 25.

[0021] The embodiment is basically as figure 1 and figure 2 Shown: a tooling for manufacturing auto parts, including a barrier cover 2, the barrier cover 2 includes an integrally formed circular ring segment 10 and a circular platform segment 11, the diameter of the upper end of the circular platform segment 11 is the same as that of the circular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com