Synchronous clamping eccentricity detection device for circular workpiece

An eccentricity detection, circular workpiece technology, applied in measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problem of not being able to find the axis offset when the cylindrical workpiece to be welded is clamped in time, so as to improve the welding performance. The effect of quality and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

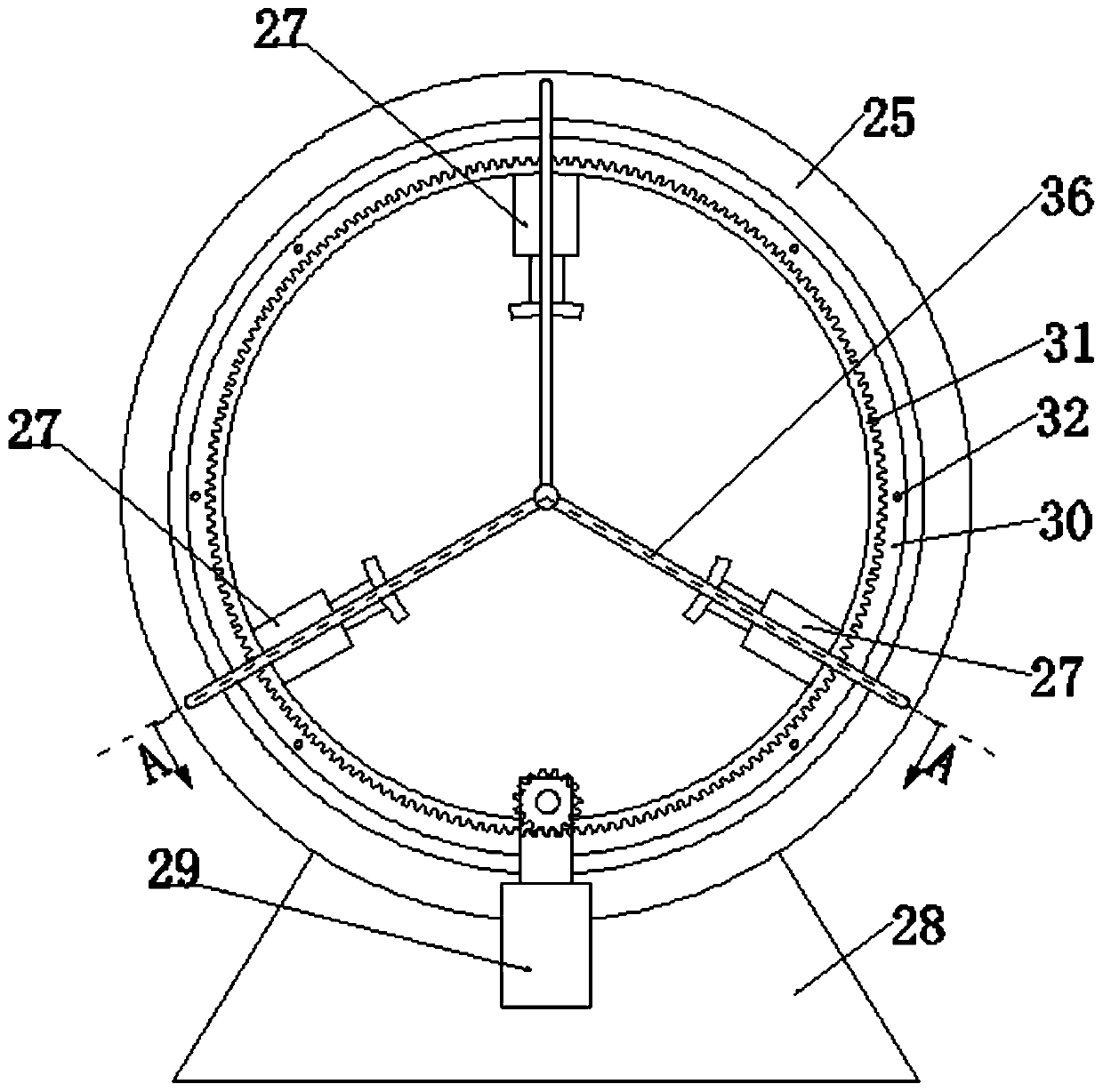

[0049] Such as Figure 1 to Figure 2 As shown, a circular workpiece synchronous clamping eccentricity detection device includes a detection device body and a clamping rotation mechanism, and the detection device body is arranged on the clamping rotation mechanism;

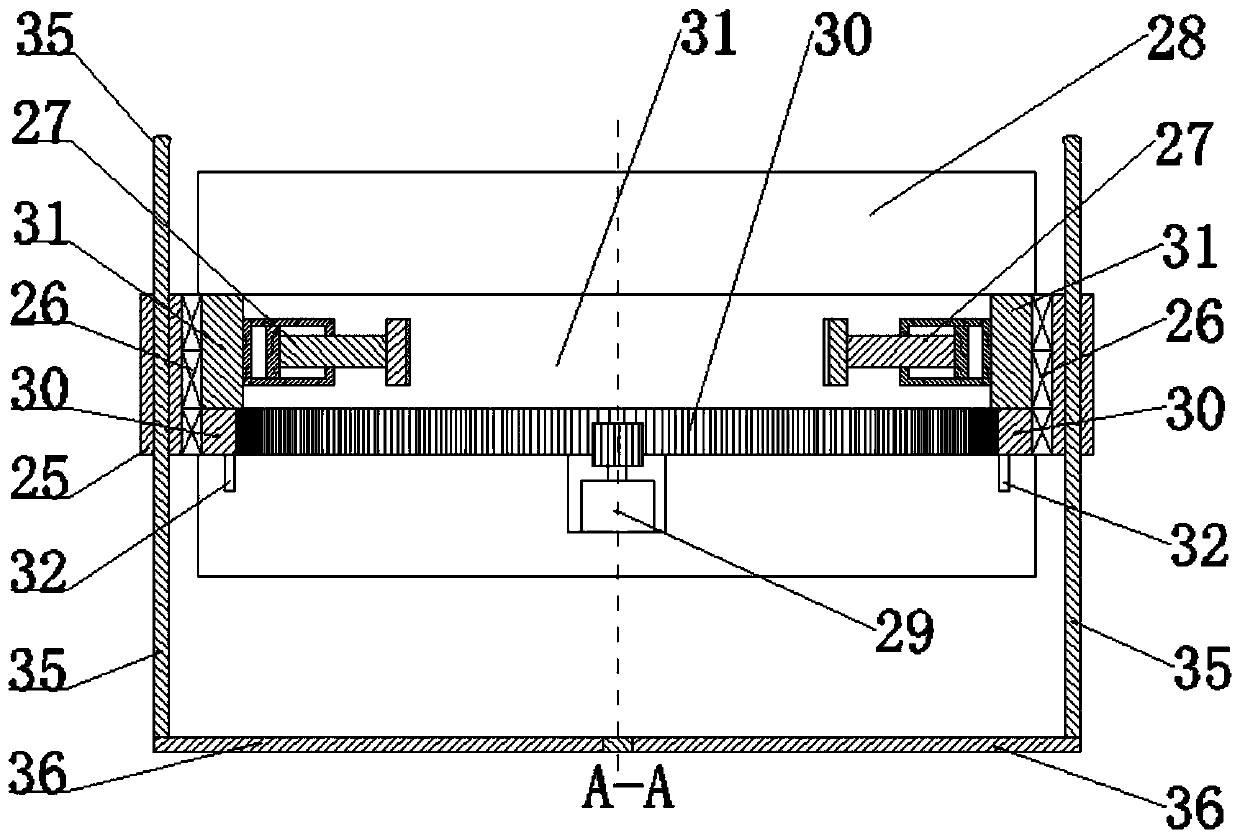

[0050] The clamping and rotating mechanism includes an annular mounting base 25, an installation inner cylinder 31, and an installation base 28. The outer wall of the annular mounting base 25 is fixed on the mounting base 28, and the centerline of the annular mounting base 25 is horizontal. set up;

[0051] The annular mounting seat 25 is cylindrical, the centerline of the annular mounting seat 25 is arranged horizontally, the inner cavity of the annular mounting seat 25 forms the clamping area, and the detection device body surrounds the annular mounting seat 25 centerline; the annular mounting seat 25 and the installation inner cylinder 31 are concentrically arranged, and the installation inner cylinder 31 is in...

Embodiment 2

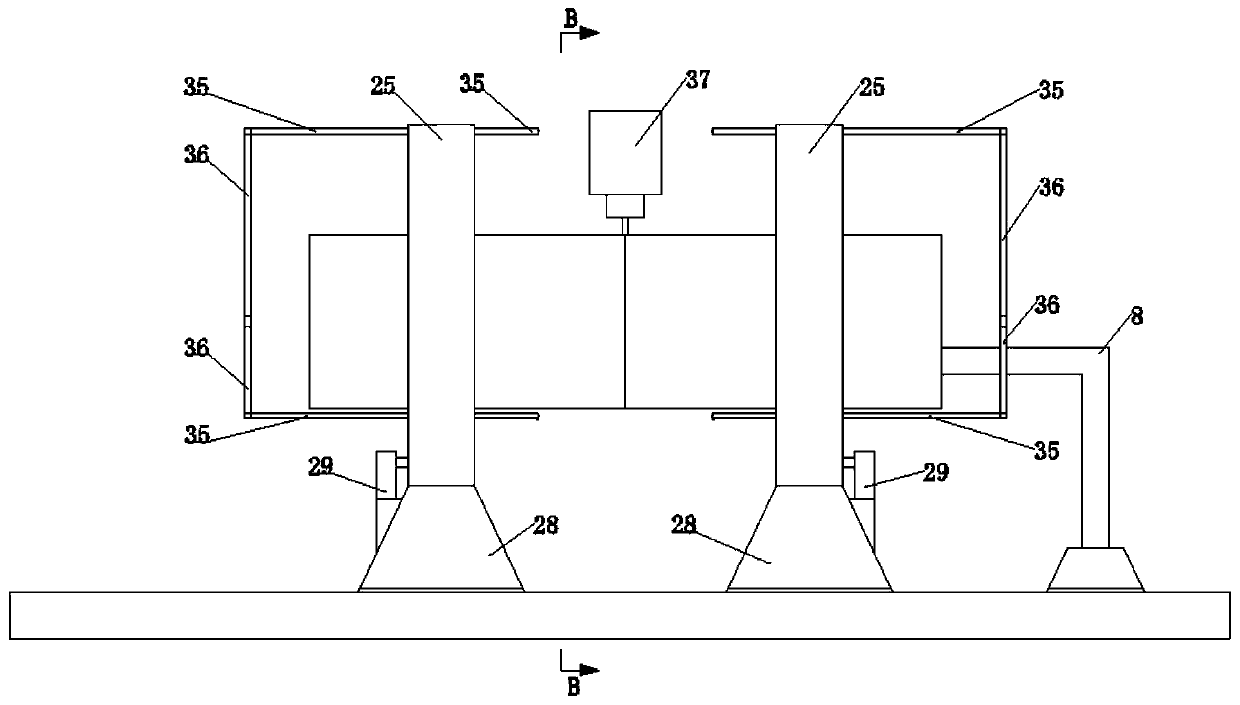

[0061] Such as Figures 3 to 18 As shown, a cylindrical workpiece friction stir welding system includes a workbench, which is provided with an inner support device, a welding tool (not shown in the figure) and two sets of clamping and rotating mechanisms. The inner support device Located between the two sets of clamping and rotating mechanisms, the stirring head 37 of the welding tool is located above the inner support device;

[0062] The clamping and rotating mechanism includes an annular mounting base 25, an installation inner cylinder 31, and an installation base 28. The outer wall of the annular mounting base 25 is fixed on the mounting base 28, and the centerline of the annular mounting base 25 is horizontal. Set, the installation base 28 is slidably fitted on the workbench, the centerlines of the ring mounting seats 25 of the two groups of clamping and rotating mechanisms coincide, and the sliding direction of the mounting base 28 is the same as that of the ring mountin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com