Electric welding machine provided with adjustable hydraulic fastening mechanism

A technology of fastening mechanism and electric welding machine, applied in the field of welding equipment and electric welding machine, can solve the problems of poor functional integration, optimized centralized storage of electric welding cables and electric welding electrodes, poor shock absorption and buffer protection effect, etc. Easy to slide assembly and take out for maintenance, easy to take and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

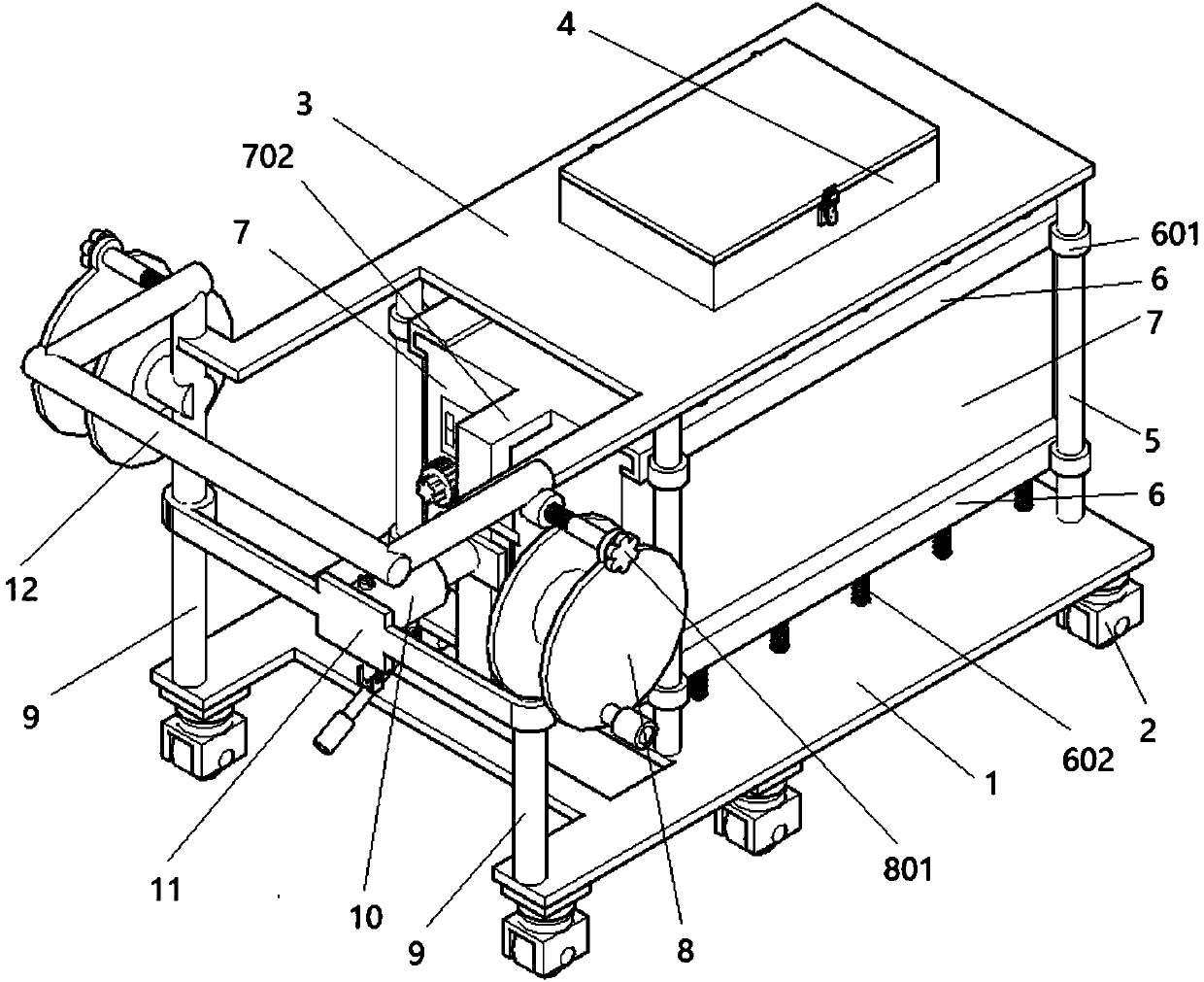

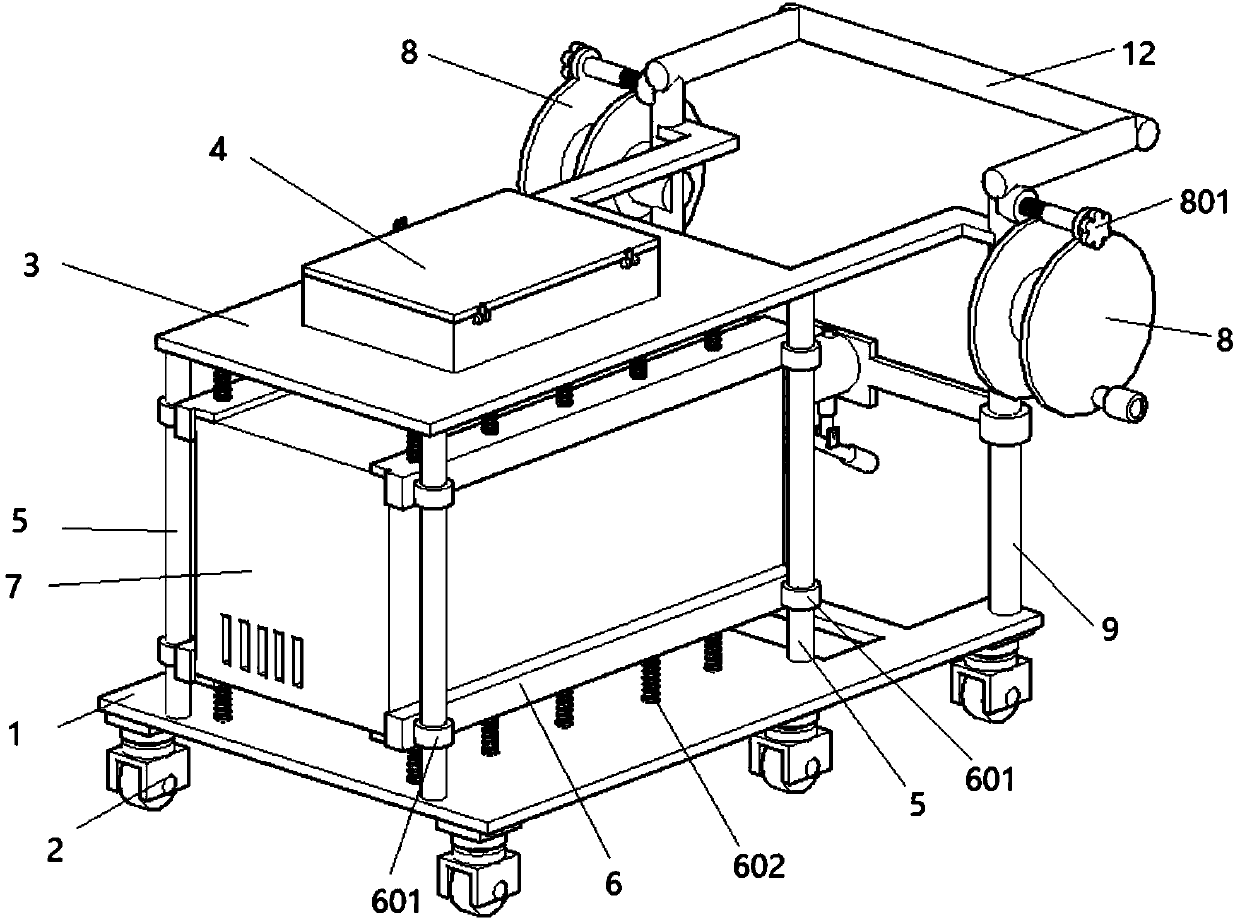

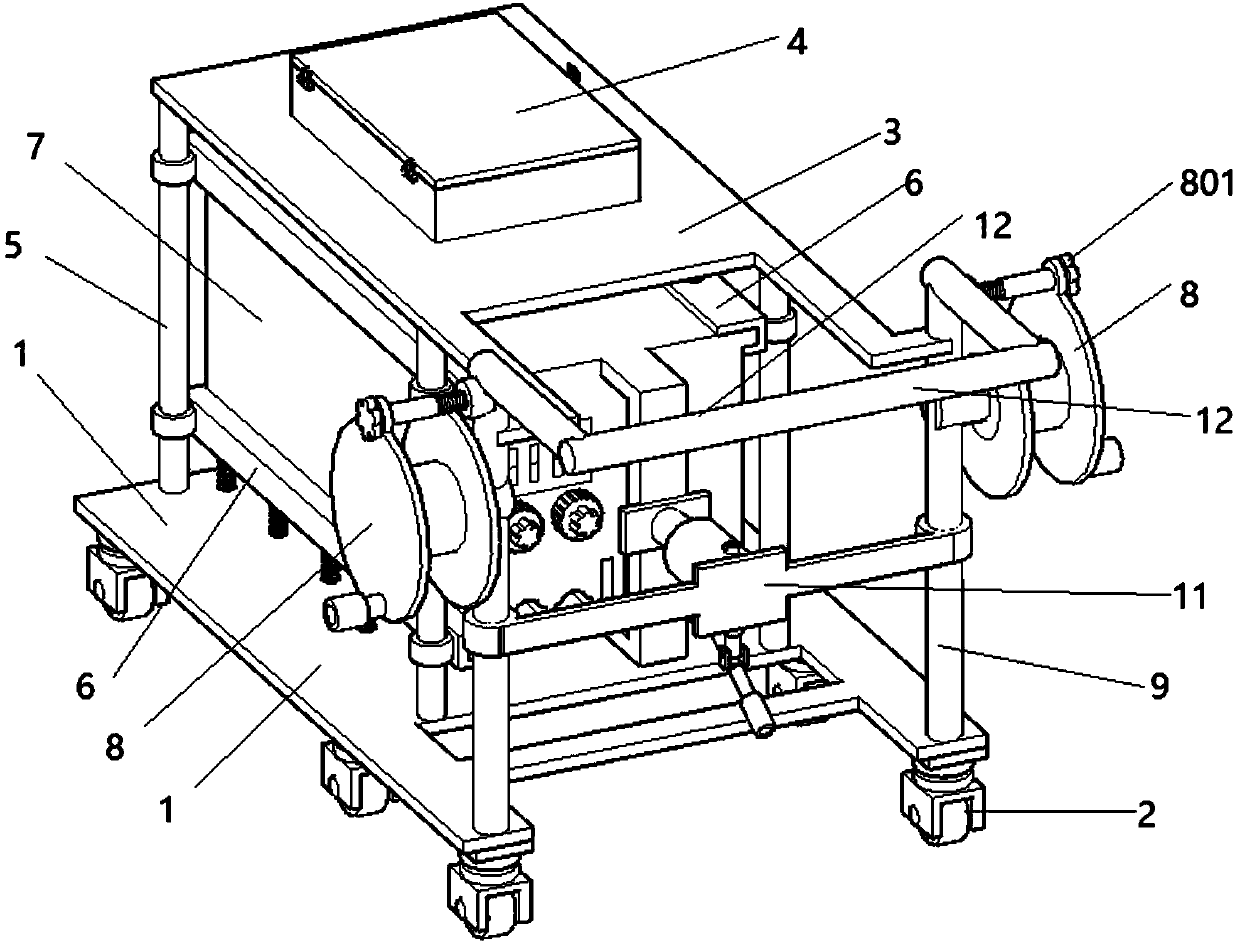

[0036] as attached figure 1 to the attached Figure 8 shown:

[0037] The present invention provides an electric welding machine equipped with an adjustable hydraulic fastening mechanism, comprising a bottom plate 1, a roller 2, a top plate 3, a welding rod holding box 4, a first support rod 5, a sliding rail 6, a sliding sleeve 601, and a damping spring 602, welding machine body 7, positioning hole 701, pulling handle 702, line roller 8, line roller positioning shaft 801, second support rod 9, hydraulic cylinder 10, pressure rod 1001, telescopic baffle 1002, pressure relief knob 1003, The oil cylinder supports the slide plate 11 and the push rod 12. The left end of the bottom plate 1 is symmetrically protruded and extended with two support plates. The tops of the two support plates are both supported and welded with a second support rod 9, and two second supports The top end of the rod 9 is bent and connected with a push rod 12; the bottom of the bottom plate 1 is symmetric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com