Auxiliary welding equipment for cylindrical foundation column steel bars

An auxiliary welding and steel bar technology, applied in auxiliary welding equipment, welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of affecting the welding effect, not being able to fix round steel bars and long steel bars, and affecting work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

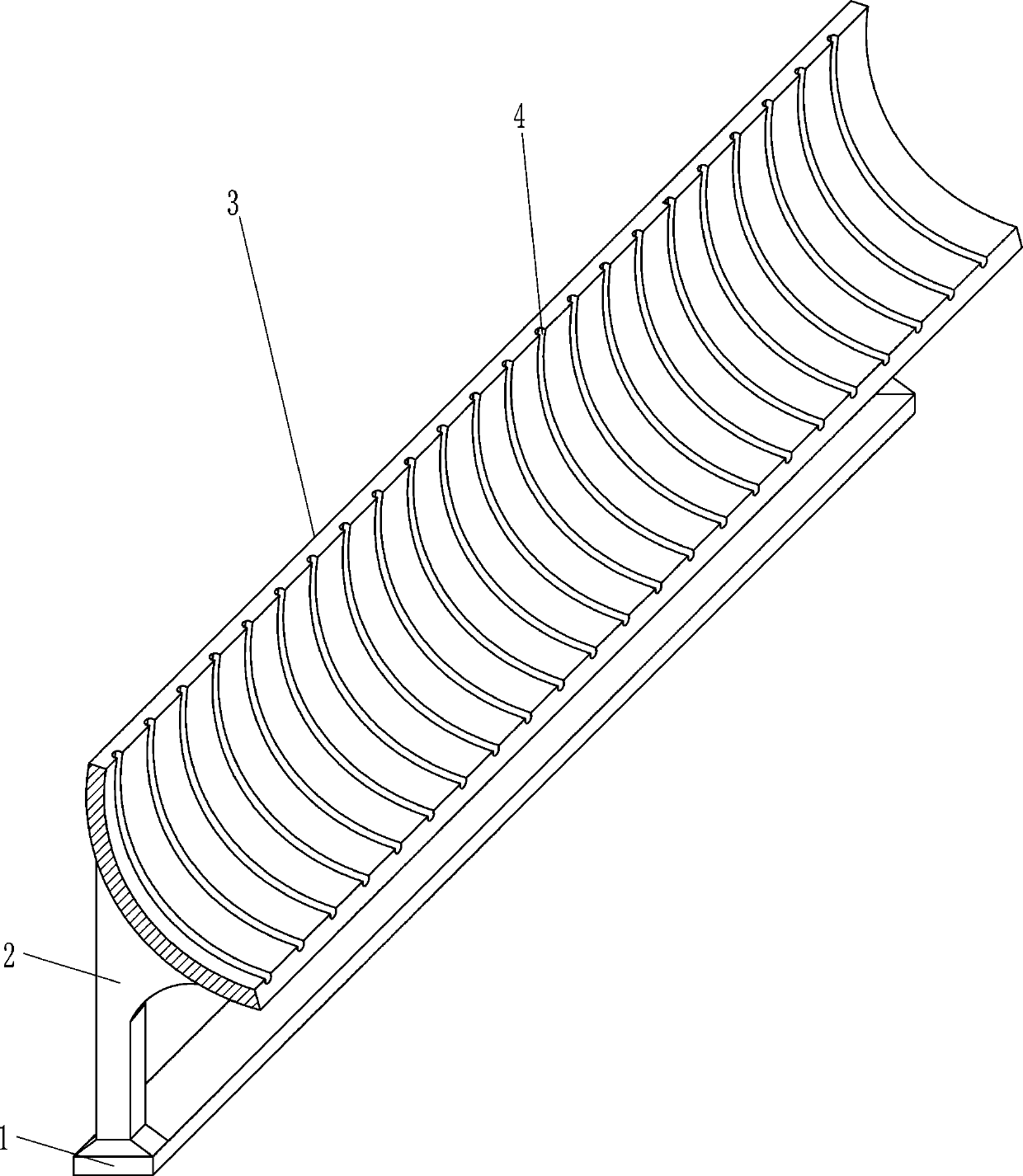

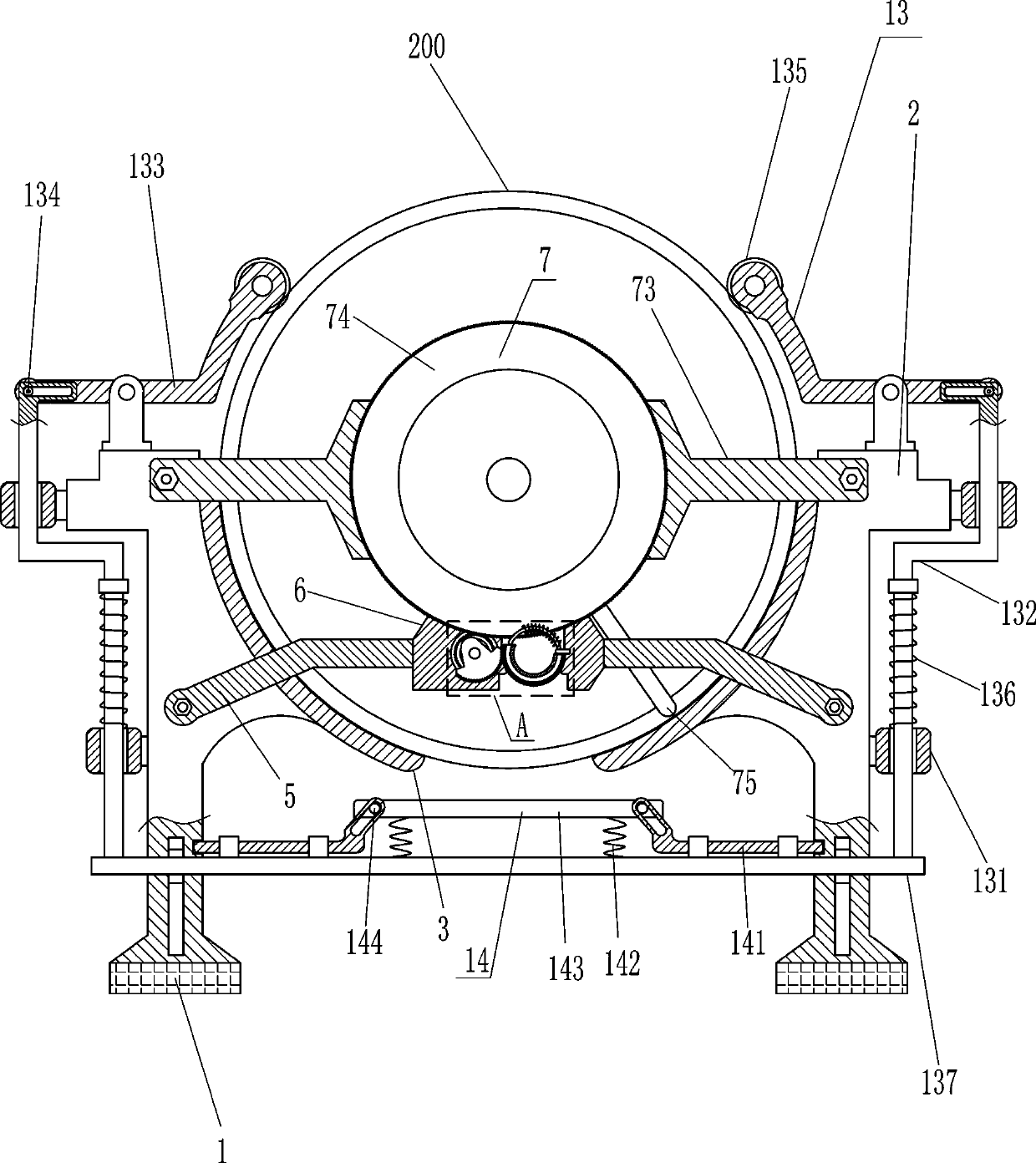

[0019] Refer to 1-2, an auxiliary welding equipment for cylindrical foundation building steel bars, including a base 1, a bracket 2 and a curved plate 3, the tops of the two bases 1 are connected to the front and rear sides of the bracket 2, and the bracket 2 and the base 1 pass through Connected by means of bolt connection, the brackets 2 on both sides are provided with arc-shaped plates 3, and the two arc-shaped plates 3 form an unconnected semicircle, and the arc-shaped plates 3 are evenly spaced with arc-shaped grooves 4. The width of 4 is slightly greater than the diameter of the steel ring, and also includes connecting frame 5, fixed plate 6 and rotating assembly 7, and the front and rear walls of both sides of support 2 are provided with connecting frame 5, and bolts are used between connecting frame 5 and support 2 The connecting frame 5 is located at the lower part of the arc-shaped plate 3, and the two connecting frames 5 at the front and rear are connected with a fix...

Embodiment 2

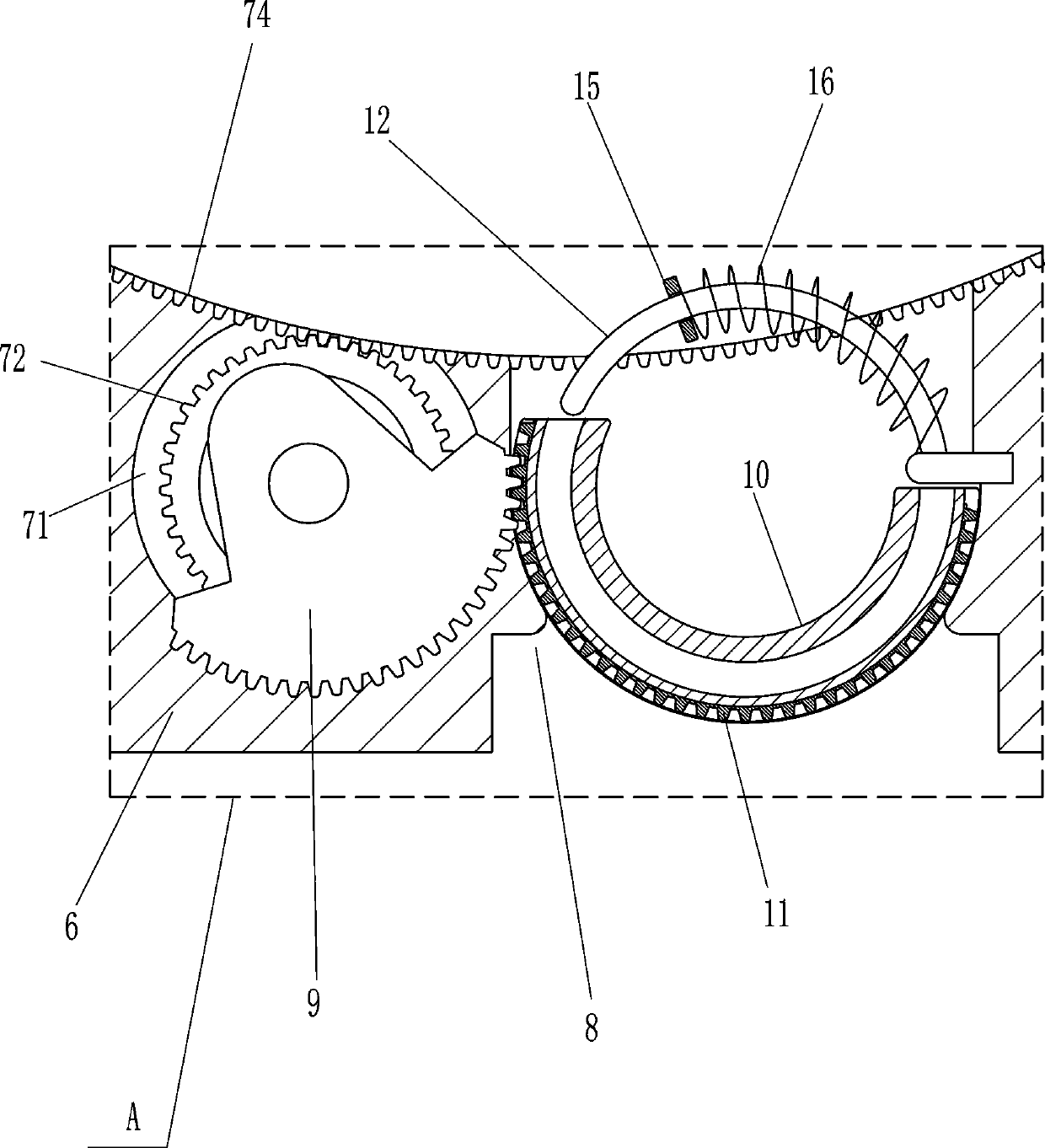

[0024] Referring to 3, it also includes a sector gear 9, an arc tube 10, an arc rack 11 and an arc guide rod 12. The middle part of the fixed plate 6 is provided with a placement groove 8, and the placement groove 8 is an arc shape with upper and lower openings. Gear 72 front end face is connected with sector gear 9, is placed with arc pipe 10 in placing groove 8, and arc pipe 10 can rotate in placing groove, and arc pipe 10 outer surface is provided with arc rack 11, and arc rack 11 is embedded on the arc tube 10, the arc rack 11 meshes with the sector gear 9, the upper part of the placement groove 8 is provided with an arc guide rod 12, and the arc guide rod 12 is connected to the fixed plate 6. There is a chute cooperating with the arc-shaped guide rod 12 inside the tube 10, and the arc-shaped tube 10 is slidably matched with the arc-shaped guide rod 12 through the chute.

[0025] When it is necessary to place a long steel bar, the arc tube 10 is placed between the insides ...

Embodiment 3

[0027] refer to figure 1 , also includes a fixed assembly 13, the fixed assembly 13 includes a guide sleeve 131, a first sliding rod 132, a swing rod 133, a first roller 134, a pressure wheel 135, a first compression spring 136 and a connecting rod 137, and the brackets on both sides 2 The front and rear sides of the outer wall are provided with guide sleeves 131, and the first sliding rod 132 is slid inside the guide sleeve 131. The shape of the first sliding rod 132 is a side "Z" shape, and the top of the first sliding rod 132 has a guide Slot, the guide groove is arranged horizontally, the front and rear sides of both sides support 2 tops are all hingedly connected with swing lever 133, and swing lever 133 one end is provided with first roller 134, and first roller 134 is positioned at guide groove, and swing lever 133 The other end is rotatably provided with a pinch roller 135 for pressing the steel bar ring, which is a rotary connection between the pinch wheel 135 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com