Full-automatic straight seam welding equipment

A straight seam welding, fully automatic technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low work efficiency, welding deviation, difficult to ensure welding quality, etc., to ensure processing quality, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

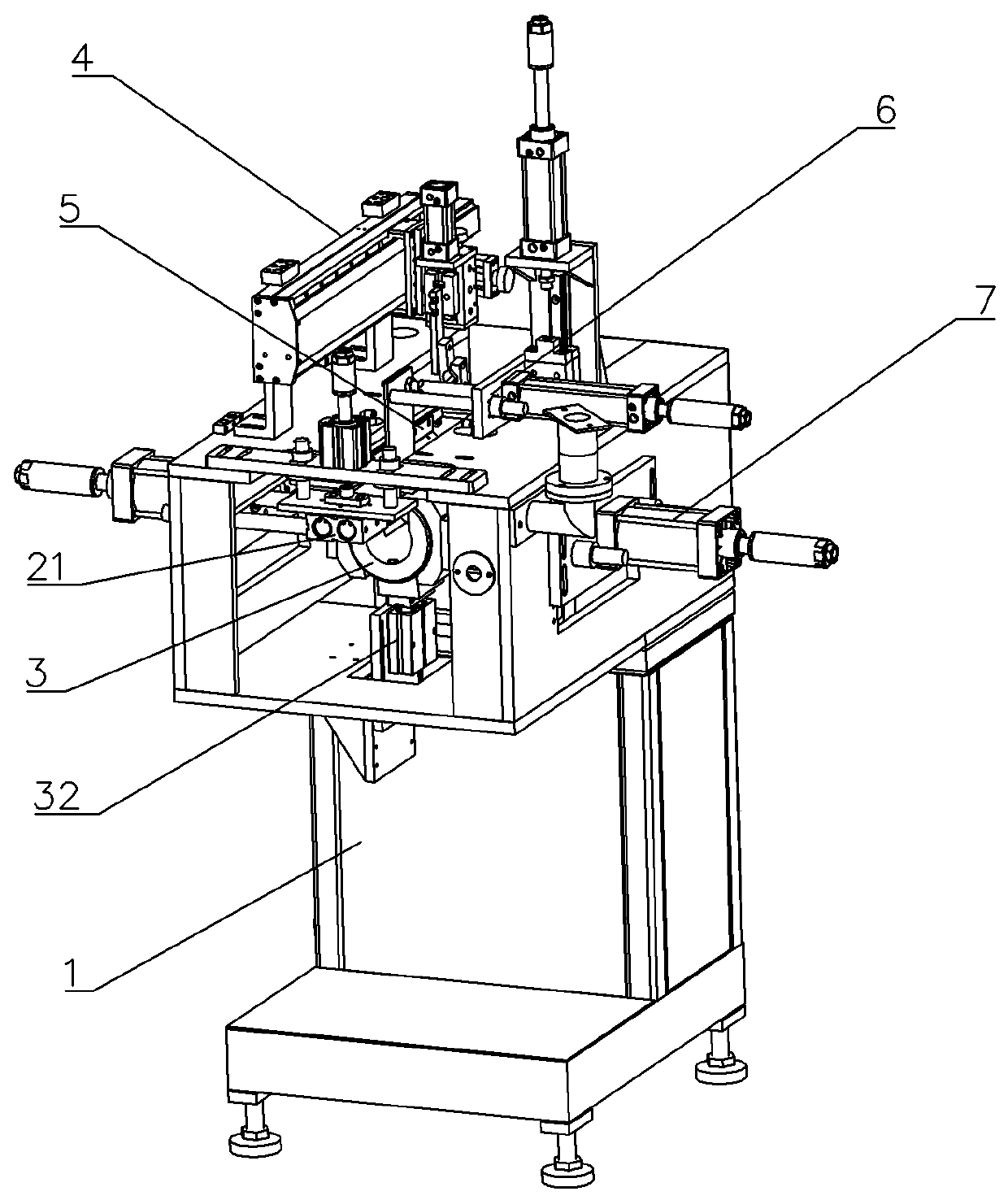

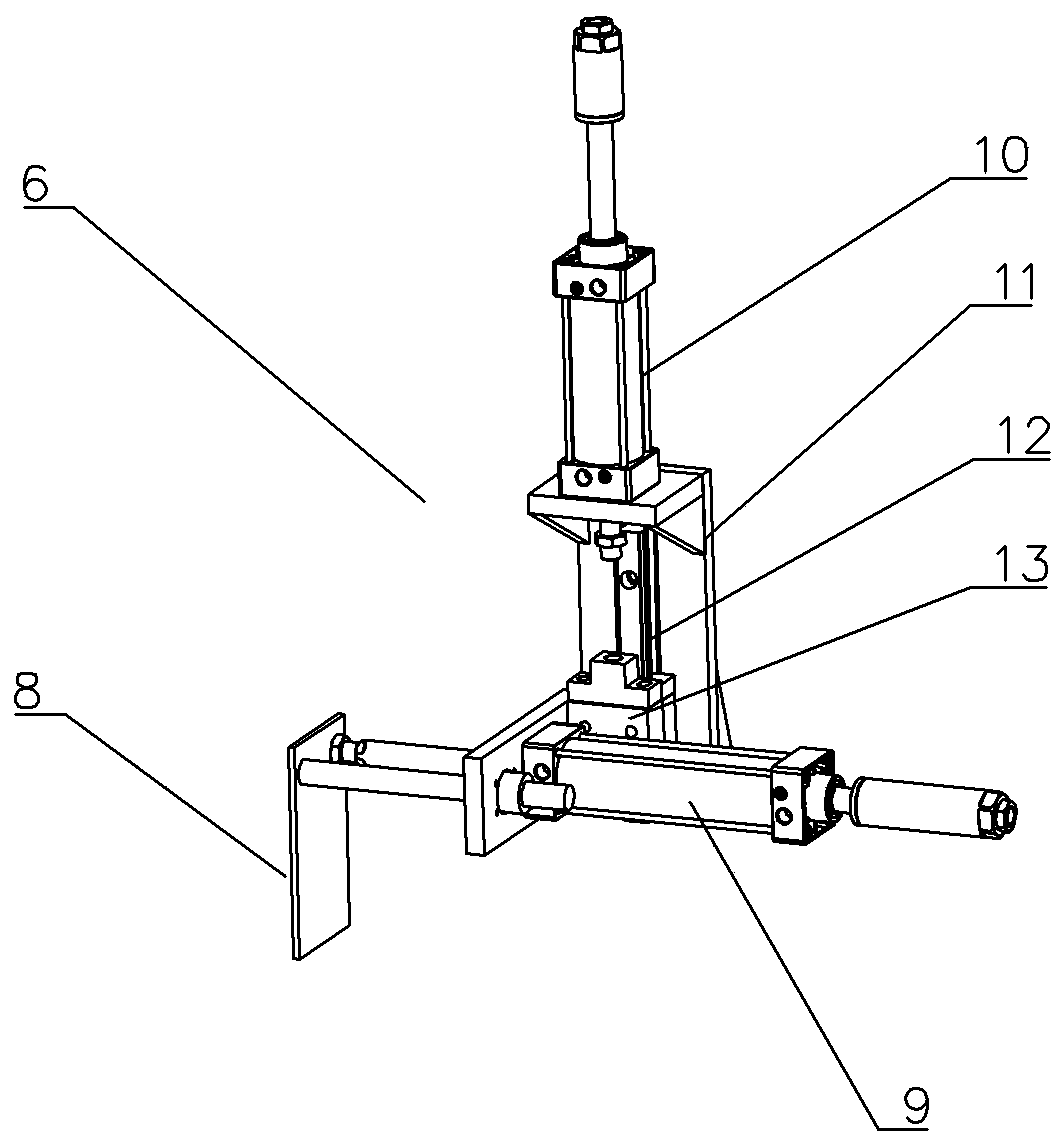

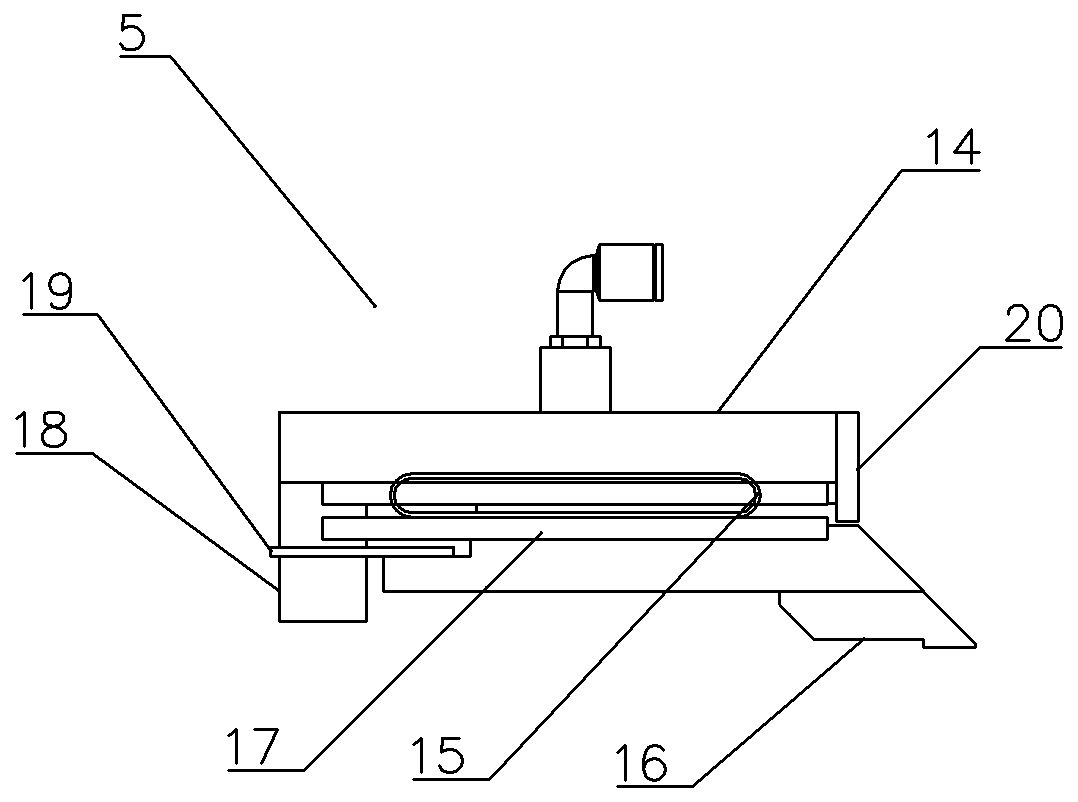

[0027] refer to Figure 1 to Figure 8 As shown, the fully automatic straight seam welding equipment includes a frame 1, the middle part of the frame 1 is provided with a main shaft 3 for placing a workpiece 2, and the periphery of the main shaft 3 is provided with a welding mechanism 4, a positioning assembly, and a clamping assembly. The welding mechanism 4 is arranged directly above the main shaft 3; the positioning assembly is at least composed of a clamping mechanism 5 arranged on the left and right sides above the main shaft 3 and a positioning plate mechanism 6 movably arranged between the clamping mechanisms 5 on the left and right sides; The clamping assembly is at least composed of side positioning mechanisms 7 arranged on the left and right sides of the main shaft 3; when forming, the positioning plate mechanism 6 is first displaced to the corresponding position for positioning, and then the workpiece 2 is aligned with the positioning plate mechanism 6 and placed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com