Planar six-head diamond dispensing machine

A drilling rig and plane technology, used in decorative arts, inlaid decorative structures, painting tools, etc., can solve the problems of low efficiency, inconvenient operation of the machine head, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

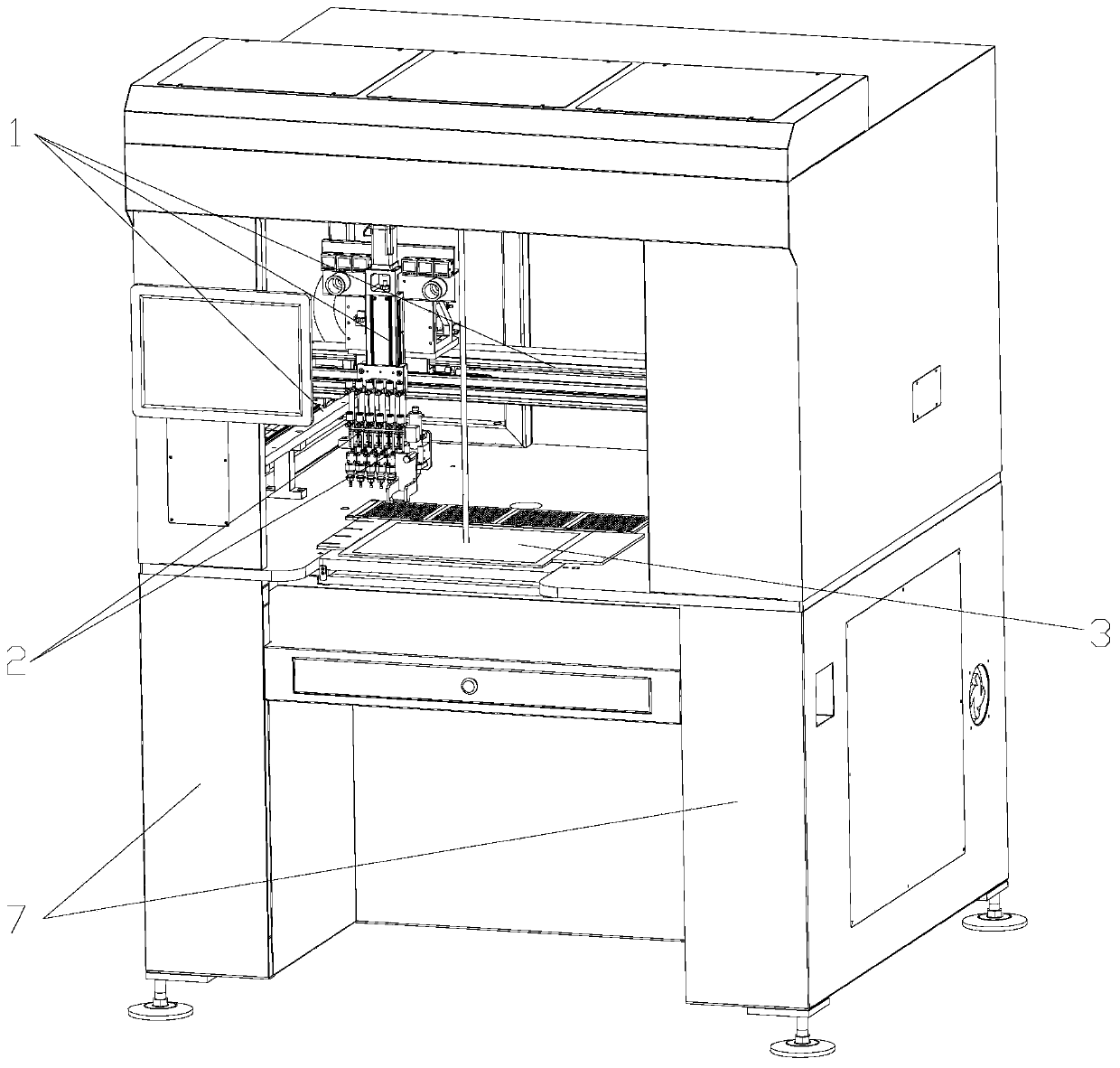

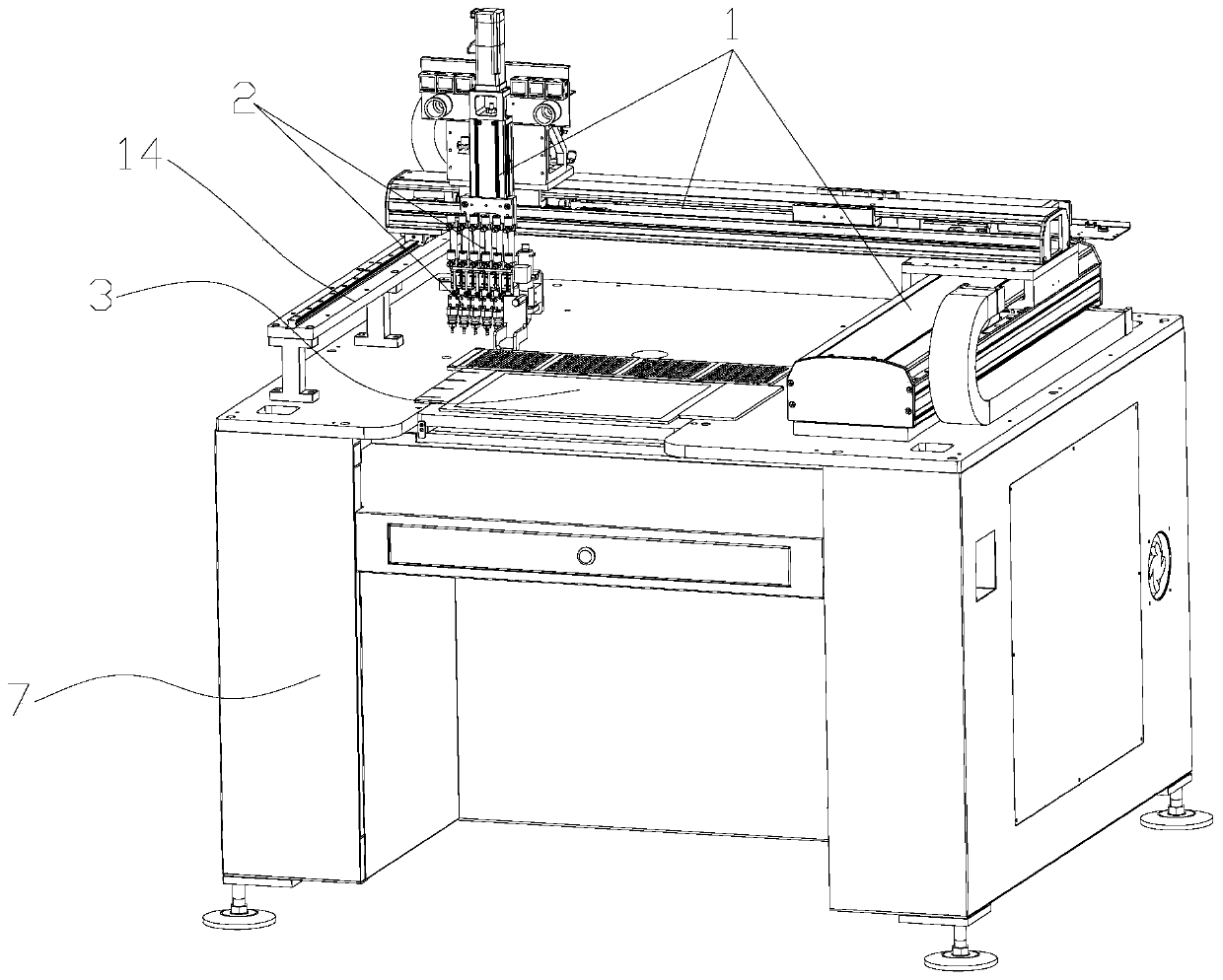

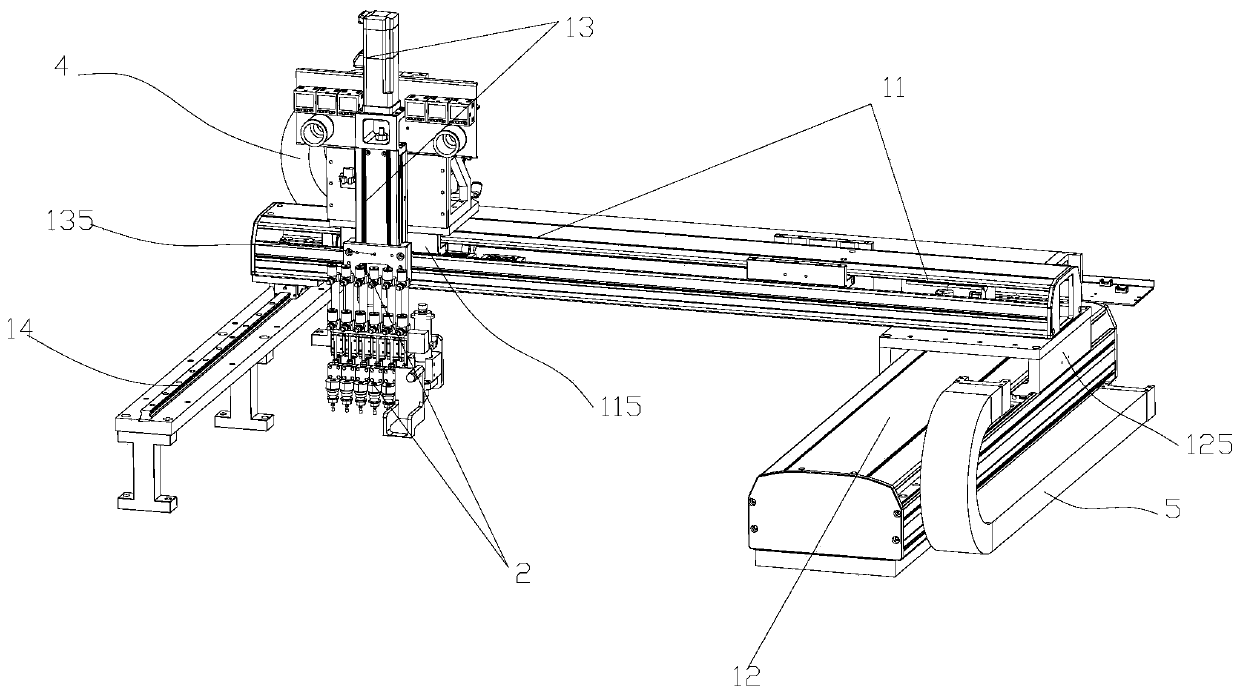

[0024] Figure 1 to Figure 9 Shown is the schematic diagram of the structure of the plane six-point drilling rig of the present invention.

[0025] The plane six-point drilling machine includes a three-dimensional motion mechanism 1, a machine head 2, a workpiece placement table 3, a first drag chain 4, a second drag chain 5, a vacuum generator 6 and a frame 7.

[0026] Such as figure 1 and figure 2 As shown, in the present embodiment, the workpiece can be fixedly installed on the workpiece placement platform 3. In the present embodiment, the workpiece can be any parts such as some decorations or some door buttons that need to be drilled. The drill mentioned here is An item used for decoration, such as a drill on a hairpin, that has a small diameter. The three-dimensional motion mechanism 1 can drive the machine head 2 to move to the workpiece, and perform glue dispensing and spot drilling on the workpiece.

[0027] The three-dimensional motion mechanism 1 is described in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com