High-efficiency spot drilling process and high-efficiency spot drilling device

A high-efficiency spot drilling technology, applied in the field of spot drilling of diamonds and rhinestones, can solve the problems of low production efficiency and high production cost, and achieve the effect of improving production efficiency, high spot drilling efficiency and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0029] High-efficiency spot drilling process, including the following steps carried out in sequence:

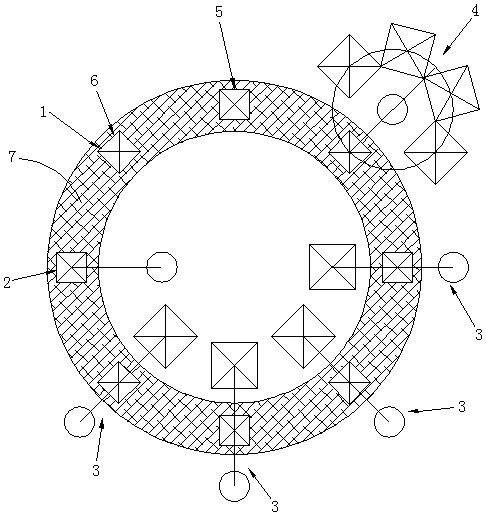

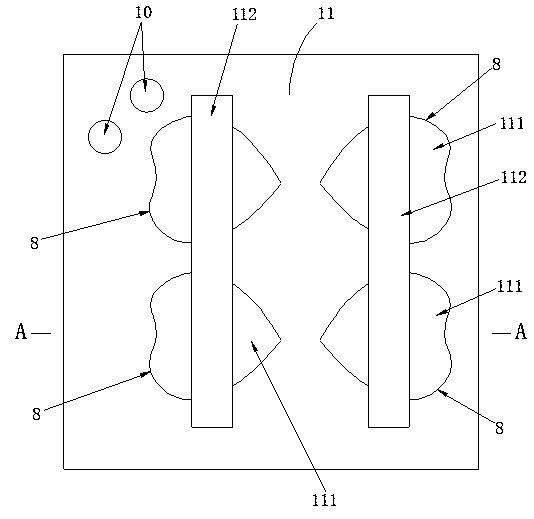

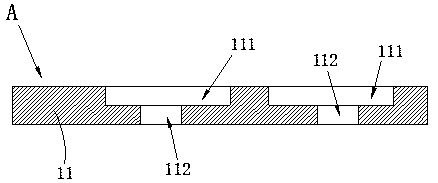

[0030] A. Making master models: Make dispensing master models, suction drill master models 31 and spot drilling master models 32 that match the shape and drill position of the workpiece to be drilled respectively; the glue dispensing master models are equipped with several dispensing needles 214, the dispensing needle 214 is in one-to-one correspondence with the drilling position of the workpiece to be dispensed; a negative pressure chamber is provided in the suction drilling template 31, and a hole communicating with the negative pressure chamber is provided in each drilling position of the suction drilling template 31. Suction holes, the drill position of the suction drill template 31 is matched with the root of the drill; the point drill template 32 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com