Mechanical spiral scanning ultrasonic imaging method

An ultrasonic imaging method and helical scanning technology, applied in ultrasonic/sonic/infrasonic diagnosis, ultrasonic diagnosis, infrasonic diagnosis, etc., can solve inaccurate correspondence between time and position, uneven speed, difficult to apply to patient body cavity scanning imaging, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

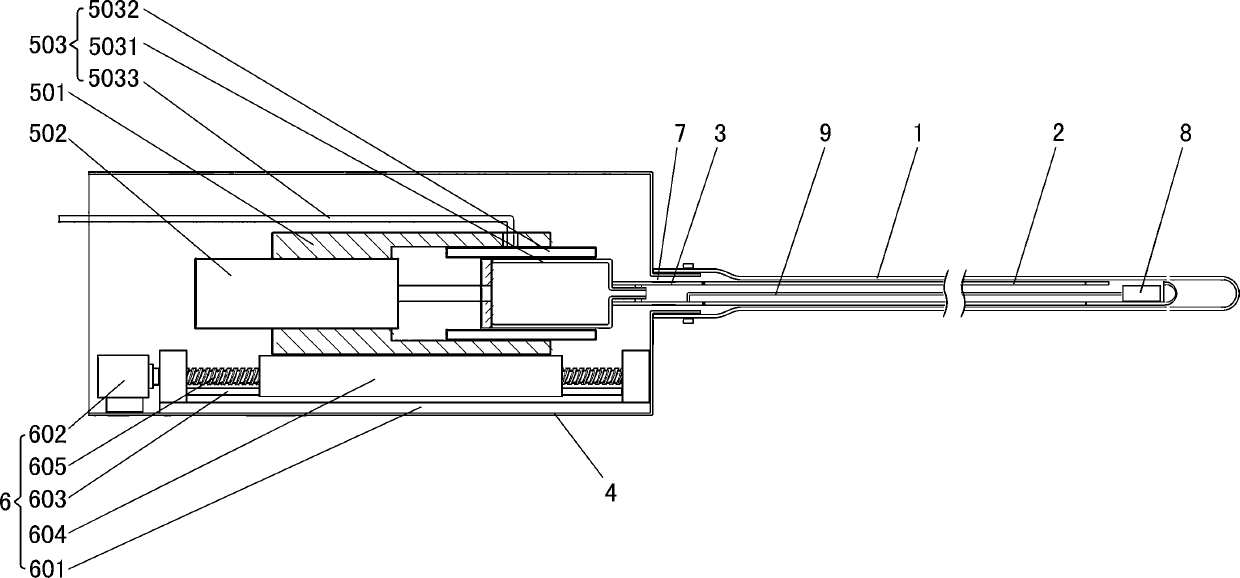

[0020] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

[0021] The scanning mode and imaging mode of this mechanical helical scanning ultrasonic imaging method are as follows:

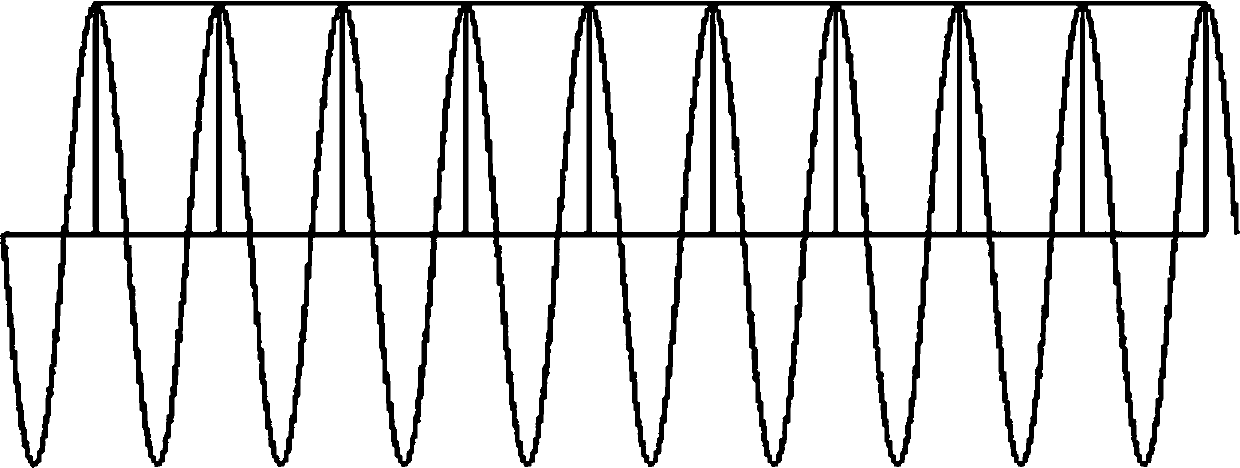

[0022] Install the ultrasonic probe on the helical drive mechanism, and the helical drive mechanism drives the ultrasonic probe to perform self-rotation motion and forward and backward linear motion at the same time, and the ultrasonic probe continuously emits and receives ultrasonic beams for helical scanning;

[0023] The image data obtained by the helical scan is recorded sequentially, and one of the image data is selected as the starting point, and the image data is grouped according to the rotation period of the ultrasonic probe from the starting point, and each image data in each group of image data are identified by angle;

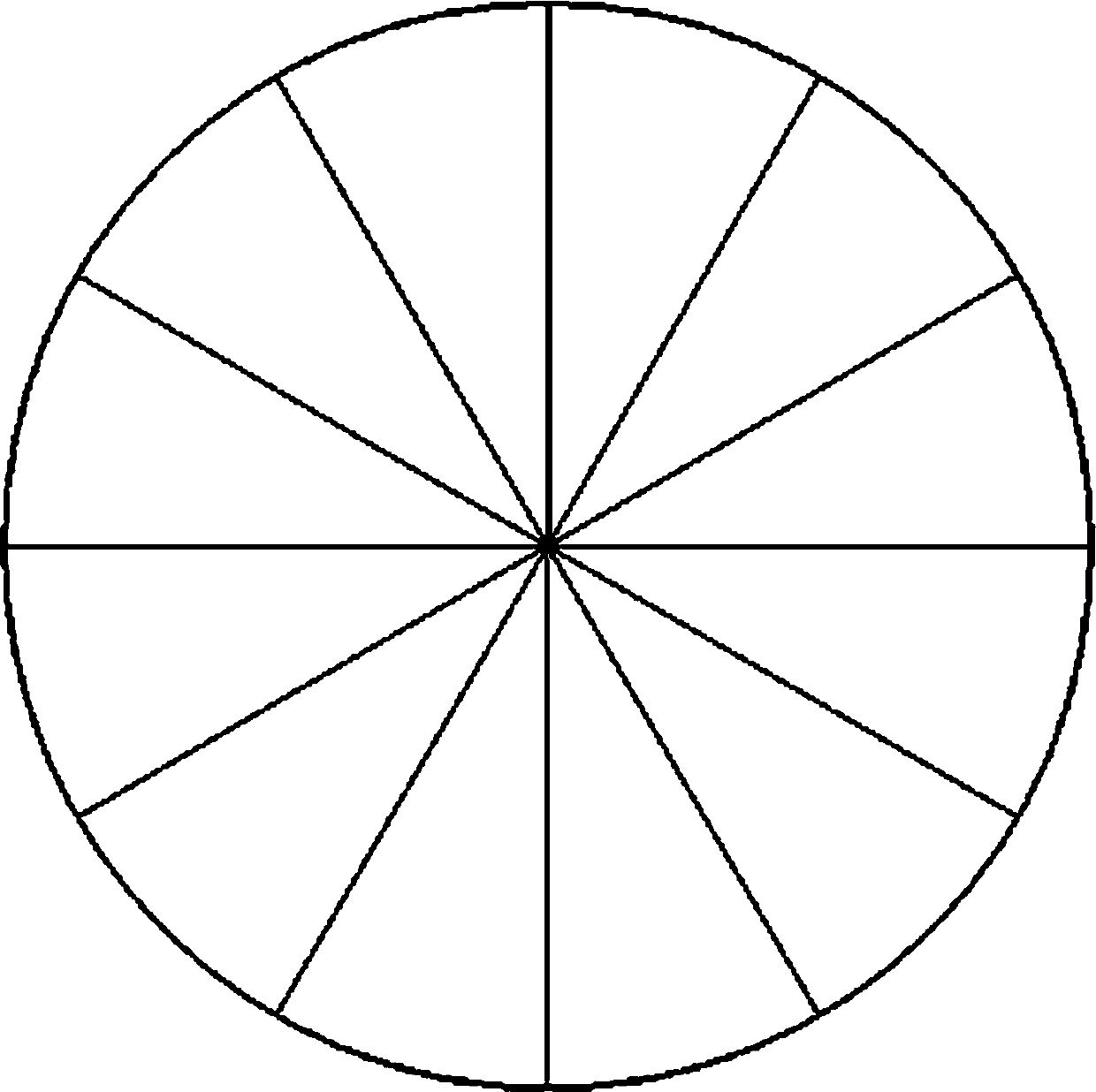

[0024] Randomly select a set of image data to form a circular two-dimensional ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com