Intelligent comprehensive test device for breather valve for oil tank truck

A technology of comprehensive testing and breathing valve, applied in the direction of mechanical valve testing, etc., can solve the problems of low degree of automation, small leakage of opening pressure valve seat and other parameters, low measurement accuracy, etc., to achieve high degree of automation, better sealing effect, The effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

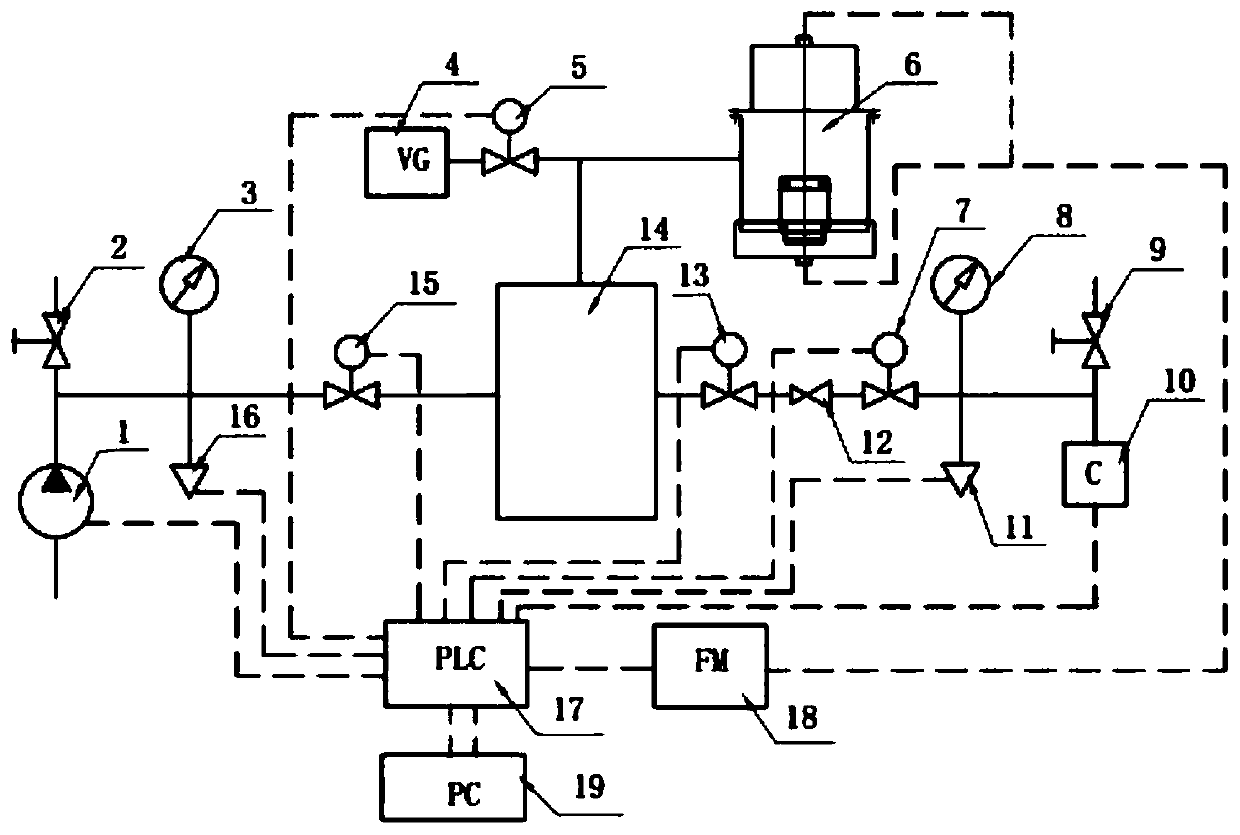

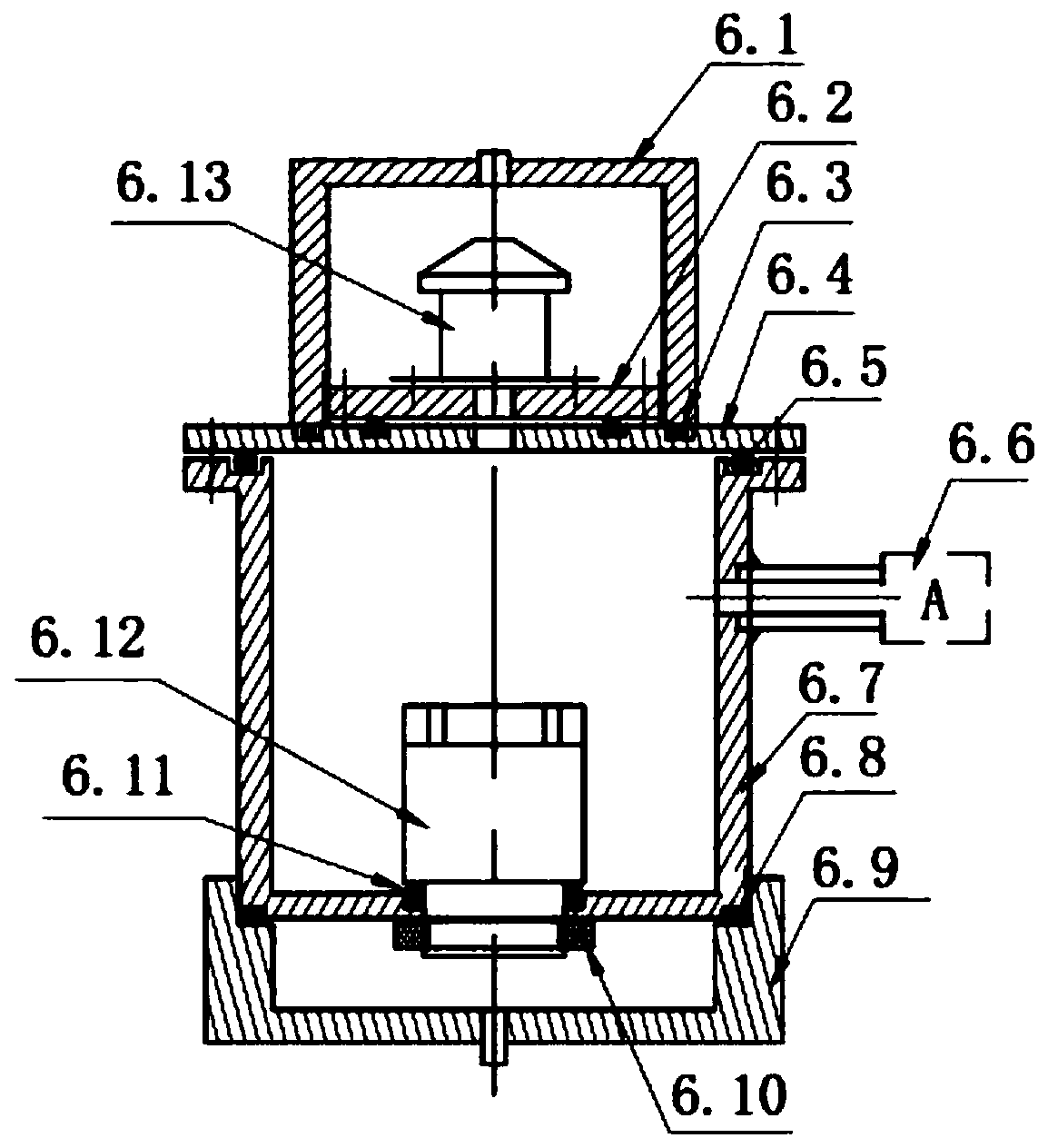

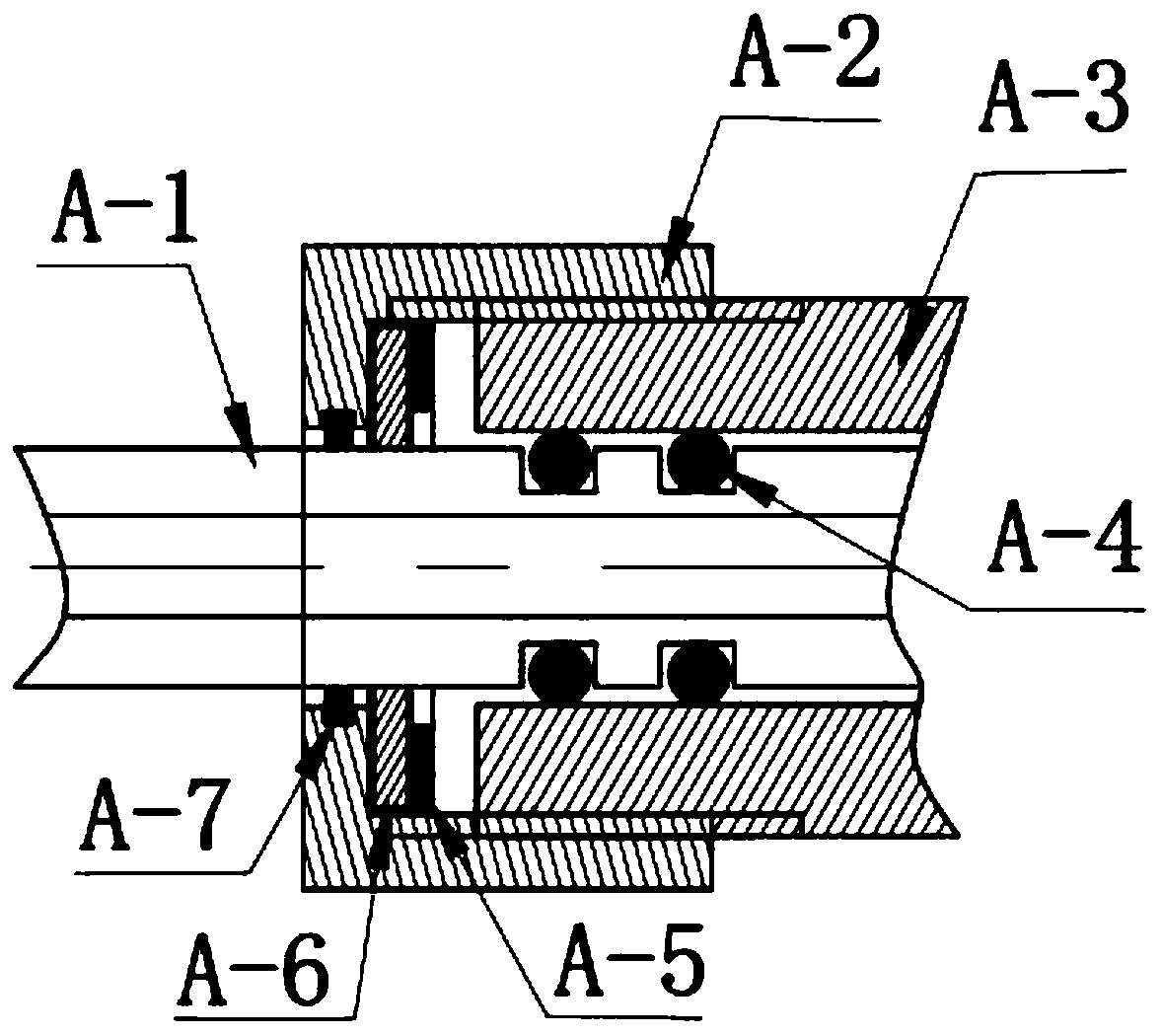

[0021] Embodiment 1 refers to Figure 1-3 , an intelligent comprehensive test device for breathing valves used in oil tankers, including a vacuum pump 1, an air compressor 10, a test container 6, a surge tank 14, a human-computer interaction computer system, a high-precision gas flow meter group 18, and a surge tank 14 is connected to the test container 6, and the vacuum pump 1 for evacuating the test container 6 is also connected on the surge tank 14, and the air compressor 10 for providing positive pressure gas medium to the test container 6 is also connected on the surge tank 14, and the test The container 6 is provided with a leakage rate detection hole, and the leakage rate detection hole is connected with a high-precision gas flow meter group 18, and is used to control the human-computer interaction computer system of the vacuum pump 1, the air compressor 10, the test container 6, and the surge tank 14 Connect the vacuum pump 1, the air compressor 10, the test container ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com