Converter valve cooling capacity multidimensional analysis early-warning method and system

A technology of cooling capacity and cooling system, applied in the direction of mechanical valve testing, etc., can solve the problems of difficult quantitative evaluation of cooling capacity of valve cooling system, insufficient application of artificial intelligence, single algorithm logic, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0093] It should be noted that the converter valve cooling system is also called the valve cooling system. In this embodiment, the monitoring and operation and maintenance data of a converter station in August 2018 are used for analysis. The data types include the valve cooling system inlet water temperature, outlet water temperature, Conductivity, water flow, expansion tank water level, external cooling water pool water level, valve hall temperature, fan operating power, main circulation pump operating power.

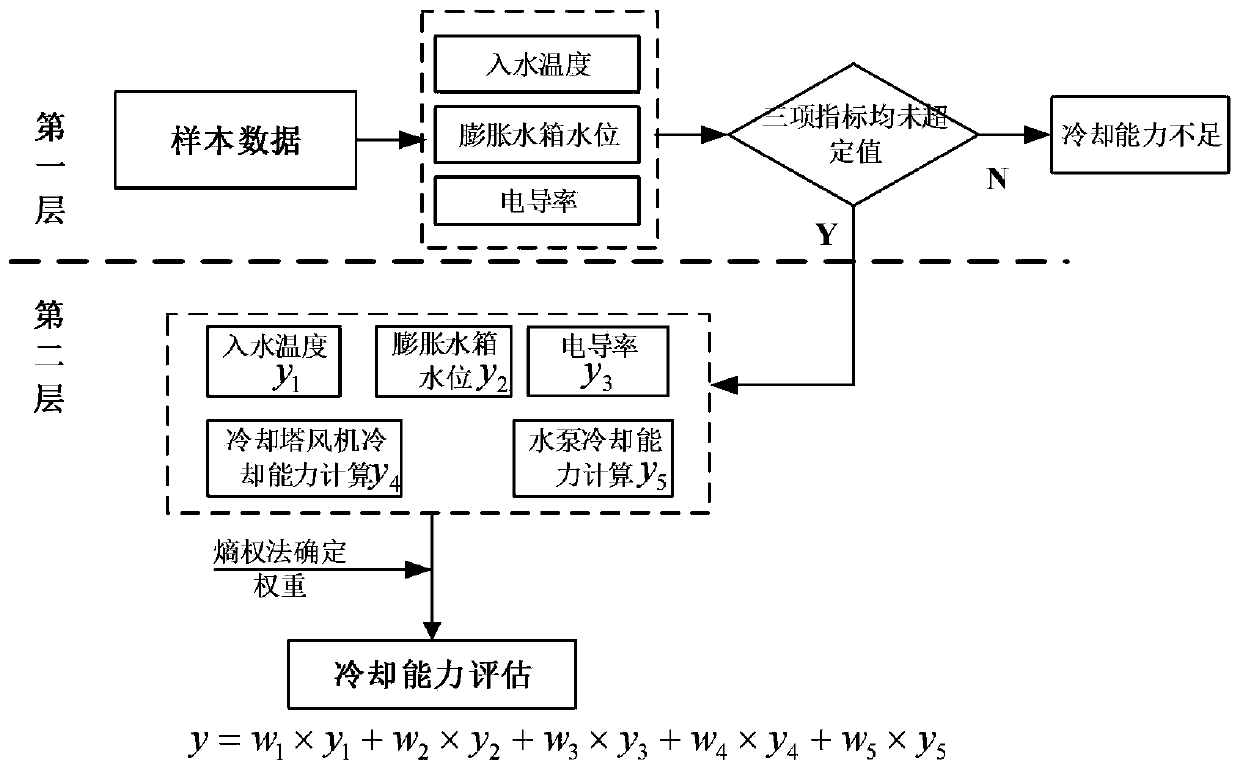

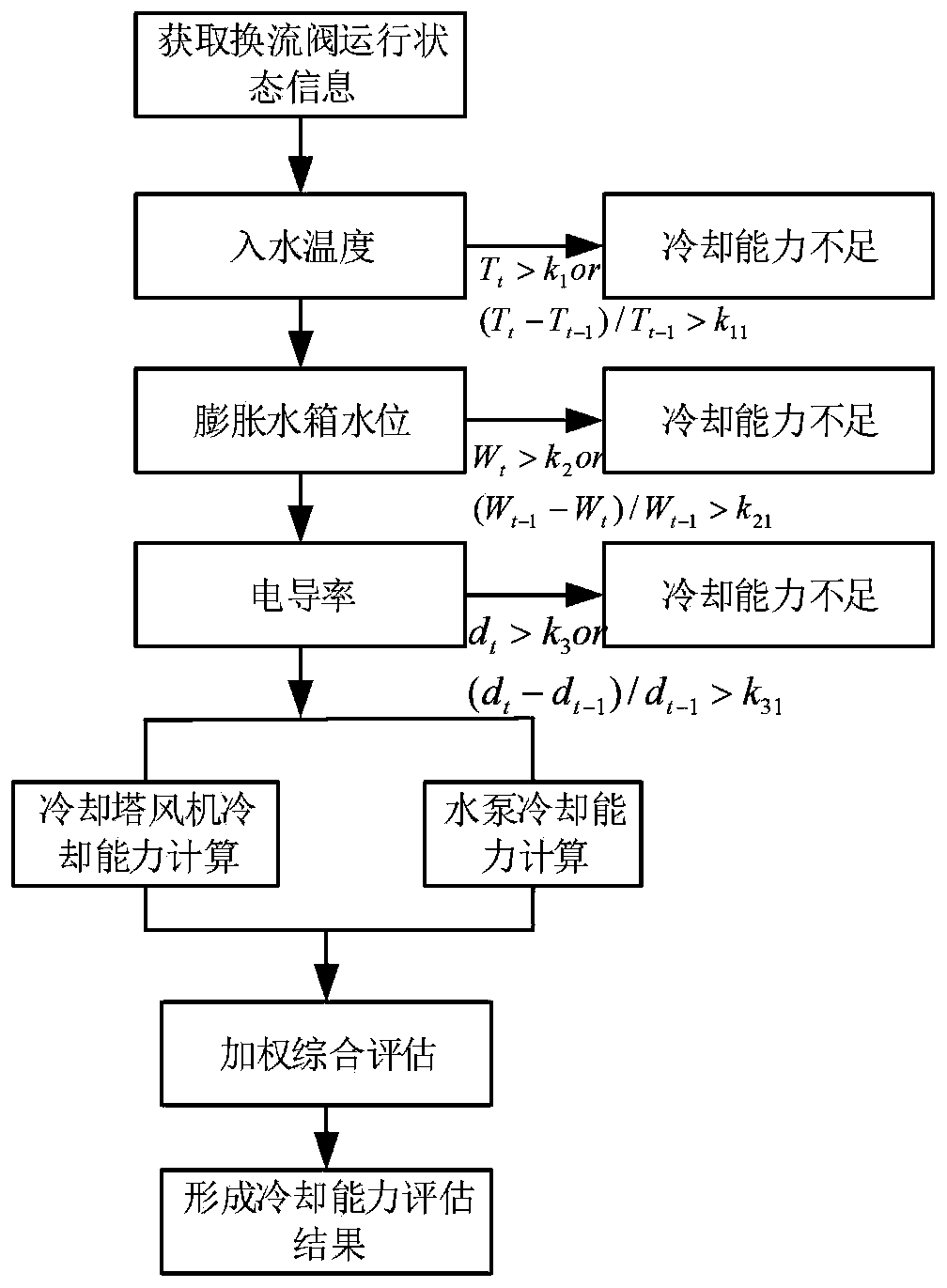

[0094] see figure 2 and image 3 , a multi-dimensional analysis and early warning method for the cooling capacity of the converter valve, including

[0095] Table 1

[0096]

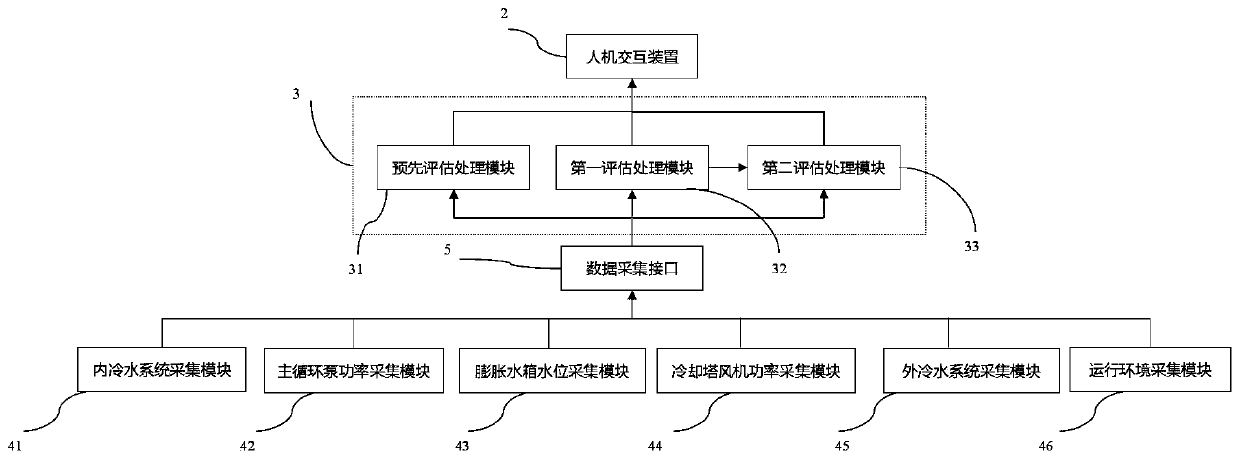

[0097] Step 1: Obtain the state monitoring value of the converter valve cooling system. Further, the converter valve cooling system includes an internal cooling water system, a main circulation pump, an expansion tank, a cooling tower, an external cooling water system, and an operating envi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com