Test apparatus and method for safety valve

一种安全阀、设备的技术,应用在用于安全阀的测试设备和方法领域,能够解决难安装测试设施、过度噪声、安全阀测试设施高成本空间等问题,达到有效冷凝和收集、减少材料、降低噪音的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

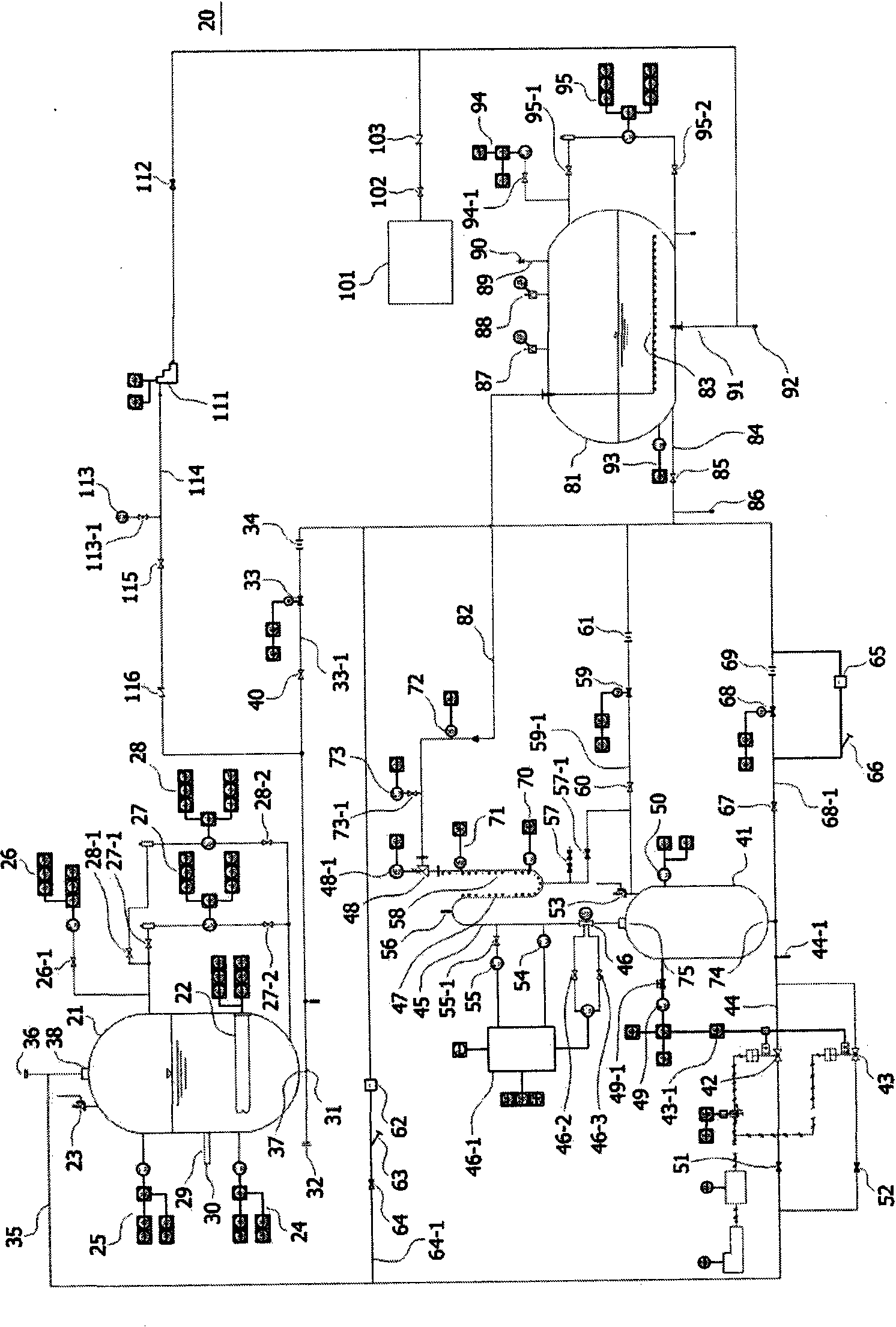

[0041] Exemplary embodiments of the present invention will now be described in more detail with reference to the accompanying drawings.

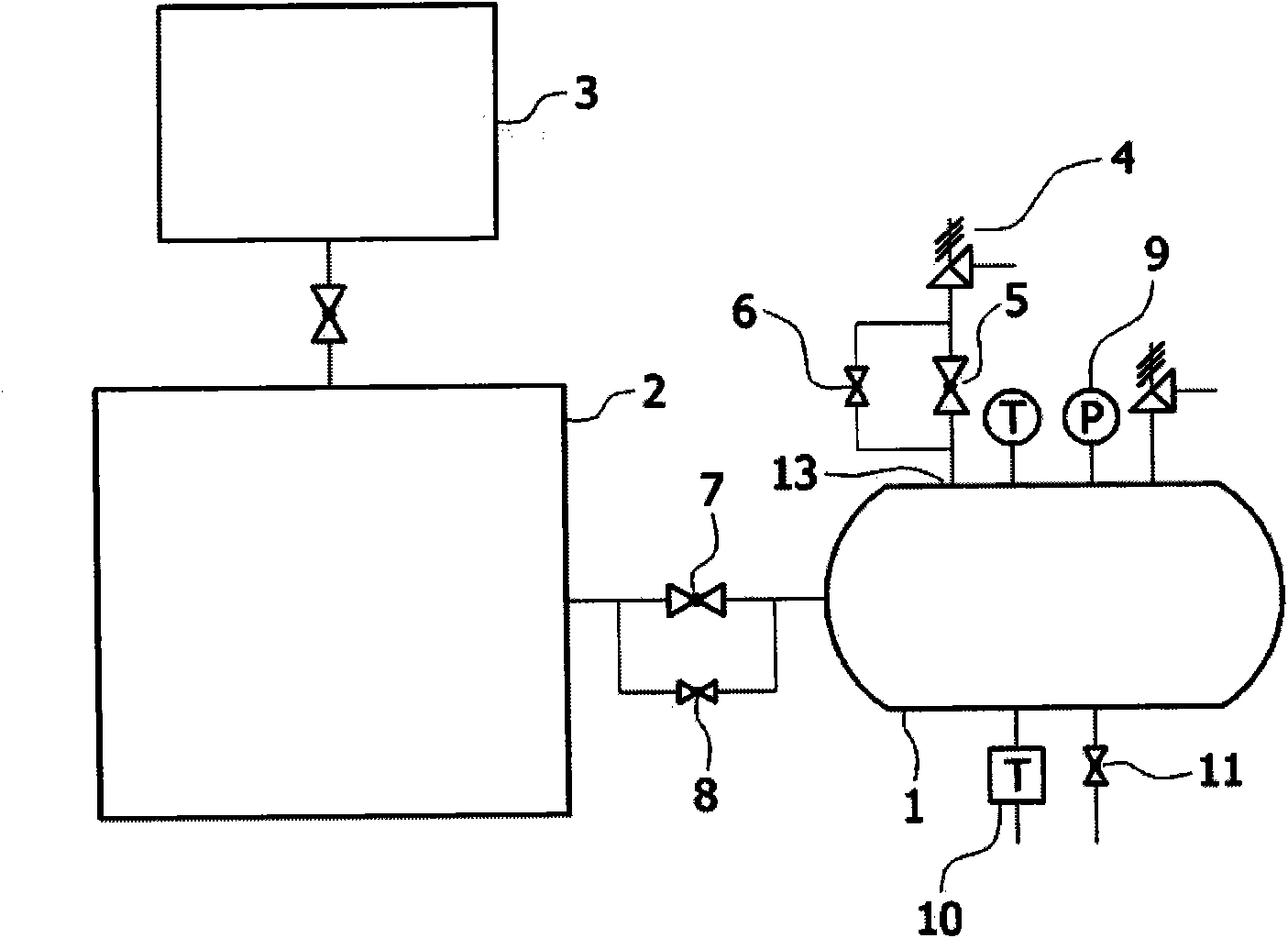

[0042] figure 2 It is a pipeline instrumentation flow diagram of a device for testing the performance of a pressure regulator safety valve according to an exemplary embodiment of the present invention.

[0043] The test equipment 20 includes a pressure accumulator 21, a test container 41, a condensation tank 81, a water supply treatment system 101, a water supply pump 111, pipes and valves, instruments, an air compression system, a control and monitoring system (not shown), a power supply (not shown) out).

[0044] The accumulator 21 is a device filled with a predetermined amount of water, and the accumulator 21 heats the water using an electric heater to generate steam and stores high-pressure steam. The pressure accumulator 21 is equipped with a plurality of electric heaters 22 each having an appropriate heating capacity (for example, 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com