Device and method for measuring unbalanced moment of bottom surface of round valve element

A measuring device and a technology for balancing torque, which are applied in the direction of measuring device, measurement of balancing force using force, static/dynamic balance test, etc. Targeted, simple to create effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with accompanying drawing.

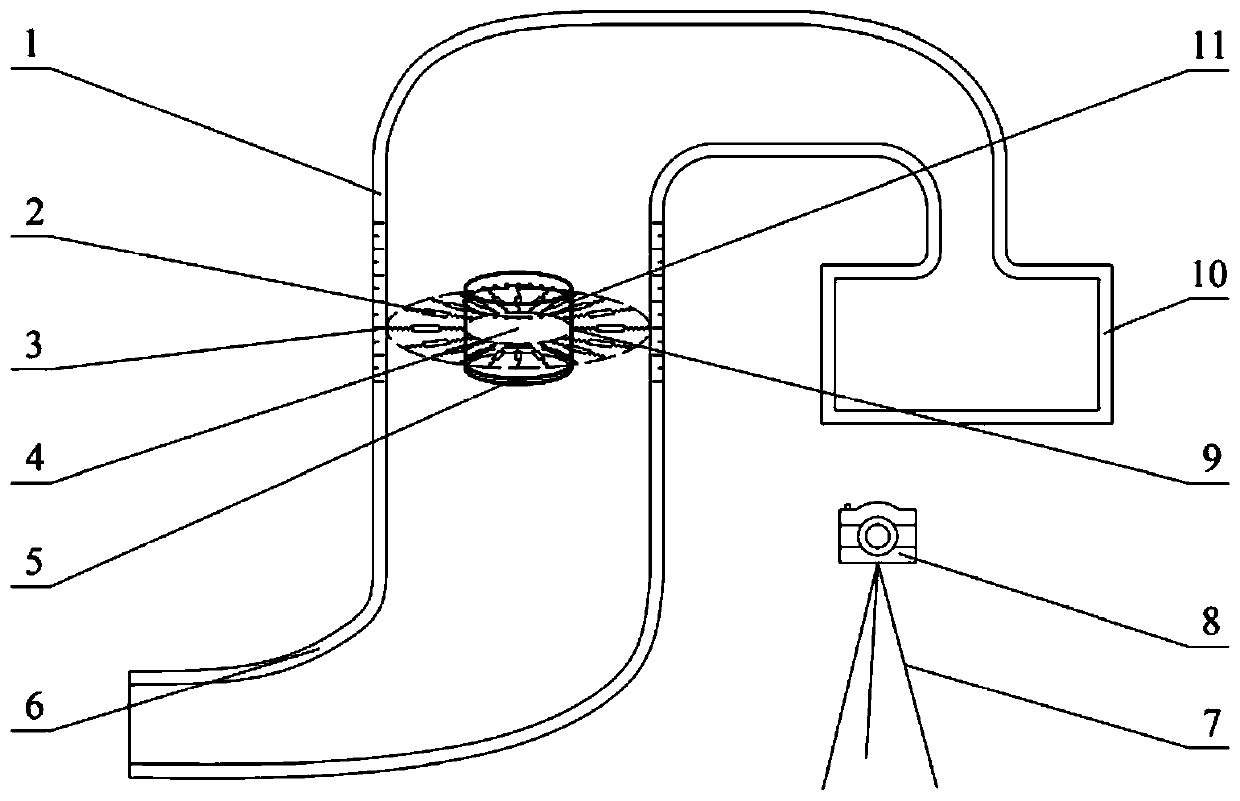

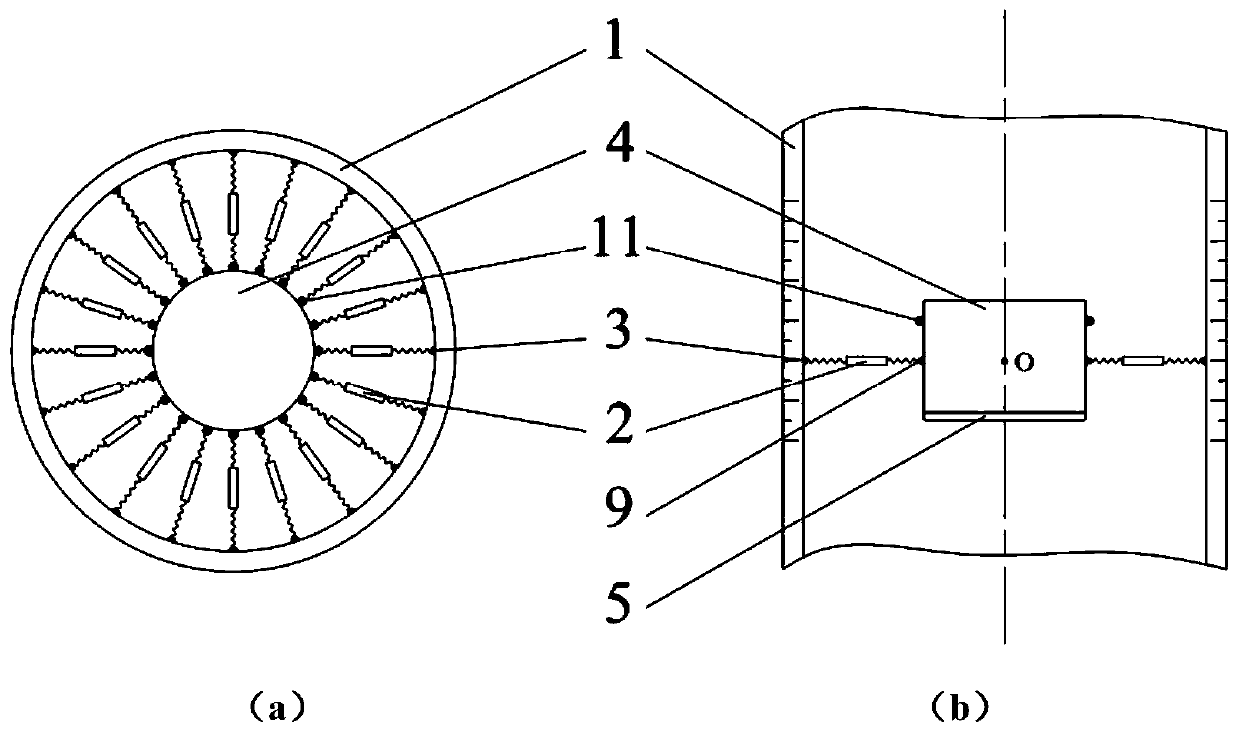

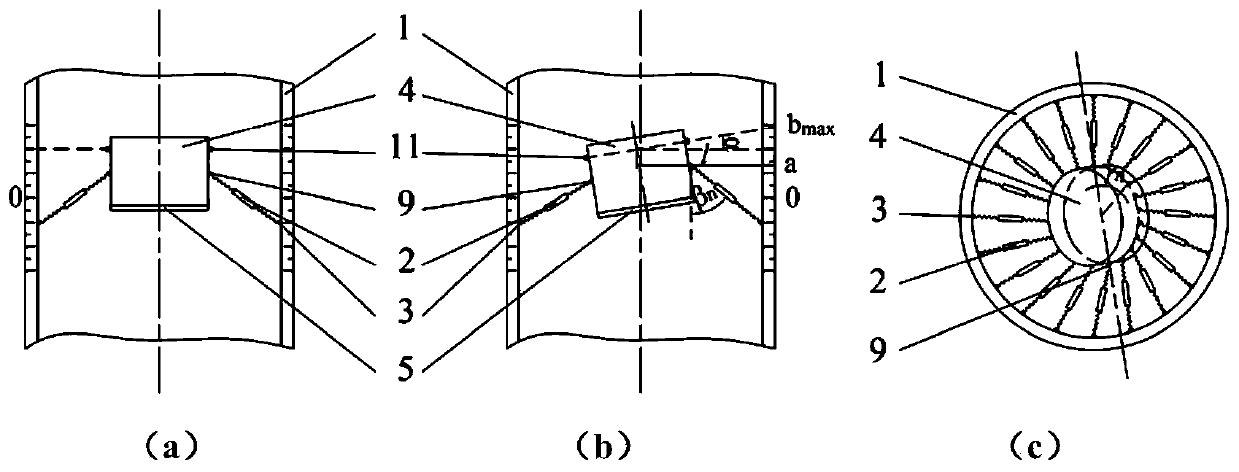

[0043] like figure 1 As shown, in this embodiment, a device for measuring the unbalanced moment at the bottom of a circular valve core includes a gradually expanding special-shaped tube 6, a water tank 10, a transparent tube 1, a spring dynamometer 2, a laser source 11, and a circular valve core 4 and high-speed cameras8.

[0044]The transparent tube 1 is a transparent acrylic tube, which can directly observe the situation inside the tube. The transparent tube 1 is placed vertically on the horizontal plane, and the circular valve core 4 to be measured is placed in the vertical transparent tube 1 . Moreover, the main part of the transparent tube 1 has a uniform diameter and a smooth inner wall, which avoids water flow fluctuations. Positioning scales are marked along the outer wall of the transparent tube 1 . Generally, 5mm is set as a scale, which is convenient for meas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com