Valve detection method and valve detection system

A detection system and detection method technology, applied in the field of valve detection, can solve problems such as large errors, and achieve the effect of reducing detection errors and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] like figure 2 As shown, the valve testing method provided by the embodiment of the present invention includes the following steps: detecting the valve core position of the tested valve 800, and calculating the orifice cross-sectional area of the tested valve 800; The position of the spool can calculate the cross-sectional area of the orifice between the spool and the inner wall of the valve cavity;

[0032] Measure the inlet pressure and outlet pressure of the tested valve 800, and calculate the pressure difference between the inlet pressure and outlet pressure;

[0033] Calculate the flow coefficient of the valve 800 under test.

[0034] Specifically, the formula for calculating the discharge coefficient is: Among them, Q is the liquid flow rate; C q is the flow coefficient, ρ is the density of the brake fluid, Δρ is the pressure difference between the inlet pressure and the outlet pressure, and A is the cross-sectional area of the orifice.

[0035] Further...

Embodiment 2

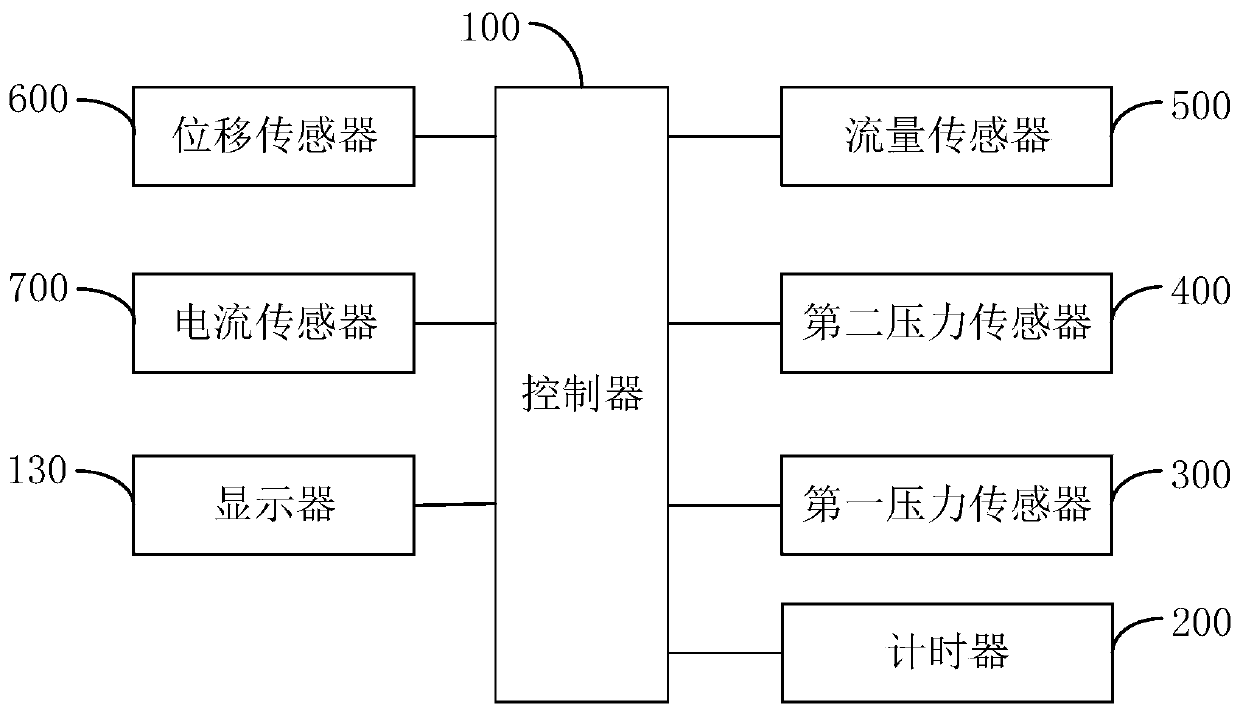

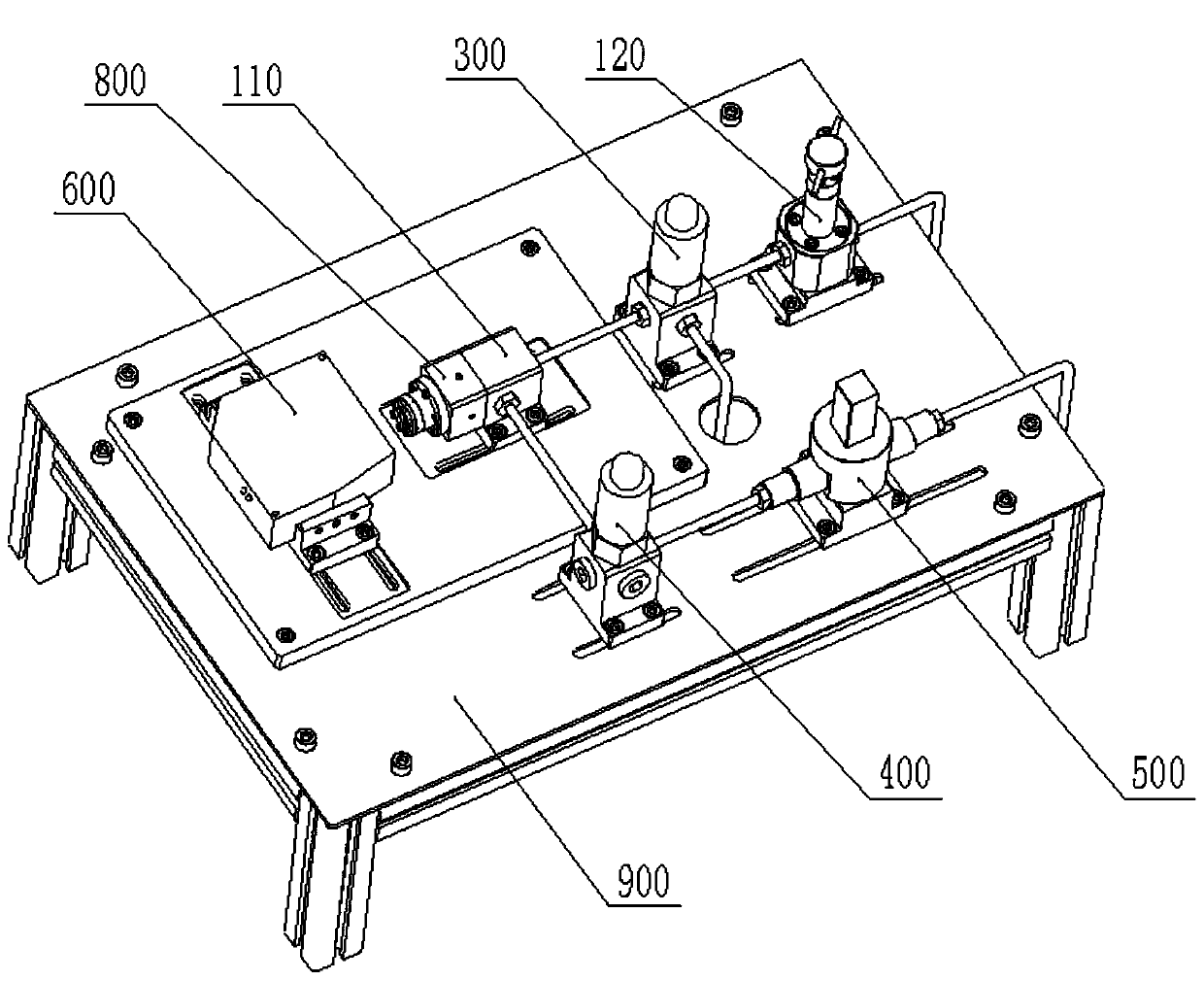

[0043] like figure 1 As shown, the valve detection system provided by the embodiment of the present invention includes: a controller 100, a first pressure sensor 300, a second pressure sensor 400, a flow sensor 500 and a displacement sensor 600, the first pressure sensor 300, the second pressure sensor 400 , the flow sensor 500 and the displacement sensor 600 are respectively connected to the controller 100; the first pressure sensor 300 is used to detect the liquid inlet pressure of the tested valve 800; the second pressure sensor 400 is used to detect the liquid outlet pressure of the tested valve 800; The flow sensor 500 is used to detect the liquid flow of the tested valve 800 ; the displacement sensor 600 is used to detect the displacement of the valve core of the tested valve 800 .

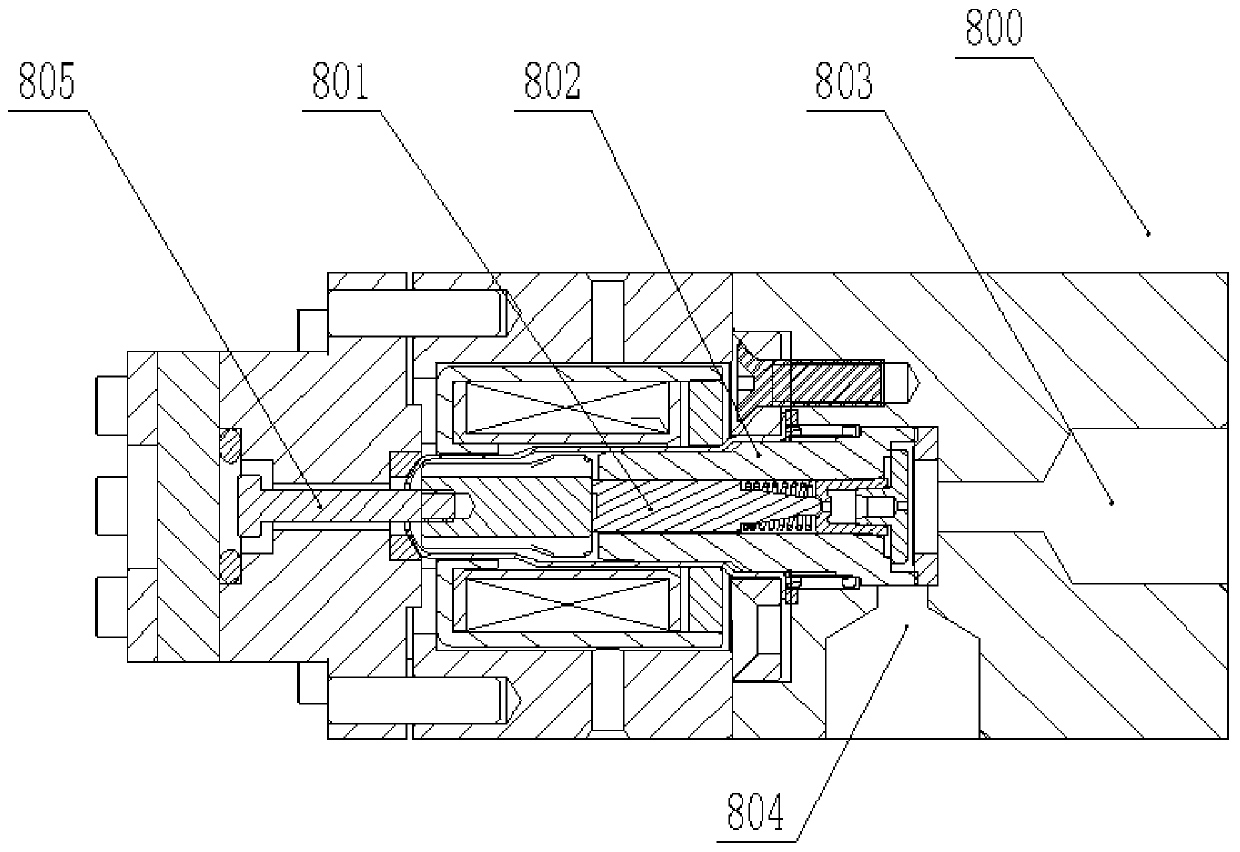

[0044] Specifically, the displacement sensor 600 is a laser displacement sensor, the valve under test 800 is a solenoid valve, the valve under test 800 includes: a moving assembly 801 and a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com