Valve detection device and use method thereof

A detection device and valve technology, which is applied in the direction of measuring device, mechanical valve test, optical device, etc., can solve the problems of simplification of detection function, unclear detection information, low detection efficiency, etc., and achieve diversified functions and high detection accuracy , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

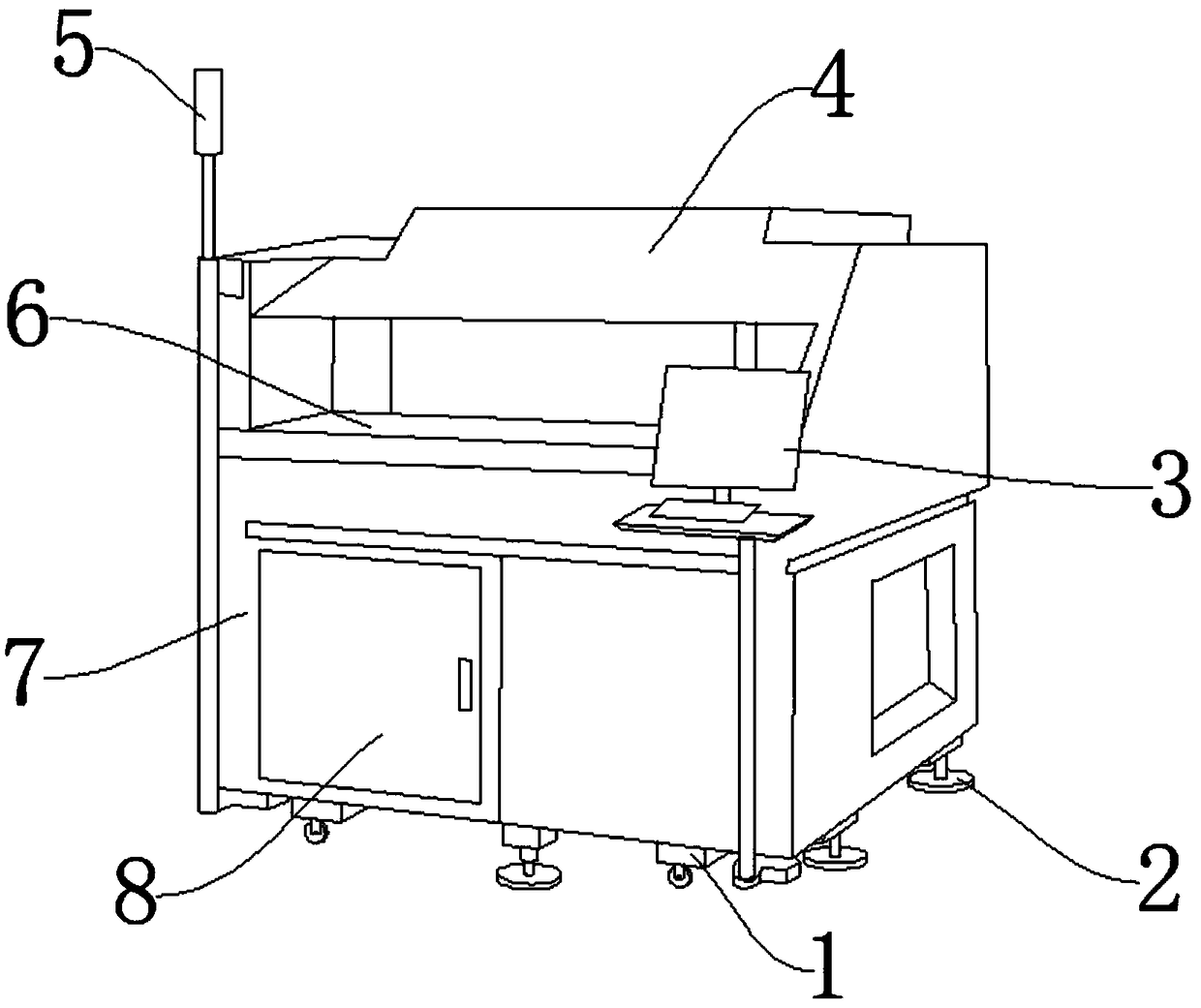

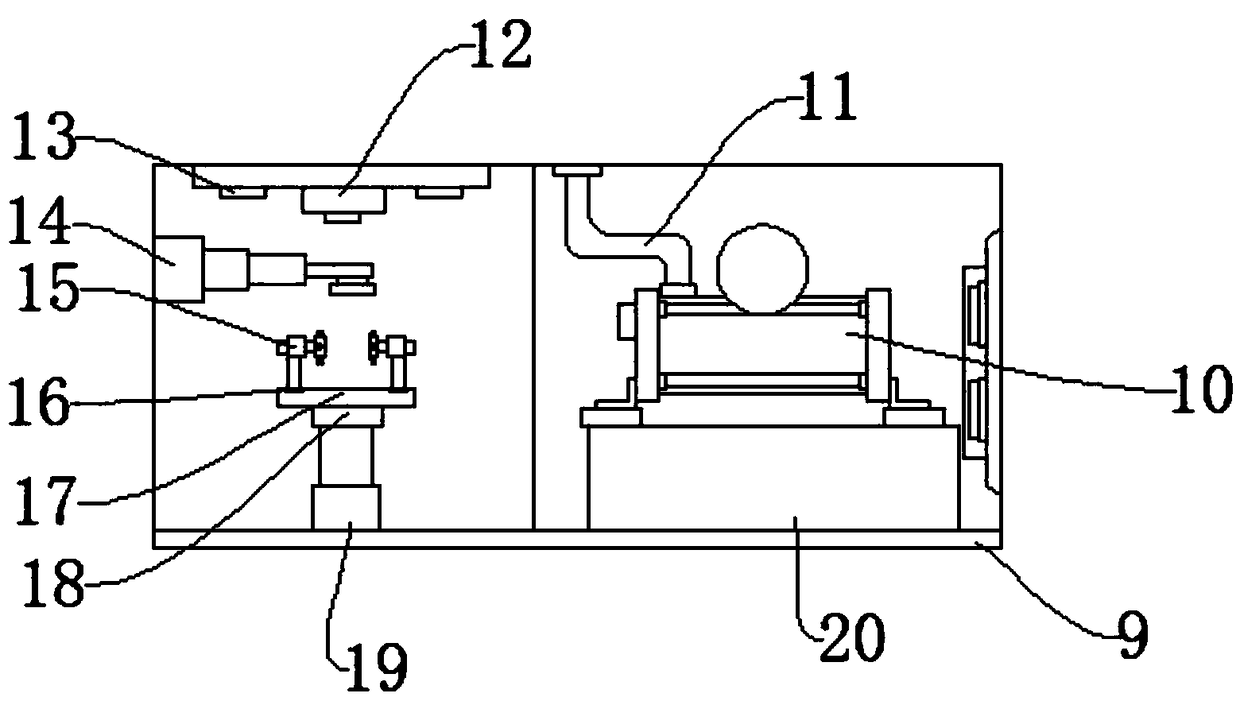

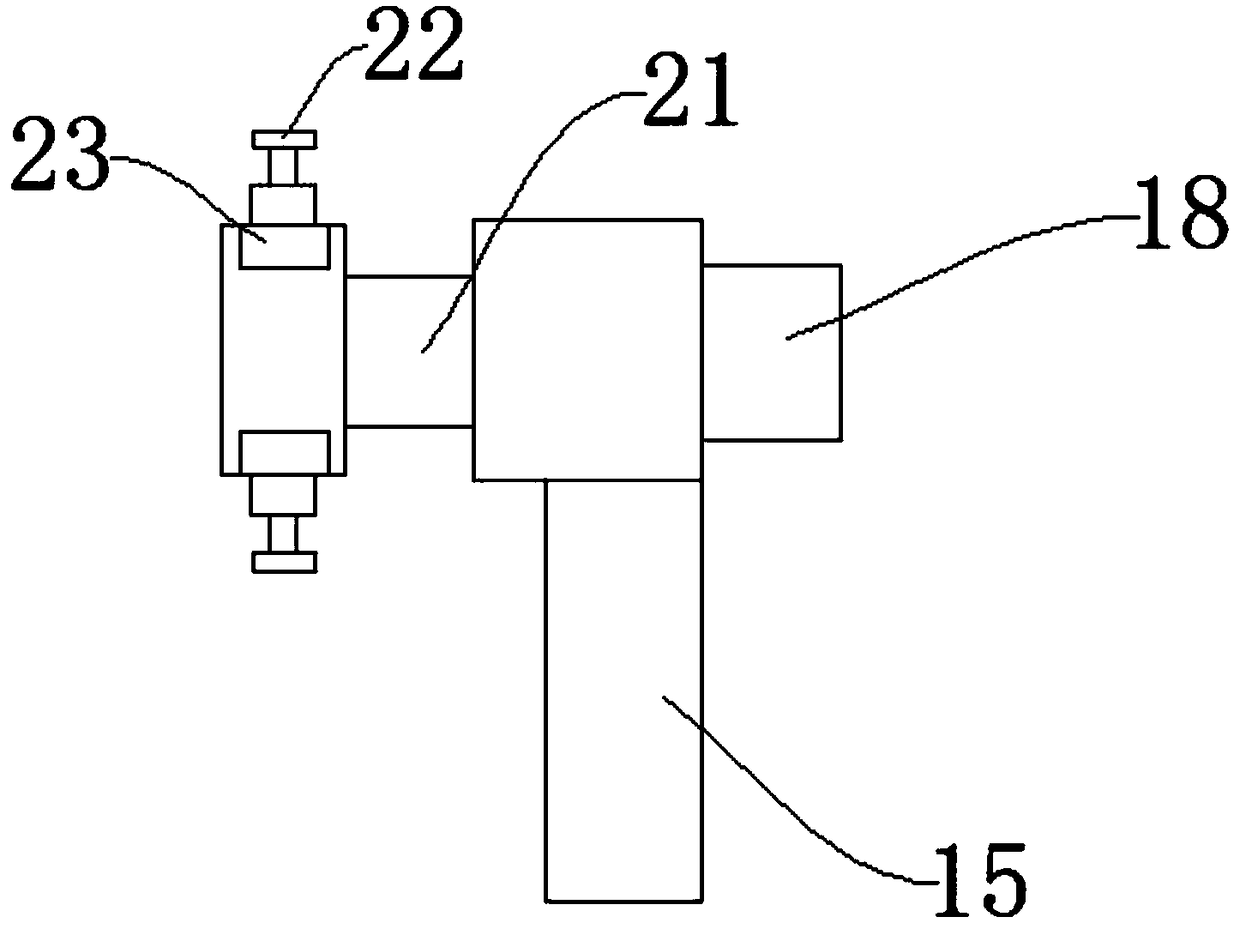

[0036] Such as Figure 1-Figure 6 As shown, a valve detection device includes a base 7, a detection platform 6, and a sealing cover 4. An alarm indicator 5 is arranged on the outer side wall of the base 7, and a controller is arranged on one side of the alarm indicator 5. 3. A moving pulley 1 is set under the base 7, a stable base 2 is set on one side of the moving pulley 1, a size detection chamber 8 is set at the bottom of the base 7, and a height is set inside the size detection room 8. Regulate the hydraulic cylinder 19, the top of the height adjustment hydraulic cylinder 19 is provided with a rotating motor 18, the specific model of the rotating motor 18 is ZYTD-38SRZ-R, the top of the rotating motor 18 is provided with a rotating disc 17, and the rotating disc 17 top is provided with weight detector 16, and the specific model of described weight detector 16 is I8001, and above described weight detector 16 is provided with fixer 15, and described fixer 15 is provided with...

Embodiment 2

[0038] The difference between this implementation and Embodiment 1 is:

[0039] The grasping head 24 is provided with a groove for fixing the opening arm of the valve, and the side wall of the size detection chamber 8 is provided with an opening and closing door for sealing.

[0040] Specifically, such setting can facilitate the detection of opening and closing of the valve body, improve the use effect of the equipment, facilitate the installation and disassembly of the valve body, and simplify the operation process.

[0041] The present invention also provides a method of using a valve detection device, which is applied to the above-mentioned valve detection device. The specific method of use is as follows: when starting the detection, the operator opens the opening and closing door on the size detection chamber 8, and it will be necessary to carry out The valve for detection processing is nested and connected to the holder 15, and then the pressure plate 22 and the clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com