Valve testing device and testing method

A testing device and testing method technology, applied in mechanical valve testing, by measuring the acceleration and deceleration rates of fluids, and using liquid/vacuum for liquid tightness measurement, etc. Achieve the effect of high measurement accuracy, convenient reading, and remote alarm prompting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation of the valve testing device and testing method of the present invention will be described in detail below in conjunction with the accompanying drawings.

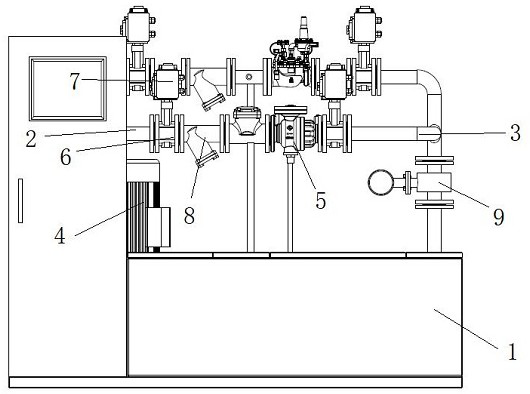

[0029] See attached figure 1 , The valve test device is installed on the test equipment, the test equipment includes water tank 1, water inlet pipe 2 and water outlet pipe 3 and various necessary pipe fittings, water inlet pump and other components. A butterfly valve 6 is arranged between the water inlet pump 4 of the water inlet pipe 2 and the test valve 5 . One end of the butterfly valve 6 is provided with a backflow preventer 7 and a filter 8, and a flow meter 9 is provided on the outlet pipe.

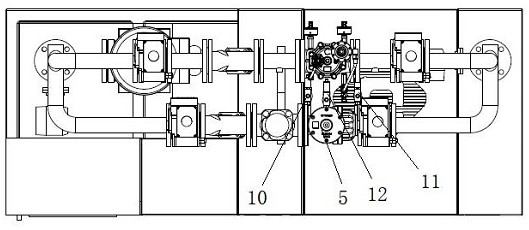

[0030] The above-mentioned test components are conventional components in the test valve test process, which are expanded in the present invention, see the attached figure 2 , a control unit is set in the test device, a first pressure sensor 10 is set on the water inlet pipe close to the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com